Scanning system, method and three-dimensional object manufacturing equipment for manufacturing three-dimensional objects

A technology of three-dimensional objects and scanning systems, which is applied in the direction of additive manufacturing, manufacturing tools, metal processing equipment, etc., can solve the problems of sintered workpiece strength differences, curves that cannot be guaranteed to be completely consistent, and affect the sintering quality of the workpiece, so as to improve the sintering quality and avoid Effects of Energy Differentiation and Avoidance of Color Differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

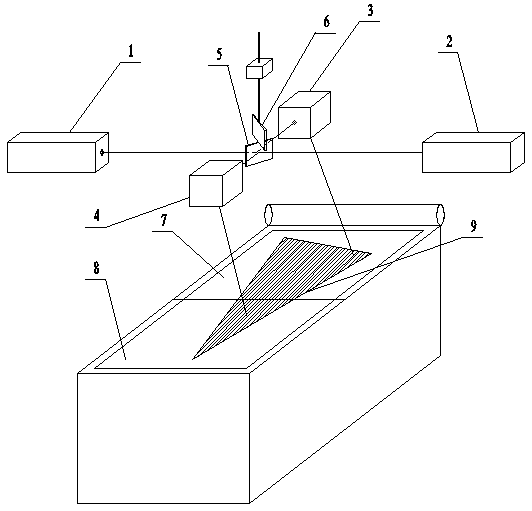

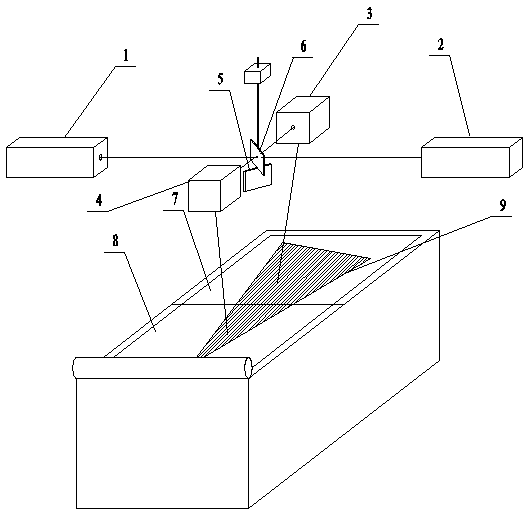

[0032] As an embodiment of the present invention, the optical path adjustment unit includes a first oscillating mirror 3, a second oscillating mirror 4, a driving unit, and two mirrors installed up and down with an angle greater than 0 degrees and less than 180 degrees. The optical lens is driven up or down by the drive unit to reflect the laser light emitted by the first laser 1 on the upper reflector 6 or lower reflector 5 of the optical lens, and the first oscillating mirror 3 or the second oscillating mirror 4 Under the control of scanning the first area 7 or the second area 8 of the sintering work area; at the same time, the reflection of the laser light emitted by the second laser 2 on the upper mirror 6 or lower mirror 5 of the optical lens, and the first vibrating mirror 3 Or under the control of the second vibrating mirror 4, the second area 8 or the first area 7 of the sintering working area is scanned.

[0033] Such as figure 1 As shown, the upper reflector 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com