Method for preparing antibacterial super-hydrophobic fabric having stable properties by using silver-deposited nanoparticles

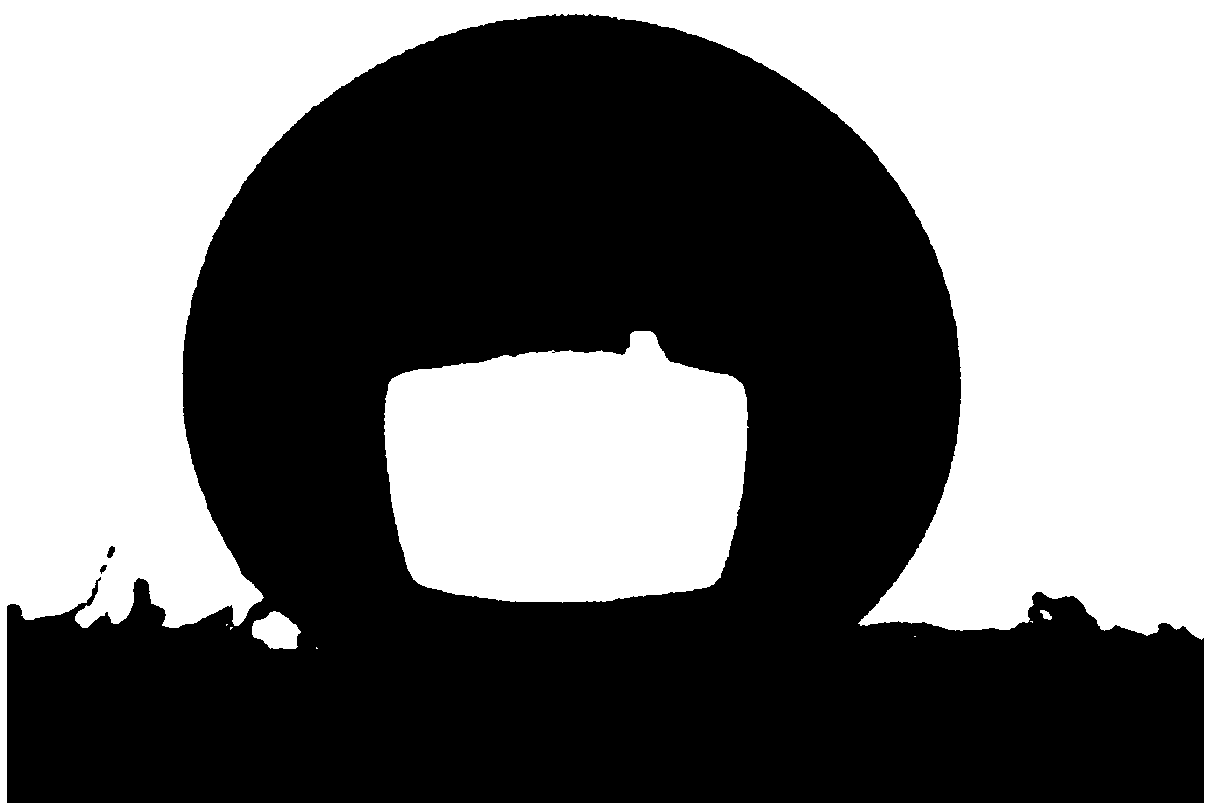

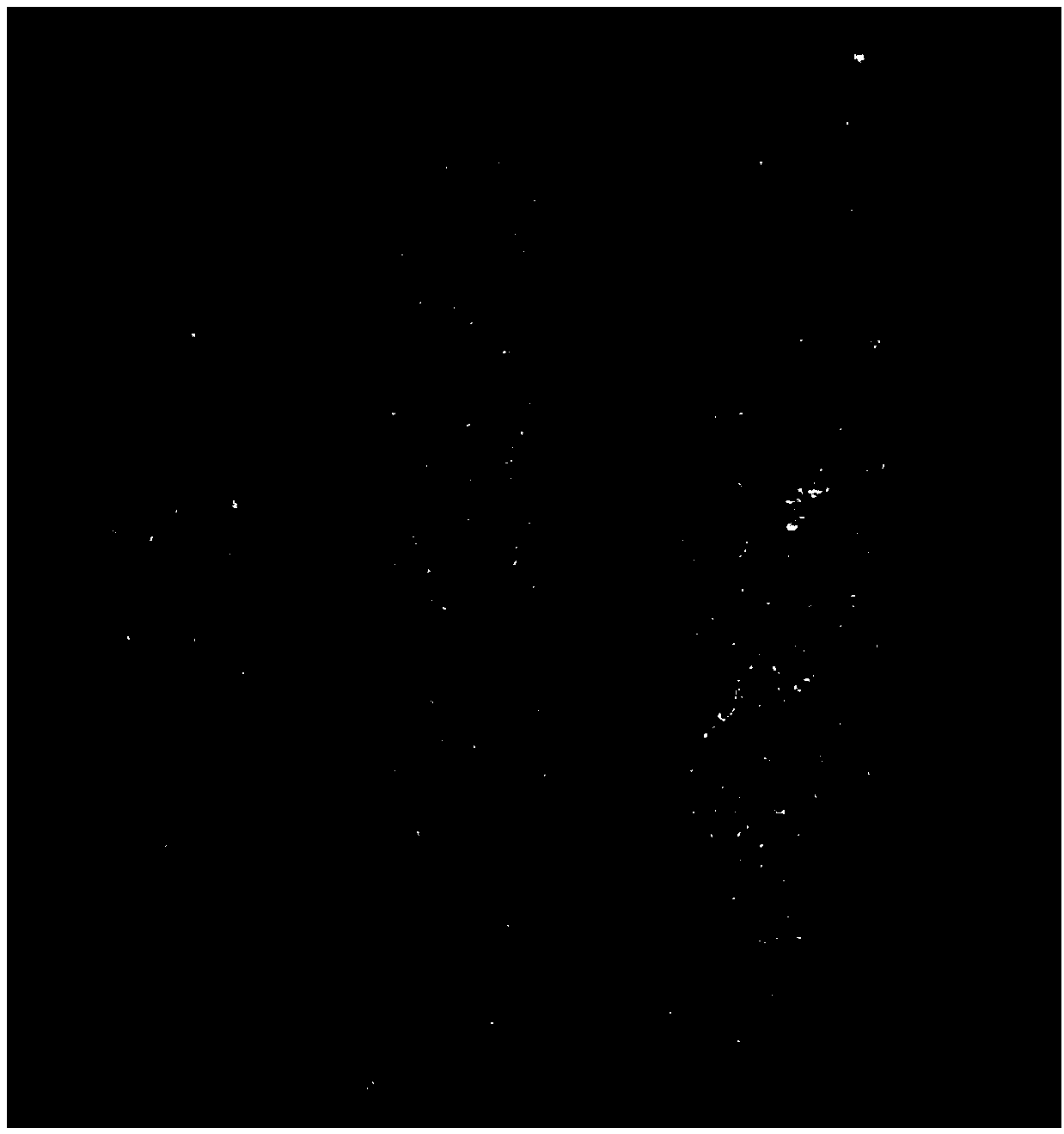

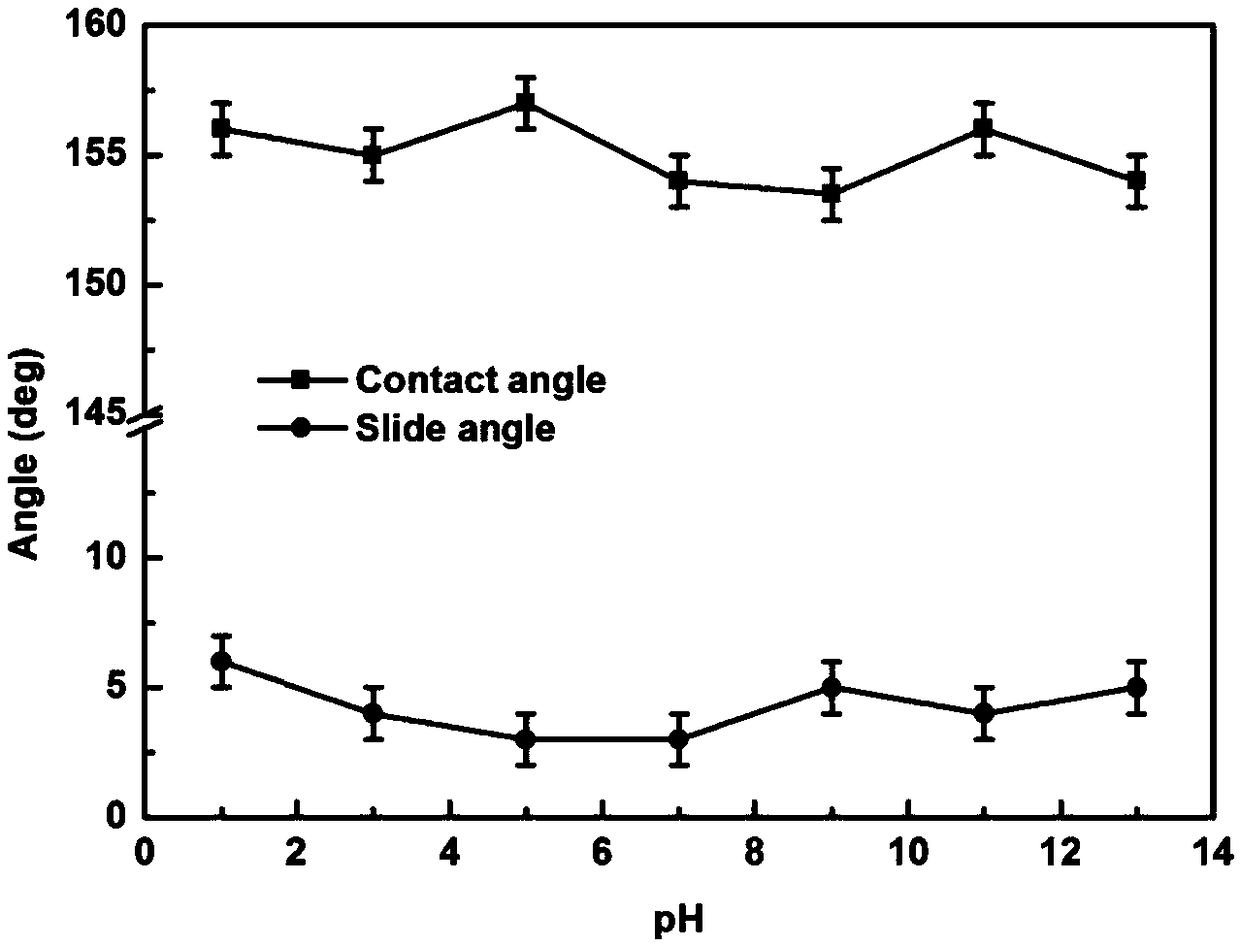

A technology of silver nanoparticles and preparation performance, which can be used in plant fibers, textiles and papermaking, and improved hand-feeling fibers, etc., can solve the problems of uneven surface of superhydrophobic film and superhydrophobic fabric, single properties of superhydrophobic fabric, and high equipment requirements. , to achieve the effect that the roughness is not easy to change, the surface is uniform, and the equipment requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the present embodiment comprises the following steps:

[0044] Step 1. Add 0.7448g EDTA (ethylenediaminetetraacetic acid) into a beaker filled with 100mL deionized water to obtain a solution A with a mole fraction of 2%. Dissolve 1.862g EDTA in 100mL of water to obtain a solution B with a mole fraction of 5%. Soak the clean fabric in solution A for 30 minutes, then soak it in solution B for 30 minutes, and dry it;

[0045] Step 2, prepare nano-silver particles with ammonia water, silver nitrate and glucose. The specific process is: drop the ammonia solution into 8mL silver nitrate solution. Precipitation disappears, and silver ammonia solution is obtained;

[0046] Soak the fabric in step 1 in silver ammonia solution, then add 10mL glucose solution, soak for 30 minutes, and then dry; wherein, the concentrations of ammonia solution, silver nitrate solution and glucose solution are all 0.1mol / L. Nano silver particles were prepared by silver mir...

Embodiment 2

[0053] The preparation method of the present embodiment comprises the following steps:

[0054] Step 1. Add 1.4896g EDTA to a beaker containing 200mL deionized water to obtain solution A, dissolve 3.7240g EDTA in 200mL water to obtain solution B, soak the clean fabric in solution A for 20 minutes, and then put Soak in solution B for 30 minutes and dry;

[0055] Step 2, prepare nano-silver particles with ammonia water, silver nitrate and glucose. The specific process is: drop the ammonia solution into 10mL silver nitrate solution. Precipitation disappears, and silver ammonia solution is obtained;

[0056] Soak the fabric in step 1 in silver ammonia solution, then add 15mL glucose solution, soak for 30 minutes, and then dry; wherein, the concentrations of ammonia solution, silver nitrate solution and glucose solution are all 0.2mol / L.

[0057] Step 3. Put the fabric obtained in step 2 into 1.0 g of aluminate in 30 mL of ethanol solution under stirring conditions, dip for two h...

Embodiment 3

[0059] The preparation method of the present embodiment comprises the following steps:

[0060] Step 1. Immerse the clean fabric in 0.3724g EDTA and add it to a beaker filled with 50mL deionized water to obtain solution A. Dissolve 0.931g EDTA in 100mL water to obtain solution B. Immerse the clean fabric in solution A for 30 minutes , and then put into solution B to soak for 20 minutes and dry;

[0061] Step 2, prepare nano-silver particles with ammonia water, silver nitrate and glucose. The specific process is: drop the ammonia solution into 9mL silver nitrate solution. Precipitation disappears, and silver ammonia solution is obtained;

[0062] Soak the fabric in step 1 in silver ammonia solution, then add 12mL glucose solution, soak for 30 minutes, and then dry; wherein, the concentration of ammonia solution, silver nitrate solution and glucose solution are all 0.05mol / L.

[0063] Step 3: Put the fabric obtained in step 2 into 0.4 g of aluminate in 15 mL of ethanol solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com