TBM pilot tunnel expansion digging method for 20km double-line double-cavity ultra-long tunnel construction

A technology for tunnel construction and tunnel guidance, which is applied in railway or bridge construction and road fields, can solve problems such as high construction cost, damage to surface vegetation, and surrounding environment, so as to reduce construction operation costs, protect construction surrounding environment, and reduce construction work. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. TBM selection

[0021] The diameter of the B-line tunnel is 3.5m, and the diameter of the A-line tunnel is TBM open type hard rock roadheader with a diameter of 4.2m.

[0022] 2. Determine the position of the pilot hole

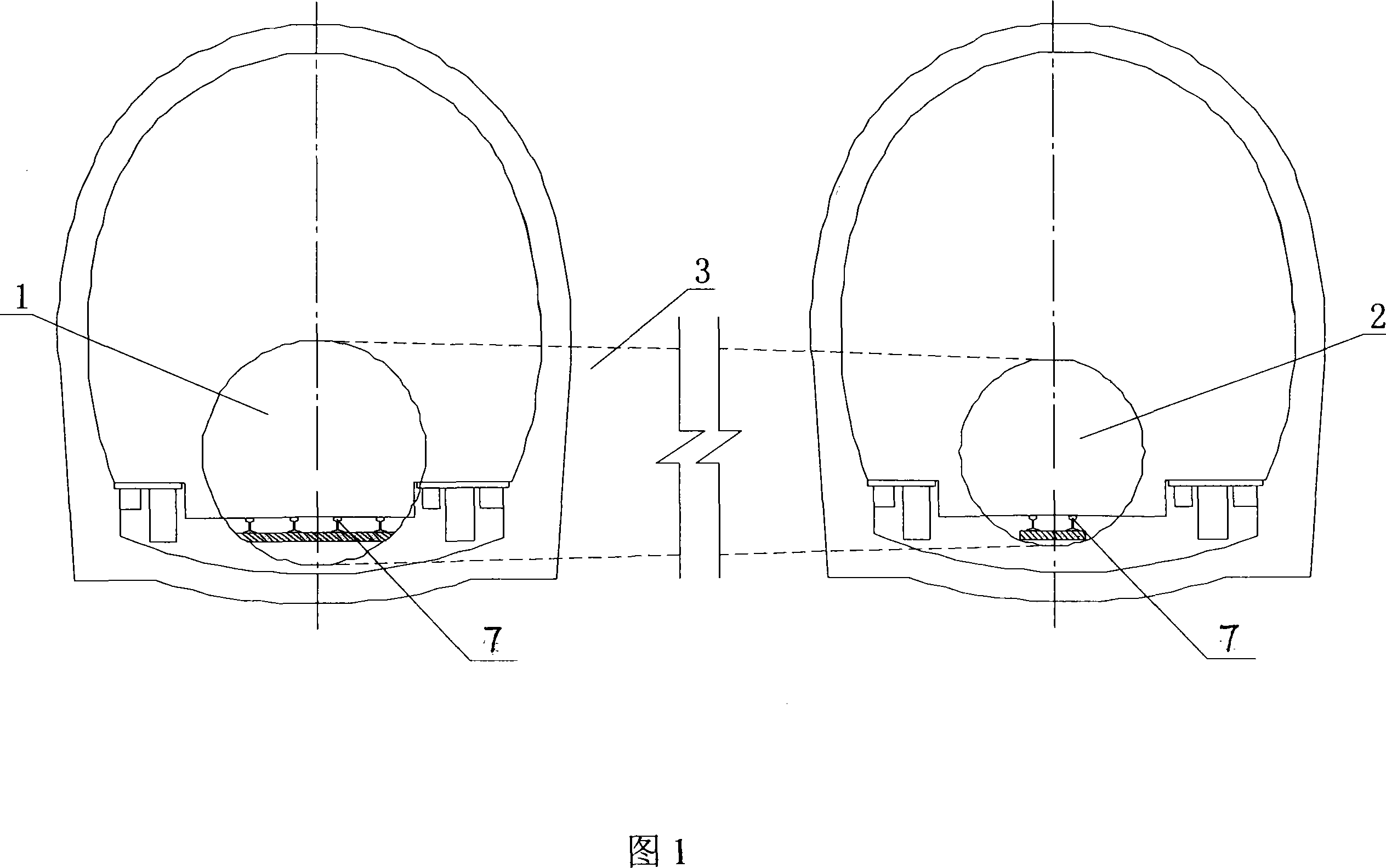

[0023] Referring to Figure 1, the pilot tunnel is arranged at the lower part of the central axis of the two tunnels. The height is controlled by the tunnel design inverted arch filling top surface as the rail top surface.

[0024] 3. Ballasting

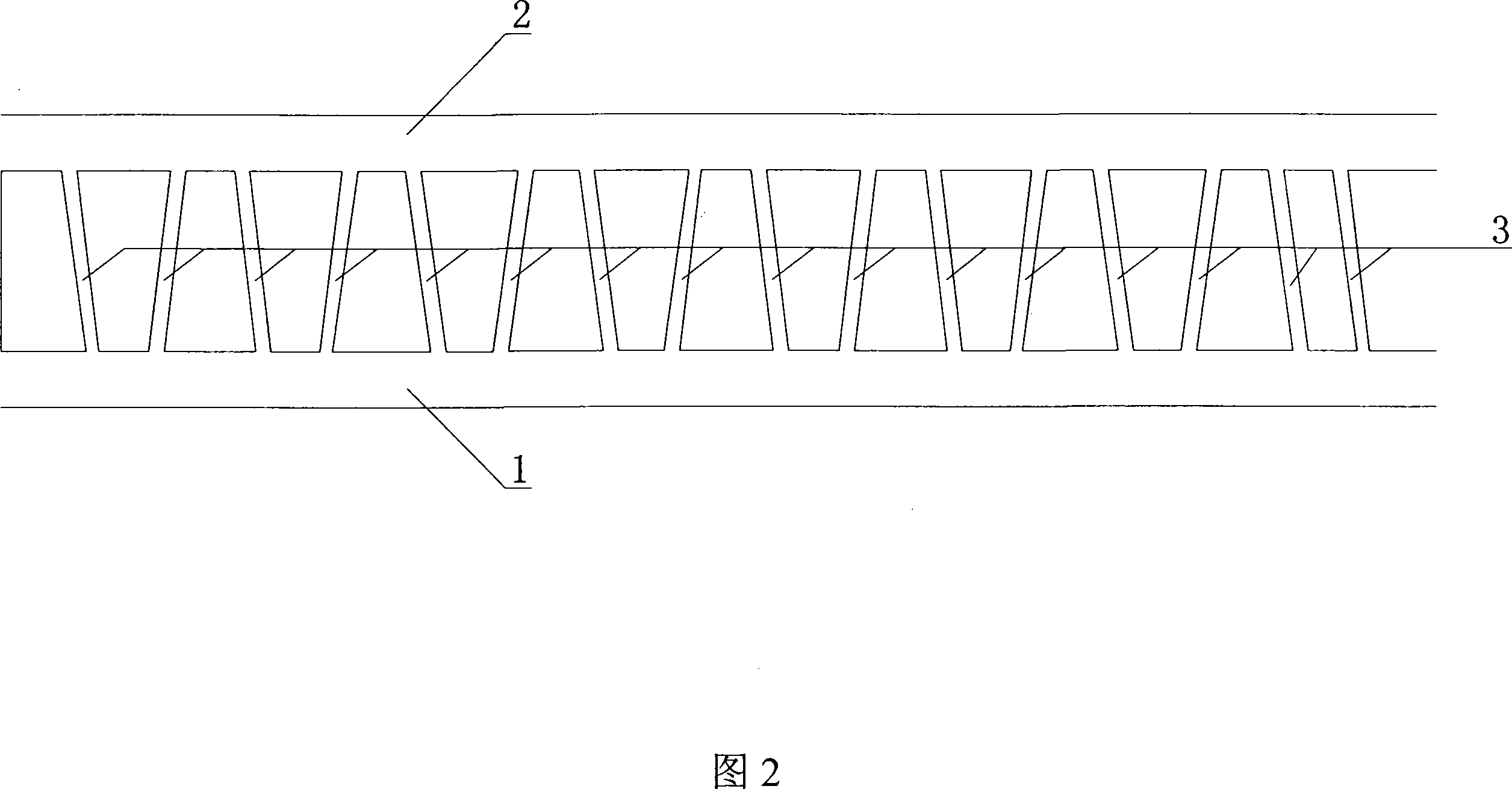

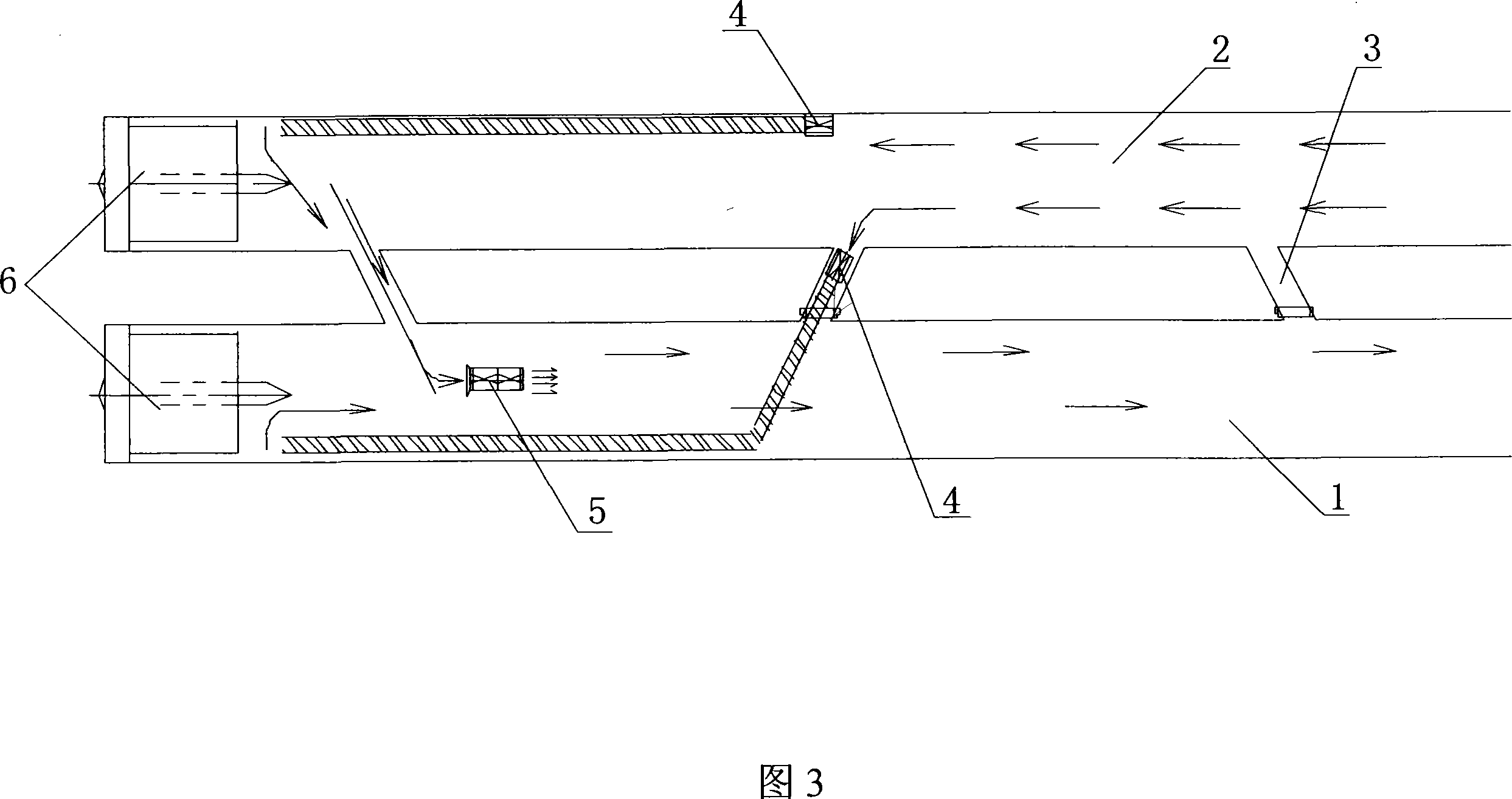

[0025] Horizontal passages are evenly arranged between the two guide tunnels A and B to form an interoperable rail transportation system. Refer to Figure 2 for the setting of cross passages. According to the "one positive and one reverse" method, one is set at an even interval of 1200m. The elevation of the bottom plate of the transverse passage shall be consistent with the elevation of the bottom of the adjacent AB line guide tunnel, so as to facilitate drainage and lay the connecting line between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com