Patents

Literature

175results about How to "Soft surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

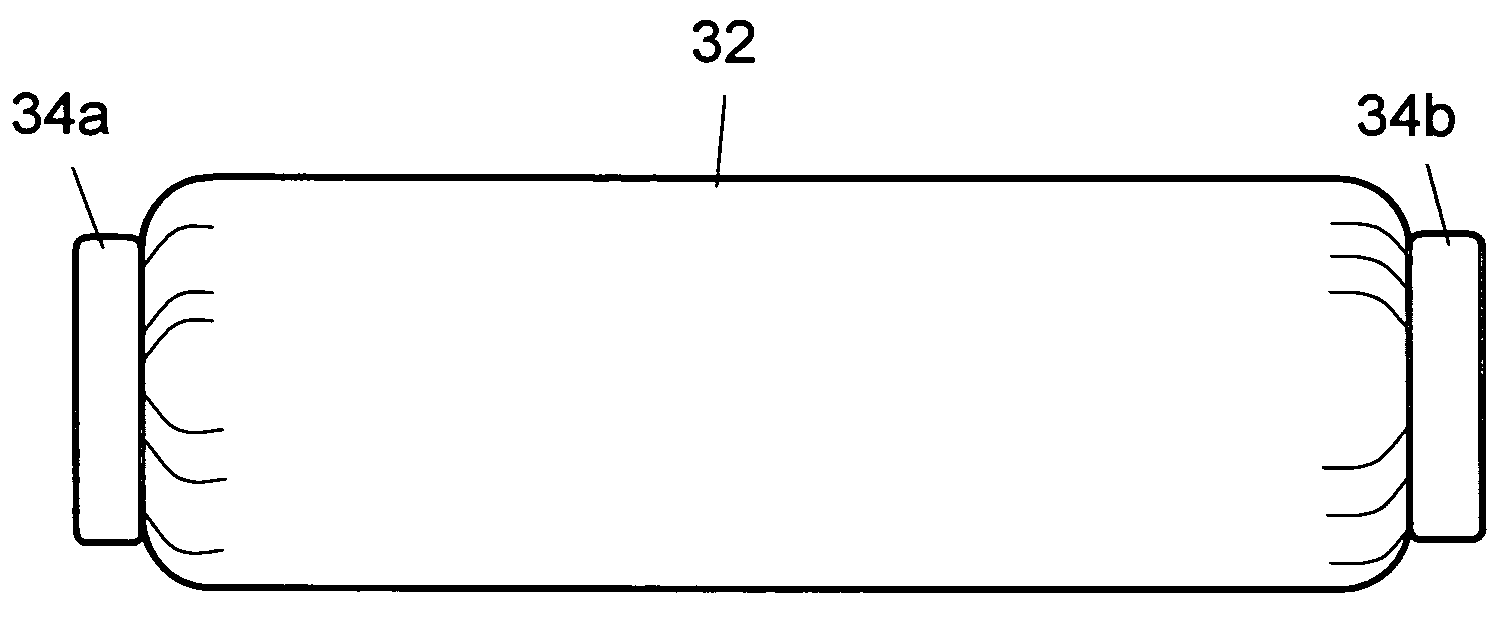

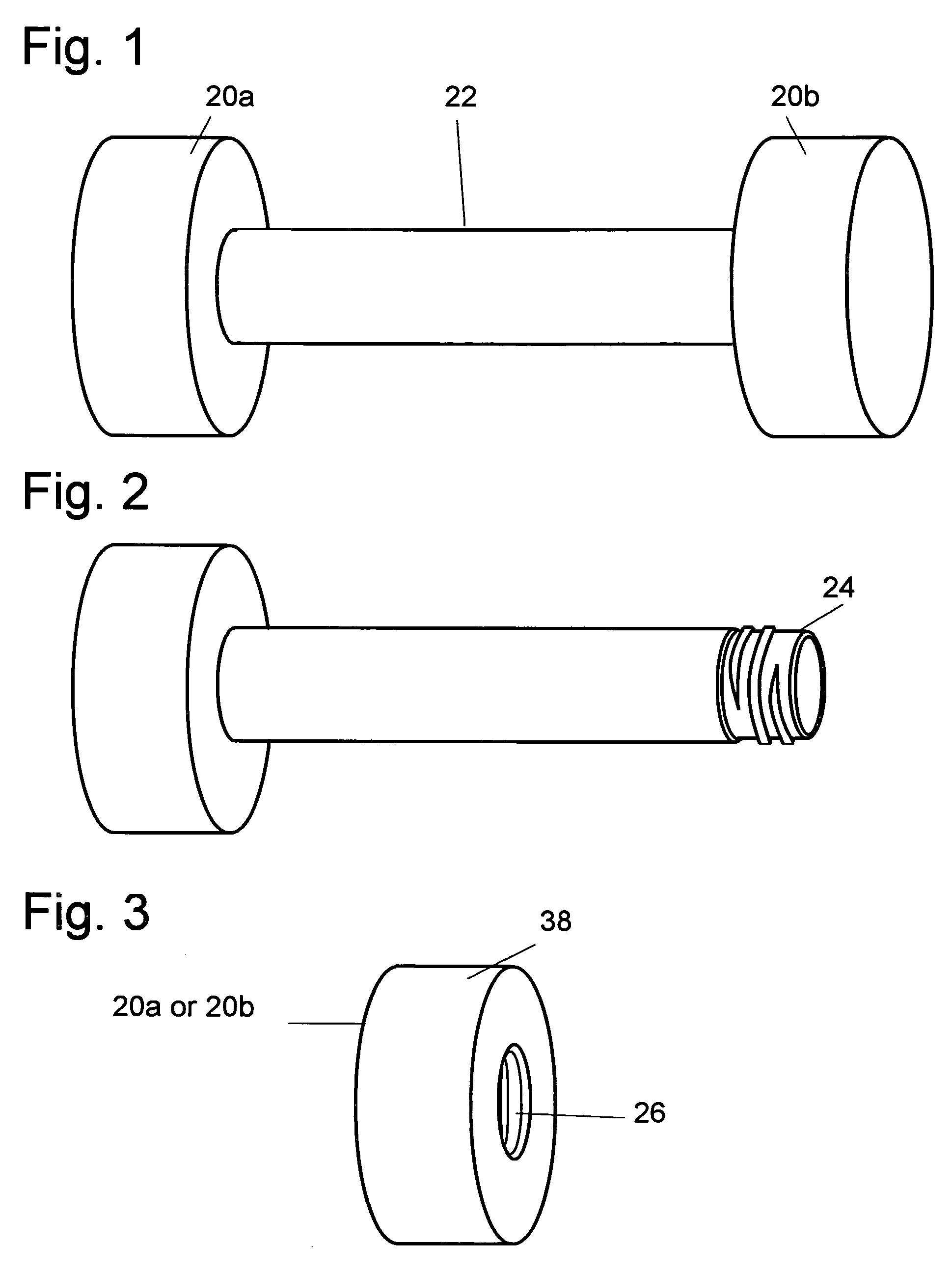

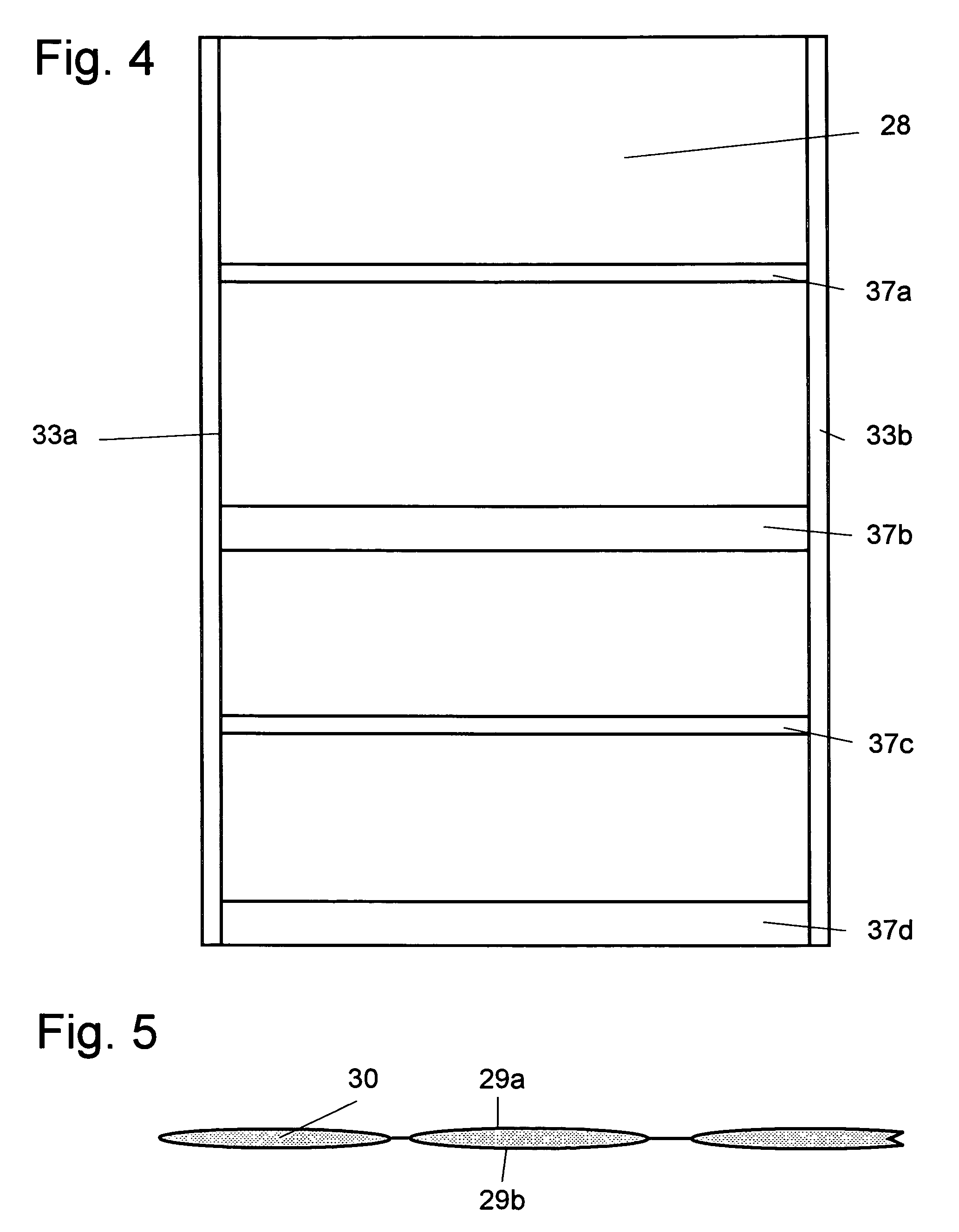

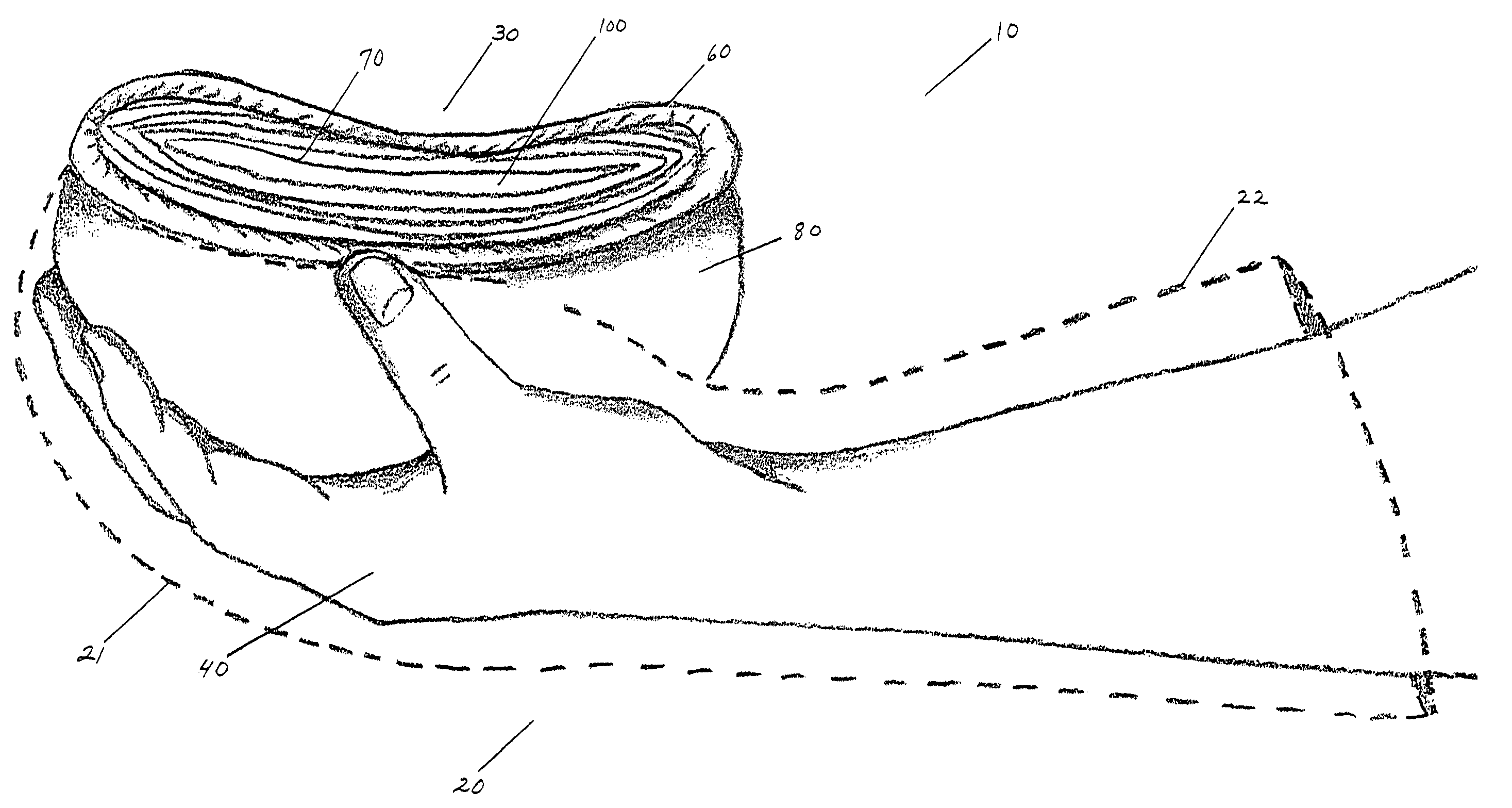

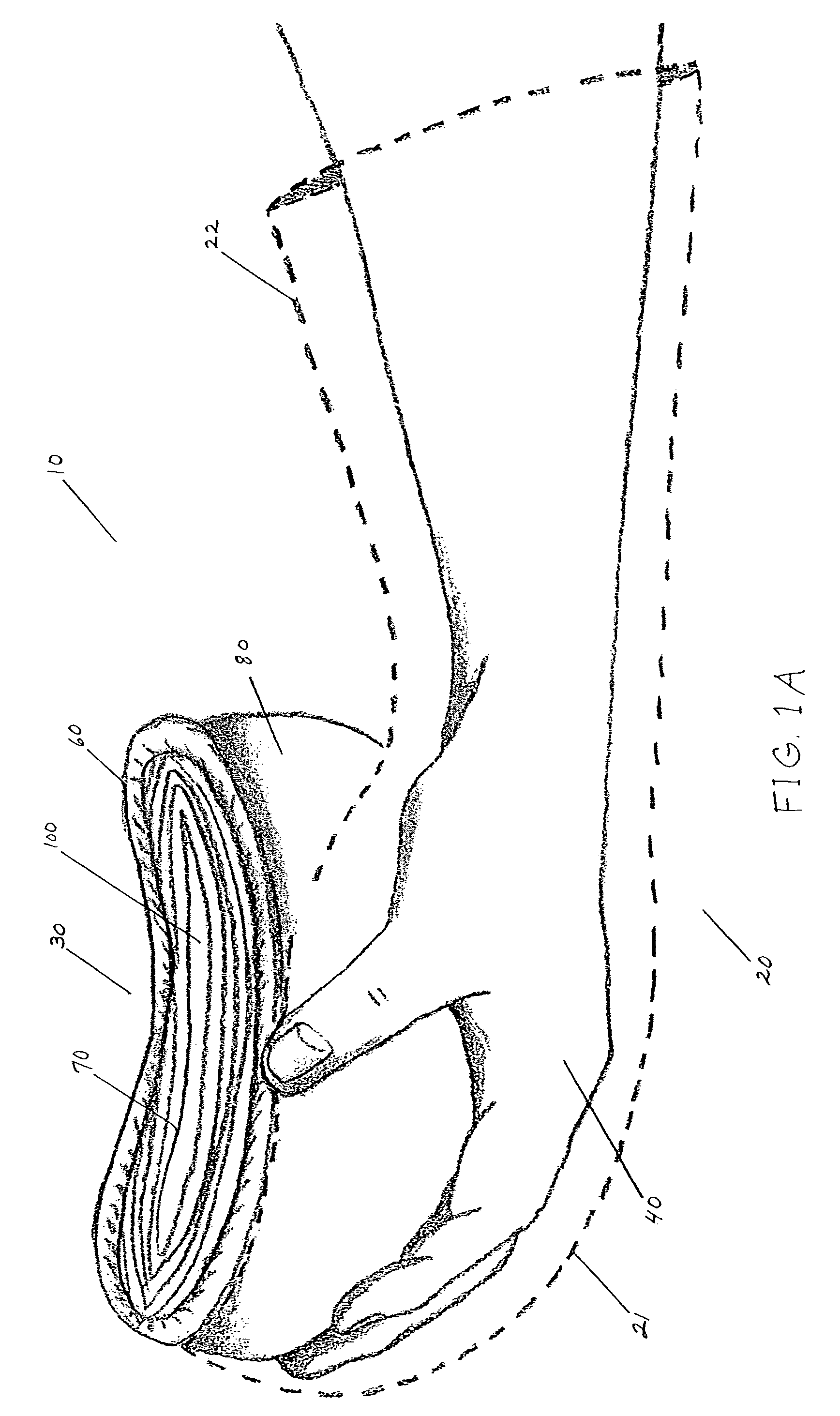

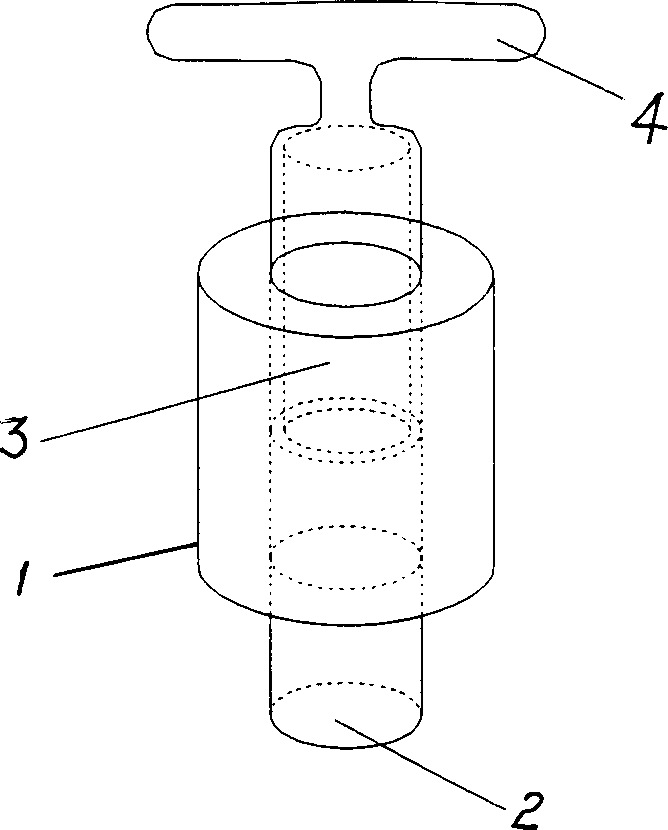

Cold therapy foot massager

InactiveUS7112178B1Prevent inflammation and swellSoft surfaceChiropractic devicesEye exercisersHollow corePhysical therapy

Owner:ROOZENBURG NANCY JEAN

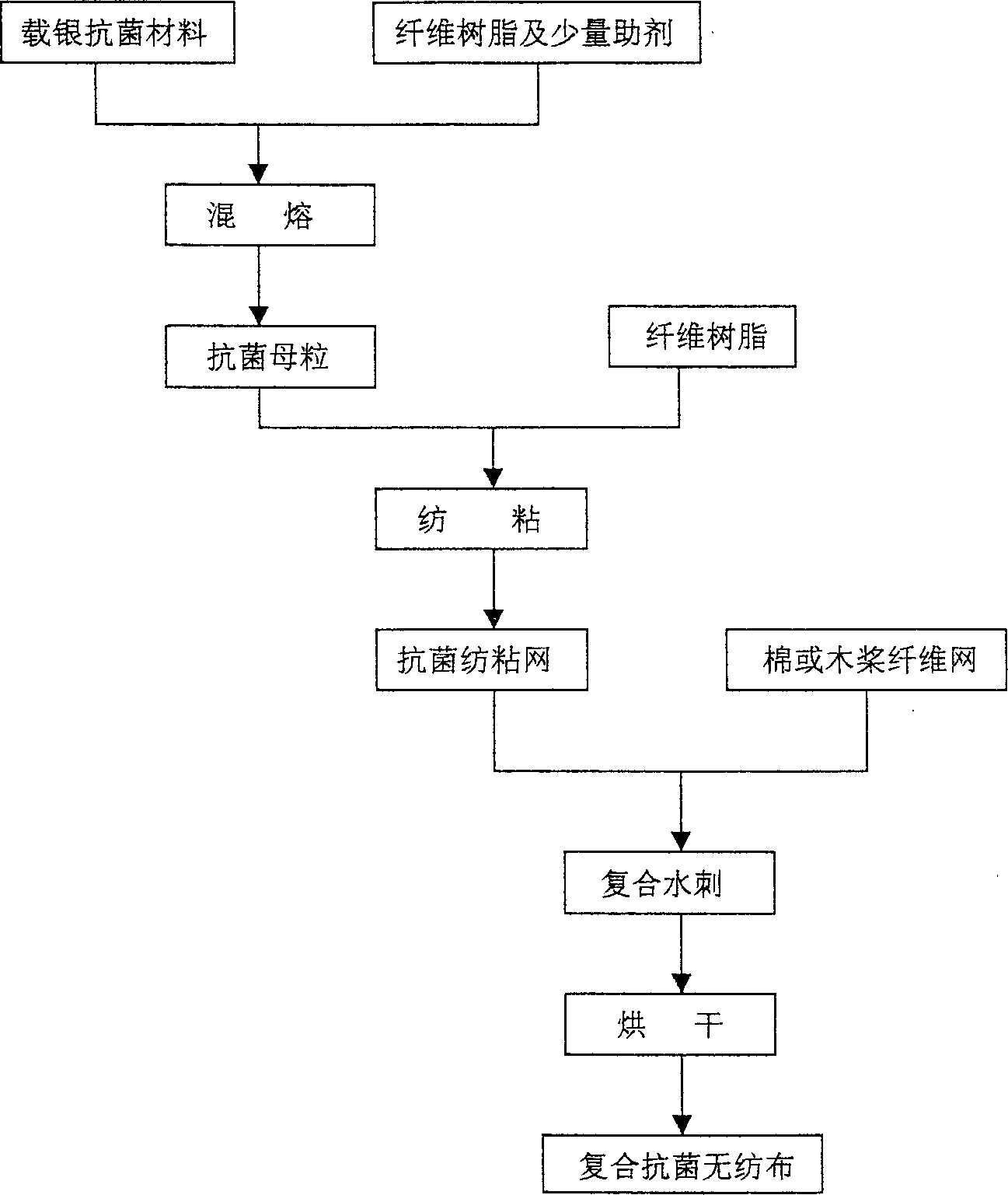

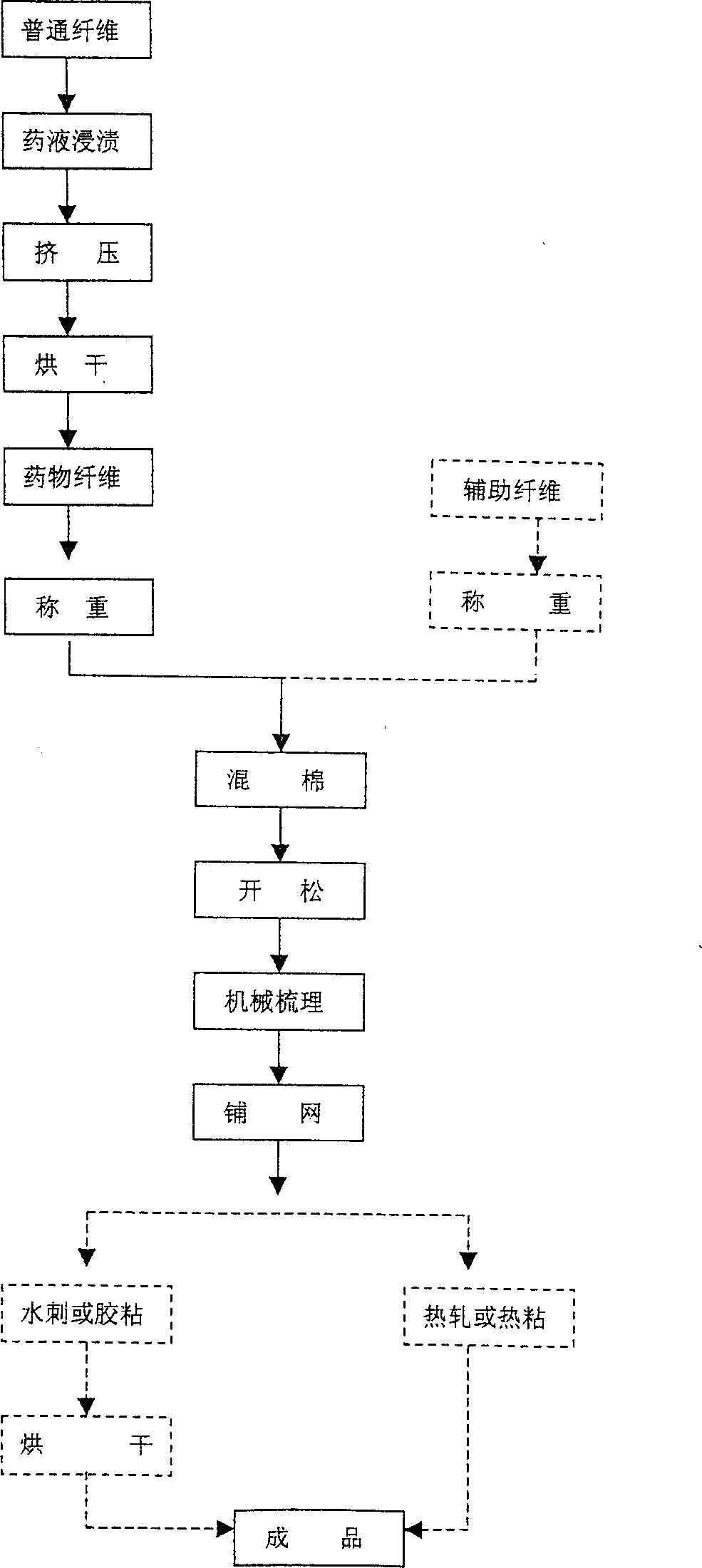

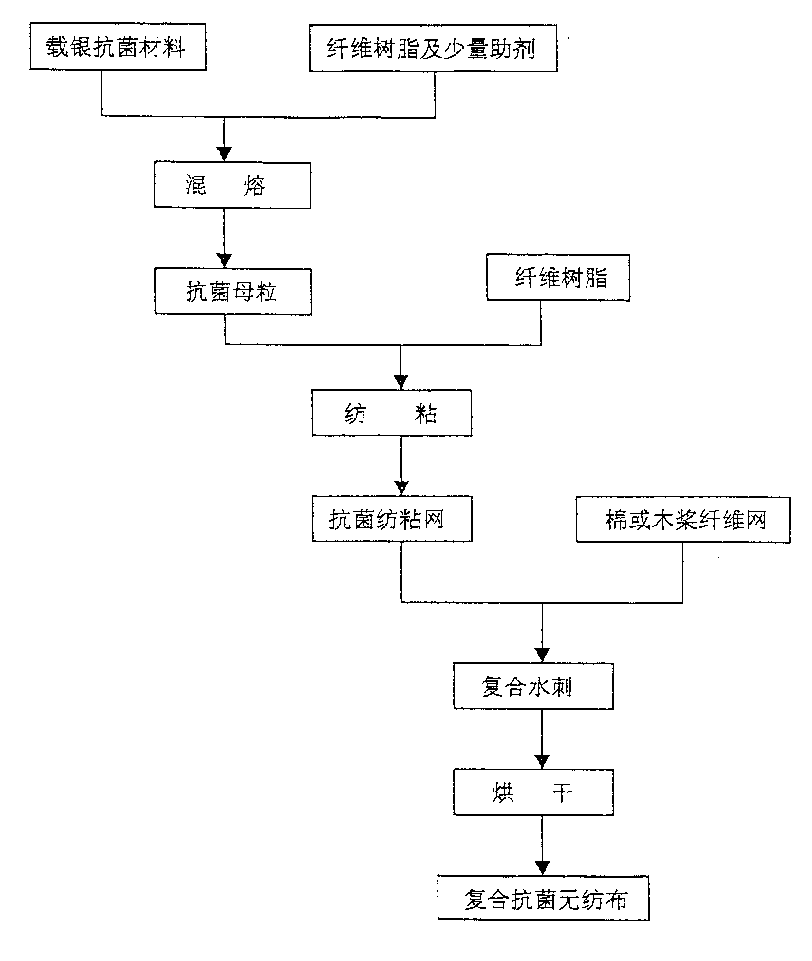

Process for preparing Ag-carried antibacterial composite non-woven fabric

InactiveCN1346905ANot easy to fall offImprove antibacterial propertiesNon-woven fabricsArtifical filament manufacturePolymer scienceCotton fibre

A process for preparing Ag-carried antibacterial composite non-woven fabric includes preparing antibacterial mother particles from Ag-carried antibacterial material, fibre resin and plastic assistant by screw extruding, preparing antibacterial spun-bonded mesh from said antibacterial mother particles and fibre resin, combining said antibacterial spun-bonded mesh with cotton fibre mesh or wood pulp fibre mesh, hydro-entangling, and drying. Its advantages are high antibacterial power and durability, and broad spectrum.

Owner:韦卫军

Disposable urine collection device

InactiveUS7171699B2Easy to carryEasy to useNursing urinalsBathroom accessoriesUrine collection deviceUrine Collections

A disposable urine collection device for use by a person which includes an absorbent pad for the collection of urine and a glove attached to the absorbent pad. The glove design includes a mitt for insertion of the user's hand into the device under the absorbent pad through the sleeve of the glove. The absorbent pad is composed of a waterproof plastic liner, a hydrophilic gel and absorbent material layer, and panels of absorbent material. Various embodiments include additional layers in the absorbent pad such as a top protective layer and an absorbent rim. The hand of the user is inserted into the mitt of the glove prior to urination and removed after urination. The sleeve of the glove is inverted over the top of the absorbent pad upon removal from the user's hand. The apparatus may then be secured prior to disposal by various closure means.

Owner:ERNEST THERESA +1

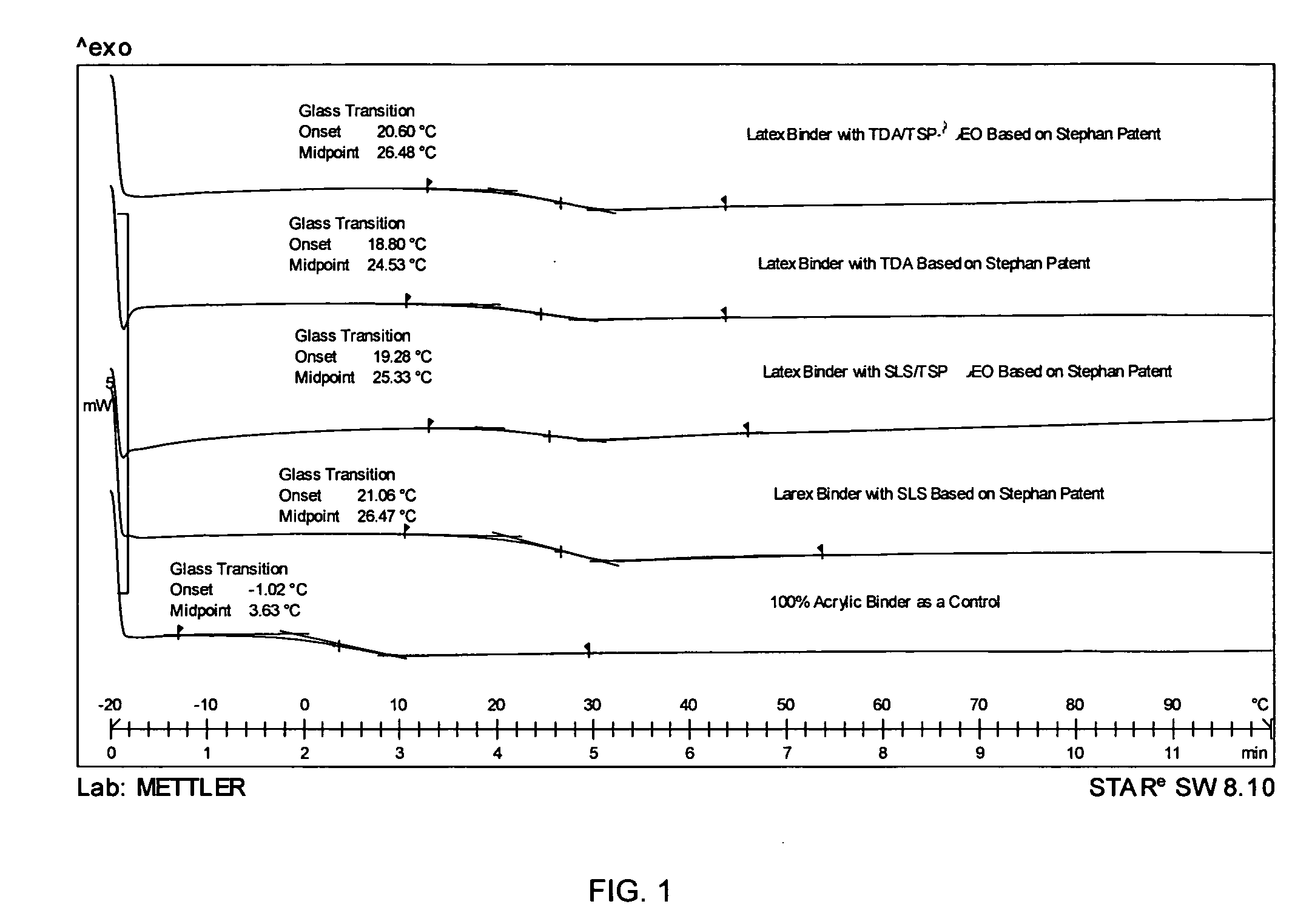

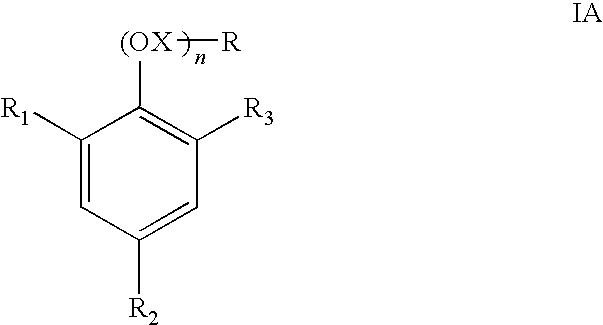

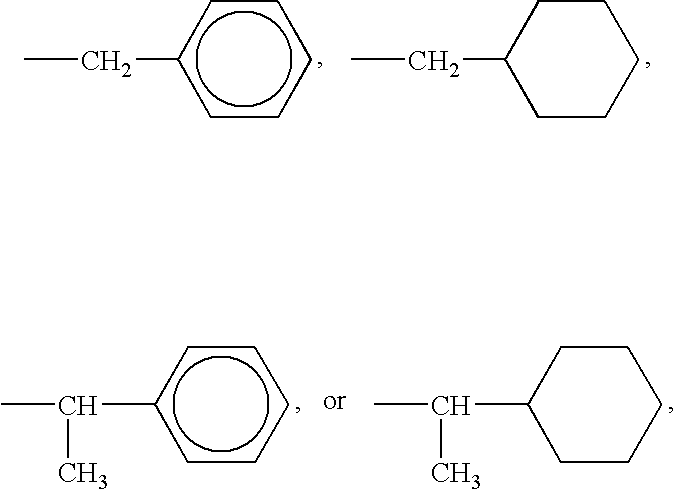

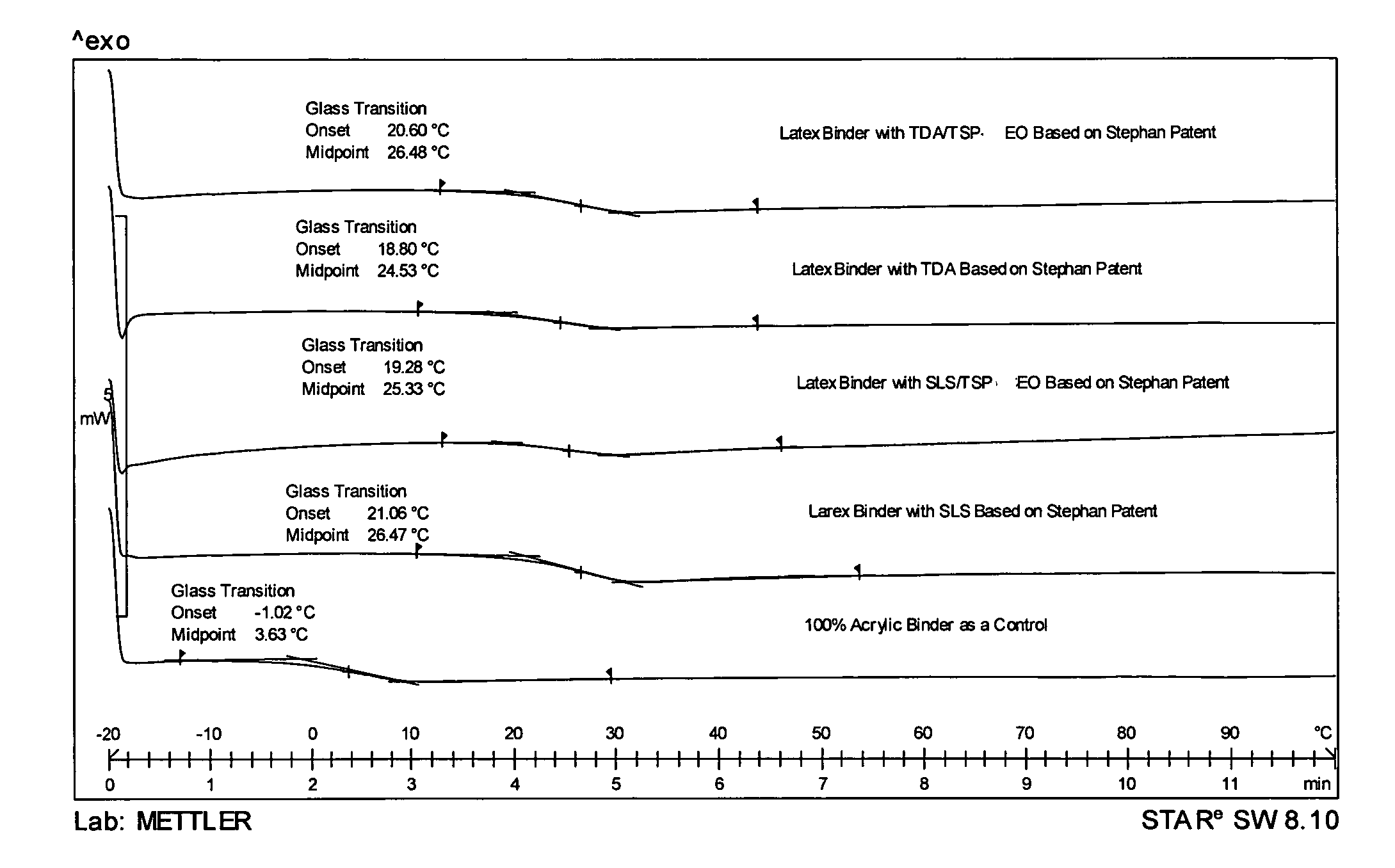

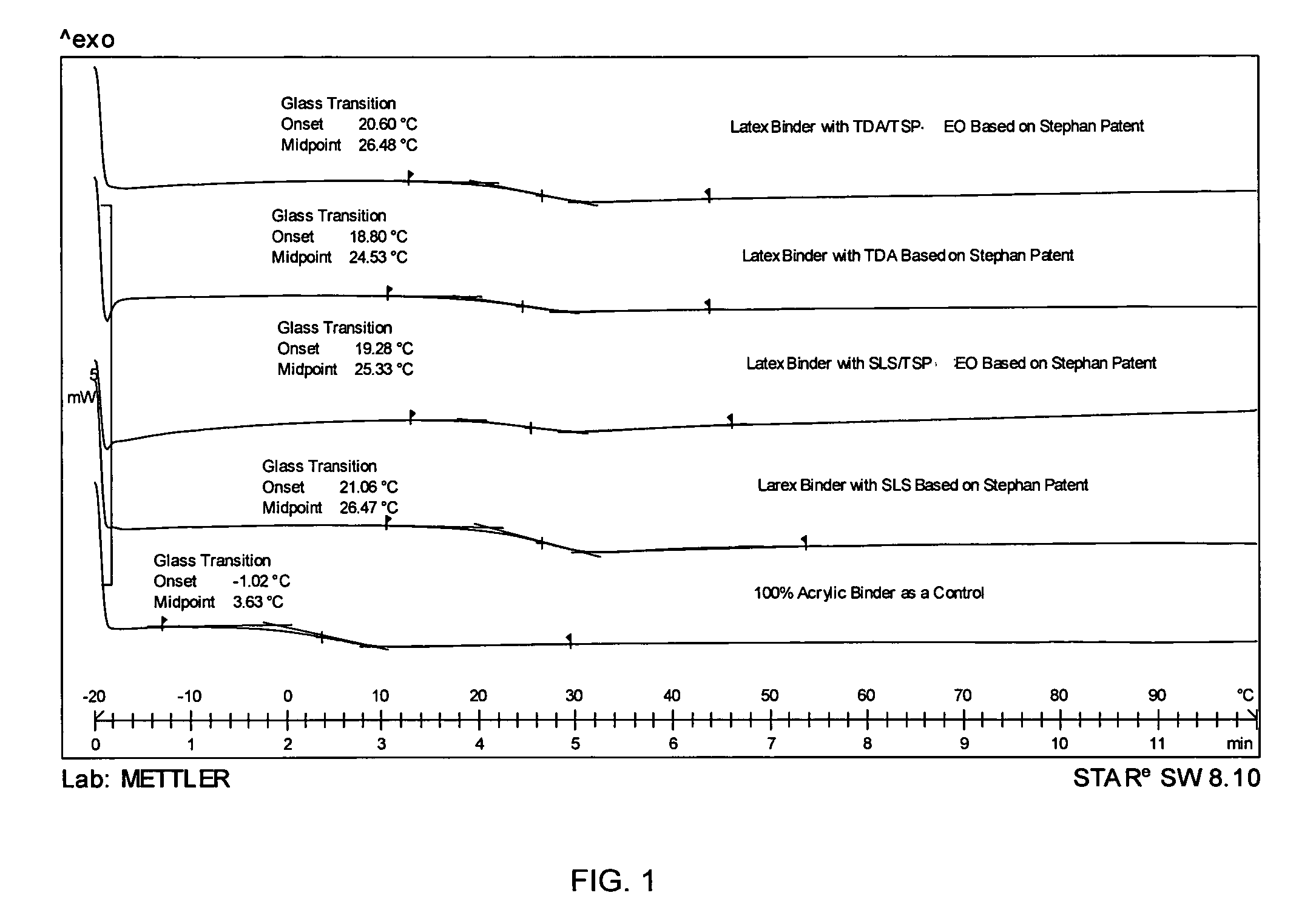

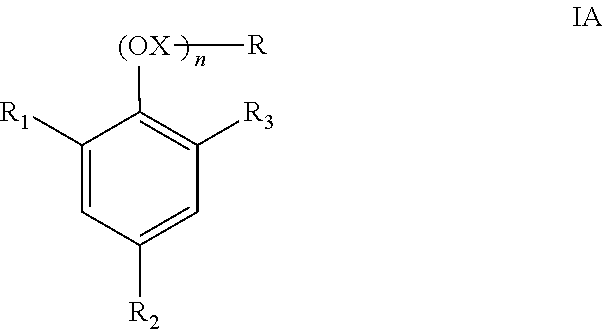

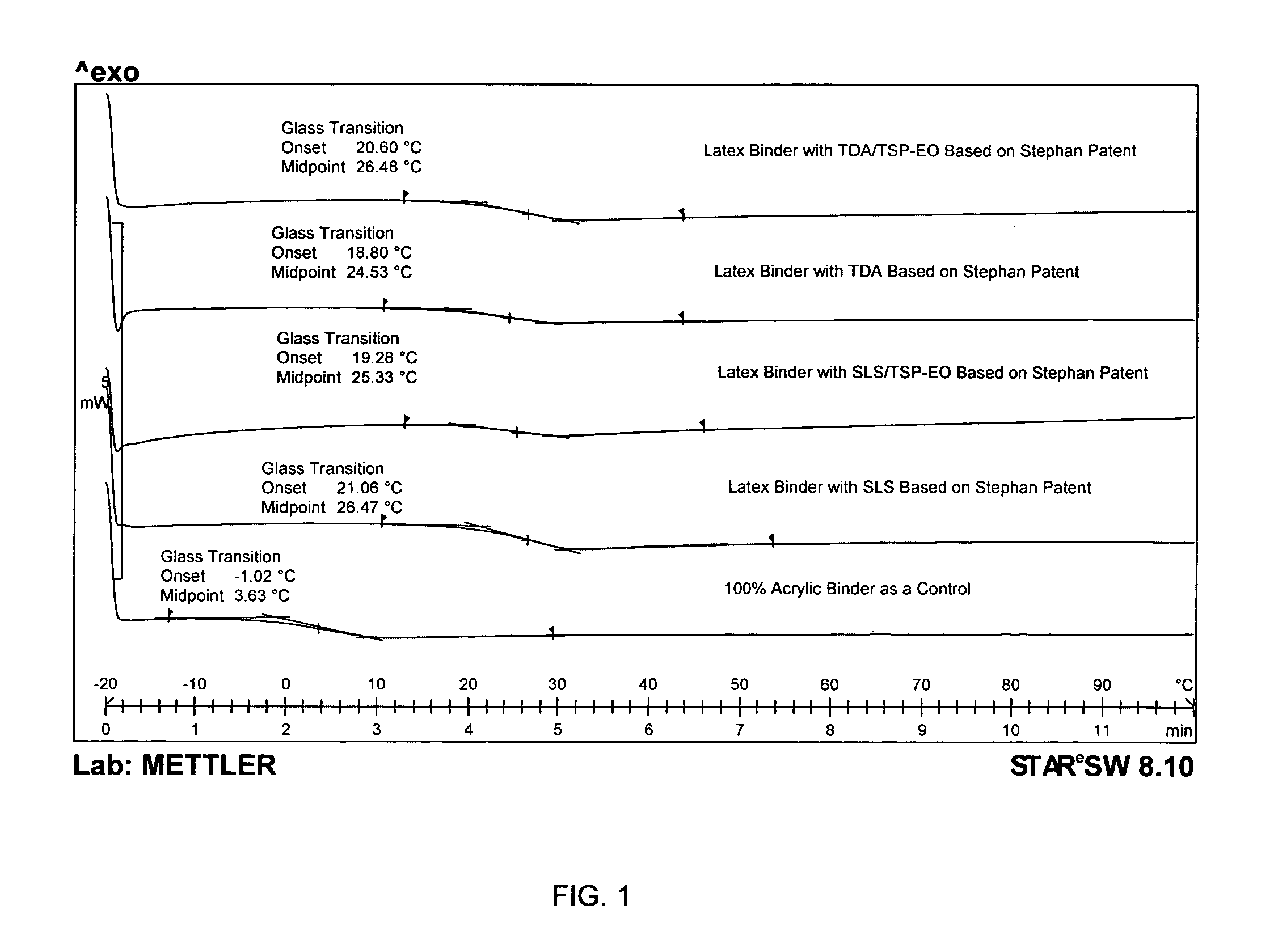

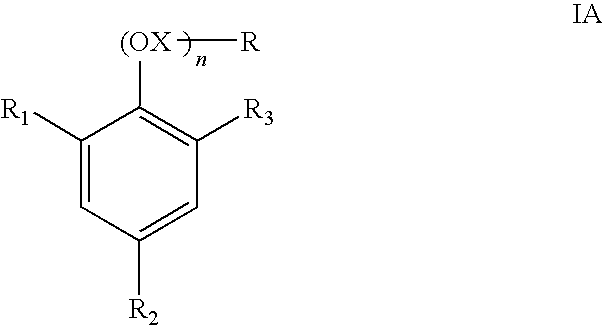

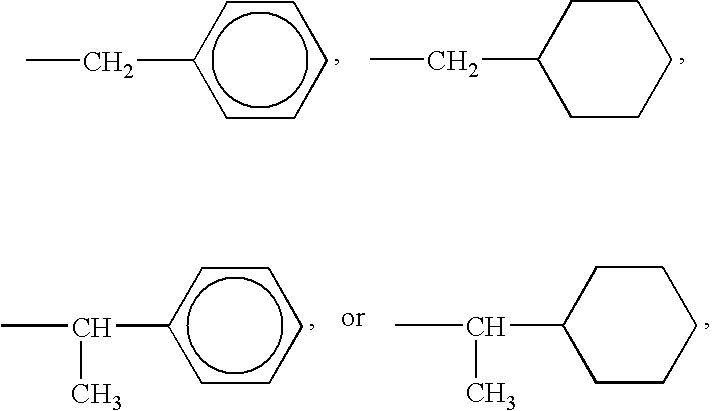

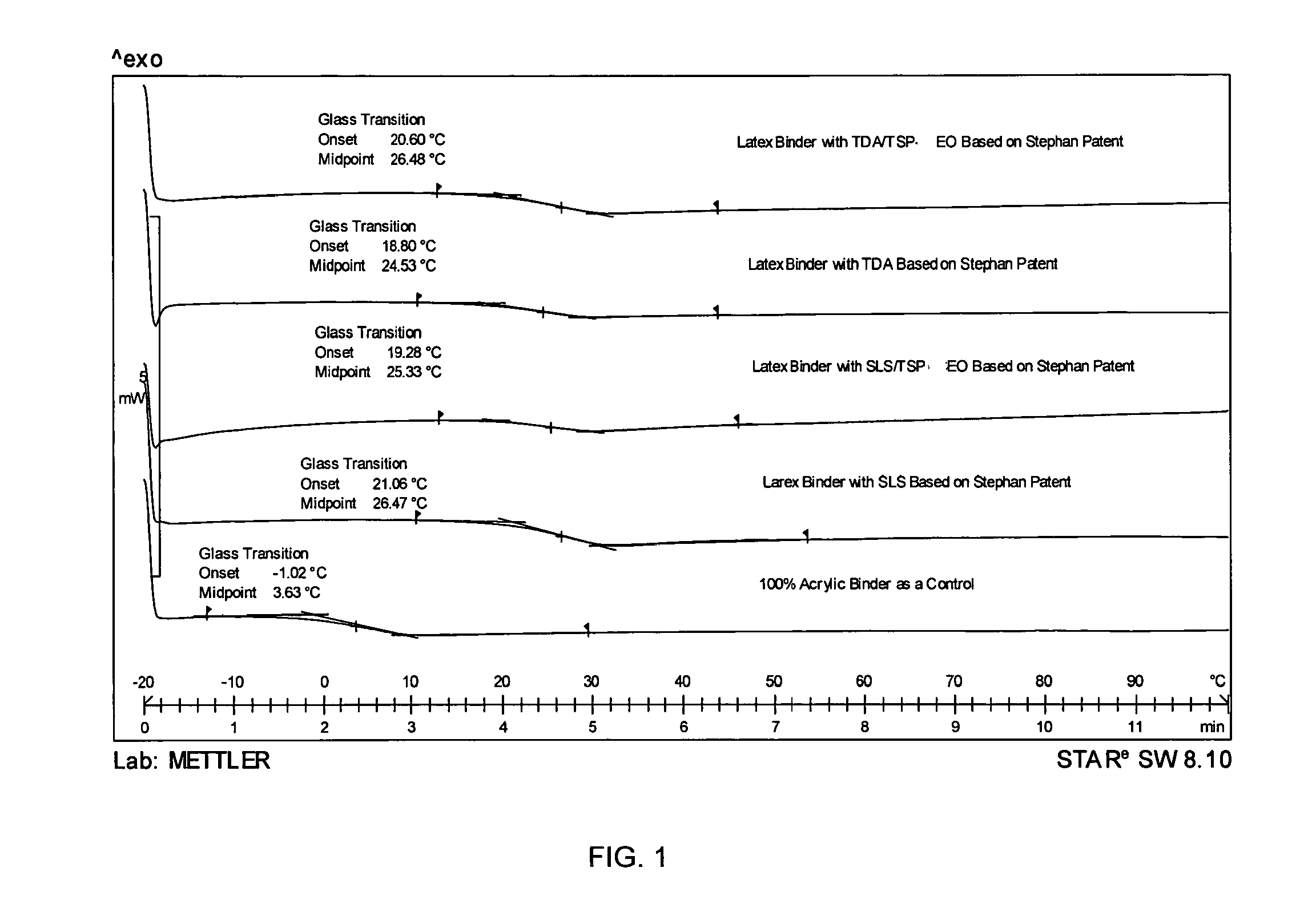

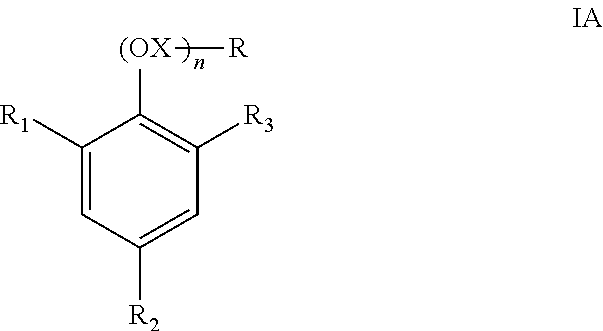

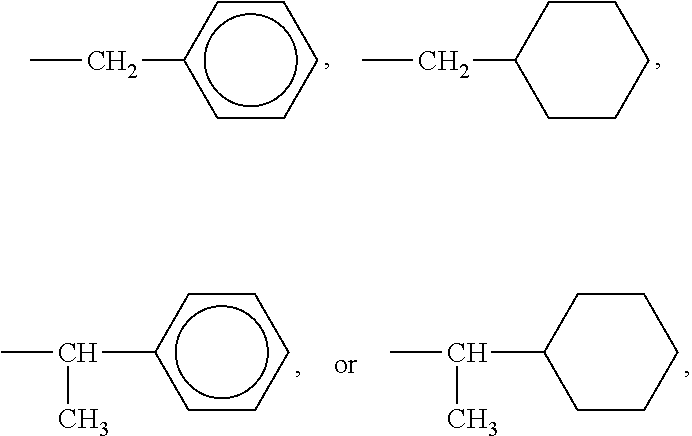

Latex binders, aqueous coatings and paints having freeze-thaw ability and methods for using same

ActiveUS20090186968A1Promote recoveryImprove freeze-thaw stabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsFreezing thawingPolymer chemistry

Disclosed are latex polymers and an aqueous coating compositions having excellent freeze-thaw stability, open time, stain resistance, low temperature film formation, foam resistance, block resistance, adhesion, water sensitivity and a low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating composition including at least one latex polymer, at least one pigment, water and at least one freeze-thaw additive. Typically, the freeze-thaw additive in an amount greater than about 1.3% by weight of the polymer, typically in an amount greater than about 2% by weight of the polymer, in an amount greater than about 4% by weight of the polymer, in an amount greater than about 7.5% by weight of the polymer, in an amount greater than about 10% by weight of the polymer or in an amount greater than about 20% by weight of the polymer.

Owner:RHODIA OPERATIONS SAS

Latex binders, aqueous coatings and paints having freeze-thaw stability and methods for using same

ActiveUS20090186972A1Improve freeze-thaw stabilityPromote recoveryPigmenting treatmentOrganic chemistryFreezing thawingPolymer chemistry

Disclosed are latex polymers and an aqueous coating compositions having excellent freeze-thaw stability, open time, stain resistance, low temperature film formation, foam resistance, block resistance, adhesion, water sensitivity and a low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating composition including at least one latex polymer, at least one pigment, water and at least one freeze-thaw additive. Typically, the freeze-thaw additive in an amount greater than about 1.3% by weight of the polymer, typically in an amount greater than about 2% by weight of the polymer, in an amount greater than about 4% by weight of the polymer, in an amount greater than about 7.5% by weight of the polymer, in an amount greater than about 10% by weight of the polymer or in an amount greater than about 20% by weight of the polymer.

Owner:RHODIA OPERATIONS SAS

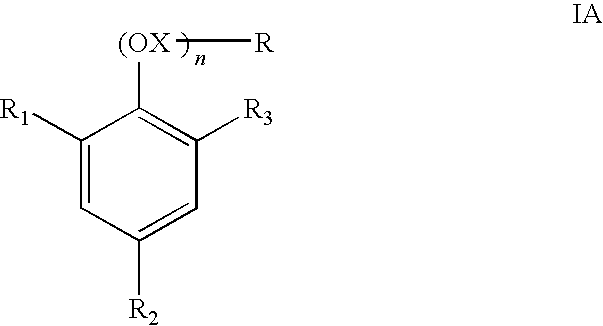

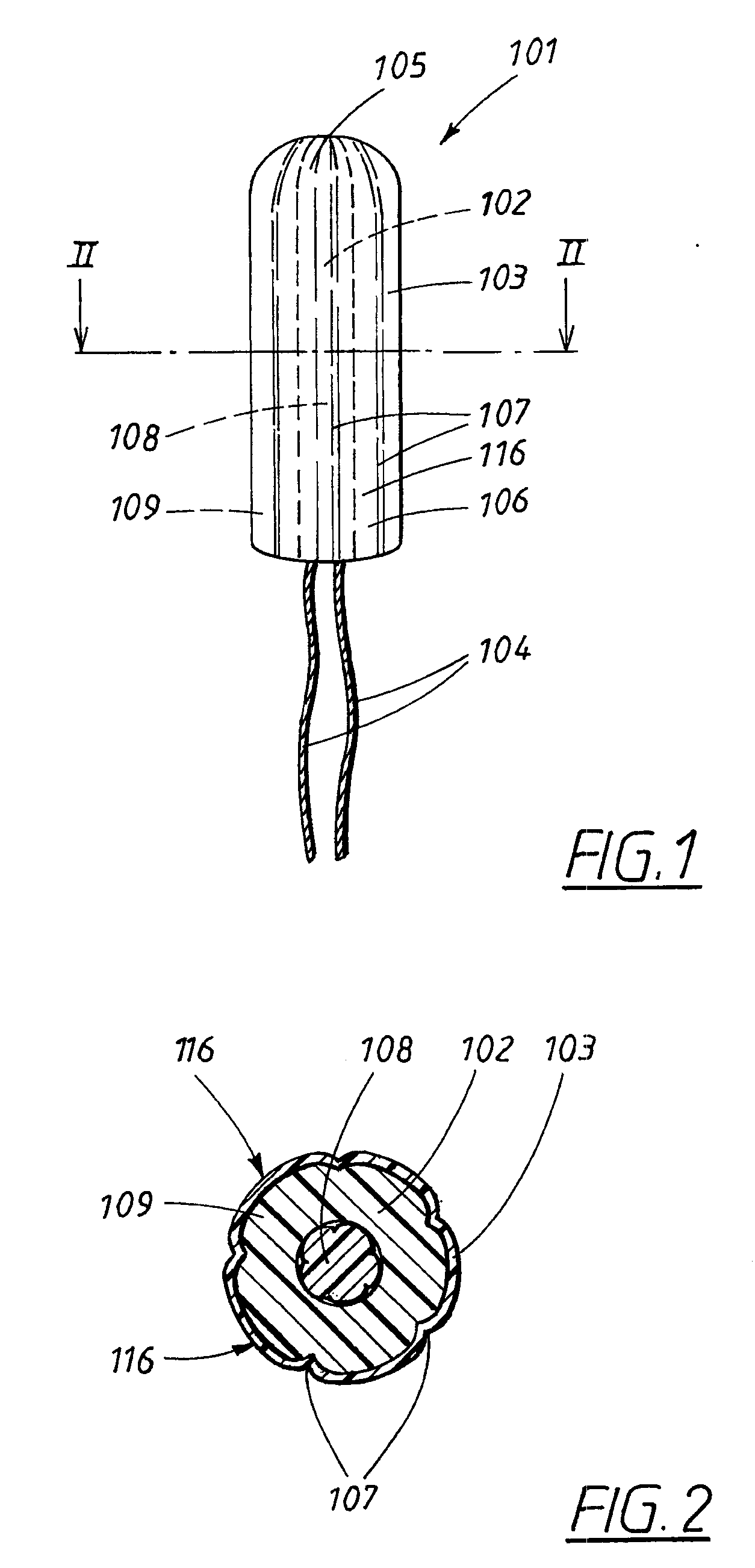

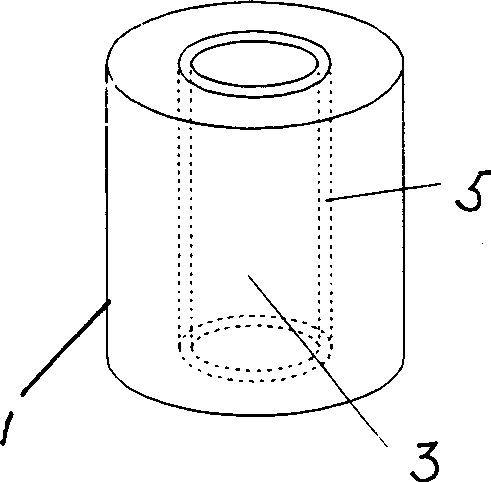

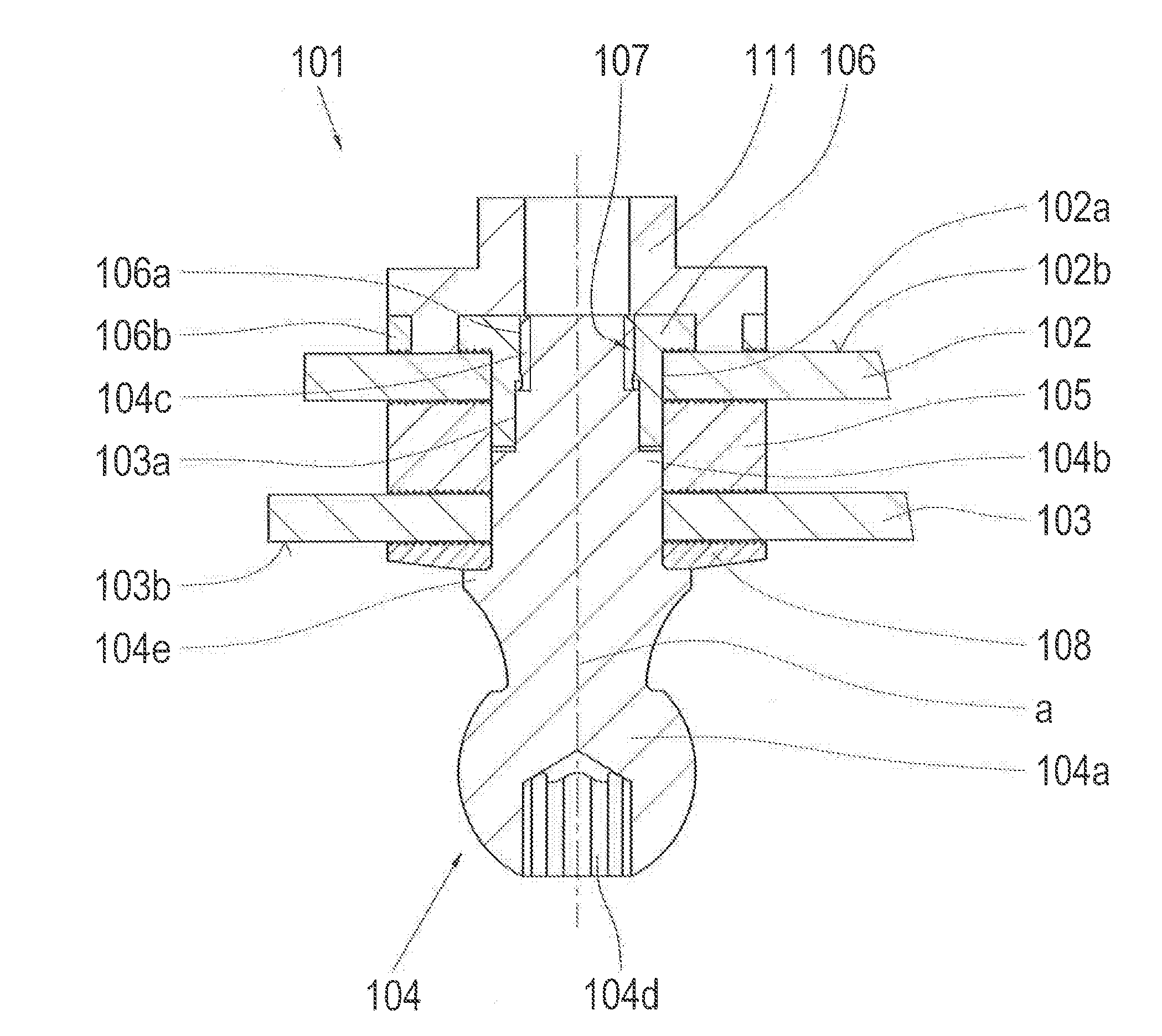

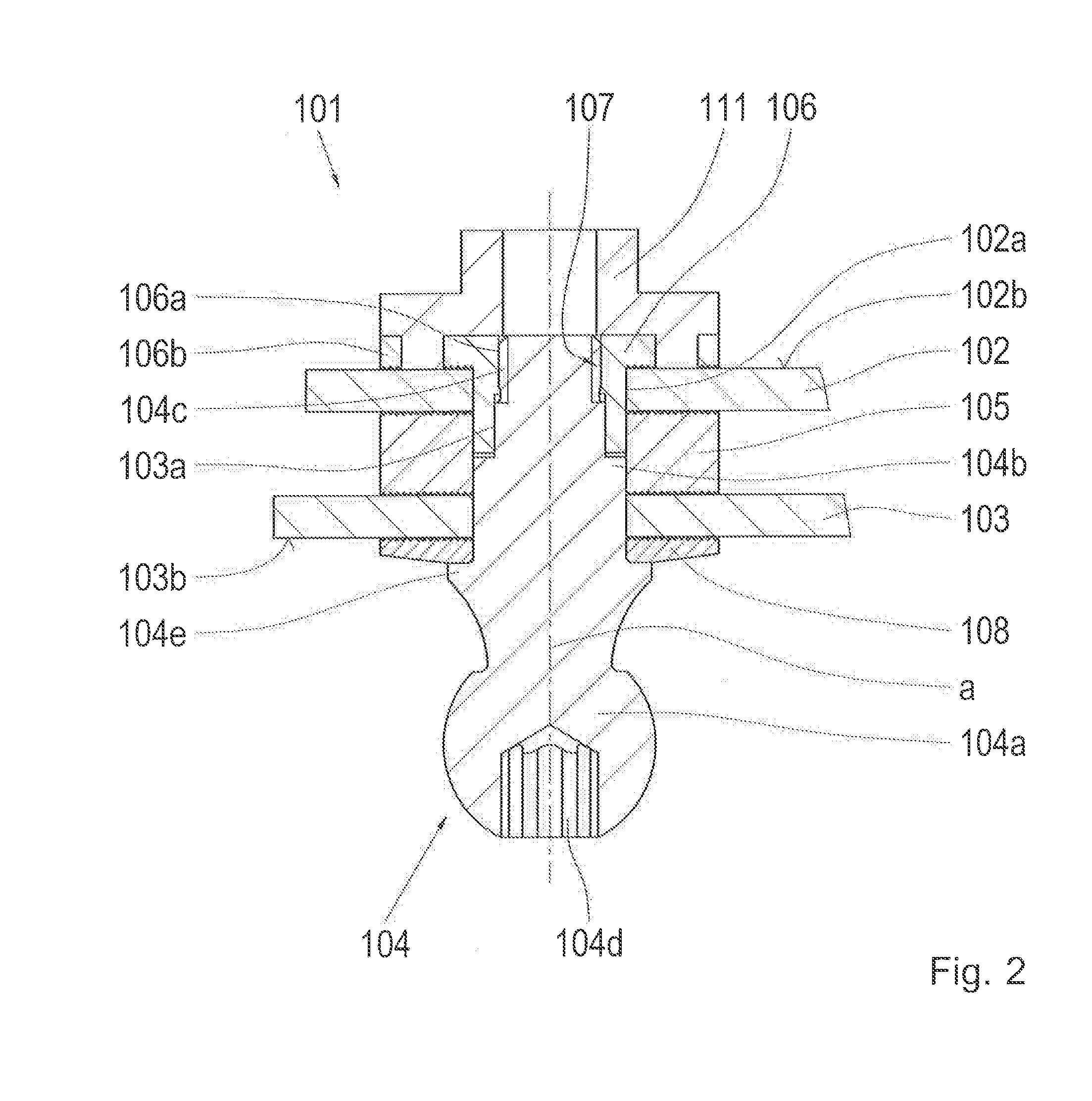

Tampon

A tampon (101) having an insertion end (105) and a withdrawal end (106), and a withdrawal string (104) extending from the withdrawal end (106), the tampon (101) having a fibrous absorbent tampon body having multi-limbed viscose fibers, said tampon body having an inner core (108) and an outer absorbent structure (109) surrounding the inner core (108), the inner core (108) being more dense than the outer absorbent structure (109). The inner core (108) is made of a fibrous blend having 0-25% by weight of multilimbed viscose fibers and the outer absorbent structure (109) is made of a fibrous blend having 30-100% by weight of multilimbed viscose fibers.

Owner:SCA HYGIENE PROD AB

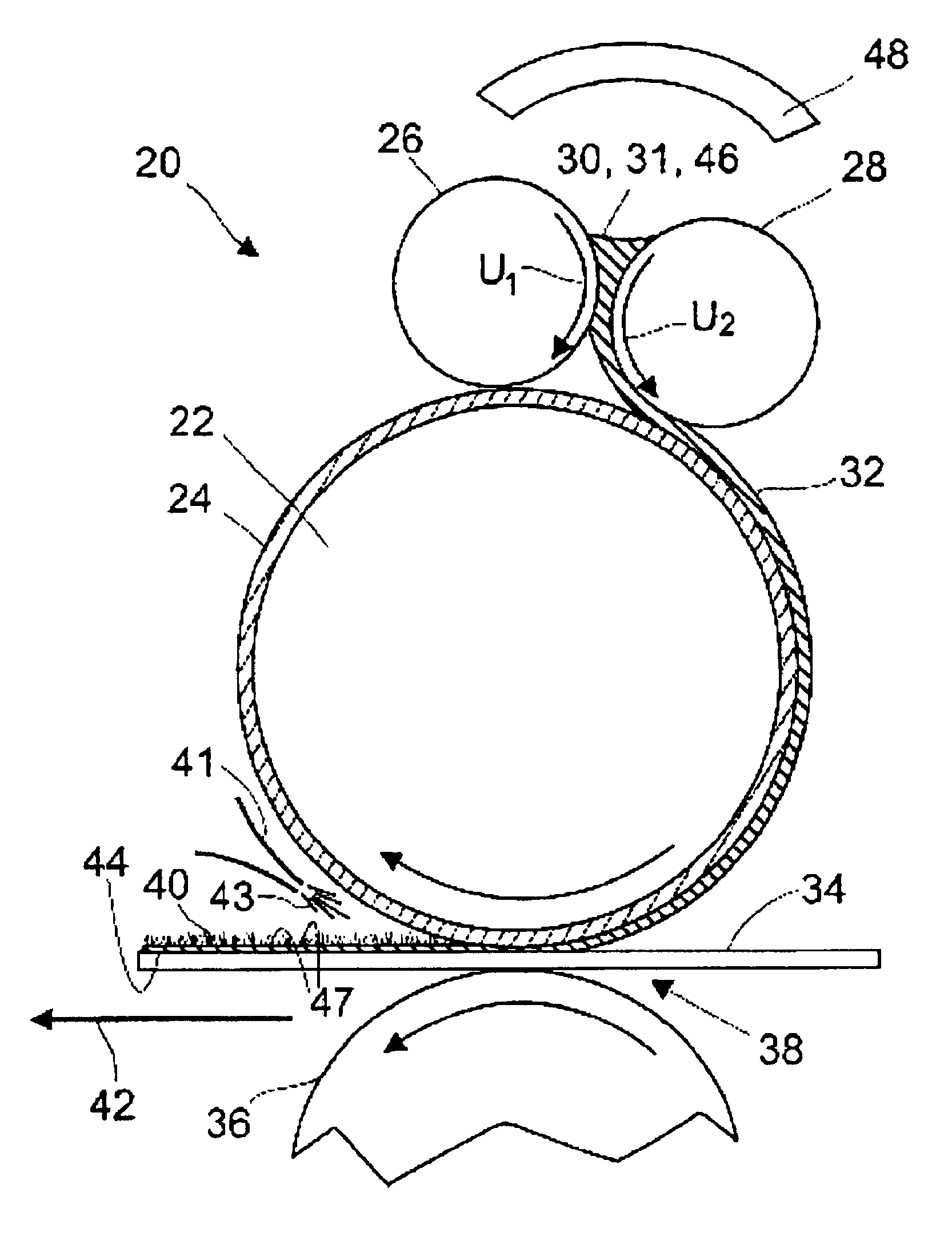

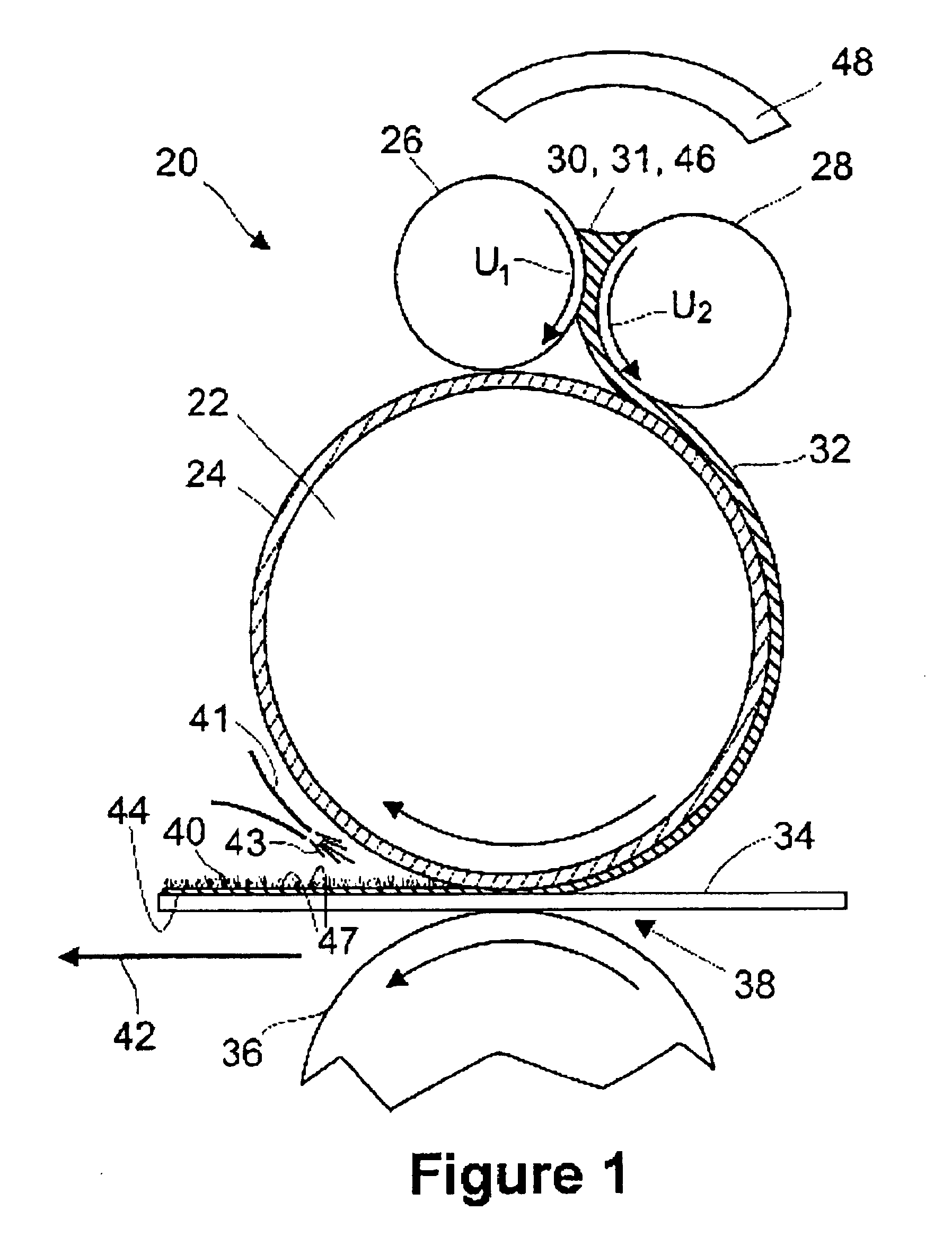

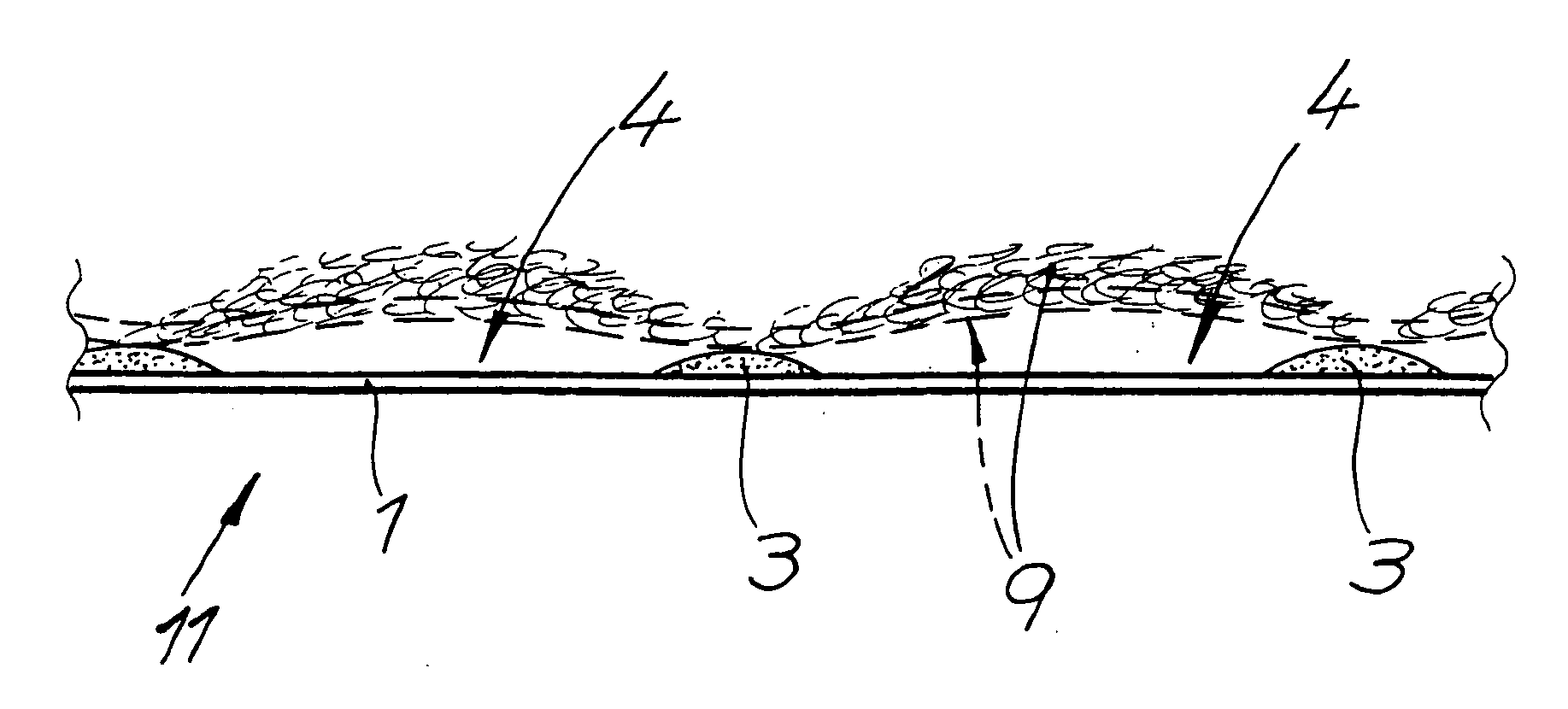

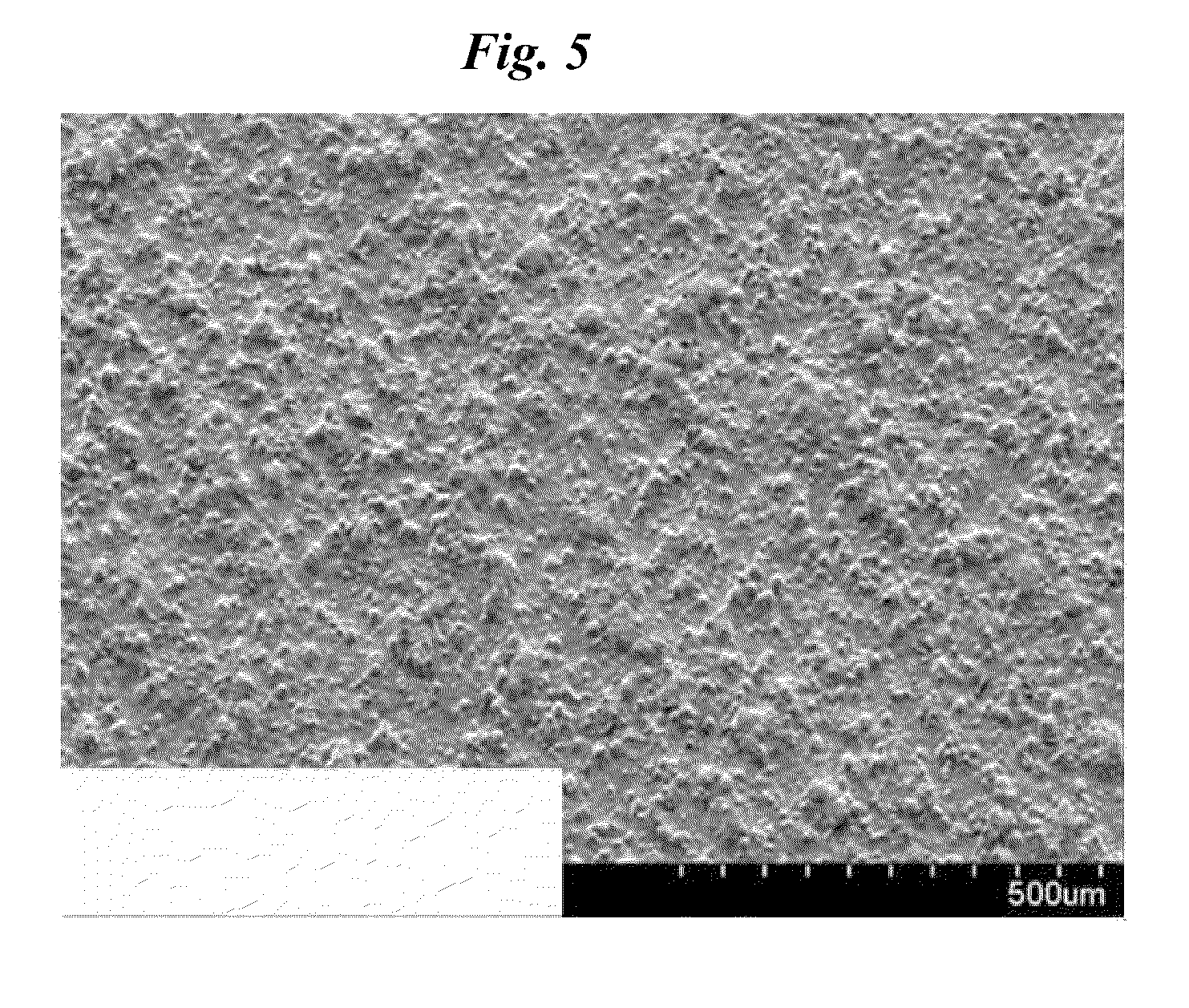

Absorbent webs including highly textured surface

InactiveUS6964726B2Improve adhesionIncrease contactNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

The present invention discloses a paper web with a highly textured surface and a method of forming the highly textured web. The process includes printing a viscous material onto the surface of a paper web in a pattern with a low pressure printing process. Specifically, it has been discovered that certain low pressure printing technologies may be used to deliver a viscous material to the surface of a paper web such as a tissue, an air laid web, or a fibrous nonwoven web with good control of material delivery. At some point after the viscous material is applied to the web, the material may be fibrillated into a three-dimensional structure and then cured. In various embodiments, the viscous material may be fibrillated and cured so as to provide a good scrubbing surface to the web, provide an attachment structure on the web, or provide a good contact surface against a second substrate in forming laminate products.

Owner:KIMBERLY-CLARK WORLDWIDE INC

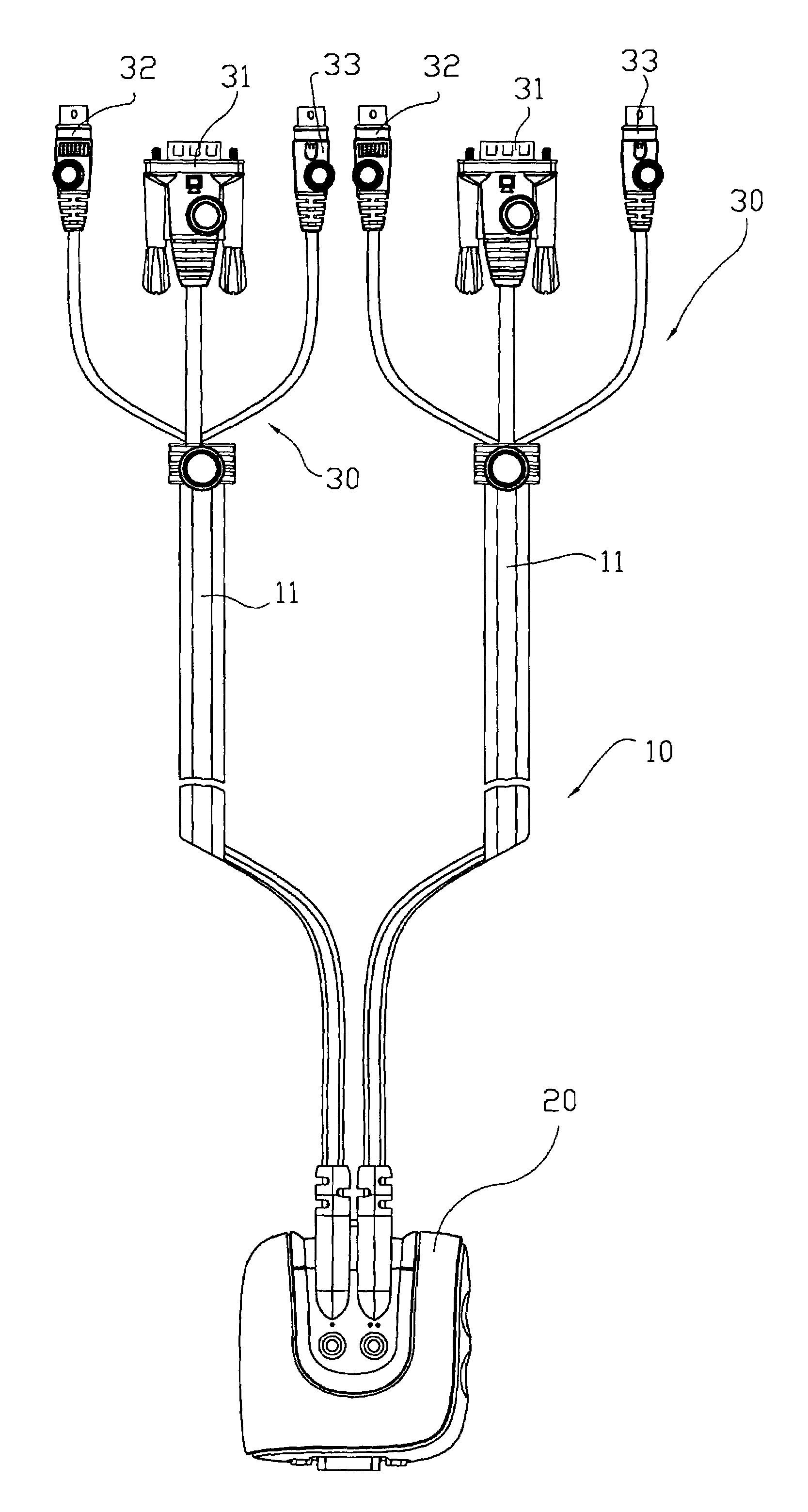

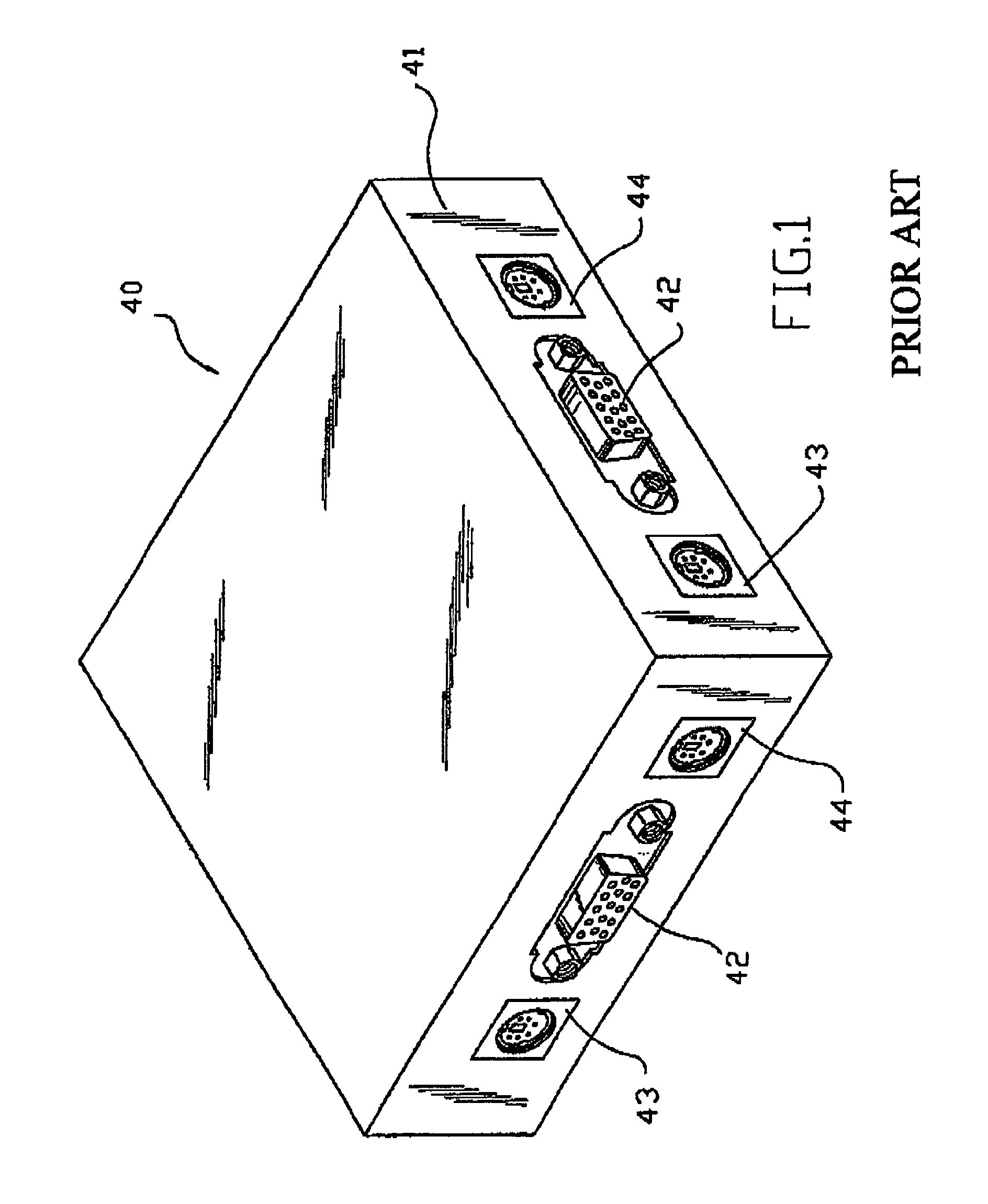

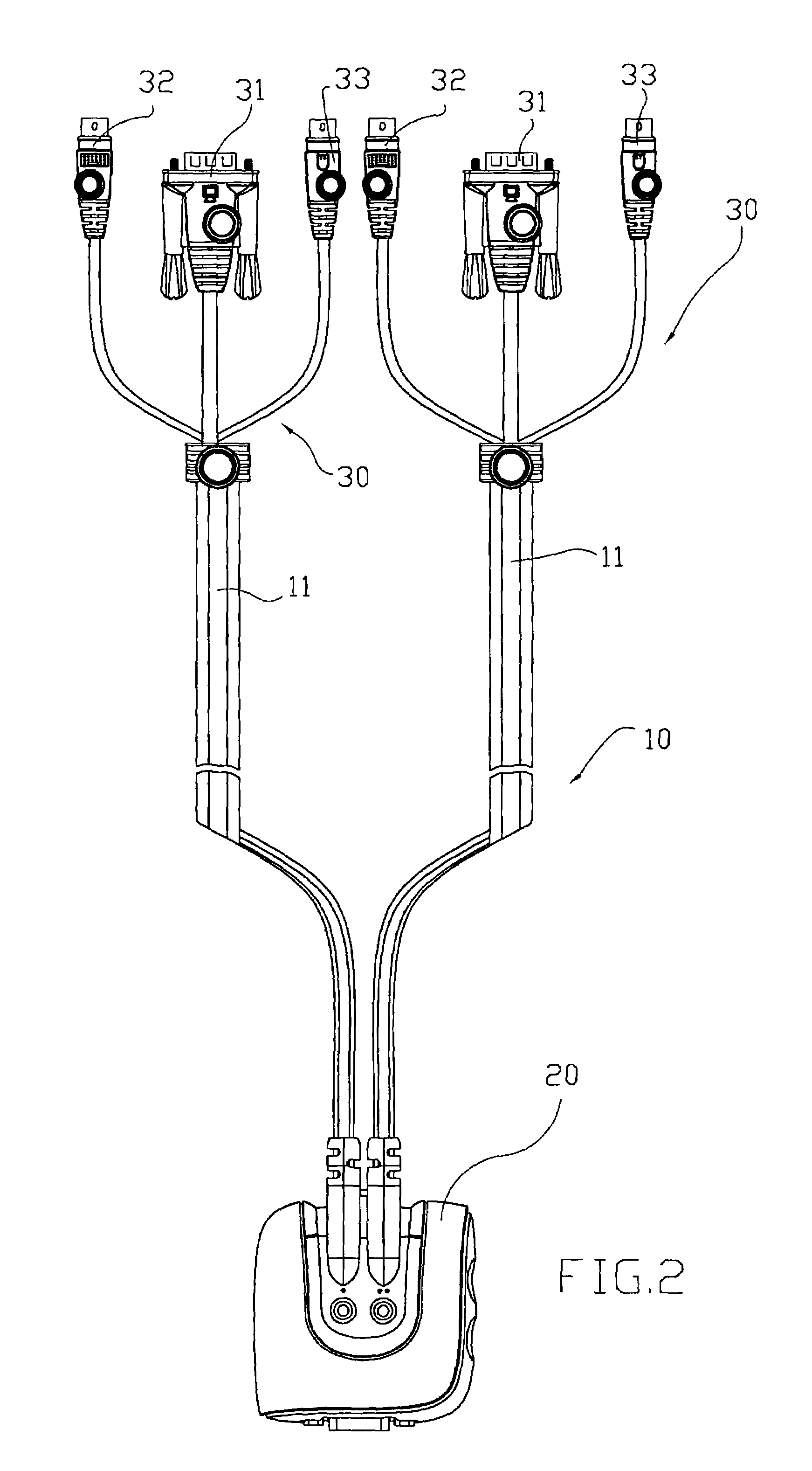

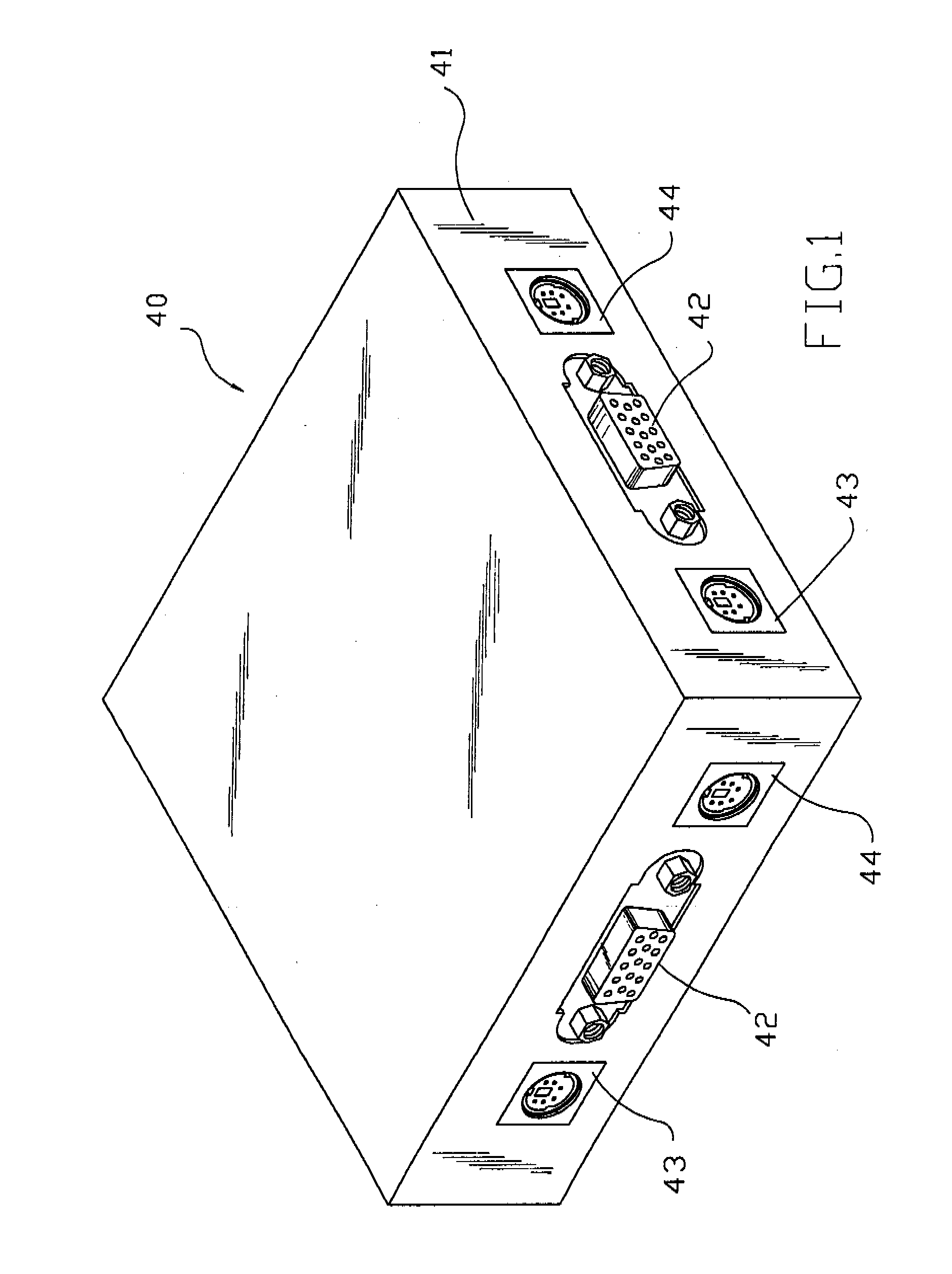

Automatic switch

InactiveUS7035112B2Improve protectionAvoid damageEngagement/disengagement of coupling partsBus-bar/wiring layoutsMulti injectionElectrical and Electronics engineering

Owner:ATEN INT CO

Elastic filament and processing method for drum dyeing of elastic yarn

ActiveCN1807741AFully contractedFlat surfaceLiquid/gas/vapor yarns/filaments treatmentBobbinPulp and paper industry

The invention relates to a flexible filament and its flexible yarn barrel dye process method, which has the following steps: convoluting the flexible filament or flexible yarn loosely around the slippery paper tube, wrapping them with the netted fabric; pressing the netted plastic tube that the dye barrel yarn used into the paper core, dropping out the wrapped paper tube; rewrapping the exchanged barrel yarn with the plastic tube again and putting them in cross and parallel direction into the flexible yarn swelling, contracting and shaping device, and they receive the first contracting through temperature rising, then the second contracting through the second temperature rising; after the yarn is tightened in the netted plastic tube, caging and dyeing; rising when dyeing to make the yarn contract again; after dyeing, soap washing - water washing - dehydrating - drying-semi - finished product checking - waxing - bobbin-winding - product checking - product casing or weaving.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

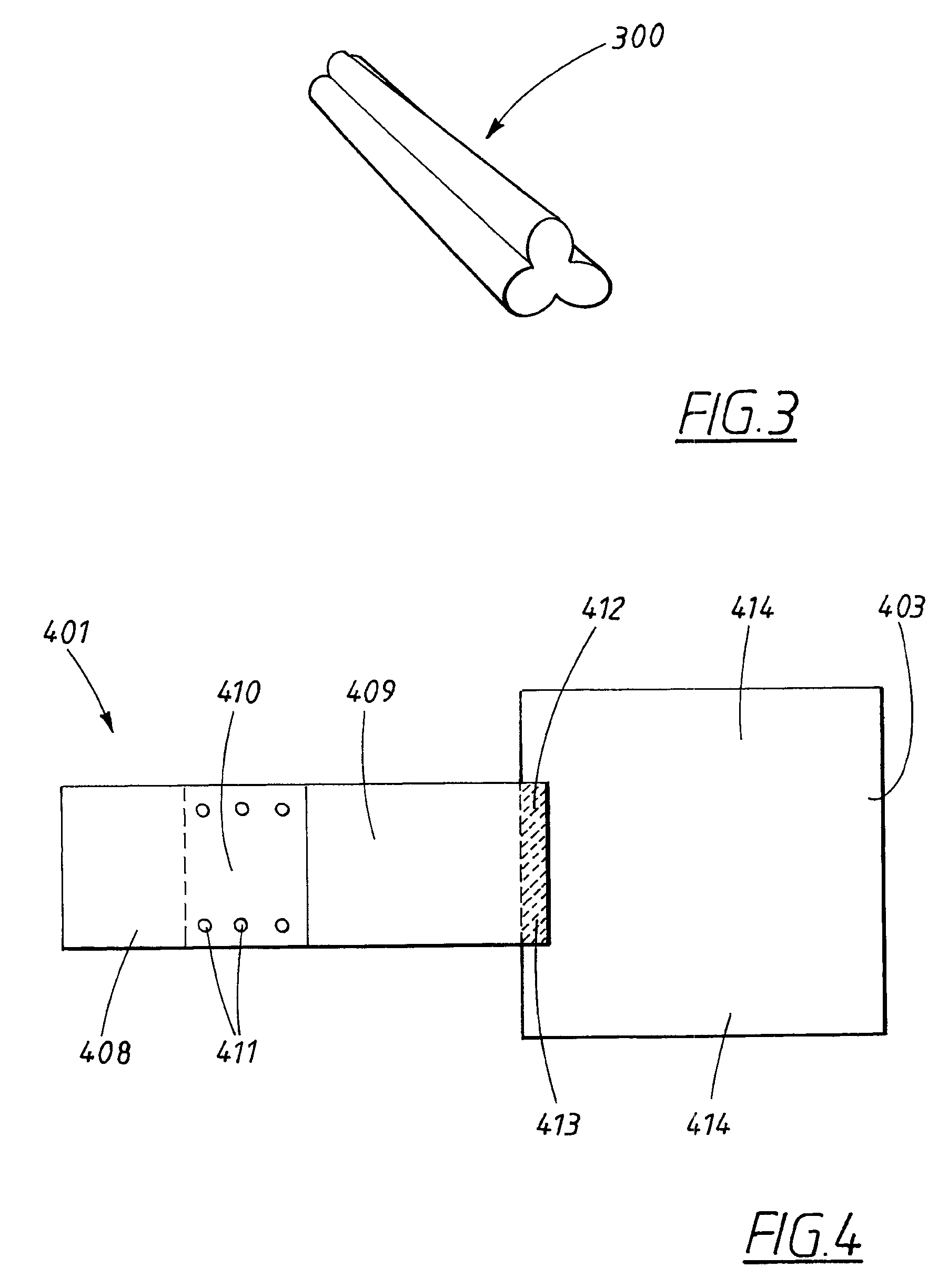

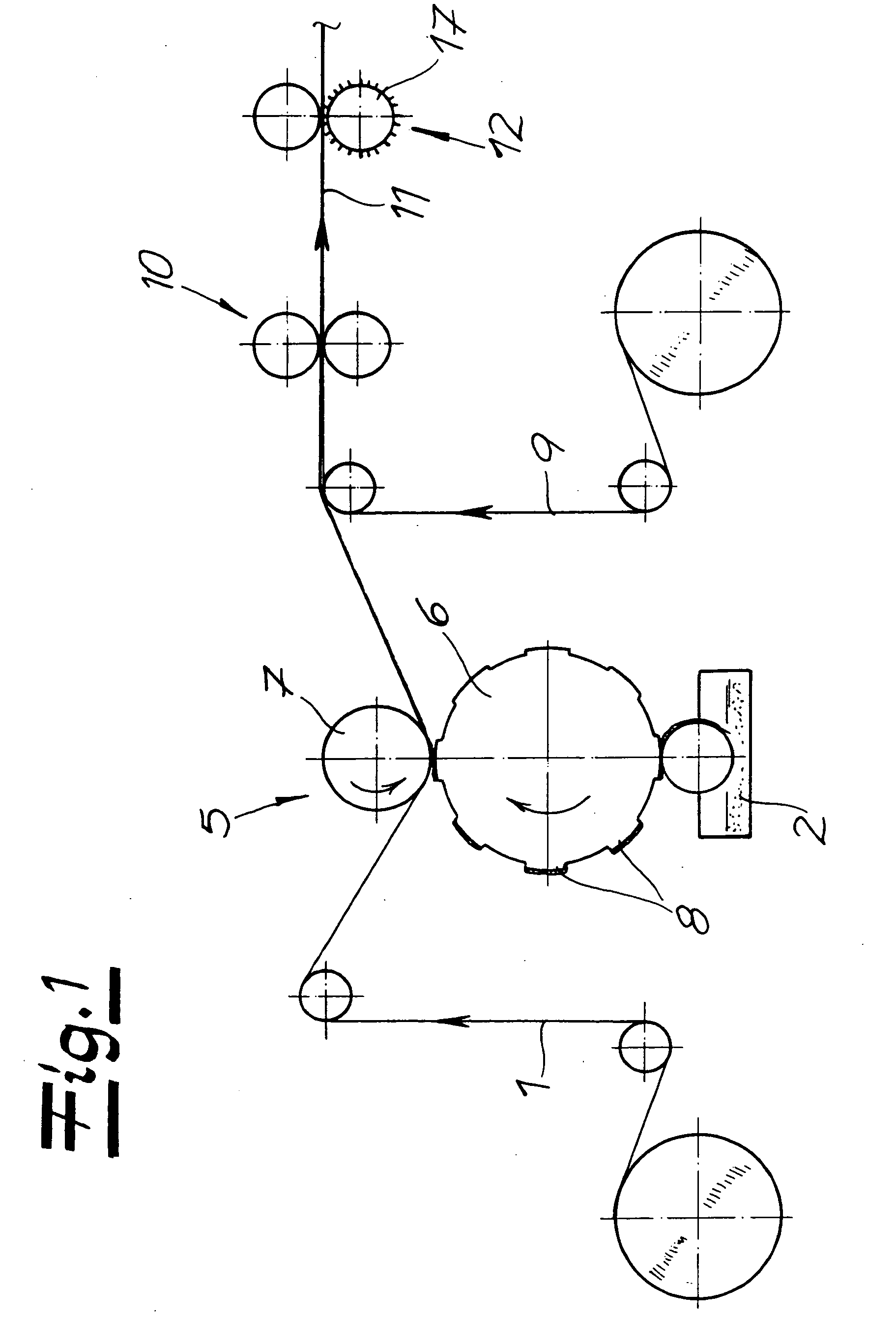

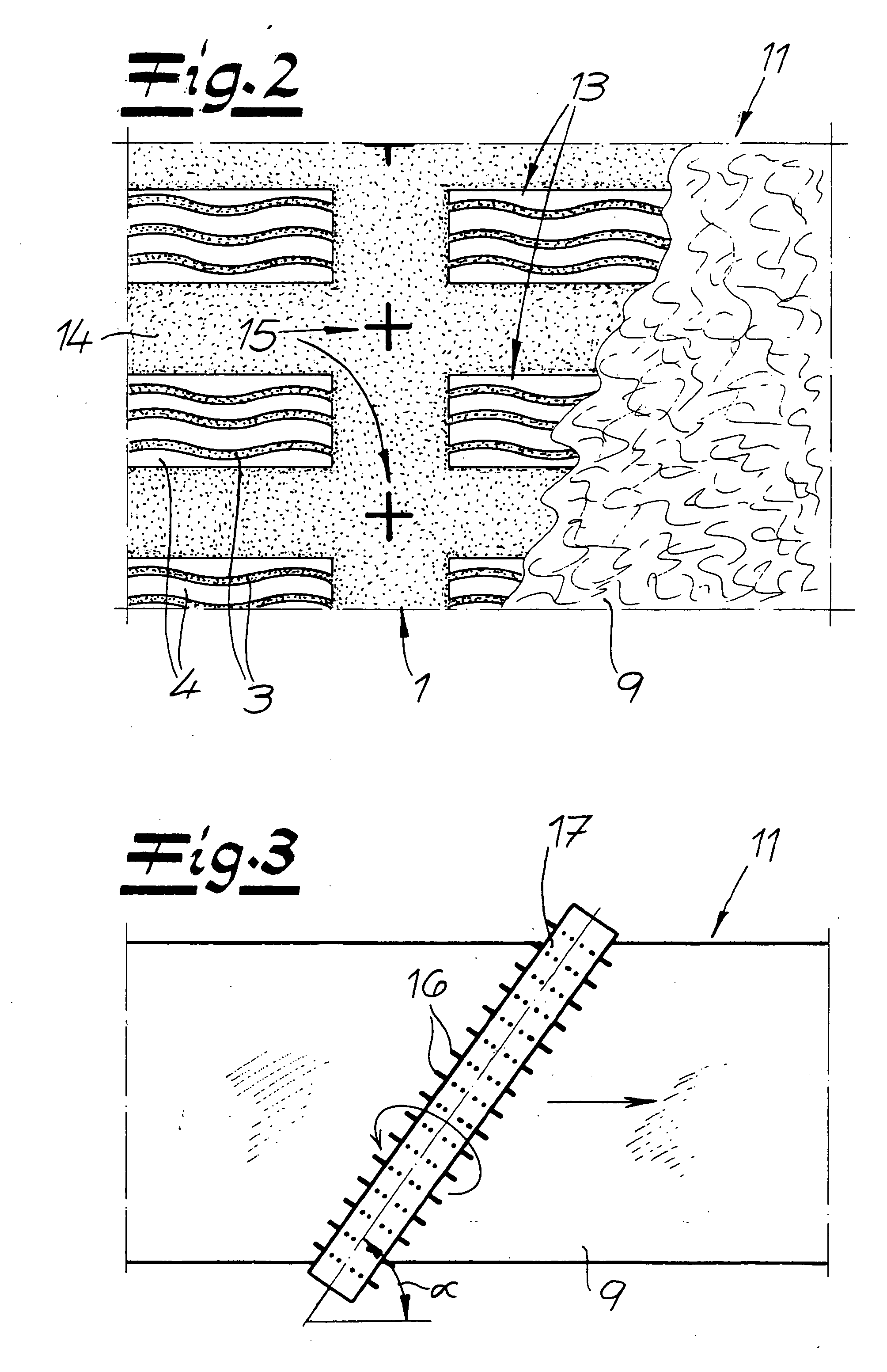

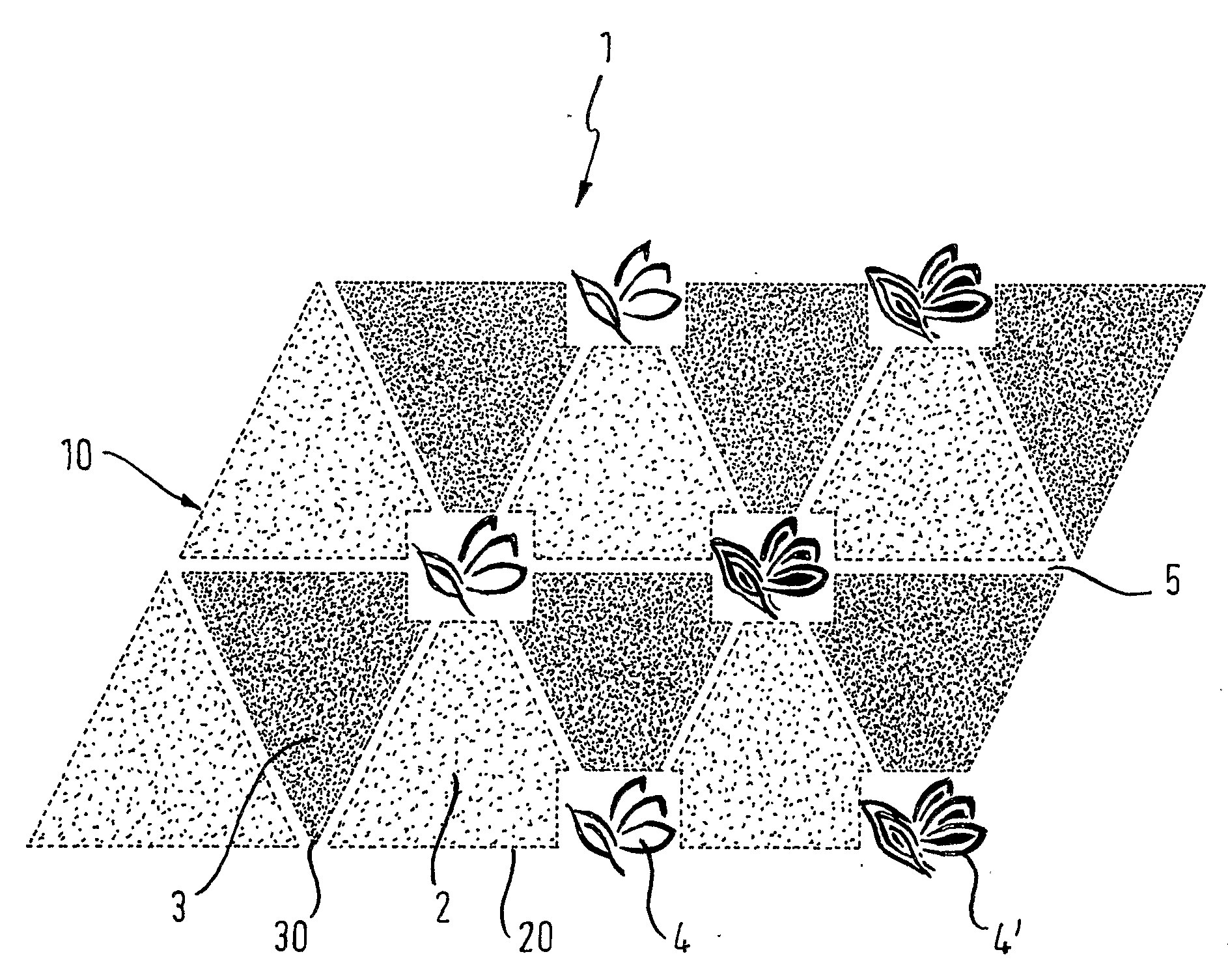

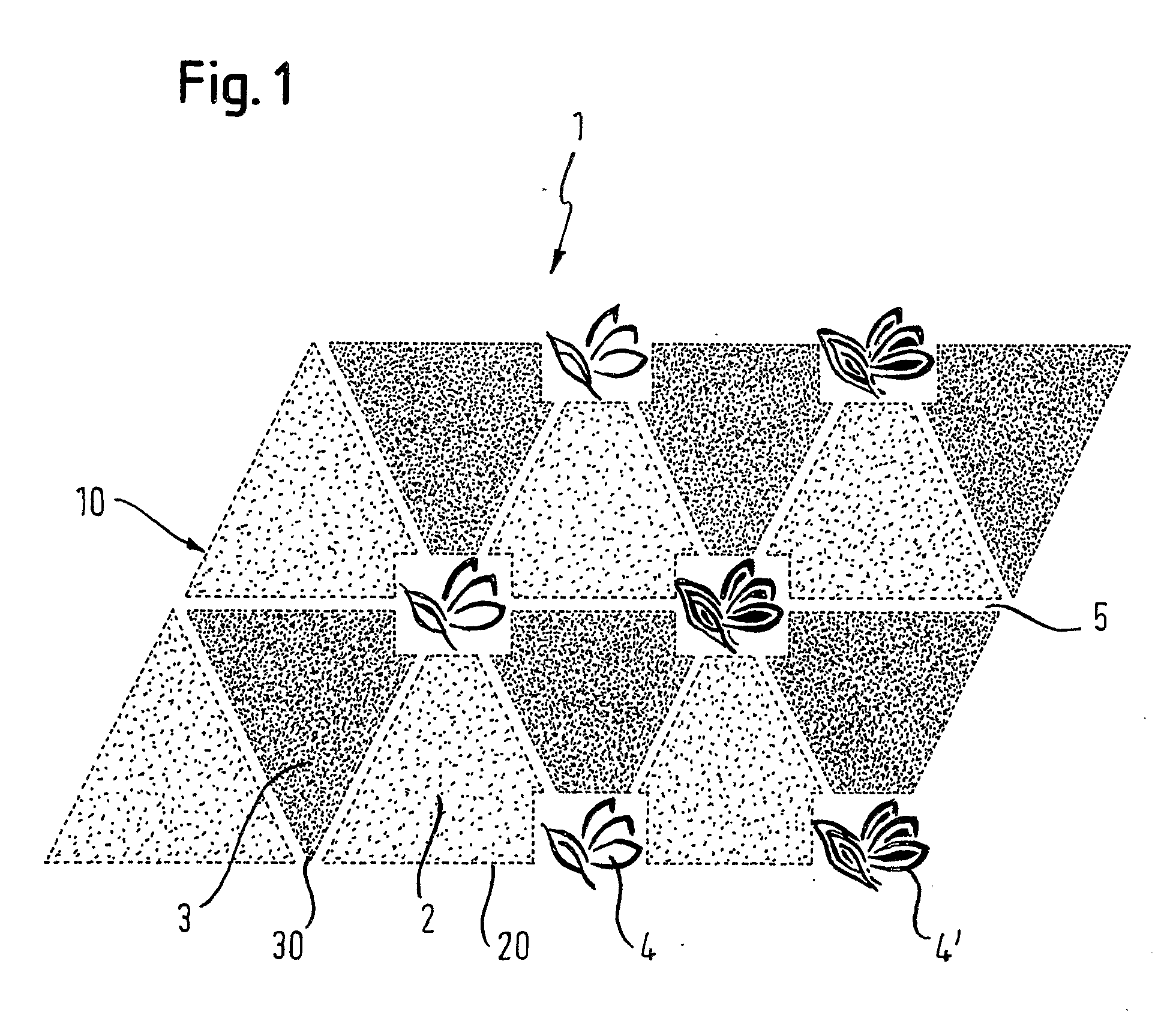

Method for the production of a laminate material for hook and loop closures

InactiveUS20060180272A1Improvement hookImprovement loop propertySlide fastenersSynthetic resin layered productsEngineeringMechanical engineering

A method for the production of a laminate material for hook and loop closures, particularly for diaper closures, comprises laminating a textile material onto a carrier film having a surface structure that is suitable for forming a connection with the hooks of a hook and loop closure. The textile material is not connected with the carrier film over its entire area, and the textile material forming the cover layer of the laminate material is brushed after lamination.

Owner:MONDI GRONAU

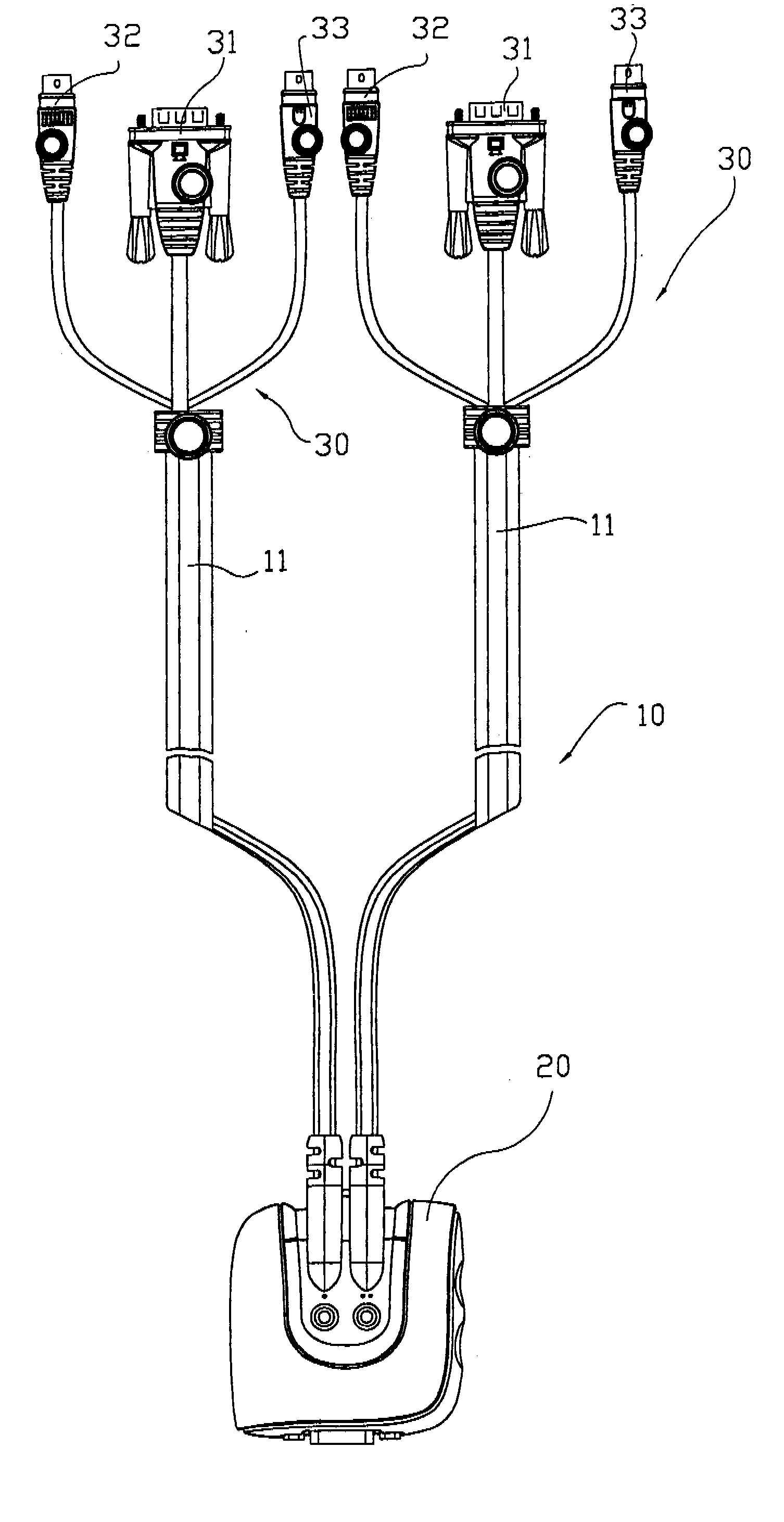

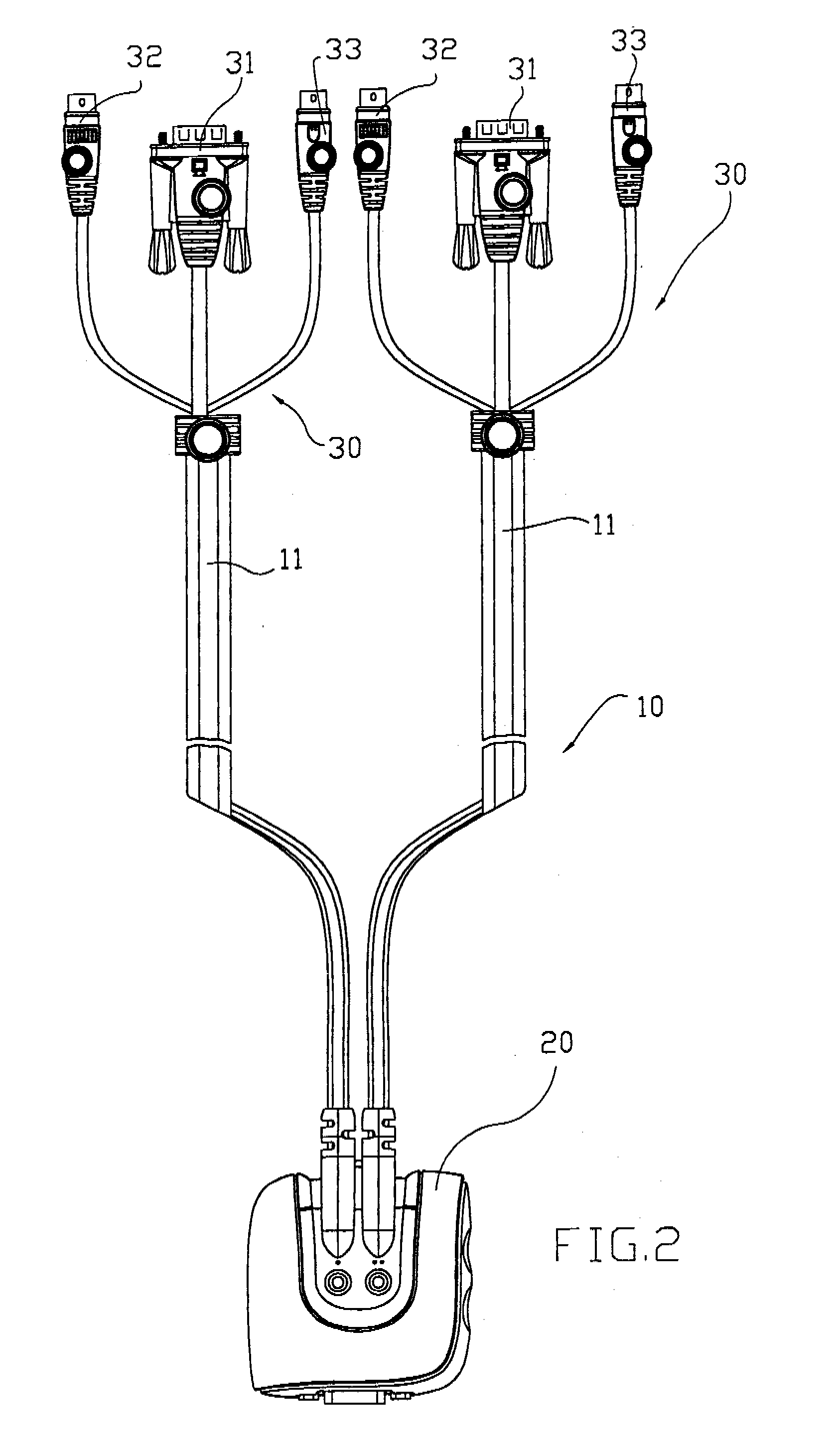

Automatic Switch

InactiveUS20040001323A1Low melting pointAvoid damageEngagement/disengagement of coupling partsBus-bar/wiring layoutsStructural engineeringElectric coupling

Abstract of the Disclosure A switch having a body containing a switching circuit; a set of connector ports electrically coupled to the switching circuit; and a plurality of cables fixedly attached to and extending from the body. Each cable in the plurality of cables electrically couples a respective connector plug to the switching circuit, wherein the switching circuit switches to connect each of the set of connector ports to one of the plurality of cables. The body can include a circuit-protecting layer surrounding the switching circuit, an outer case surrounding the circuit-protecting layer, and an anti-slipping layer coating.

Owner:ATEN INT CO

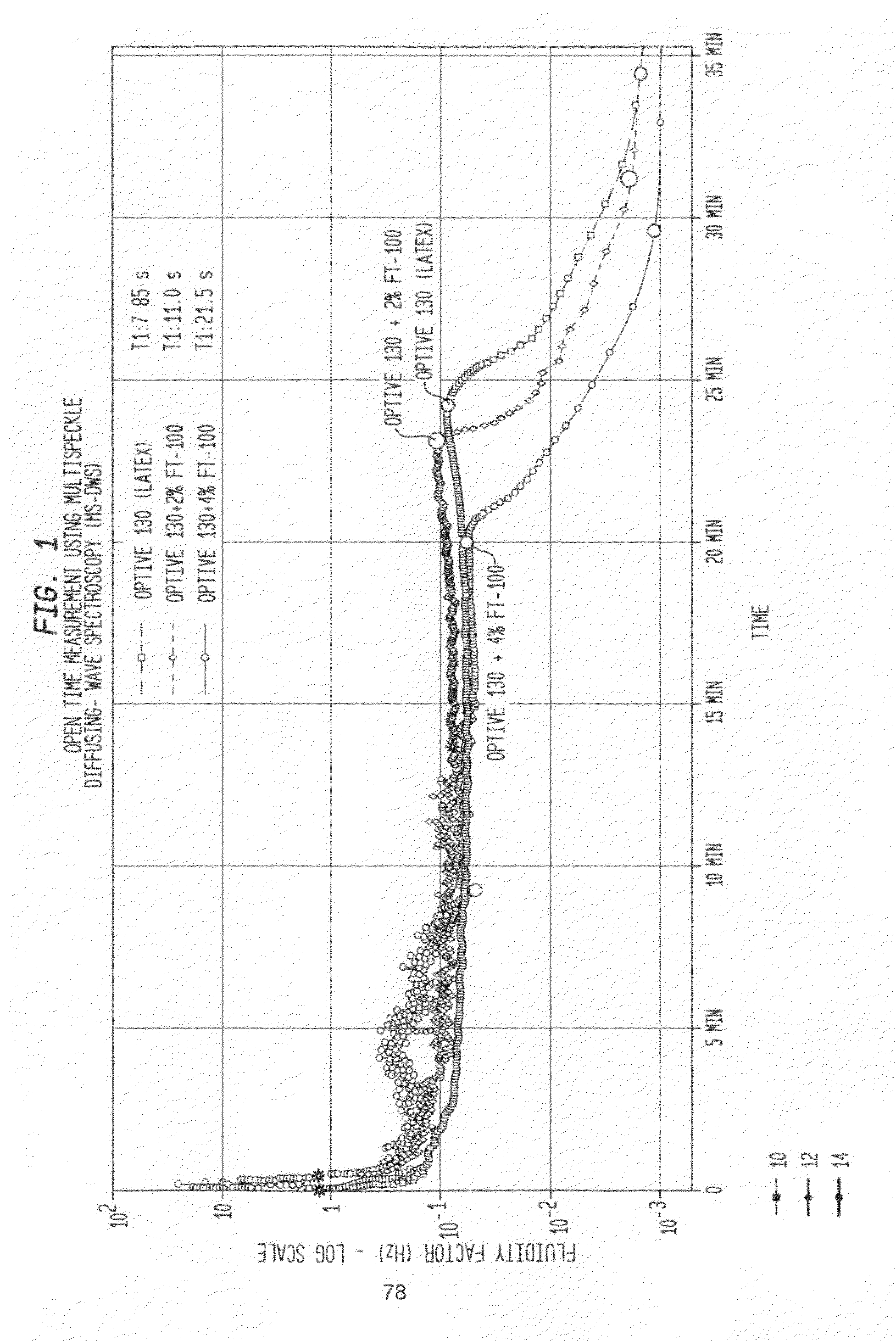

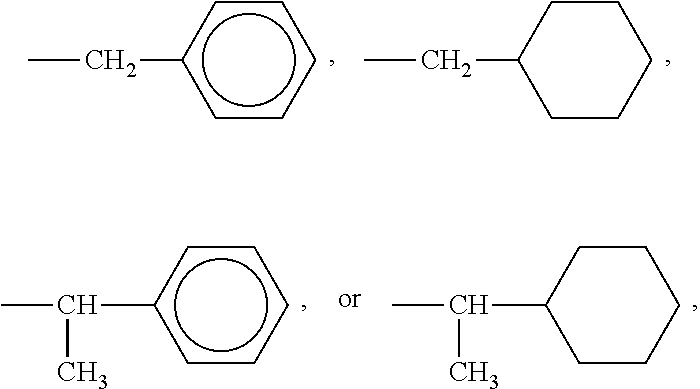

Methods and systems for improving open time and drying time of latex binders and aqueous coatings

ActiveUS20110144248A1Improving open time characteristicExtended opening timeOrganic chemistryOther rubber coatingsTime profileDrying time

Disclosed are low Tg latex polymers and low VOC aqueous coating compositions having an improved open time profile, as well as drying time, stain resistance, wet edge time, low temperature film formation, block resistance, adhesion, water sensitivity and low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or alkoxylated compounds or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating or adhesive composition including at least one latex polymer, water and one or a blend of two or more open time additives or drying time additives. The blend can comprise nonionic and anionic open time additives. Typically, the open time and / or drying time additive is present in an amount greater than about 1.3% by weight of the polymer or composition, typically in an amount greater than about 2% by weight of the polymer or composition, in an amount greater than about 4% by weight of the polymer or composition, in an amount greater than about 7.5% by weight of the polymer or composition, in an amount greater than about 10% by weight of the polymer or composition or in an amount greater than about 20% by weight of the polymer or composition.

Owner:RHODIA OPERATIONS SAS

Paper product and method of producing a paper product

InactiveUS20090029106A1Good flexibilityHigh liquid absorbanceNon-fibrous pulp additionNatural cellulose pulp/paperVolumetric Mass DensityPulp and paper industry

Owner:SCA HYGIENE PROD AB

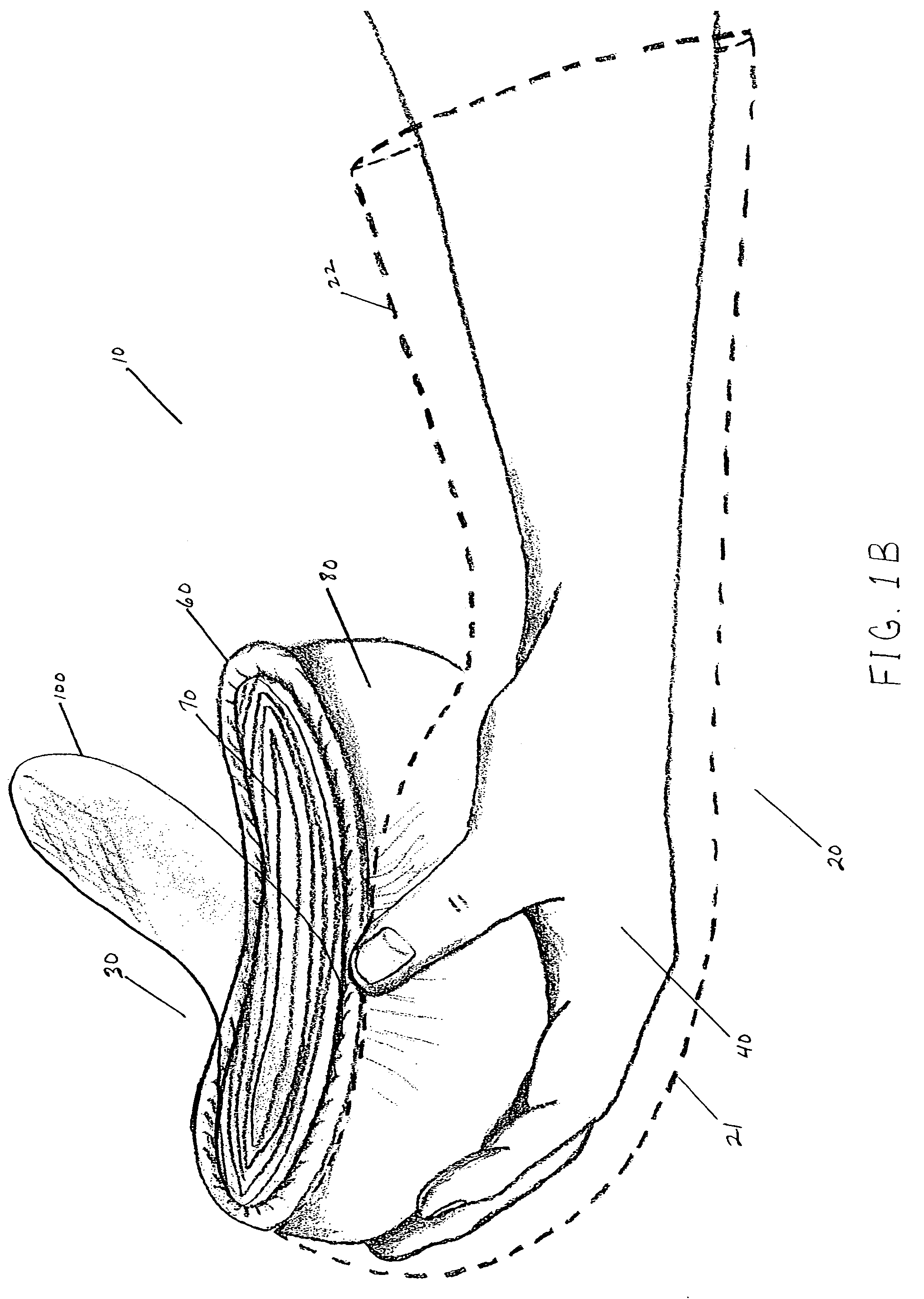

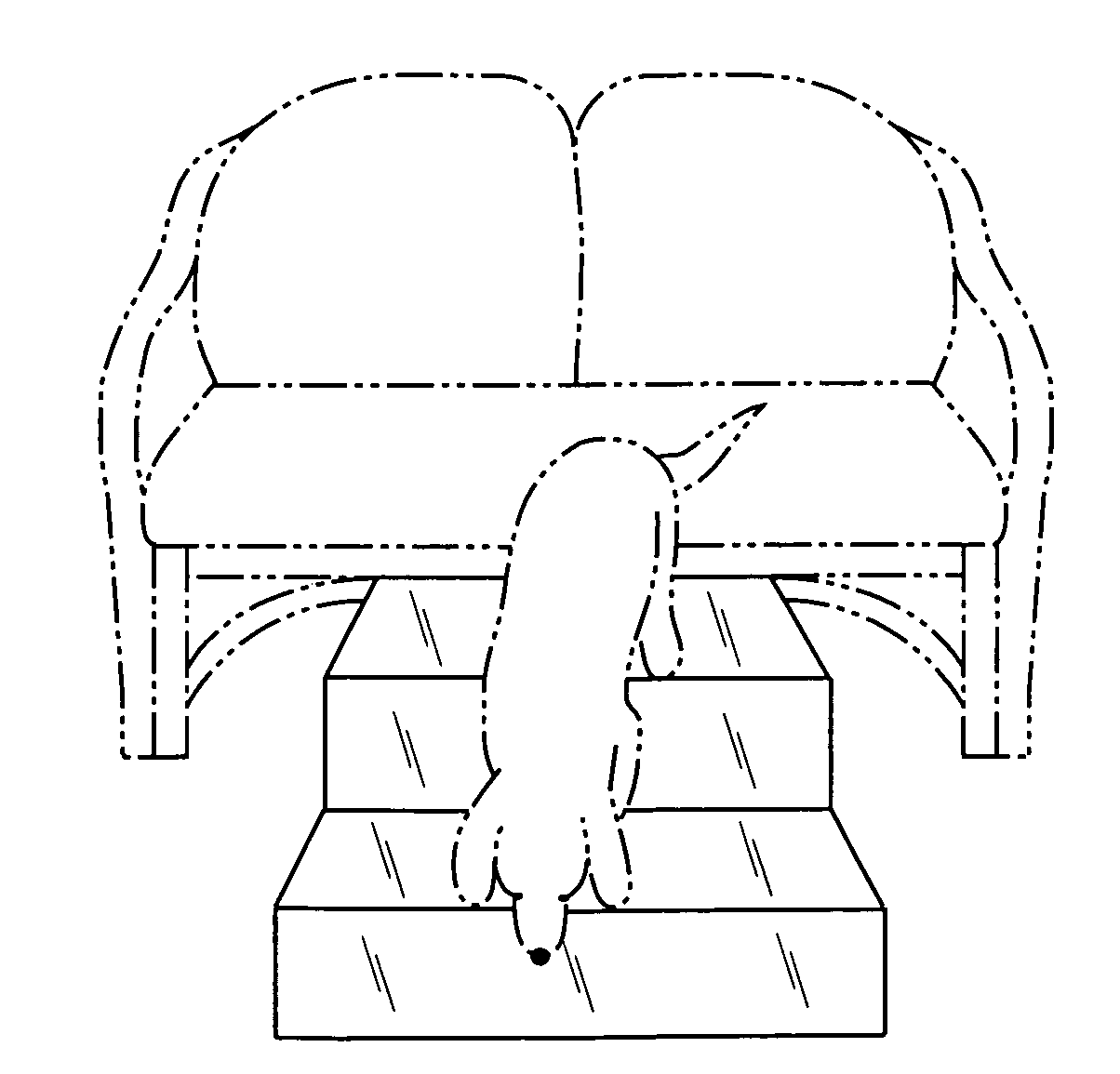

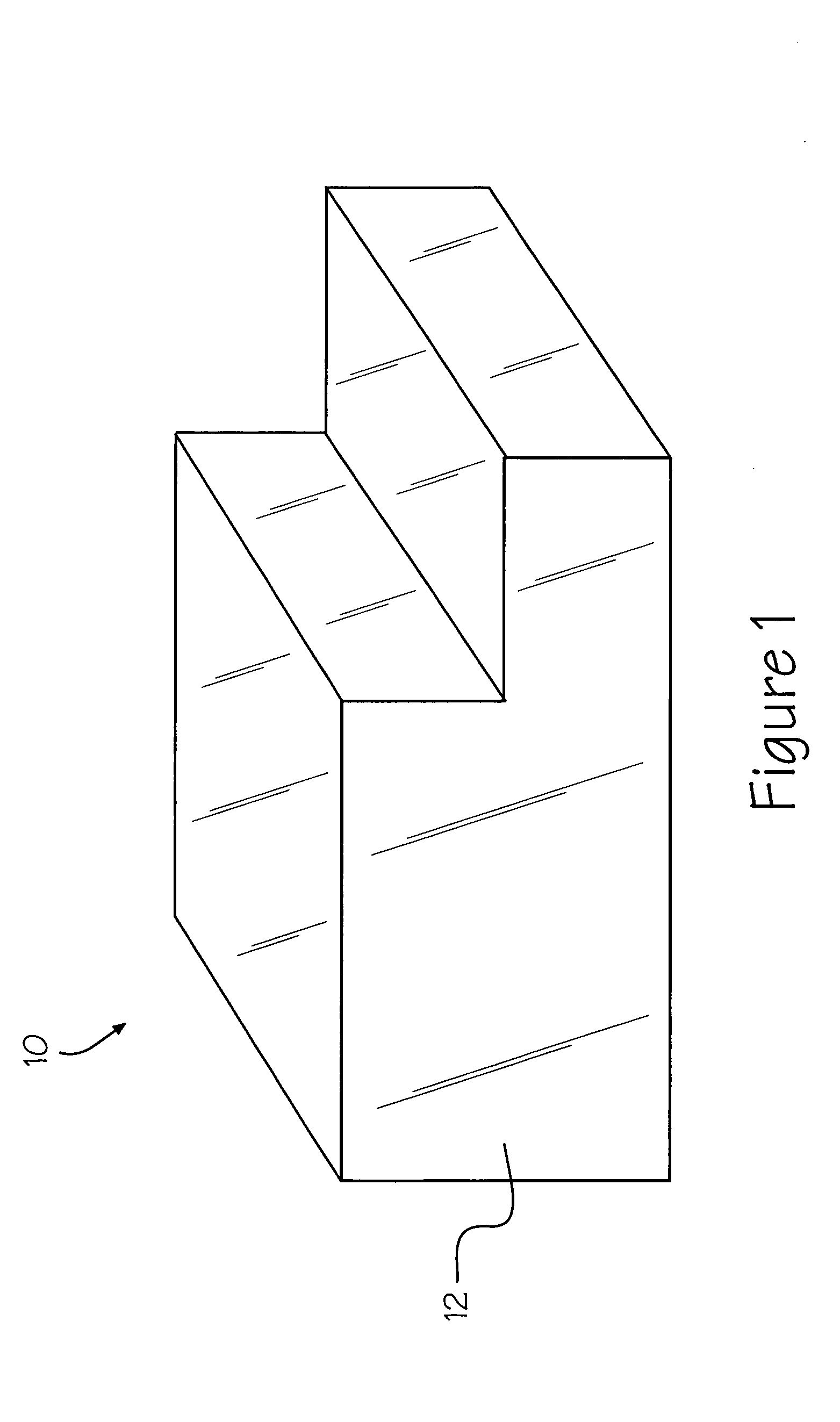

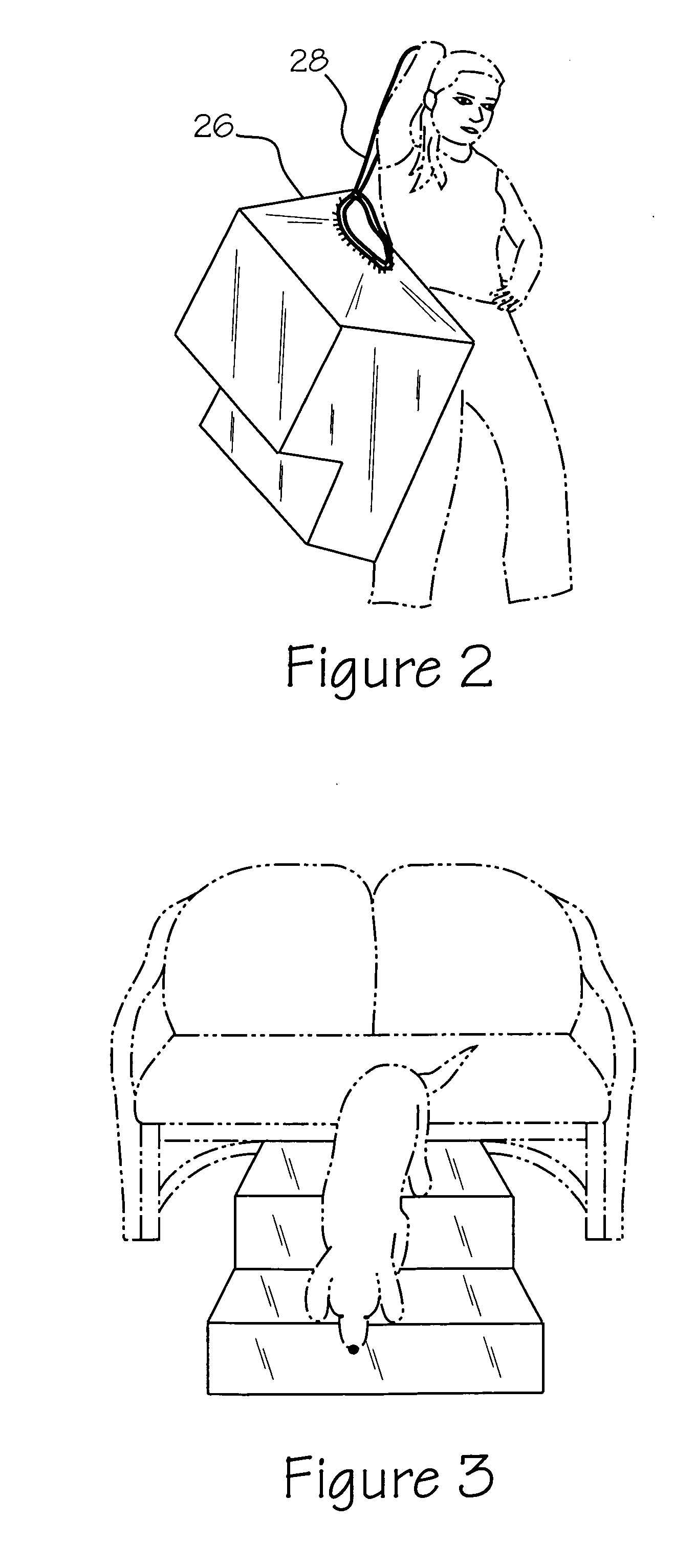

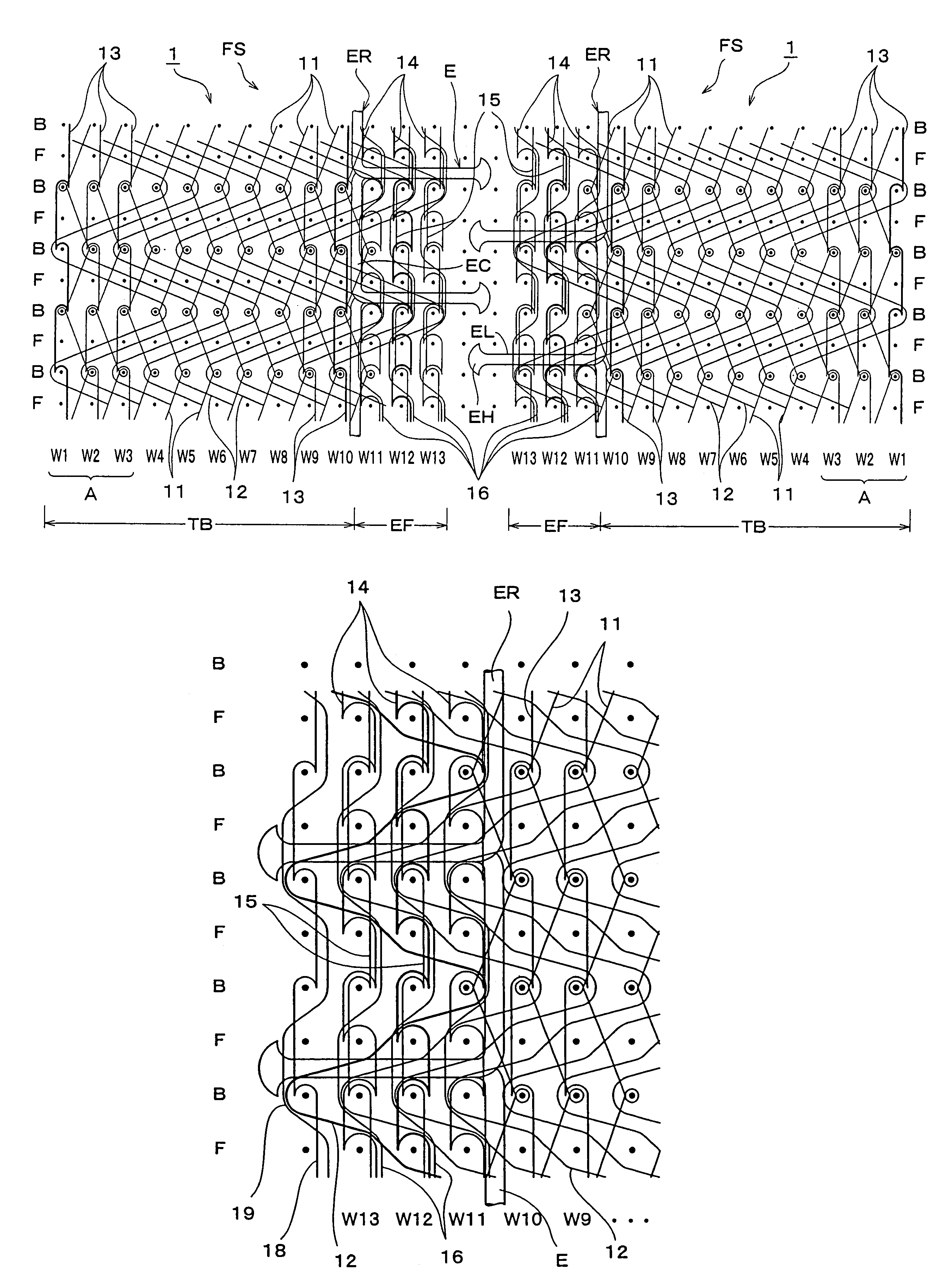

Portable stair assembly for pets

InactiveUS20060225372A1Quickly putSoft surfaceAnimal housingLaddersCompanion animalMechanical engineering

A portable set of stairs for use by a domesticated animal, a small child, or a disabled or aged individual. The stairs have an L-shaped inner core with a lower platform portion and an upper platform portion. A form-fitting, removable cover surrounds the L-shaped inner core for protecting it from soiling and condensation and for providing means for transporting and storing the portable set of stairs. The lower platform portion and the upper platform portion are horizontal with respect to the ground or floor. Both of the platform portions having respective upper surface areas, the upper platform portion upper surface area being greater than the lower platform portion upper surface area. Also provided is a rope or string for dragging or carrying the set of stairs. The rope or string is connected to the form-fitting cover. The inner core consists of deformable material, such as foam. The portable set of stairs in another embodiment has an intermediate platform portion disposed between the upper platform portion and the lower platform portion, forming a third step.

Owner:GONZALEZ LINDA MARIE

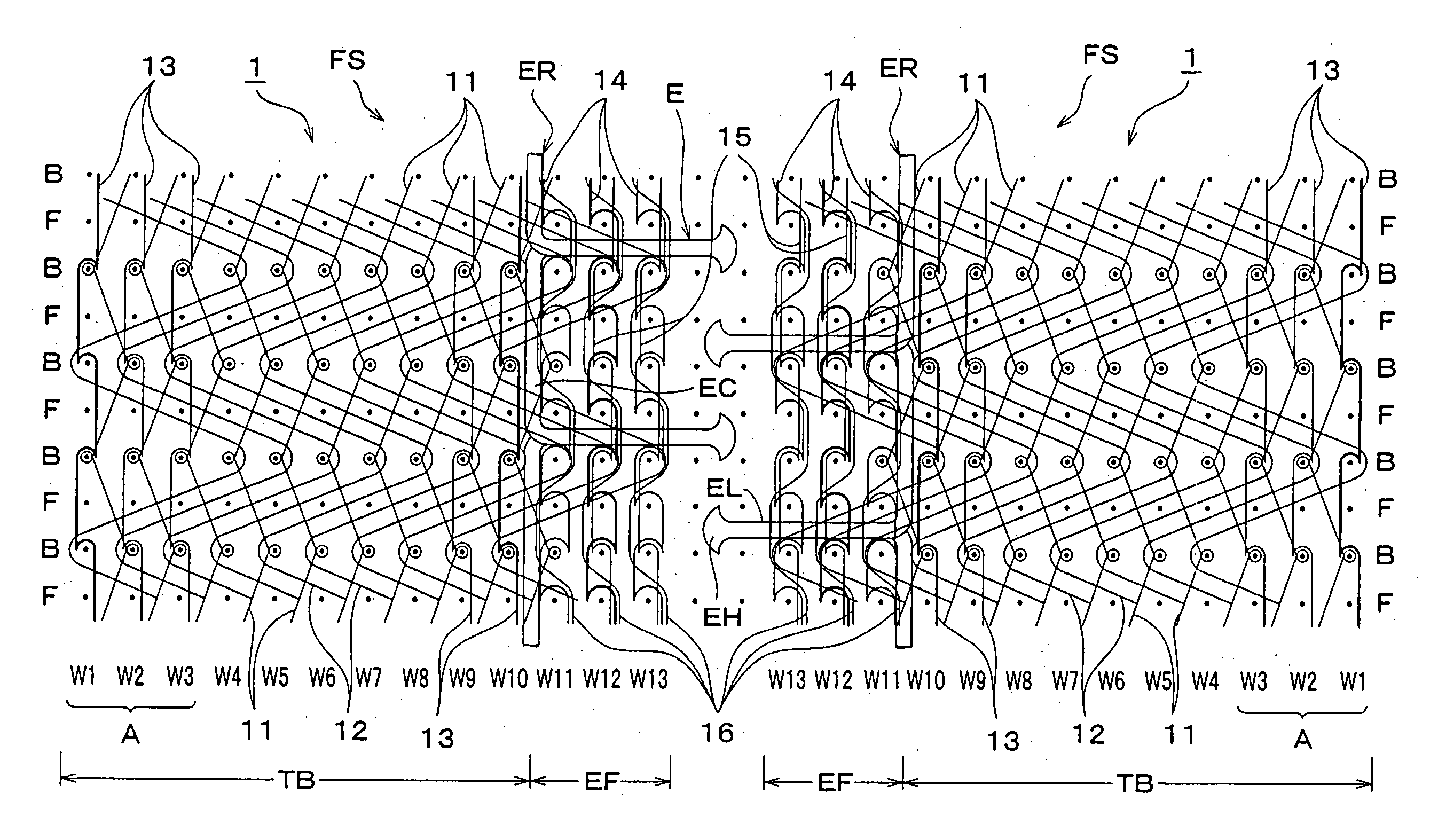

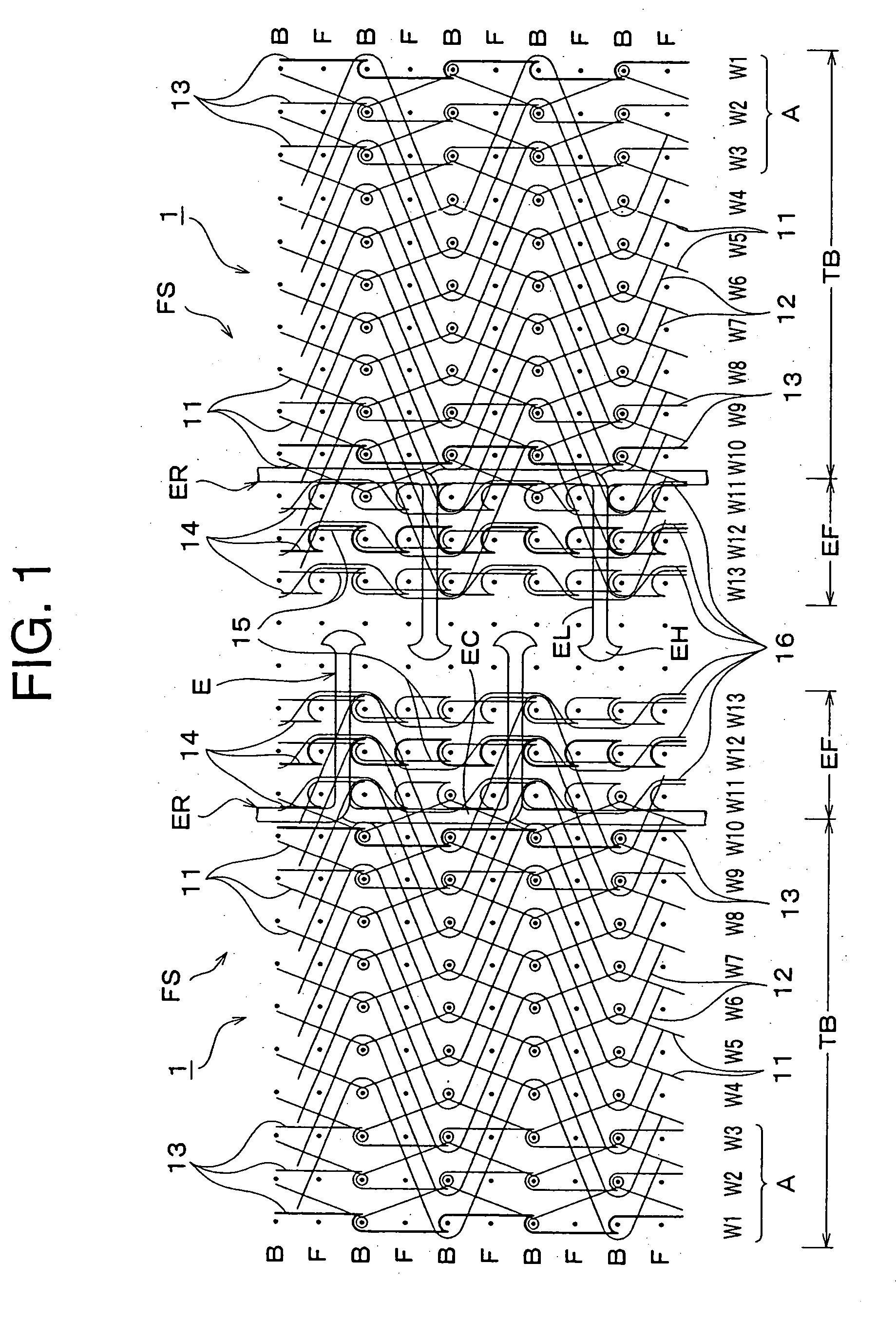

Knitted slide fastener

ActiveUS6971253B2Prevent extensionHigh strengthWater treatment parameter controlSlide fastenersYarnEngineering

Owner:MICROSOFT CORP +1

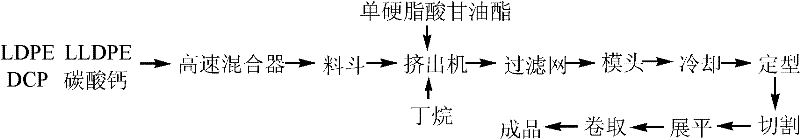

Preparation method of high performance expanded polyethylene product

ActiveCN102558647AHigh densityHigh surface hardnessLow-density polyethyleneLinear low-density polyethylene

The invention relates to a preparation method of a high performance expanded polyethylene product. The material of the invention comprises the following component in parts by weight: 50 parts of LDPE (low-density polyethylene) and LLDPE (linear low-density polyethylene), 0.01-1 parts of peroxide, 0.3-2 parts of talcum powder and / or calcium carbonate, 0.02-0.06 parts of antishrinking agent and 0.1-0.4 parts of foaming agent. In the invention, butane is used as the foaming agent, and the LDPE and the LLDPE are used as resin raw materials. The expanded polyethylene prepared by the preparation method of the invention has the advantages of high density and high surface hardness, the density of the expanded polyethylene is 60-400g / m<3> and the surface hardness is 40-70 degrees. The high performance expanded polyethylene product has good anti-scraping performance and puncture resistance as well as good rebound resilience and anti-quake effect. The high performance expanded polyethylene product meets the requirements of high performance of current packaging materials and fully protecting the substances being packaged. In addition, the high performance expanded polyethylene product has theadvantage of long sustainable using time as a panel and good market potential.

Owner:XIAMEN SANDEXIN SCI&TECH CO LTD

Latex binders, aqueous coatings and paints having freeze-thaw stability and methods for using same

ActiveUS20100016485A1Promote recoveryImprove freeze-thaw stabilityPlastic/resin/waxes insulatorsOrganic compound preparationFreezing thawingStain

Disclosed are latex polymers and an aqueous coating compositions having excellent freeze-thaw stability, open time, stain resistance, low temperature film formation, foam resistance, block resistance, adhesion, water sensitivity and a low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating composition including at least one latex polymer, at least one pigment, water and at least one freeze-thaw additive. Typically, the freeze-thaw additive in an amount greater than about 1.3% by weight of the polymer, typically in an amount greater than about 2% by weight of the polymer, in an amount greater than about 4% by weight of the polymer, in an amount greater than about 7.5% by weight of the polymer, in an amount greater than about 10% by weight of the polymer or in an amount greater than about 20% by weight of the polymer.

Owner:SPECIALTY OPERATIONS FRANCE

Heat bonding non-woven fabric and preparation method thereof

The invention relates to the technical field of non-woven fabric production, and provides a heat bonding non-woven fabric and a preparation method thereof. The heat bonding non-woven fabric comprises 60 percent by weight of thermoplastic fibers; the surface of the heat bonding non-woven fabric is provided with bumps; the gram weight is 25-35 g / m<2>, the integrated softness is less than or equal to 55 nN, the water absorption is more than or equal to 600%, and the liquid penetrability is less than or equal to 3 s. The heat bonding non-woven fabric provided by the invention has the advantages of simple production process, less energy consumption, high softness and fluffy degree and difficult product surface deformation, namely, the heat bonding non-woven fabric is good in hand feeling and more comfortable to use.

Owner:WEIFANG ZHIHE NON WOVEN CO LTD

Latex binders, aqueous coatings and paints having freeze-thaw stability and methods for using same

InactiveUS20150133604A1Improve freeze-thaw stabilityEasily recoverCoatingsFreezing thawingPolymer chemistry

Disclosed are latex polymers and an aqueous coating compositions having excellent freeze-thaw stability, open time, stain resistance, low temperature film formation, foam resistance, block resistance, adhesion, water sensitivity and a low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributyiphenol. Also provided is an aqueous coating composition including at least one latex polymer, at least one pigment, water and at least one freeze-thaw additive. Typically, the freeze-thaw additive in an amount greater than about 1.3% by weight of the polymer, typically in an amount greater than about 2% by weight of the polymer, in an amount greater than about 4% by weight of the polymer, in an amount greater than about 7.5% by weight of the polymer, in an amount greater than about 10% by weight of the polymer or in an amount greater than about 20% by weight of the polymer.

Owner:RHODIA OPERATIONS SAS

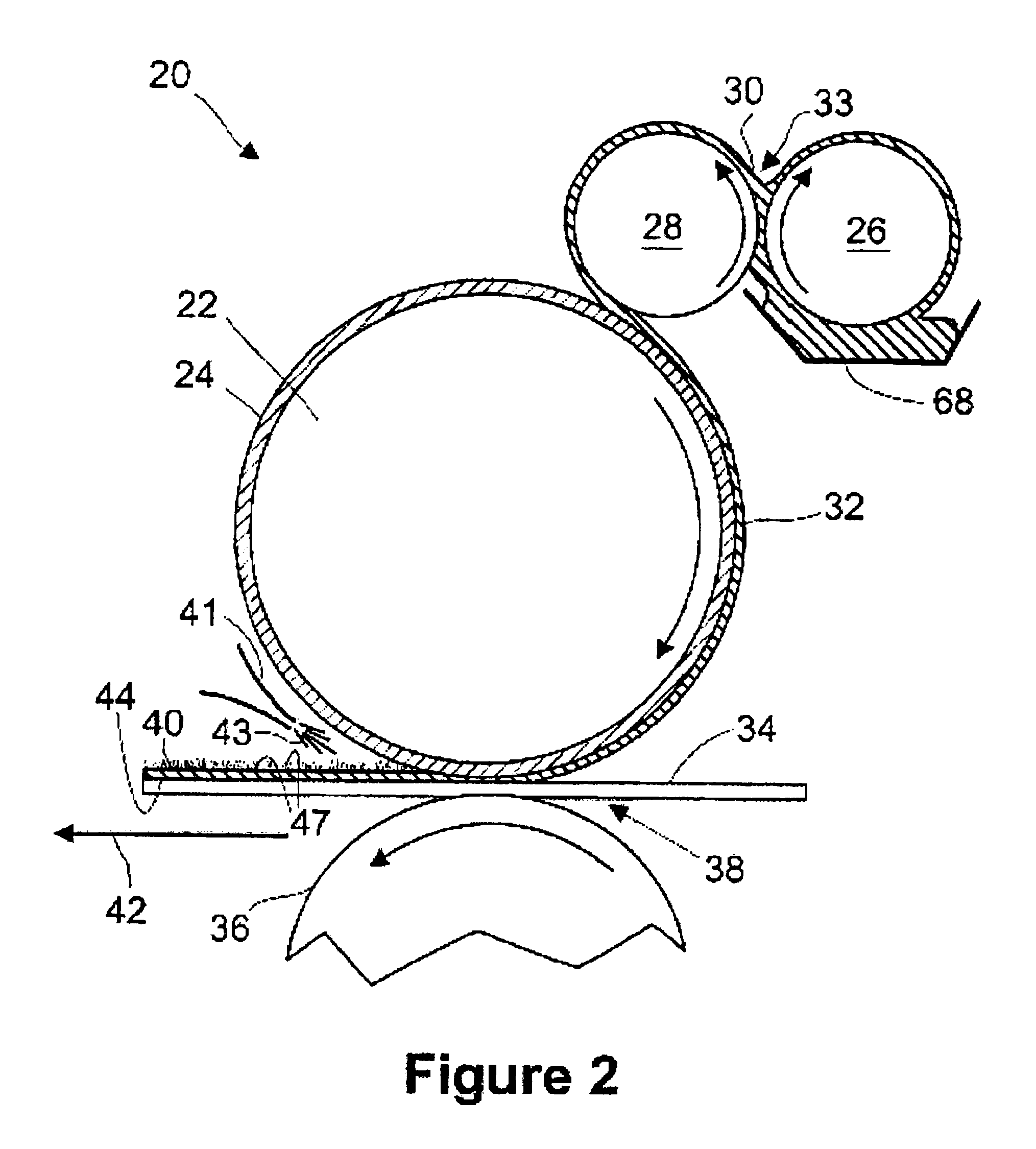

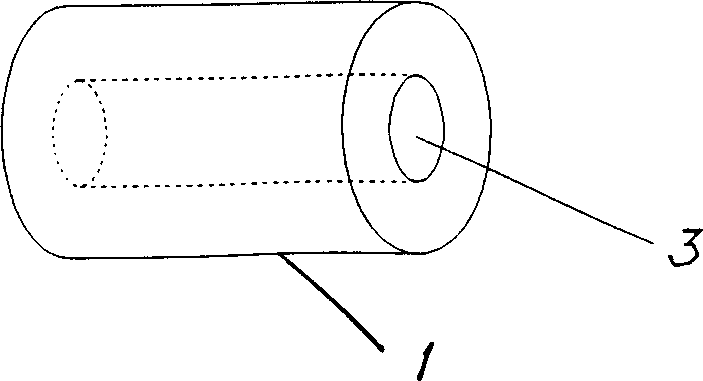

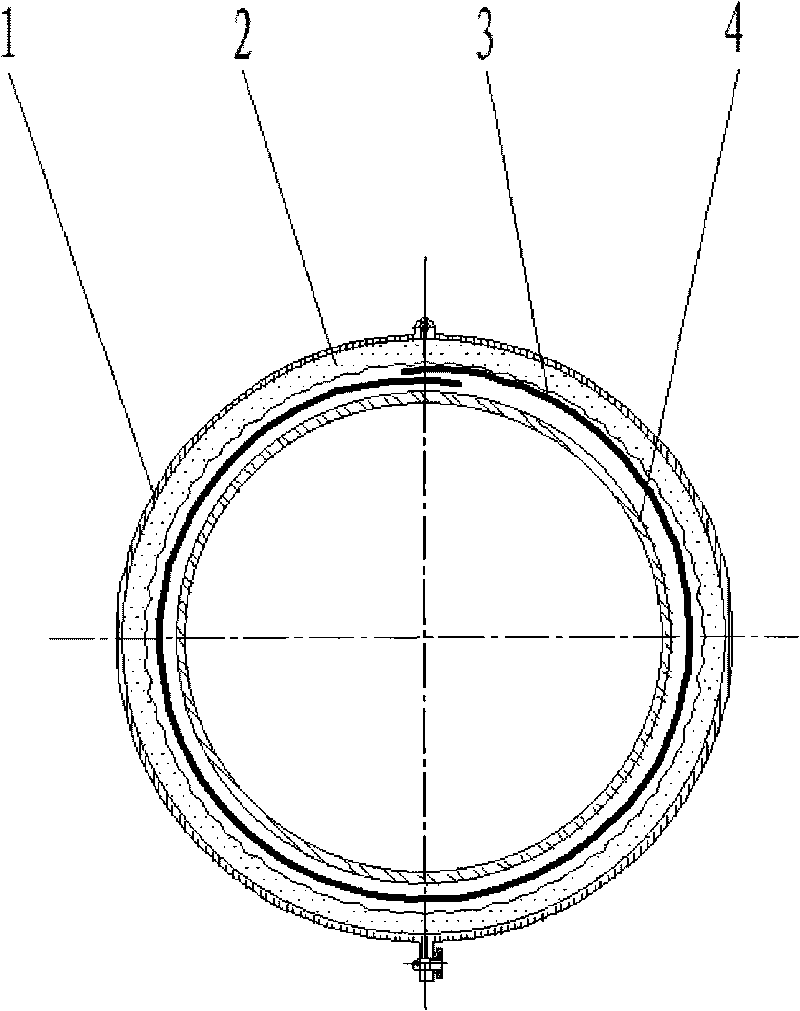

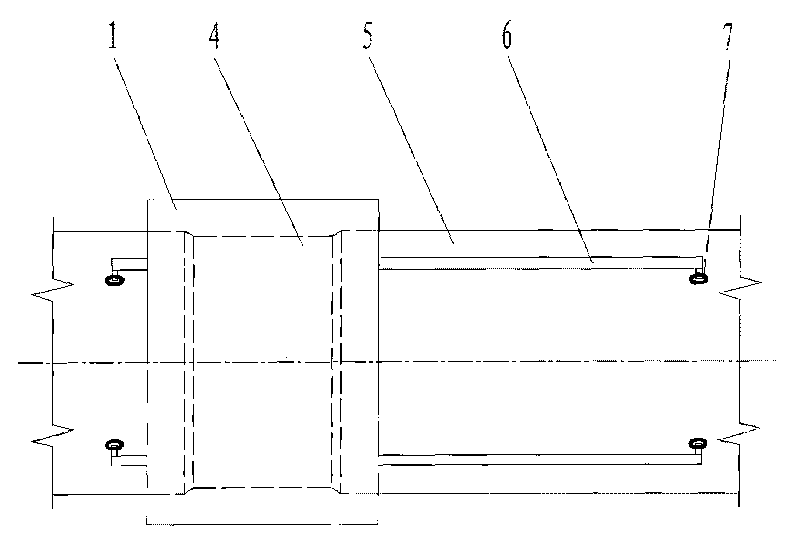

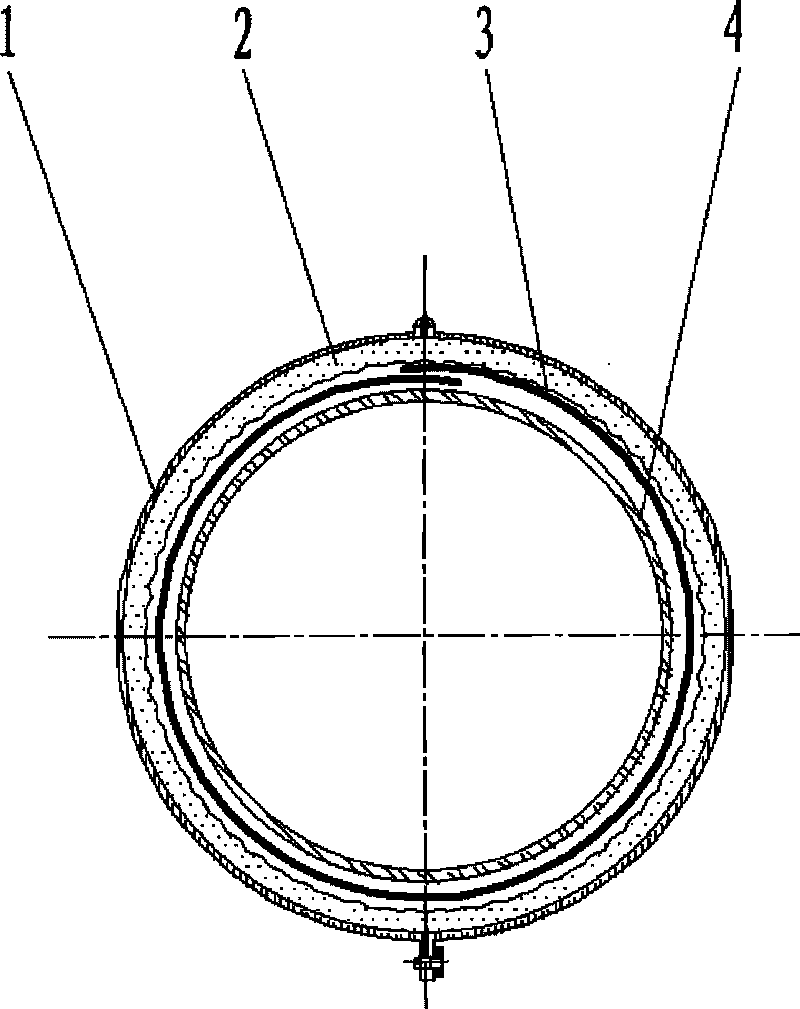

Hole repairing construction machine for polyethylene anti corrosive coating of metallic tube and construction method thereof

ActiveCN101737587ALow costImprove construction qualityCorrosion preventionPipe elementsAir compressionEngineering

The invention provides a hole repairing construction machine for a polyethylene anti corrosive coating of a metallic tube and a construction method thereof. A main body of the hole repairing construction machine consists of a tubular pressurizing sleeve and a tubular rubber air bag adhered to the inner wall of the main body; and the pressurizing sleeve and the rubber air bag are kept coaxial with the tube by four support arms arranged on each of the two sides of the pressurizing sleeve along the axial direction of the tube and rubber rolling wheels arranged at the tail ends of the pressurizing sleeve, and a polyethylene hole repairing band is artificially inserted in the pressurizing sleeve from the side of longer support arms and closely attached to the inner wall of the rubber air bag by the recurrent force of the polyethylene hole repairing band. The polyethylene hole repairing band may be of an electric heating fusion shrinking type or external heating shrinking type, the rubber air bag is pressurized by air compression equipment and a thermal conduction oil pump, and after the polyethylene hole repairing band is electrified for heating fusion or fused by the heat transfer of the thermal conduction oil, the rubber air bag is gradually pressurized to 0.01 to 1MPa until the adhesion is completed. In the hole repairing process of the invention, main operational steps are automatically completed by the equipment, and the construction quality is good; and the polyethylene hole repairing band withstands a huge pressure in a softening process, so that the bonding strength is greatly improved, and the cost is also low.

Owner:KINGFA SCI & TECH CO LTD +2

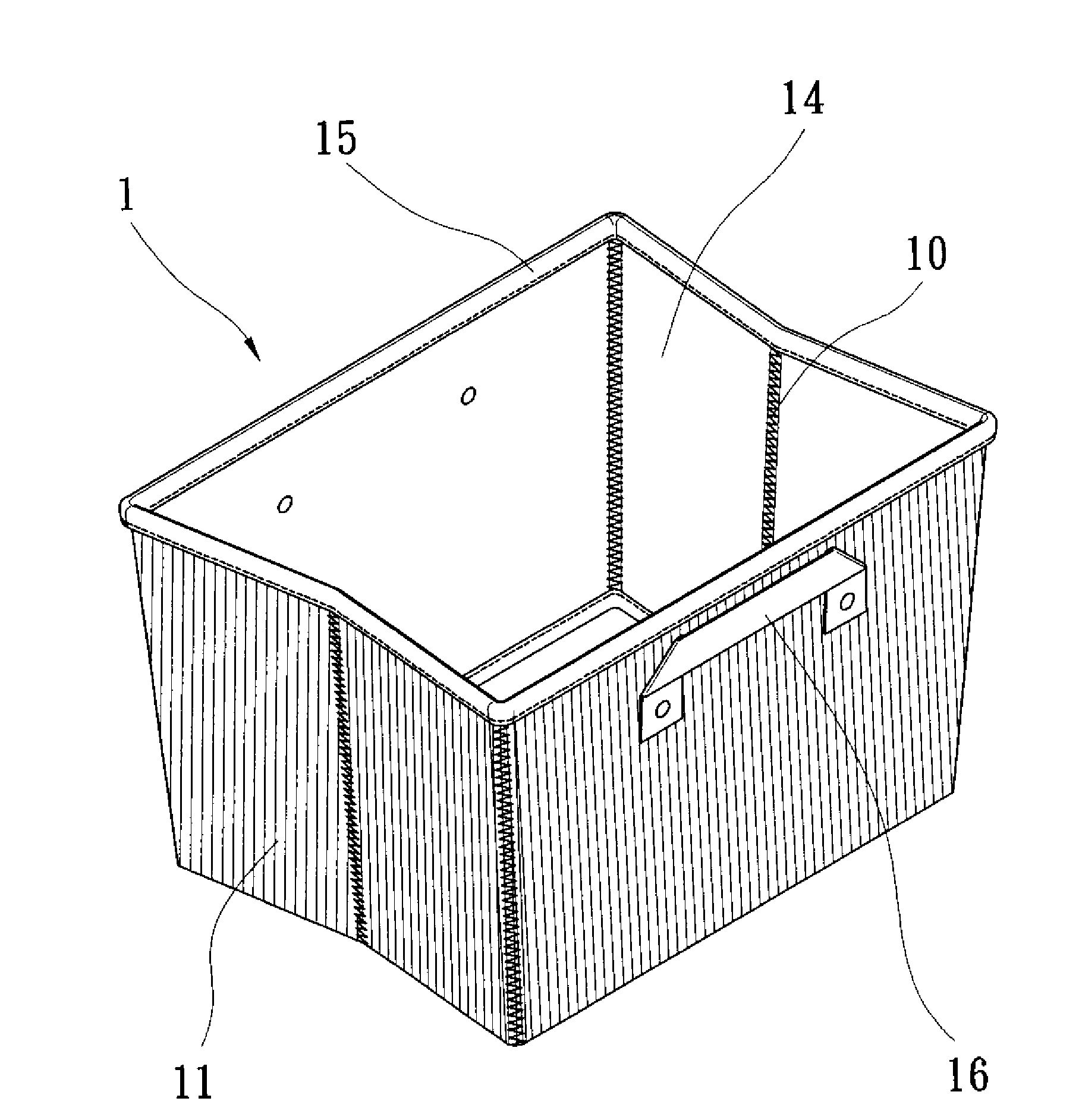

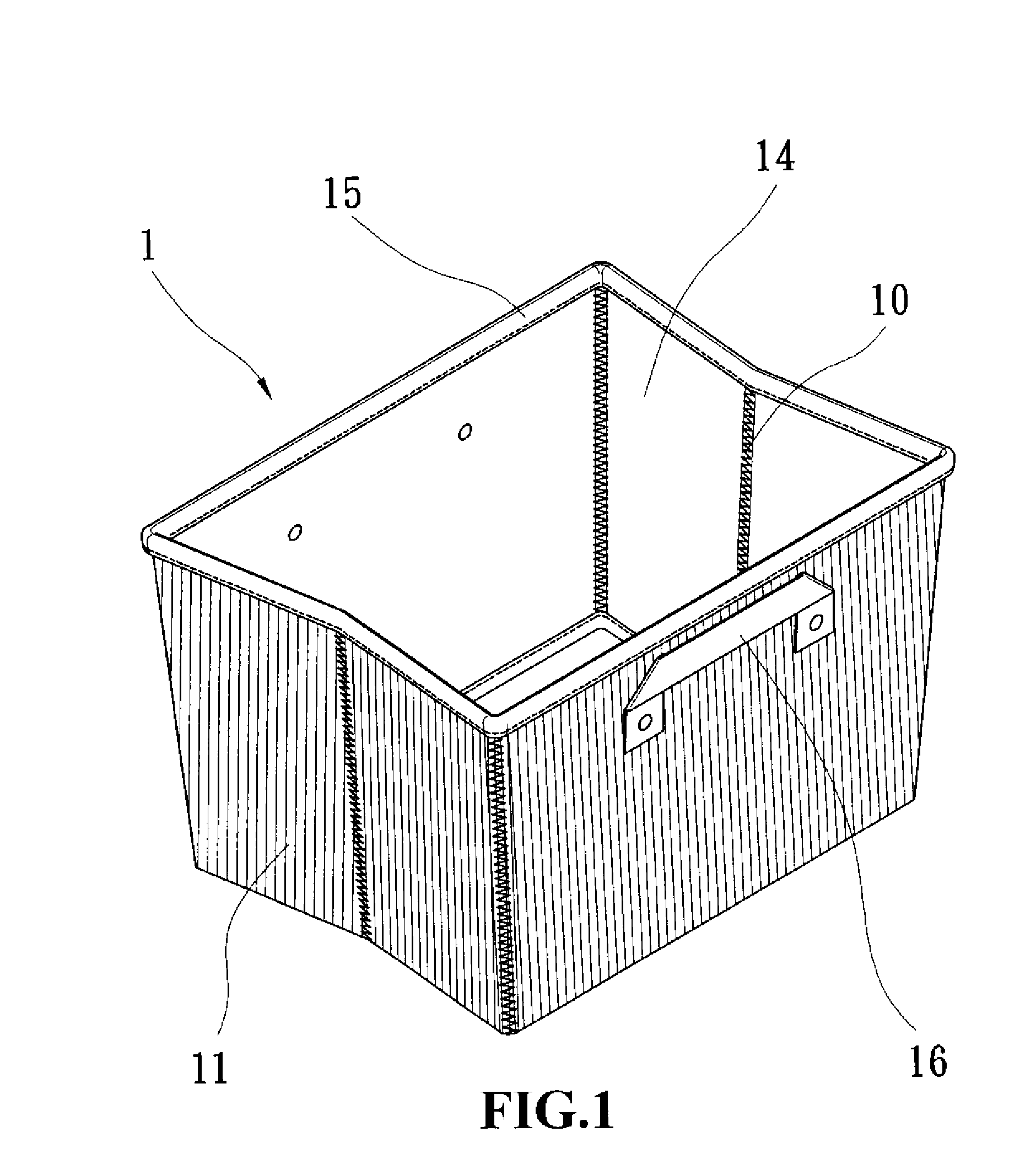

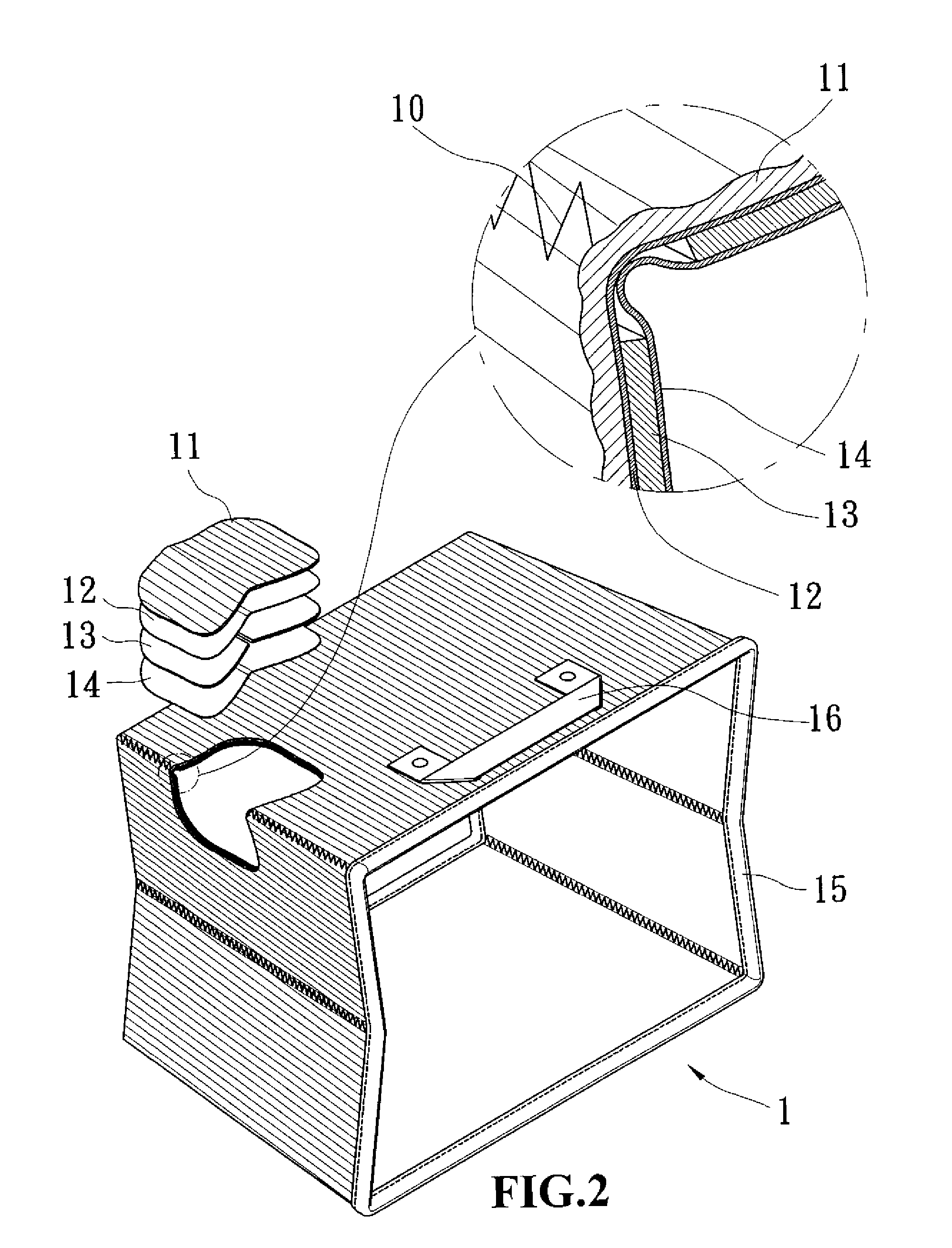

Structure of box

InactiveUS20100326985A1Soft surfaceImprove space utilizationSacksPortable flexible containersSmooth surfaceFiber layer

A structure of box includes a body having a foamed layer arranged at the outer side. The foamed layer has an outer surface forming an anti-skidding non-smooth surface and an inside surface bonded to an artificial fiber layer. The box body has an inner side formed by an artificial fiber lining layer. Rigid boards are interposed between the artificial fiber layer and the artificial fiber lining layer and stitching is applied to fix the foamed layer, the artificial fiber layer, and the artificial fiber lining layer together. The box body has a top edge covered by a covering layer. Hand-carrying handles are mounted to the outer surface of the box body in a symmetric manner. When expanded, the box maintains an expanded shape of a container, and when collapsed, the box is collapsed through the sites of stitching to form a flat configuration.

Owner:LIN CHIEN JEN

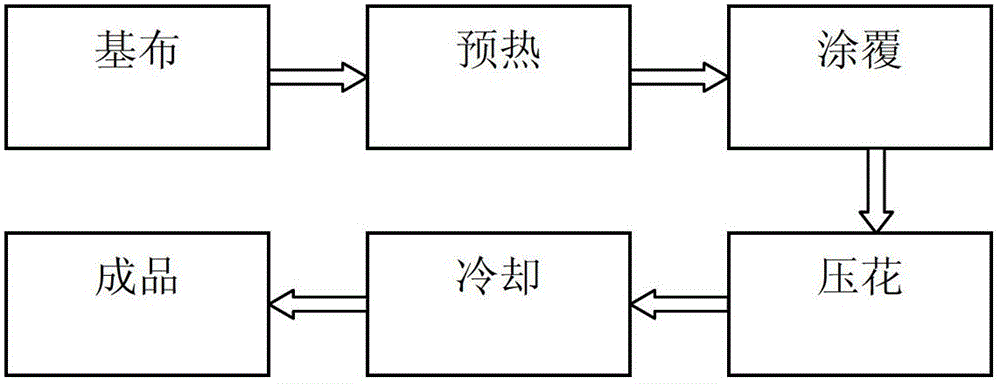

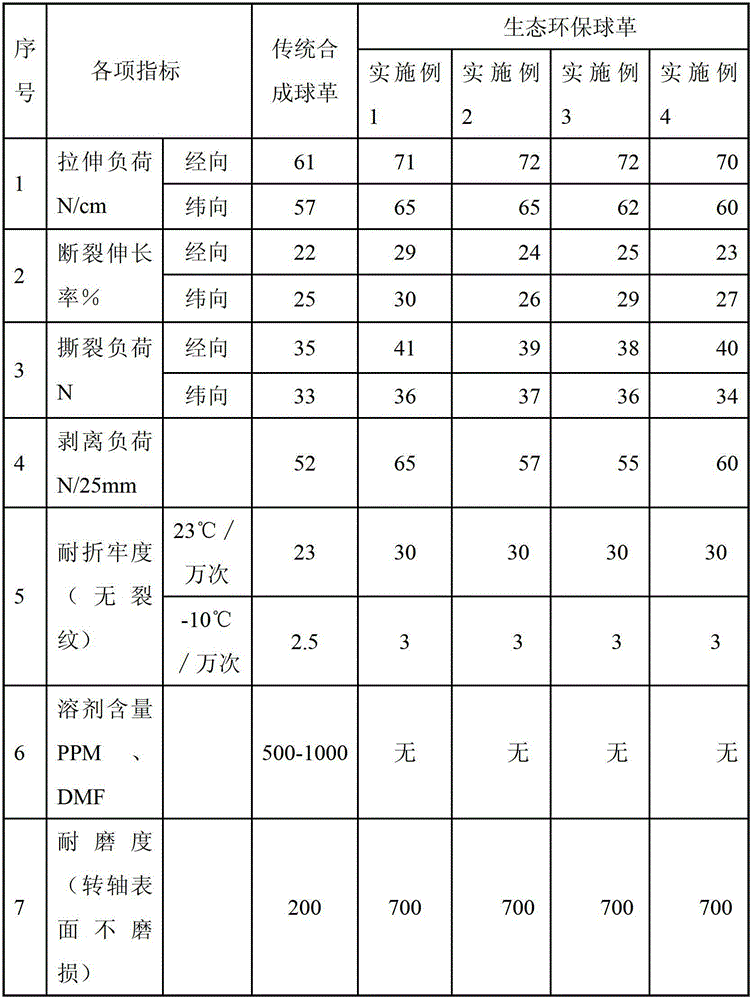

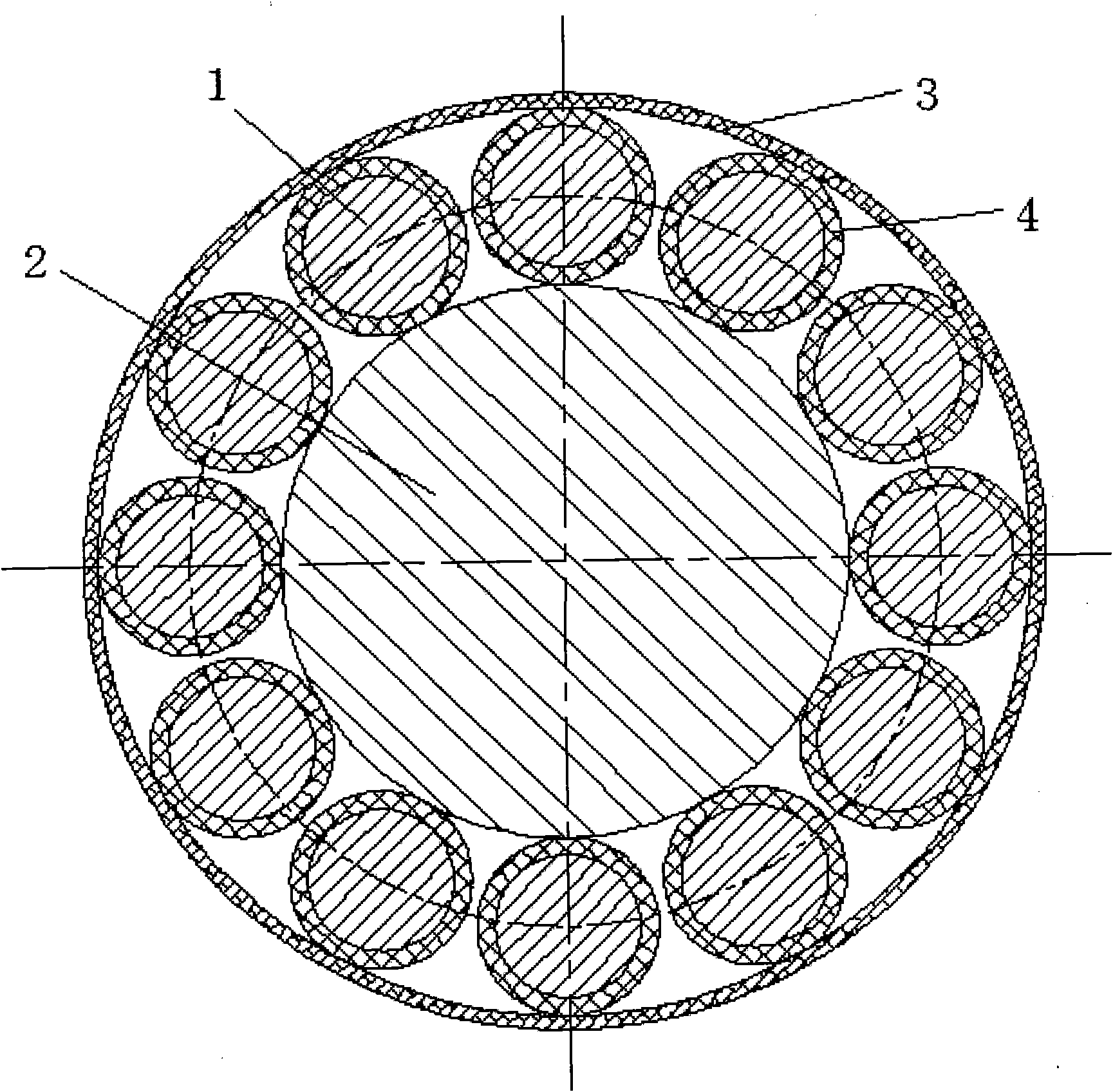

Preparing method of thermoplastic elastomer environment-friendly basketball leather

ActiveCN102720072AImprove performanceStrong astringencyLamination ancillary operationsSynthetic resin layered productsElastomerFoaming agent

The invention provides a preparing method of a thermoplastic elastomer environment-friendly basketball leather, which includes the following steps: applying hot melt adhesive to a base fabric, heating and melting a thermoplastic elastomer and a modifying agent to be adhered to the treated base fabric; mixing the thermoplastic elastomer and a foaming agent to be heated and melted into a foaming body, and the foaming body is adhered to the product; and mixing the thermoplastic elastomer and a coloring agent to be adhered to the product and pressed and cooled through a press roll with ball leather pattern, so as to make the thermoplastic elastomer environment-friendly basketball leather. The method avoids the solvent during the production process, has no influence and pollution on the environment, and adopts the environment-friendly material as the raw material. The basketball leather prepared through the preparing method has flexible surface, excellent hand feel and high elasticity, and is corrosion-resistant, ageing-resistant and hydrolysis-resistant.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

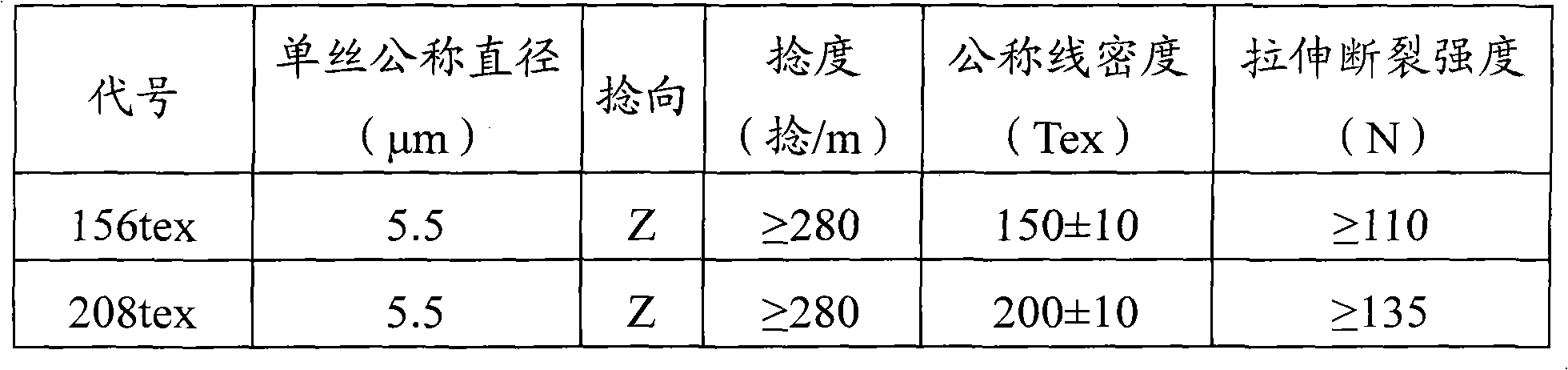

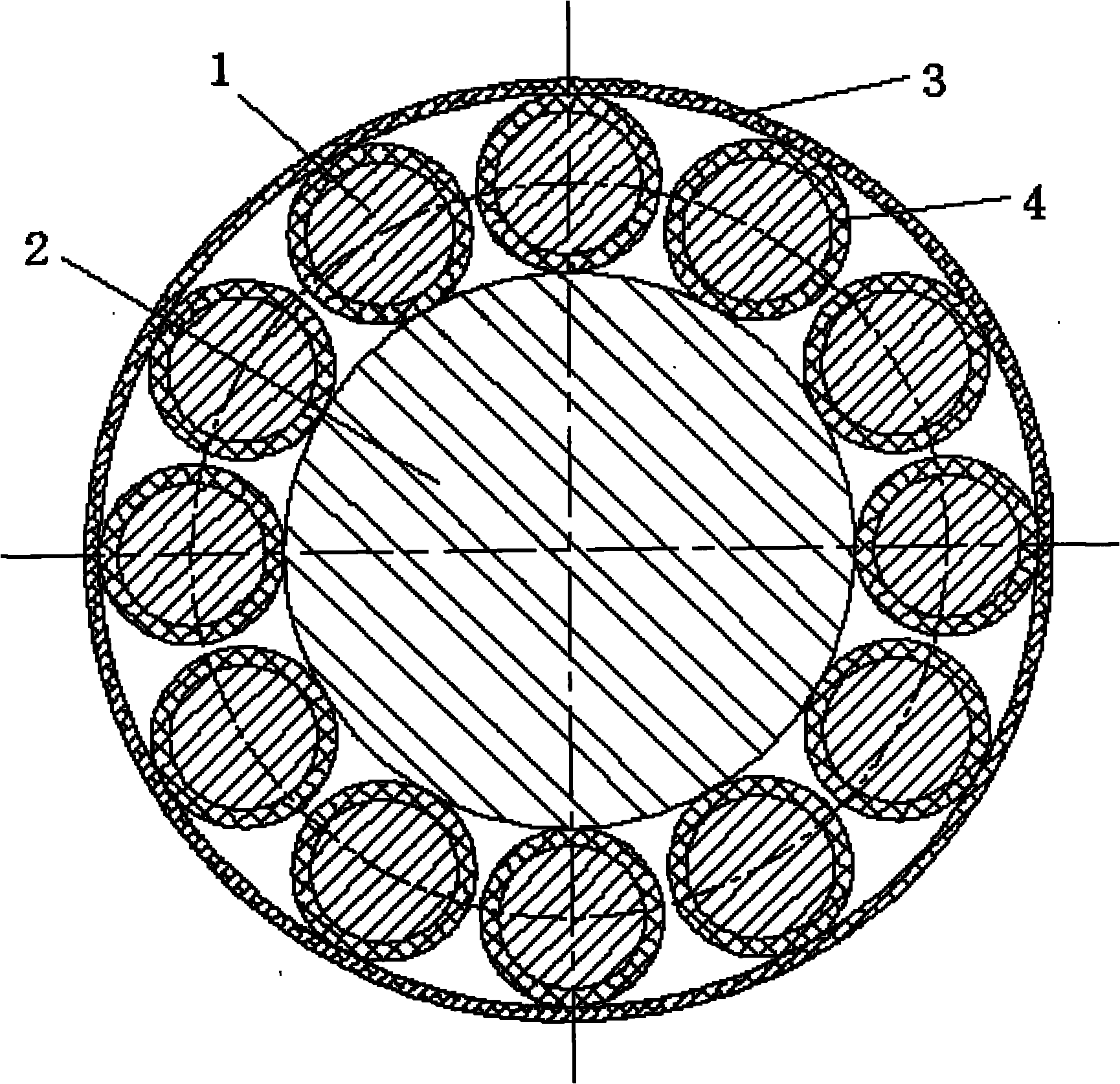

Heat-resistant complex glass fiber sewing thread and preparation method thereof

The invention provides a heat-resistant complex glass fiber sewing thread which has high tensile strength, thermostability, good corrosion resistance, static resistance, low production cost and long service life, and a preparation method thereof so as to meet the using requirements of a sewing thread in environments with high temperature, strong corrosive performance, large static electricity, and the like. The heat-resistant complex glass fiber sewing thread comprises a plurality of glass fiber monofilaments and at least one metal filament which are twisted together, a sintered layer is arranged on the surface of the heat-resistant complex glass fiber sewing thread, and an impregnated layer is arranged on the surface of each glass fiber monofilament. The impregnated layer and the sintered layer can improve the flexibility, the folding resistance, the wear resistance, the corrosion resistance and the like of the crude filaments and the sewing thread.

Owner:辽宁新洪源环保材料有限公司

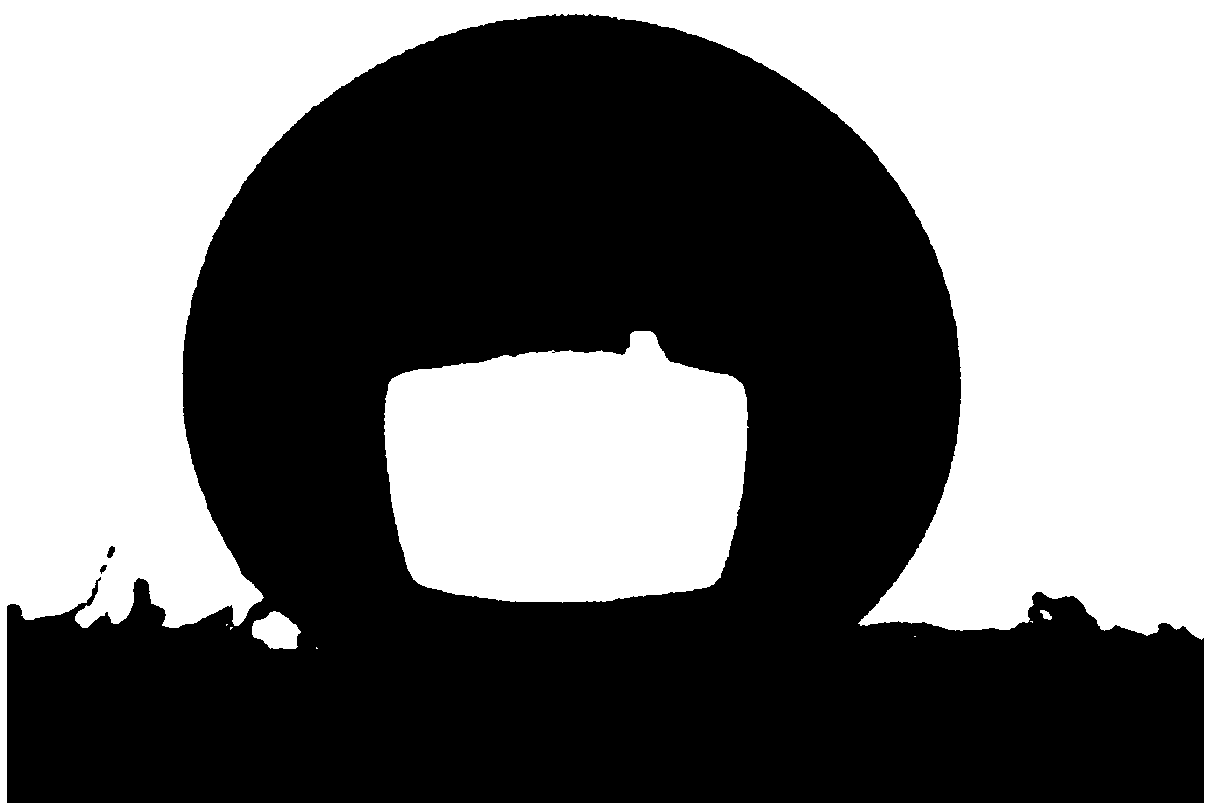

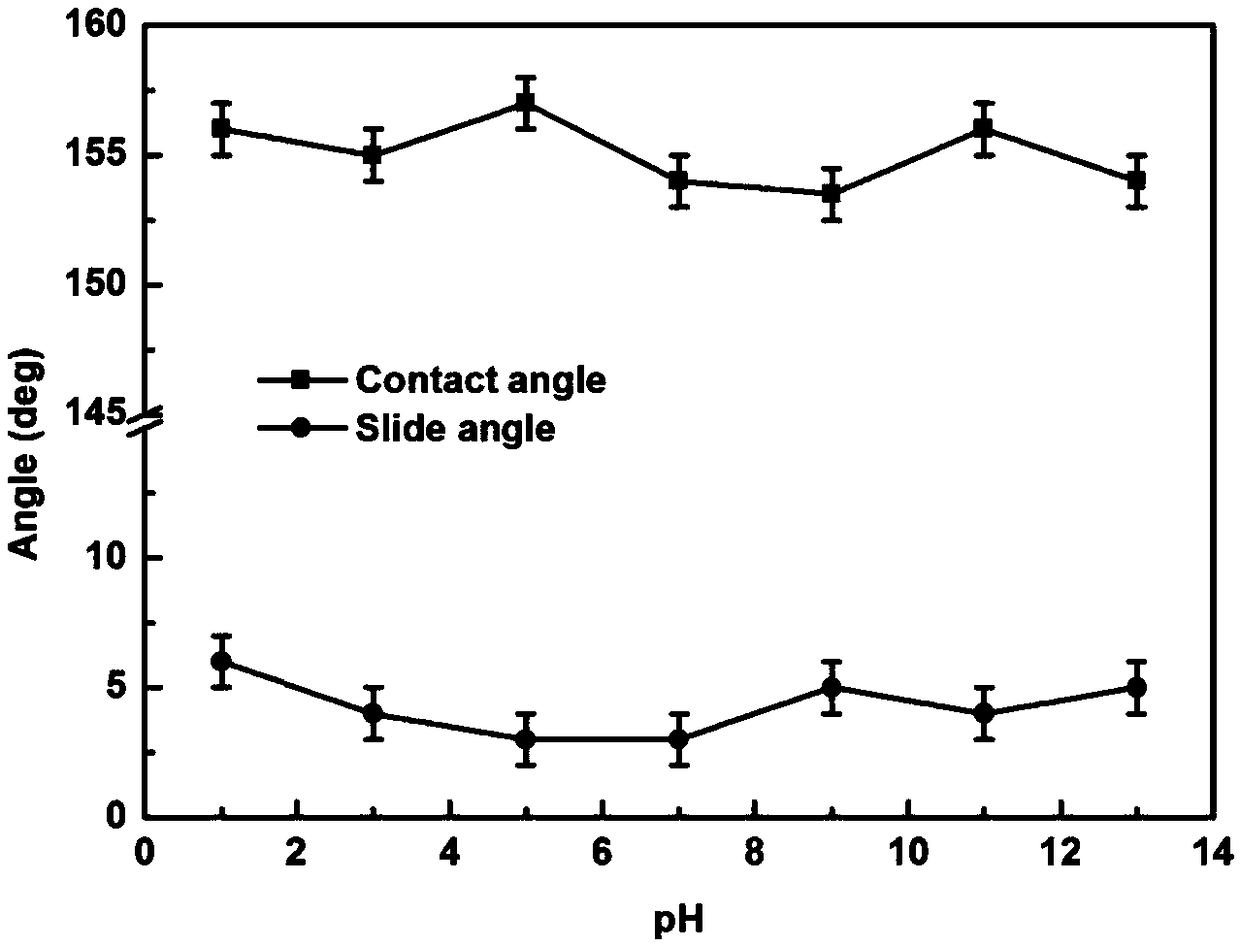

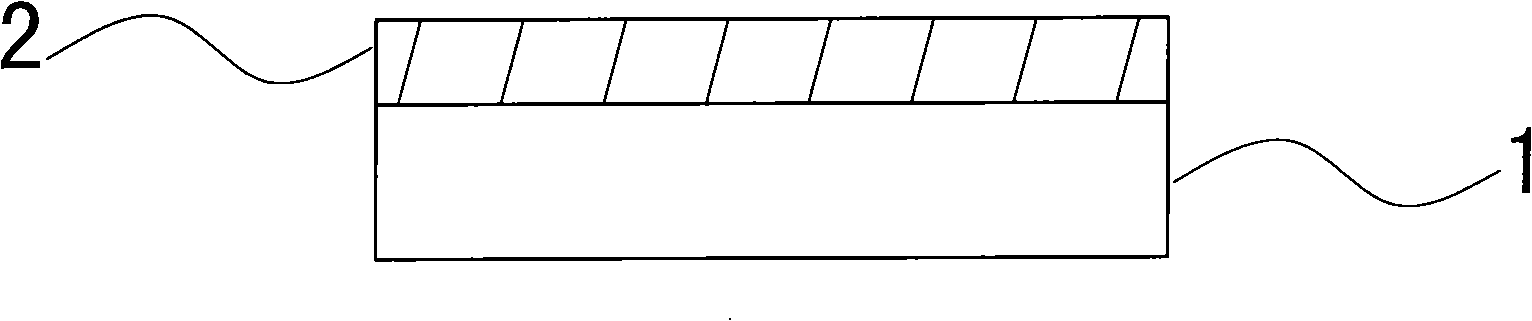

Method for preparing antibacterial super-hydrophobic fabric having stable properties by using silver-deposited nanoparticles

ActiveCN108755111AFree from destructionThe roughness is not easy to changeLiquid repellent fibresGrip property fibresNanoparticleSurface roughness

A method for preparing antibacterial super-hydrophobic fabric having stable properties by using silver-deposited nanoparticles comprises the steps that a fabric is soaked by adopting an EDTA solutionand then is dried; the dried fabric is impregnated in a silver-ammonia solution, then a glucose solution is added, and soaking and drying are performed; the fabric is put in an ethanol solution of aluminic acid ester under the stirring condition, and soaking and drying are performed to obtain the antibacterial super-hydrophobic fabric. According to the method, EDTA is adopted as a complexing agent, hydroxide radicals on the surface of the fabric can be bound with the EDTA, and silver particles can be complexed with the EDTA, so that the EDTA makes a substrate and the silver particles bound together through chemical bonds, the surface roughness is not likely to change, and the fabric has very good stability. The fabric and the silver particles are tightly grafted together, so that the stability of the fabric is improved. The fabric reacts with the cheap low-surface-energy substance aluminic acid ester easy to obtain, high-price organosilane is replaced, and the cost is reduced. In addition, the fabric has better antibacterial properties.

Owner:XIAN UNIV OF SCI & TECH

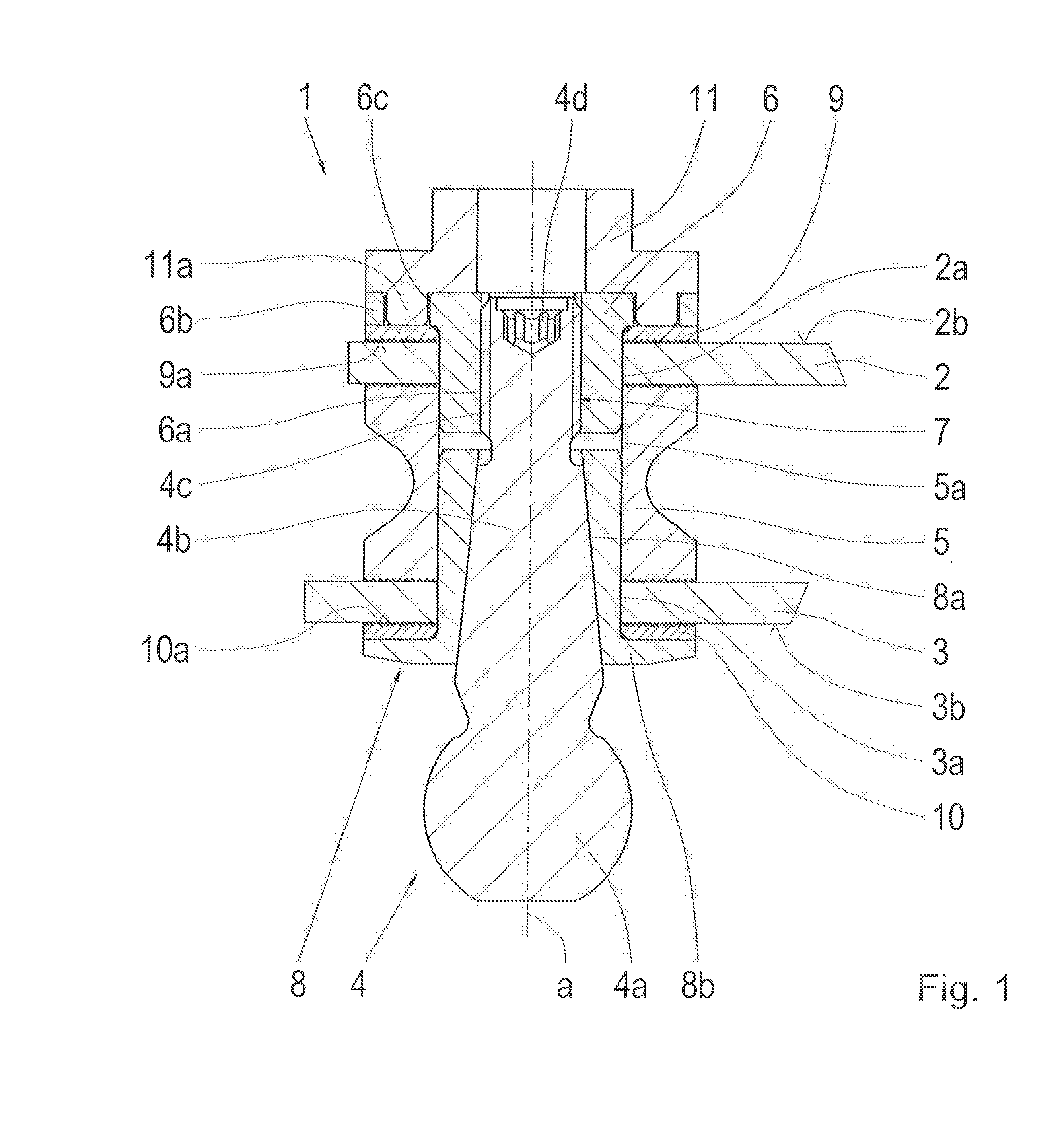

Arrangement for connecting chassis components and wheel carriers for motor vehicles

InactiveUS20170008558A1Increase coefficient of frictionSoft surfaceSteering linkagesSheet joiningMobile vehicleDouble wall

An arrangement for connecting chassis parts, in particular a screw connection, between a structure made of a fiber-plastic composite and a metallic load-introducing element, designed as a traction member. The structure is double-walled having a first wall and at least a second wall spaced from the first wall. The first and second walls have each coaxially positioned recesses and a spacer, having a through hole, is positioned between the first and second walls. The load-introducing element extends through at least one recess and the hole of the spacer. The load-introducing element has a holding part assigned to it, and the load-introducing element and the holding part are connected to one another by a connecting segment. The connecting segment and / or the holding part essentially pass through the first and / or the second wall.

Owner:ZF FRIEDRICHSHAFEN AG

Baby textile fabric

InactiveCN106939465ASoft surfaceImprove antibacterial propertiesBiochemical fibre treatmentWoven fabricsChemistrySmooth surface

The invention discloses a baby textile fabric and a preparation method thereof. The baby textile fabric comprises the following components in parts by weight: 50 to 80 parts of plant fibers, 50 to 80 parts of animal fibers, 1 to 3 parts of carbon nanotube, and 0.1 to 1 part of antibacterial agent. The baby textile fabric prepared by the preparation method disclosed by the invention is prepared by blending the natural plant fibers and the animal fibers, and is immersed with the carbon nanotube and the antibacterial agent, has a soft, breathable and smooth surface, is high in antimicrobial property, not only can resist daily common bacteria, but also can effectively kill invasion of pathogenic bacteria, such as escherichia coli O157, staphylococcus aureus, trichophyton mentagrophytes and the like.

Owner:太仓绒彩纺织品有限公司

Grain-Finished Artificial Leathers

InactiveUS20070231547A1Good flexibilityIncrease flexibilitySynthetic resin layered productsWoven fabricsElastomerSingle fiber

A grain-finished artificial leather composed of a base layer and a coating layer Y formed on one of the surfaces of the base layer. The base layer is composed of an entangled nonwoven fabric X made of bundles of microfine fibers having an average single fiber fineness of 0.07 dtex or less and impregnated with a polymeric elastomer A and a polymeric elastomer B. The entangled nonwoven fabric X is composed of a lower layer XA and an upper layer XB wherein the lower layer XA is impregnated mainly with the polymeric elastomer A which is substantially not adhered to the bundles of microfine fibers and the upper layer XB is impregnated mainly with the polymeric elastomer B which is substantially not adhered to the bundles of microfine fibers. The coating layer Y is composed of a coating layer YB having a thickness of 1 to 10 μm which is made of the polymeric elastomer B and formed on the upper layer XB, a coating layer YC which is made of a polymeric elastomer C and formed on the coating layer YB, and a finished layer YE which is formed on the coating layer YC. The grain-finished artificial leather having the above structure combines a natural leather-like, delicate appearance, a good softness and flexibility, and a high peel strength.

Owner:KURARAY CO LTD

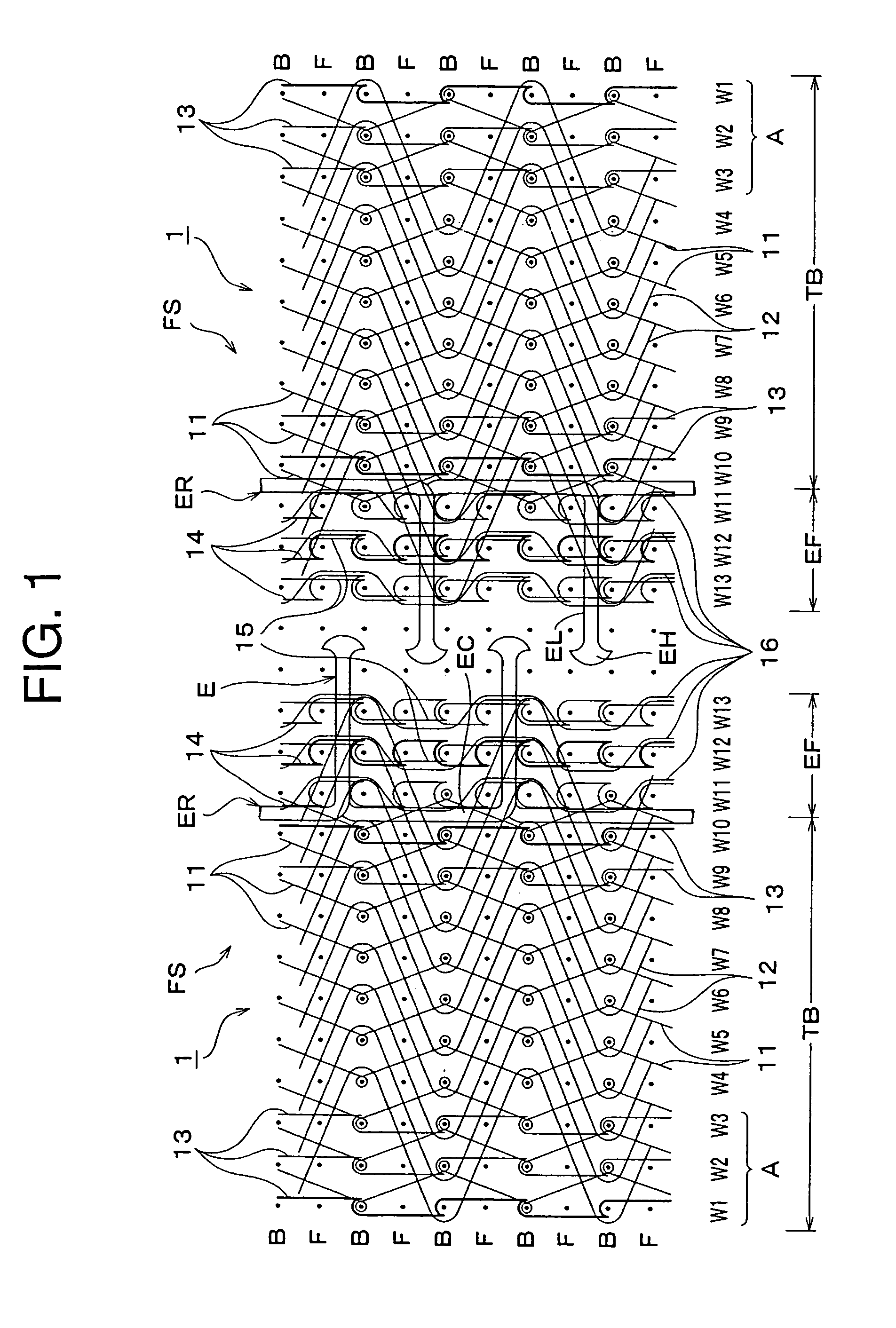

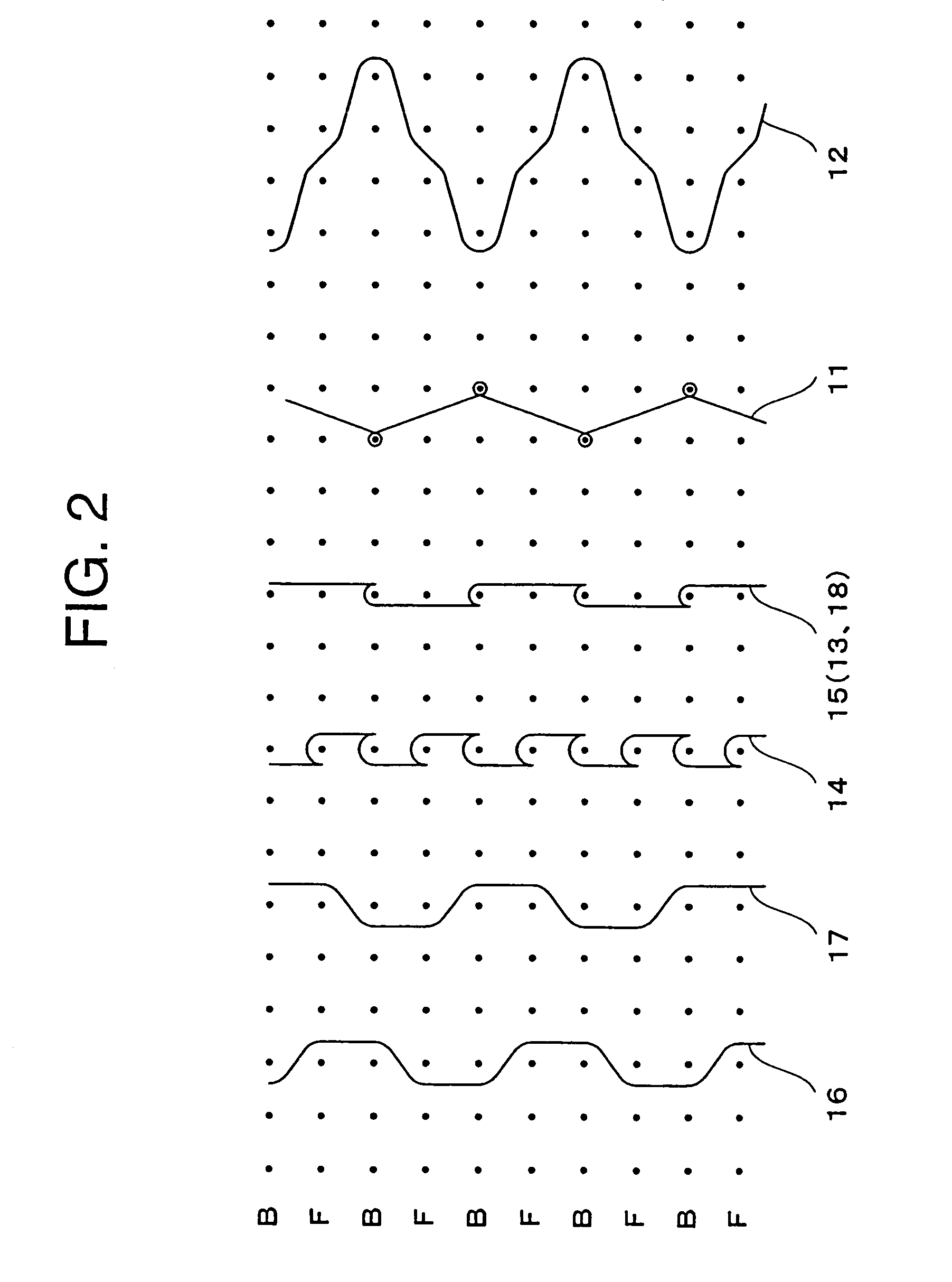

Knitted slide fastener

ActiveUS20050178161A1Prevent excessive expansionPrevent extensionWater treatment parameter controlSlide fastenersYarnEngineering

This invention provides a knitted slide fastener, wherein at least a part of a base structure composing respective wales (W11 to W13) of a fastener element attaching portion (EF) of a fastener tape includes a ground chain knitting yarn composed of a single structure, and a partial needle loop of a fixing chain knitting yarn composes a double base structure while being interlaced only with the needle loop of the ground chain knitting yarn of the second wale (W12), the partial needle loop of a fixing chain knitting yarn to be formed on at least the second wale (W12) at a second row from the side nearest to a coupling head portion (EH) of the fastener element attaching portion (EF) among the three or more fixing chain knitting yarns of the fastener element attaching portion (EF), the knitted slide fastener being organized at a high speed with few kinds of stitches without an excess load on a needle, an element being solidly fixed.

Owner:MICROSOFT CORP +1

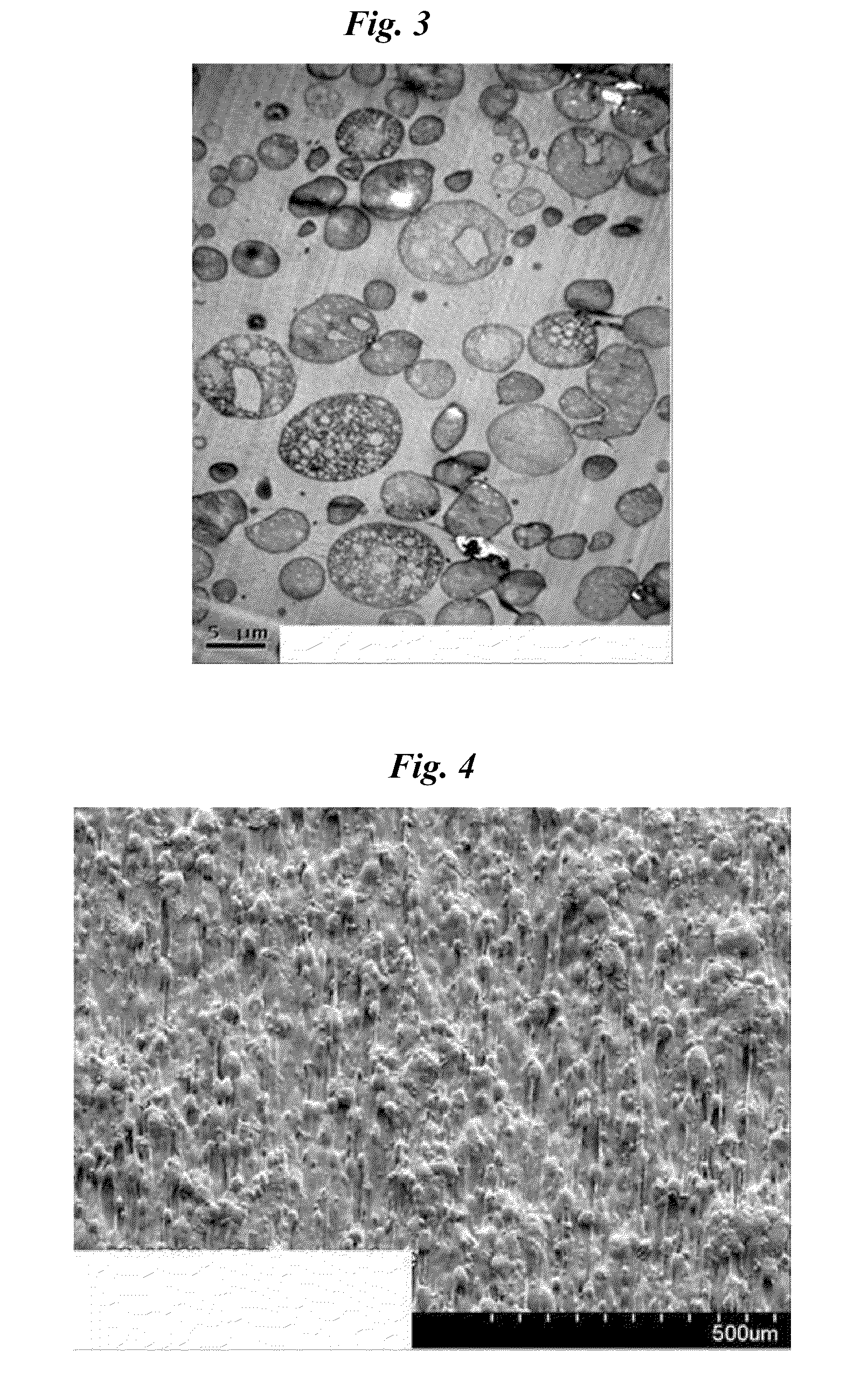

Low Gloss Thermoplastic Resin Composition with Soft Touch Surface and Molded Article Therefrom

Disclosed herein is a low gloss thermoplastic resin composition with a soft touch surface comprising (A) about 10 to about 80% by weight of a soft rubbery aromatic vinyl copolymer resin which comprises rubber particles with a graft ratio of about 40 to about 90% and an average particle diameter of about 6 to about 20 μm as a dispersed phase; (B) about 4 to about 60% by weight of a rubber-modified aromatic vinyl copolymer resin; and (C) about 5 to about 80% by weight of an aromatic vinyl-vinyl cyanide copolymer resin. The molded article molded from the thermoplastic resin composition can have a soft touch surface as well as excellent low gloss and impact strength.

Owner:LOTTE ADVANCED MATERIALS CO LTD

LCD hard type protection film

ActiveCN101281306AAvoid scratchesLess prone to relative motionScreening apparatusSynthetic resin layered productsPolyethylene terephthalateLiquid-crystal display

The present invention relates to a hard protective film applied in the protection of the liquid crystal display, including a layer of polyethylene glycol terephthalate layer, and one layer of polyethylene cob-webbing film, wherein, the liquid crystal display hard protective film is formed by mounting an adhesive layer on the surface of the polyethylene glycol terephthalate layer, and then cementing and compounding with the cob-webbing surface of the polyethylene cob-webbing film. The hard protection film has strong anchorage force and large friction coefficient, when the liquid crystal display hard protective film is used to protect the liquid crystal display, the PE film surface of the hard protective film faces to the liquid crystal display and overlays the display surface of the liquid crystal module, the perimeter of the hard protection film is fixed by the adhesive tape, which can prevent the liquid crystal display from being scratched and meanwhile has strong ventilation property, high temperature and high humidity resistance, and electrostatic resistance.

Owner:SUZHOU JINFU TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com