Patents

Literature

39results about How to "Reduce construction work costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

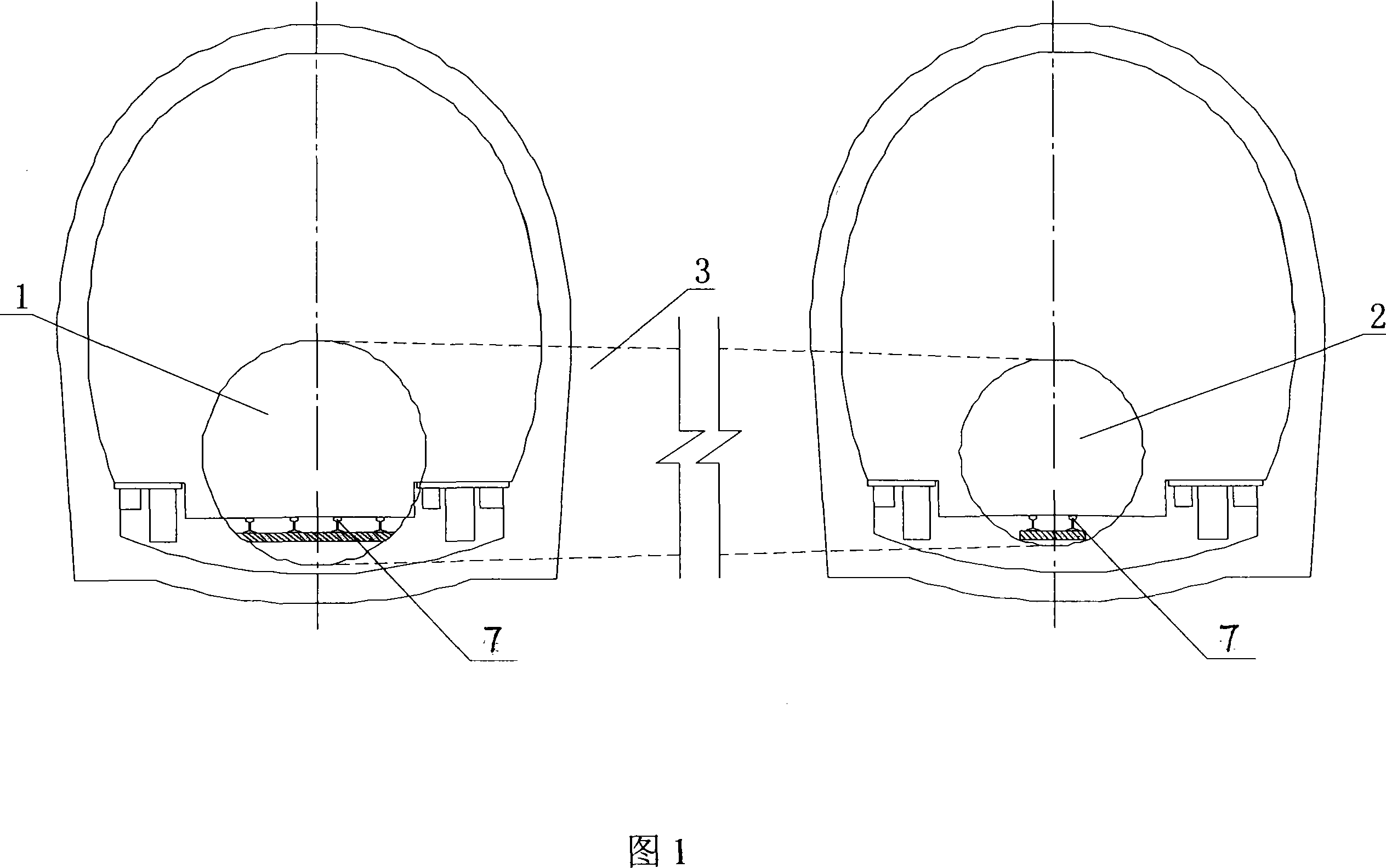

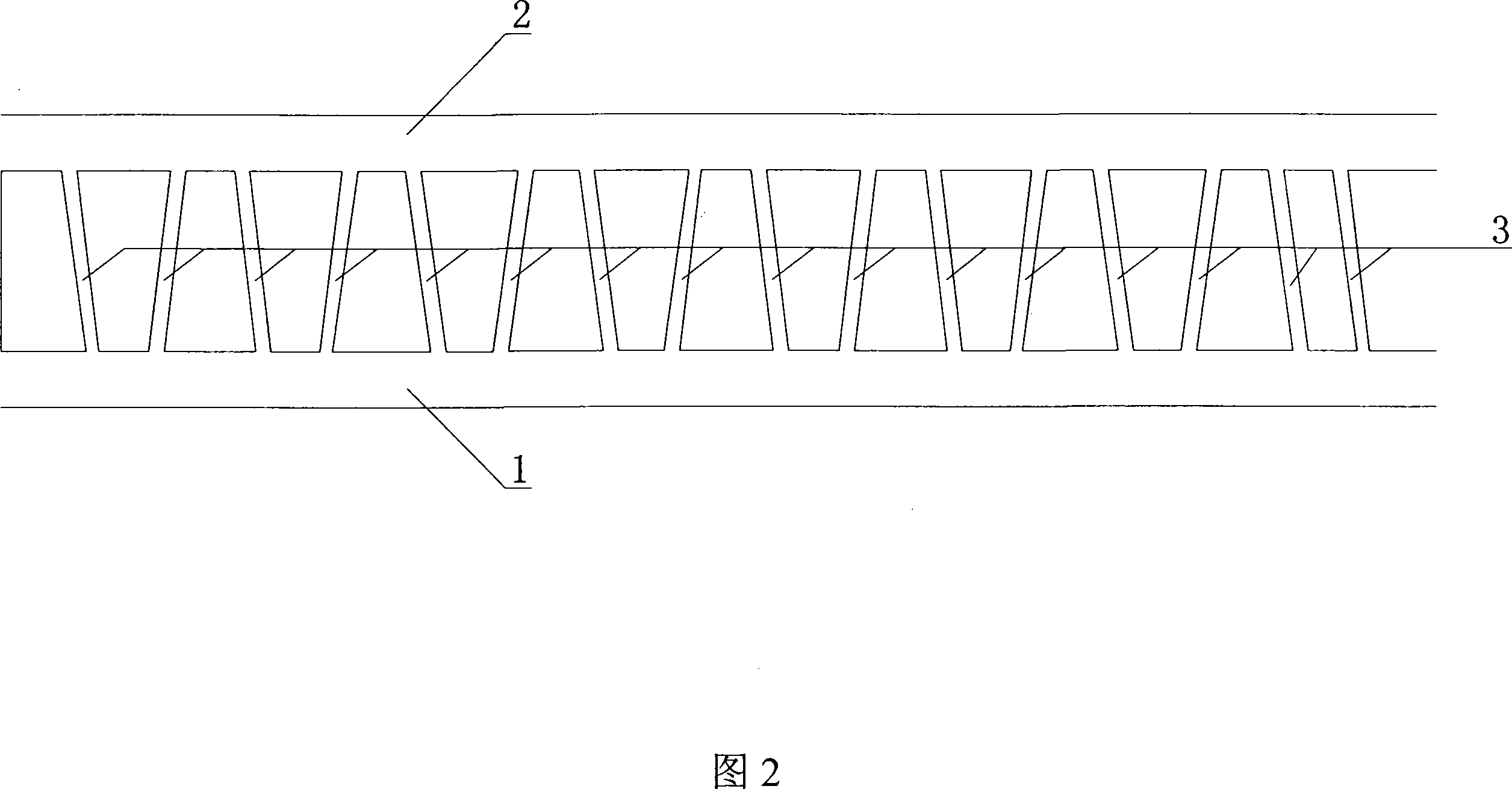

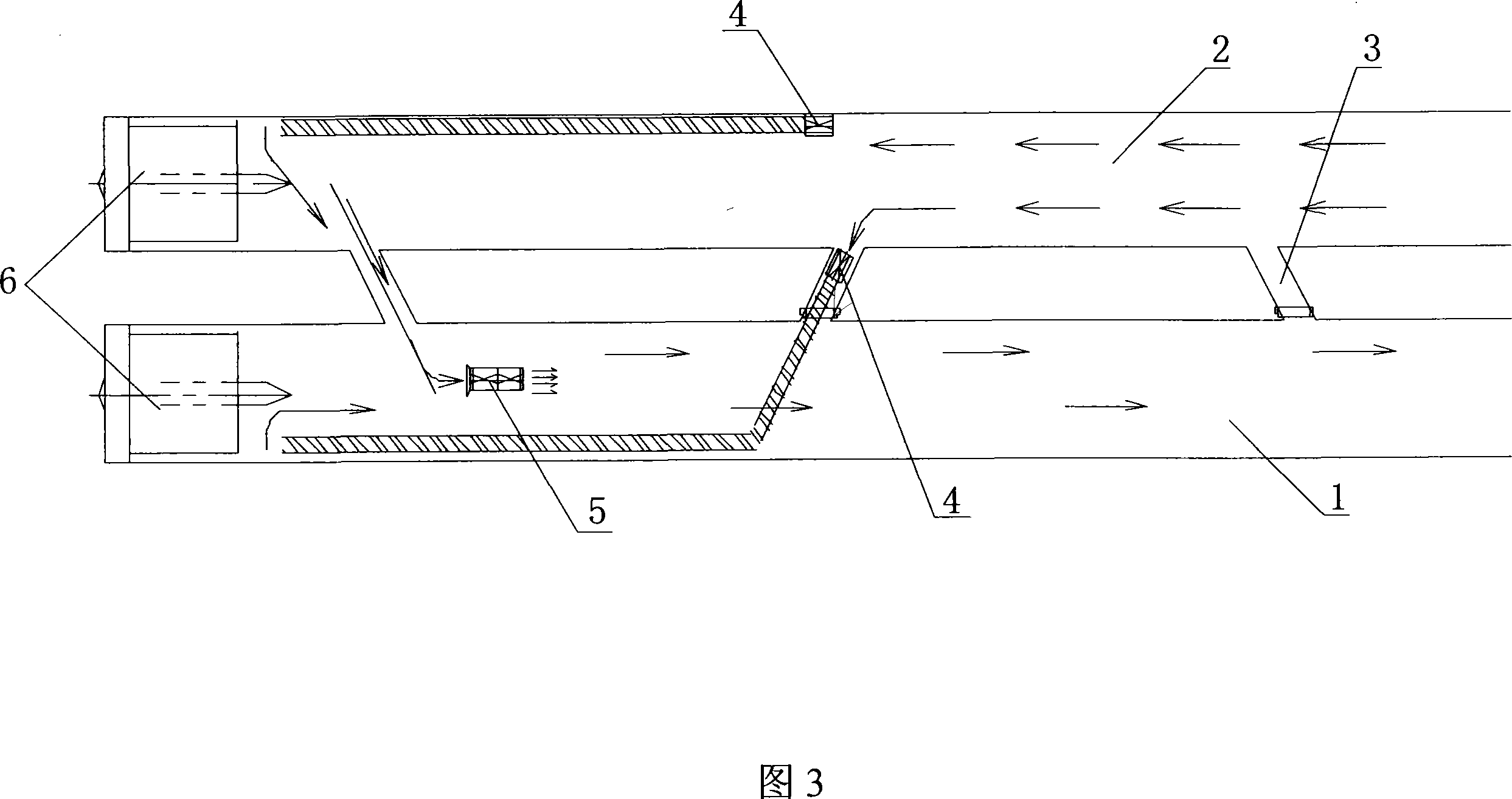

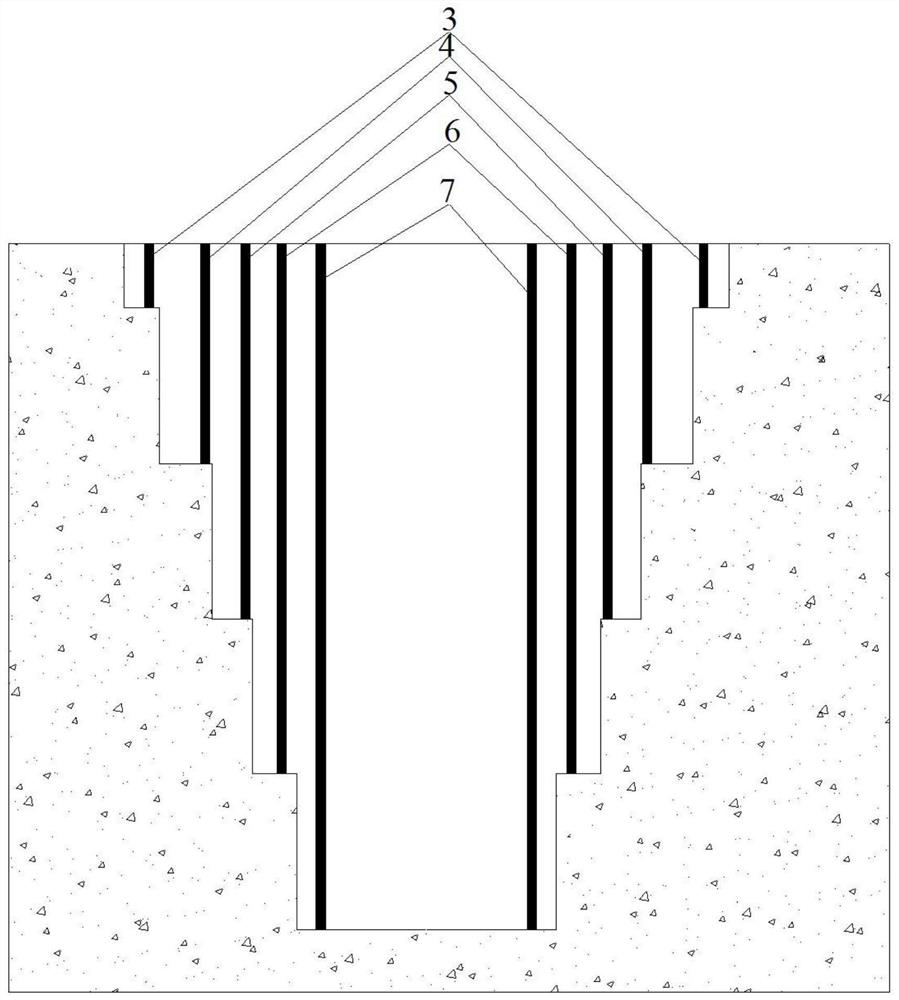

TBM pilot tunnel expansion digging method for 20km double-line double-cavity ultra-long tunnel construction

The invention provides a TBM pilot tunnel enlarging excavation method which is adopted in 20km dual-line dual-tunnel super-long tunnel construction, belonging to the building technical field of road, railway or bridge. The method is that a. two TBMs respectively with the diameters of 4.2m and 3.5m are adopted so as to excavate from the bottom center of the lower-end tunnel opening of the two parallel tunnels to the high-end direction of the tunnel to form two pivot tunnels A and B; b. enlarged excavation and lining operation are firstly carried out in the B pivot tunnel which passes through a tunnel-typed ventilation air exchange system and a communicated track delivering system which consist of the A pivot tunnel and a transverse passage; c. after the pivot tunnel A and the pivot tunnel B are interpenetrated, only two coal faces at the inlet and the outlet of A line are arranged; d. after the enlarged excavation in B line is completely achieved, 8-10 coal faces are opened to achieve the enlarged excavation of the A line. The invention has the advantages of fast construction speed, small construction operation quantity, economics and safety, has no damages or effects to the plants out of a mountain body, damaging slightly the self-flowing water system which is formed in the mountain body and protecting the around environment of the construction.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

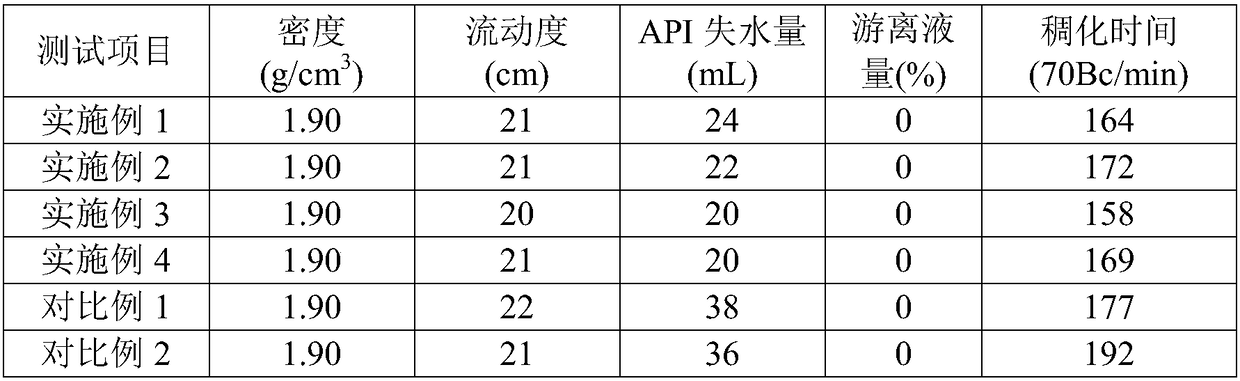

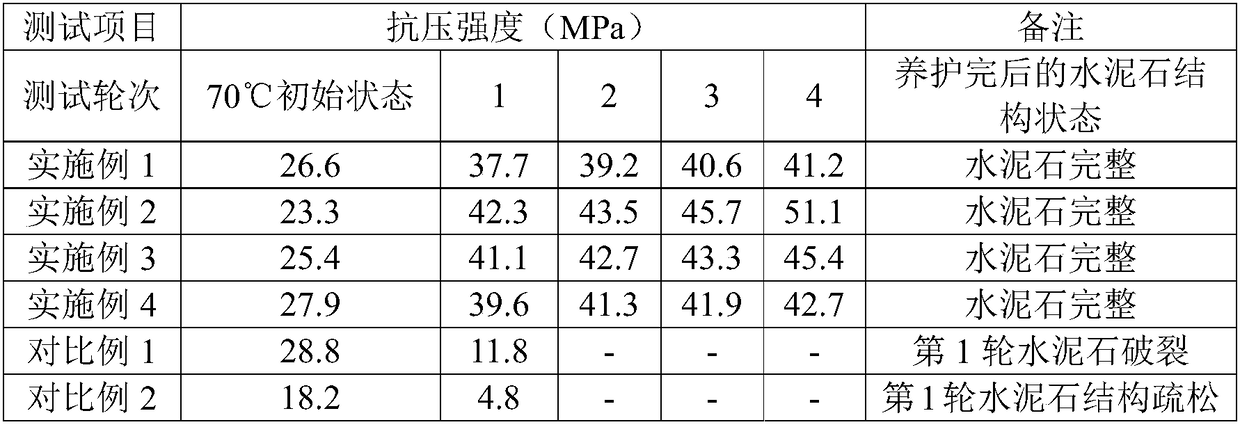

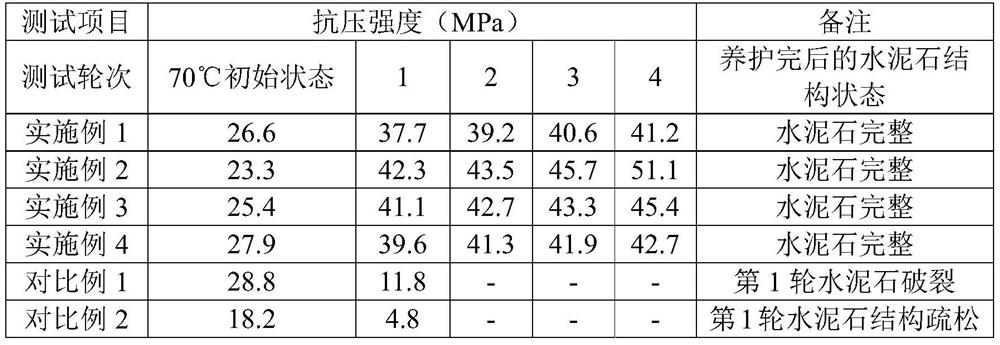

High temperature resistant silicate cement paste and preparation method thereof

ActiveCN108298902AGood settlement stabilityRapid development of strengthDrilling compositionWell cementingFresh water

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

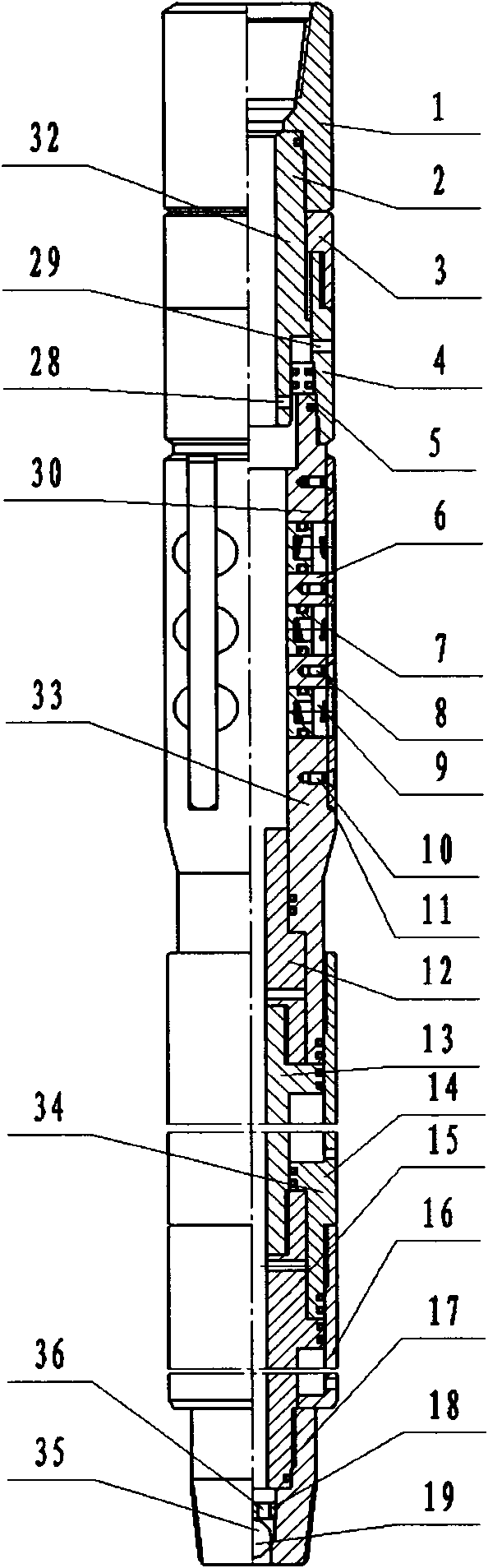

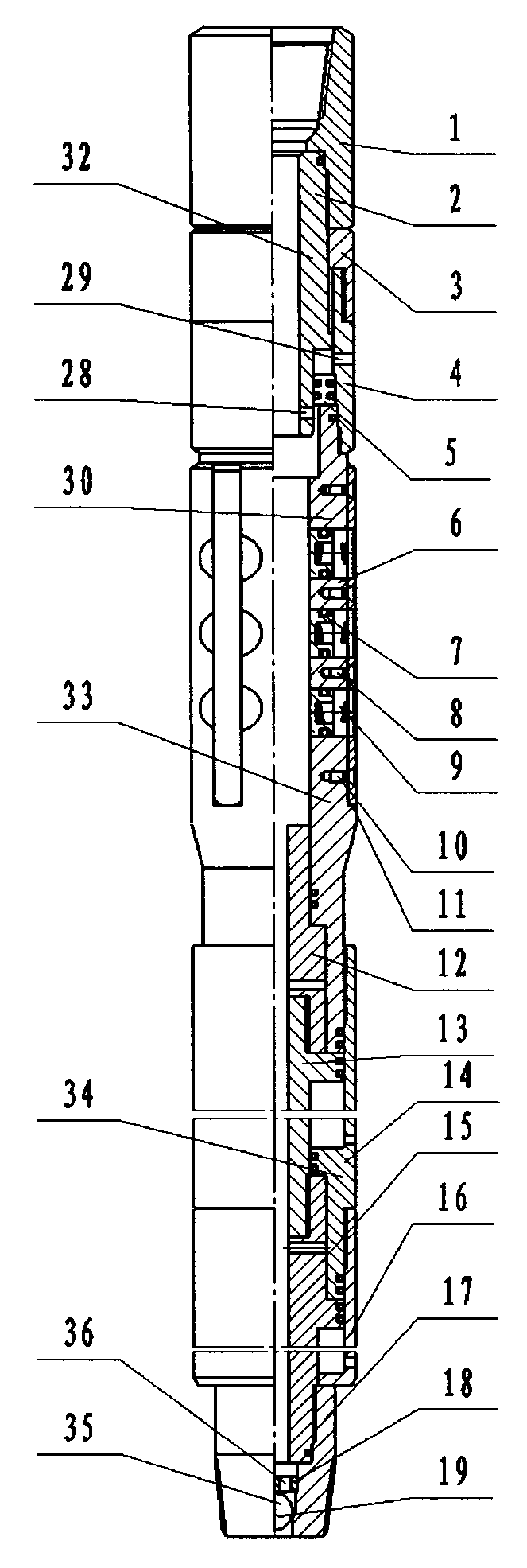

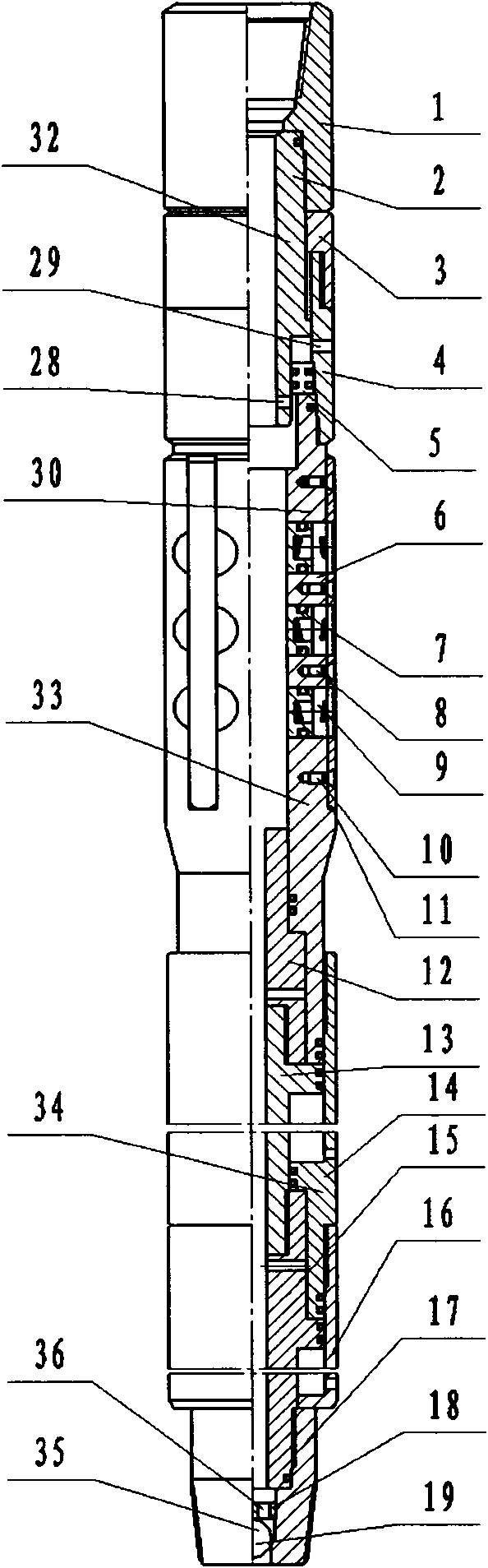

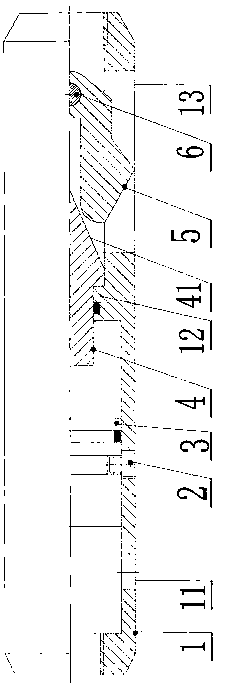

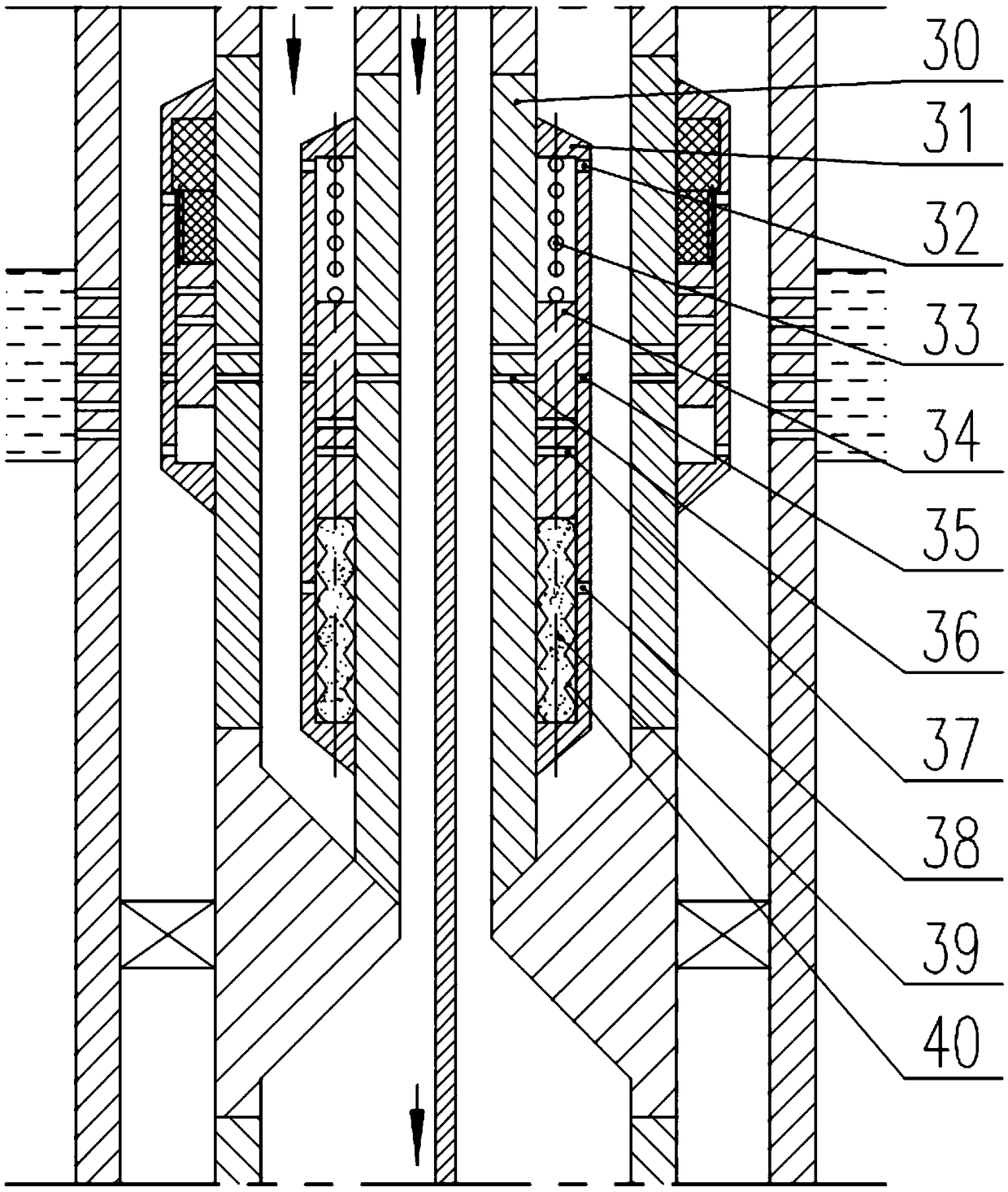

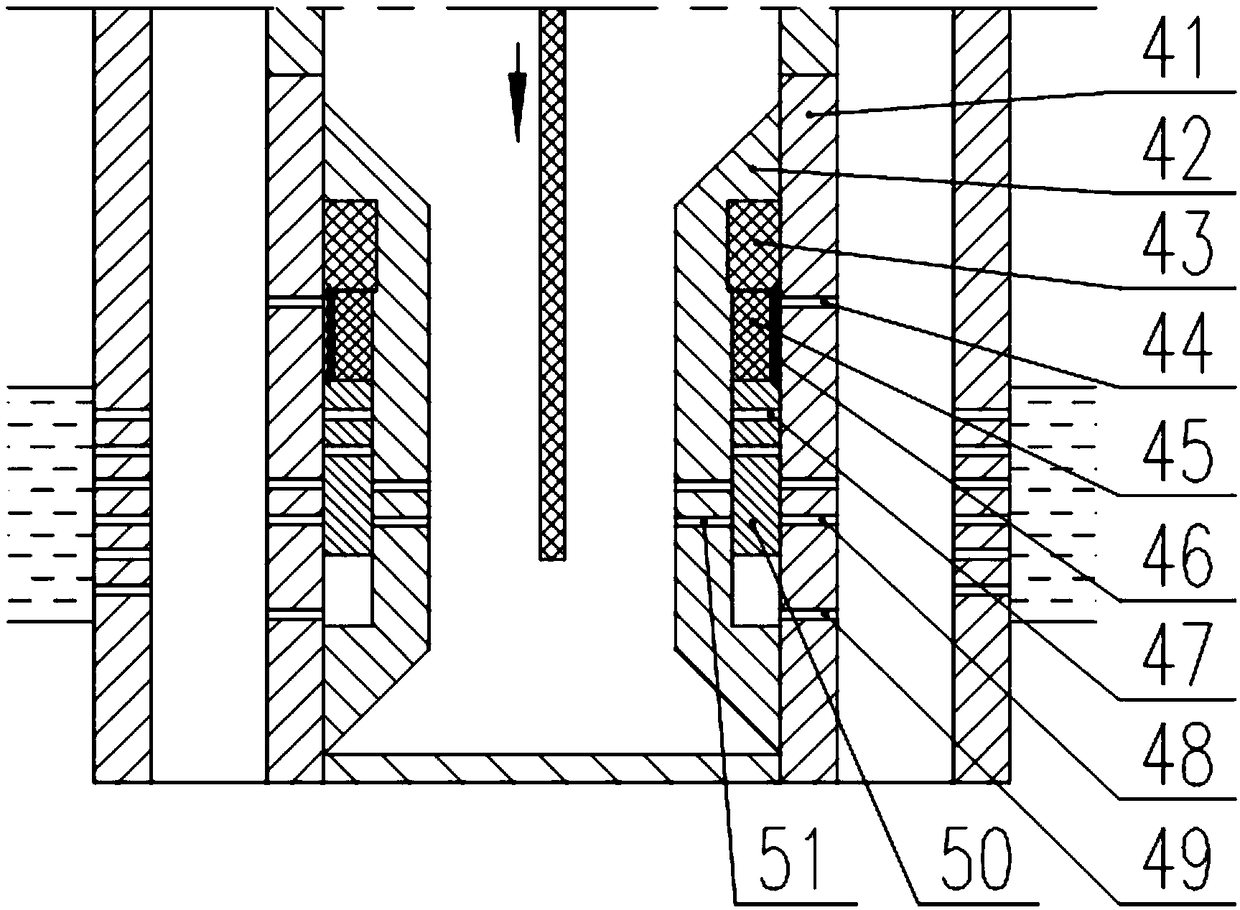

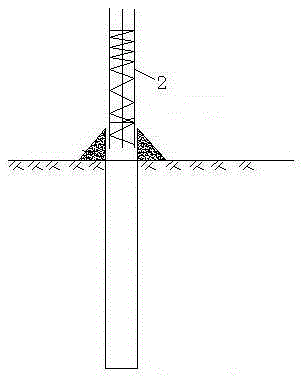

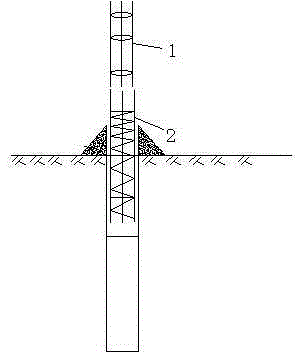

Anchoring ball type casing truing unit and truing method thereof

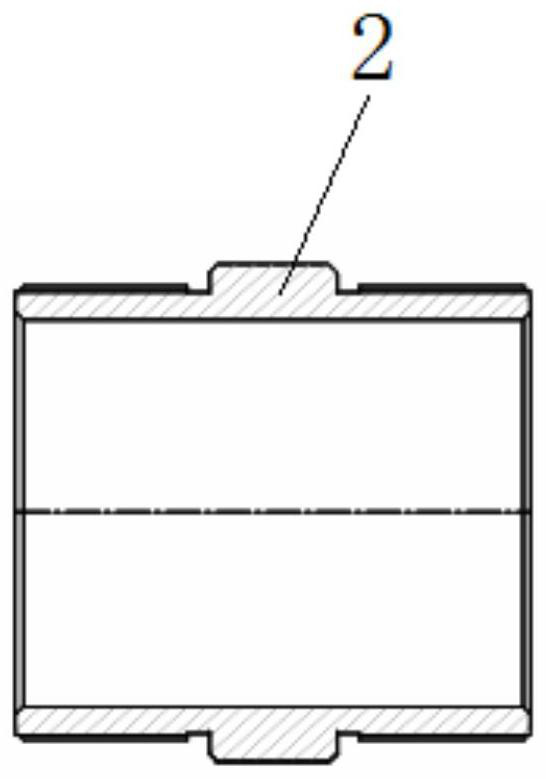

ActiveCN101942979AAvoid damageSimple structureBorehole/well accessoriesHydraulic cylinderWork performance

The invention relates to an anchoring ball type casing truing unit and a truing method thereof, and overcomes the defects that during the repairing casing operation, the existing roll type truing unit is easy to damage a drilling rig, and the unstable state of a tubular column enables the time for repairing the operation and the operation cost to be increased. In the invention, an upper joint (1), an aerial drainage assembly (32), an anchoring assembly (33), a hydraulic cylinder assembly (34) and a lower joint (17) are arranged on an anchoring device (30) and fixedly connected in sequence; a lower joint (17) is internally provided with a check valve (35); the lower joint (17) of the anchoring device (30) is fixedly connected with the upper end of the ball truing unit (31), or the lower joint (17), a drill collar and the ball truing device (31) are fixedly connected from up to down. The invention has the following benefit effects of simple structure and reasonable design, is convenientto operate, is safe and reliable, avoids the damage to the drill, reduces the construction period, has high working performance and reduces the field operation cost.

Owner:DAGANG OIL FIELD GRP +2

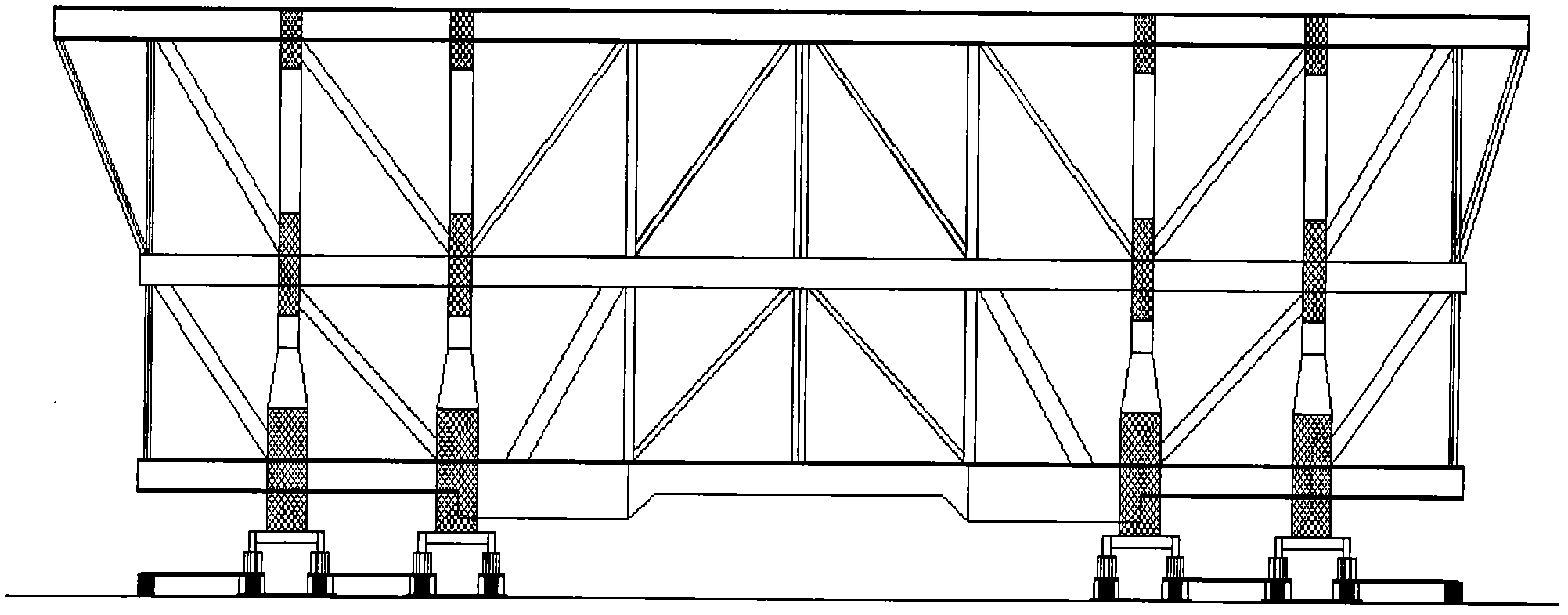

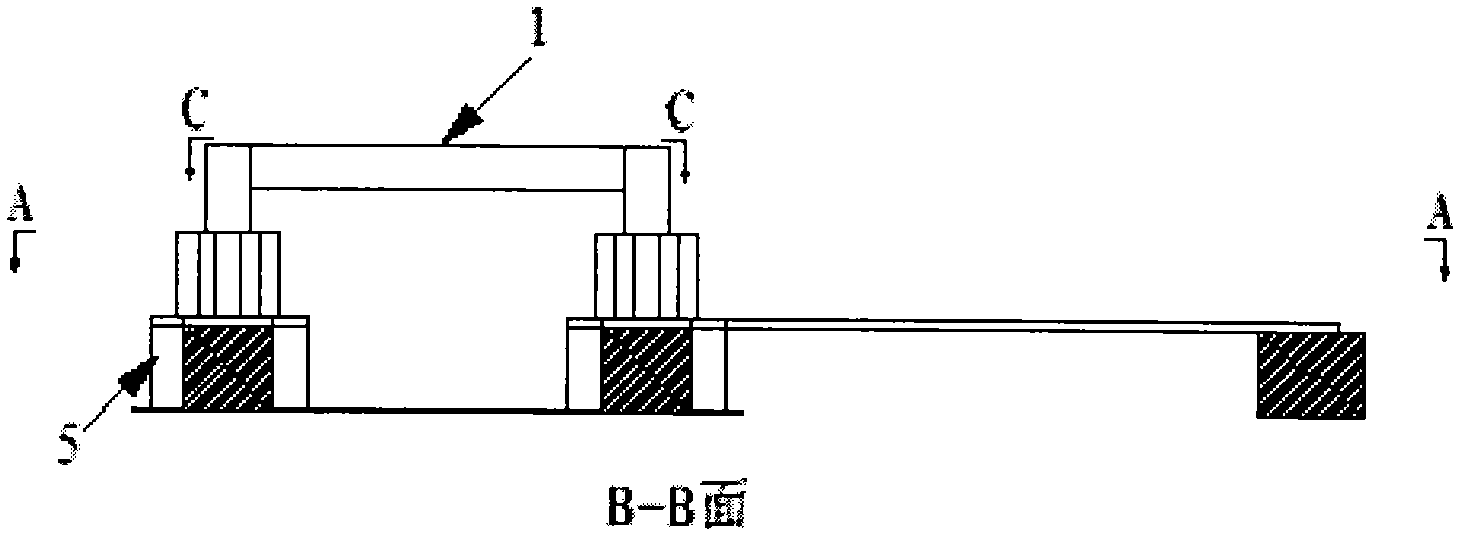

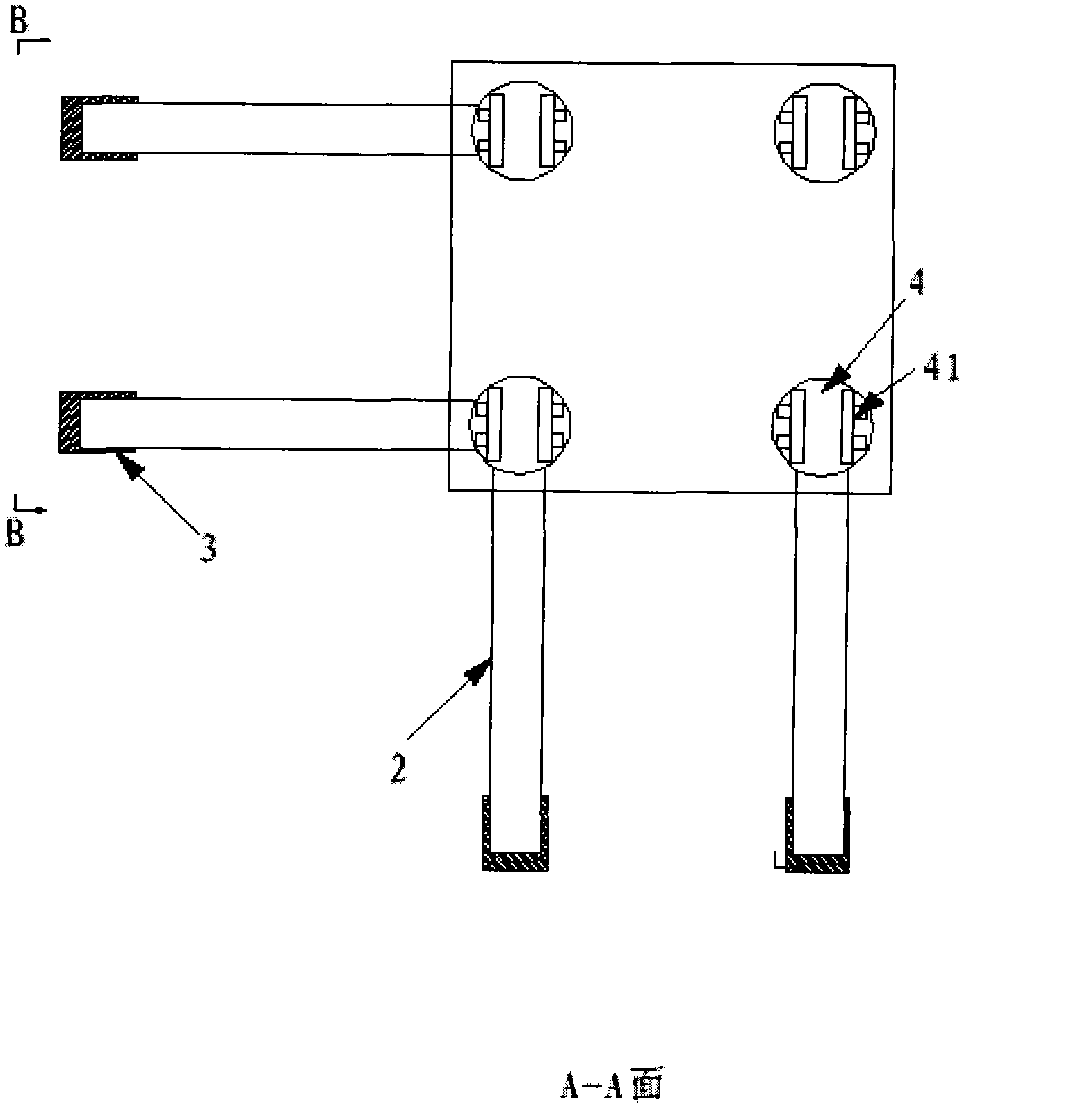

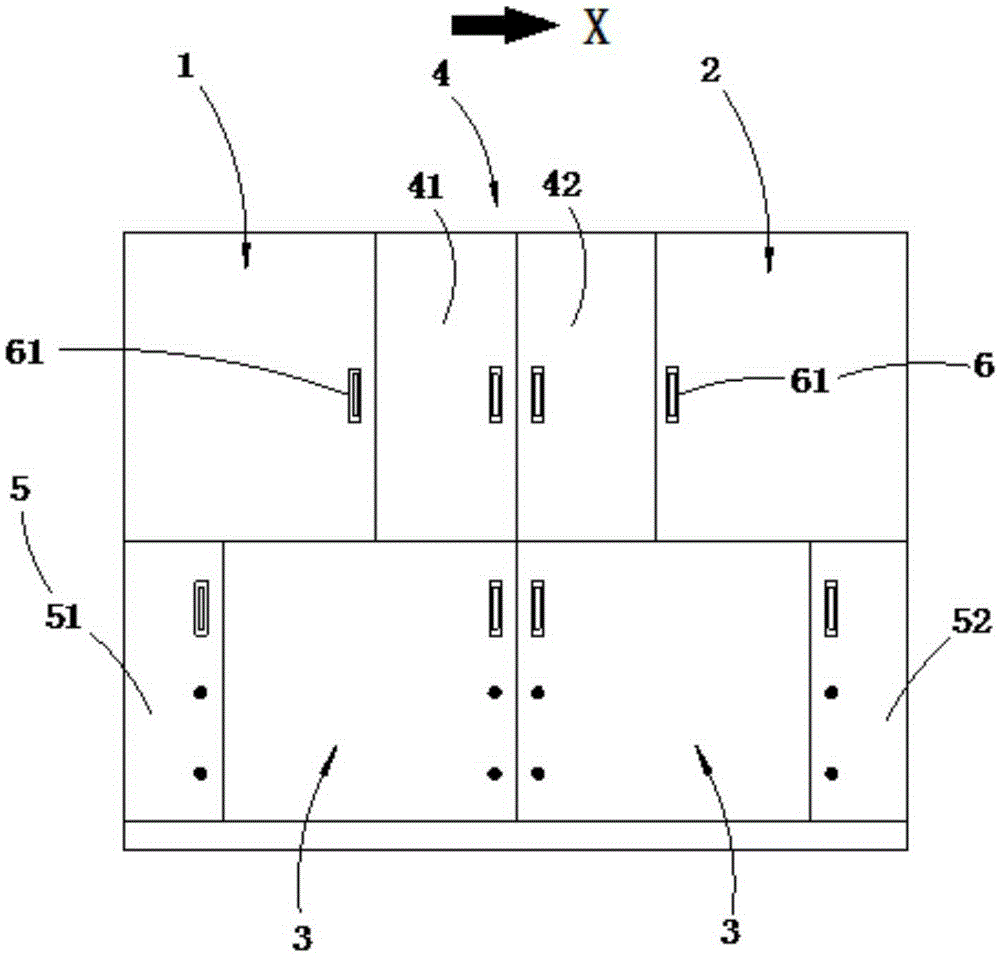

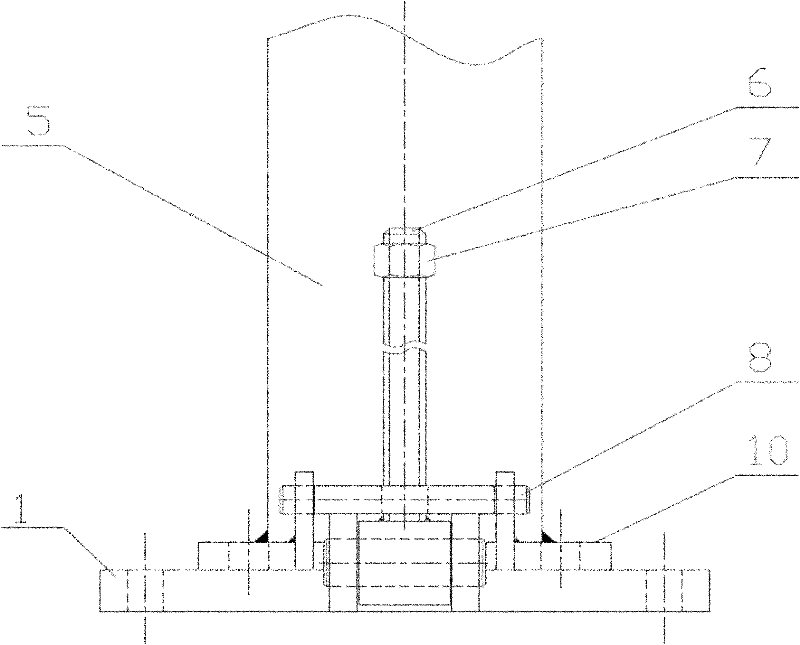

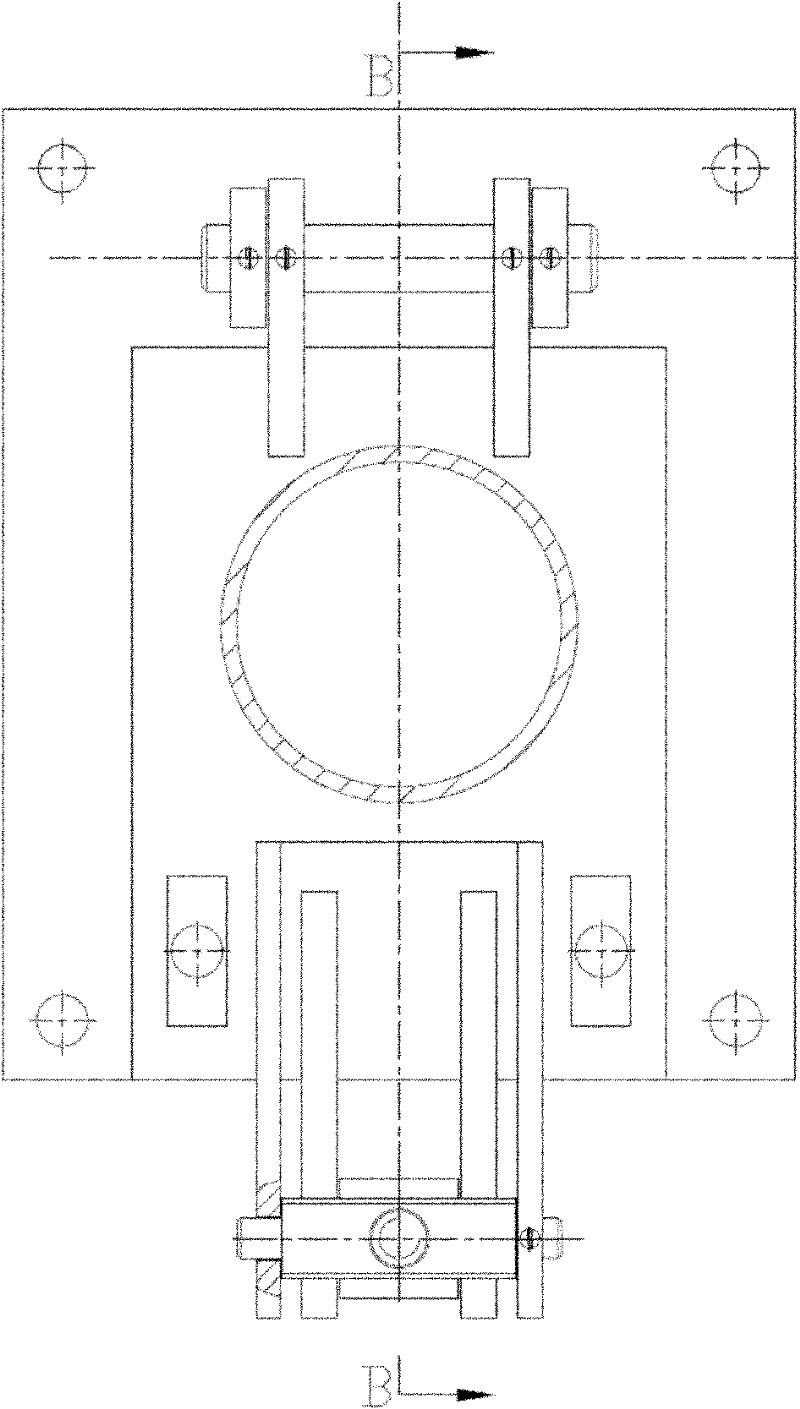

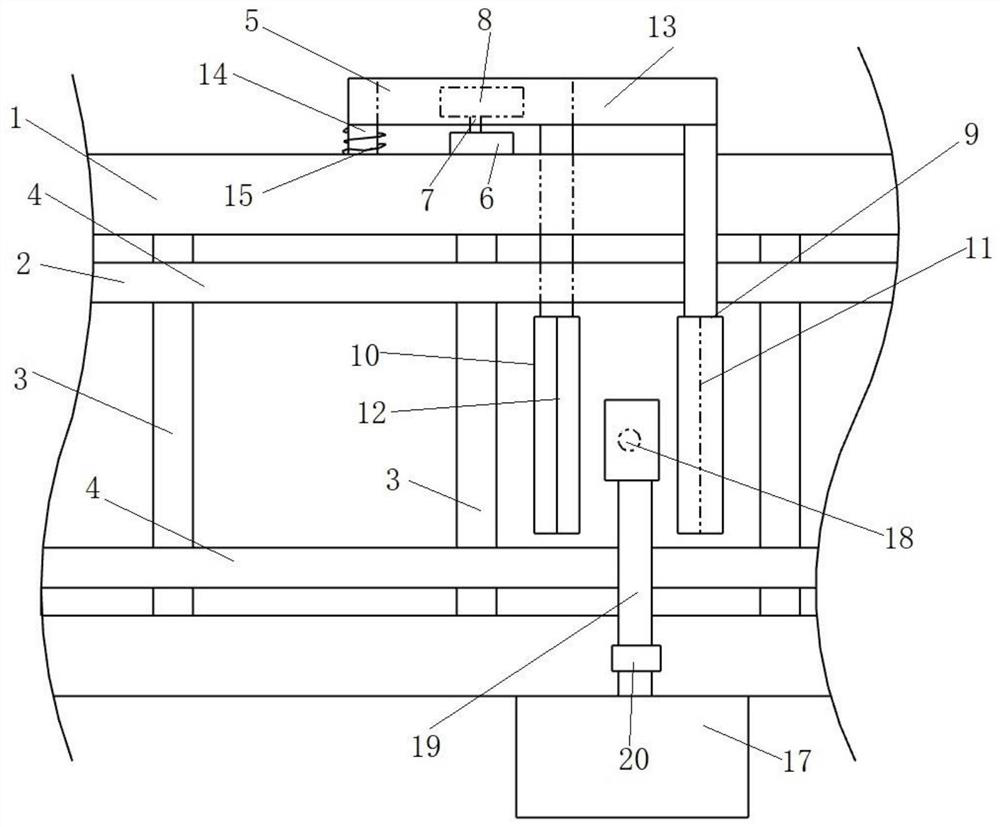

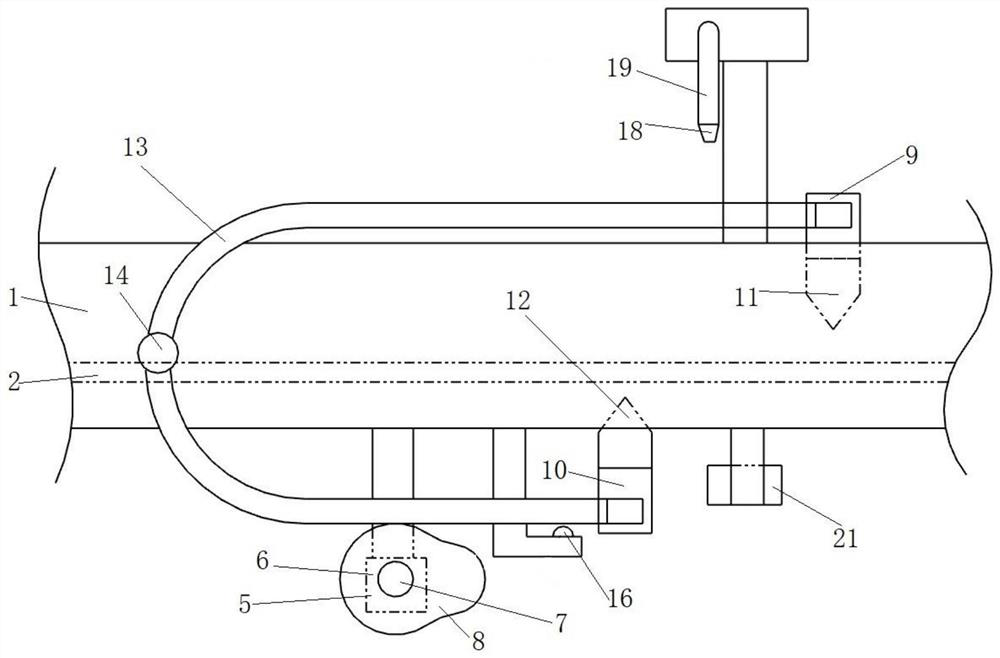

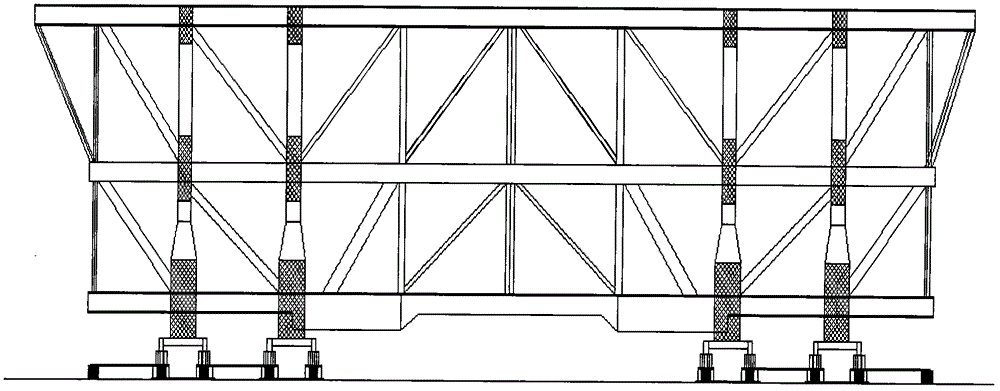

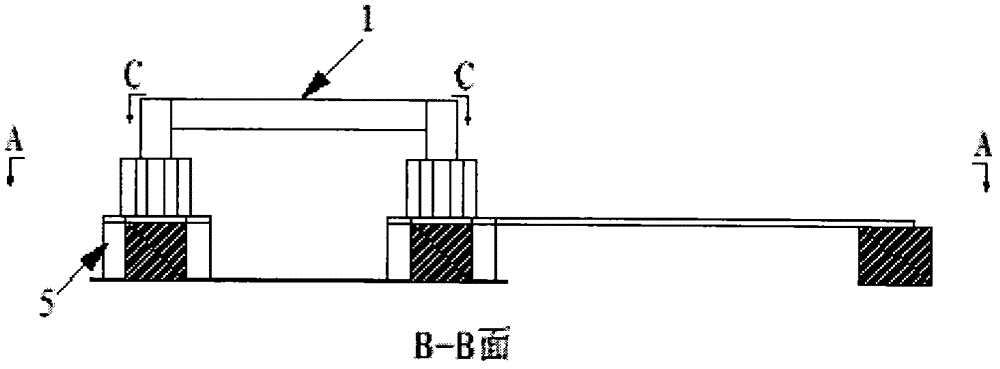

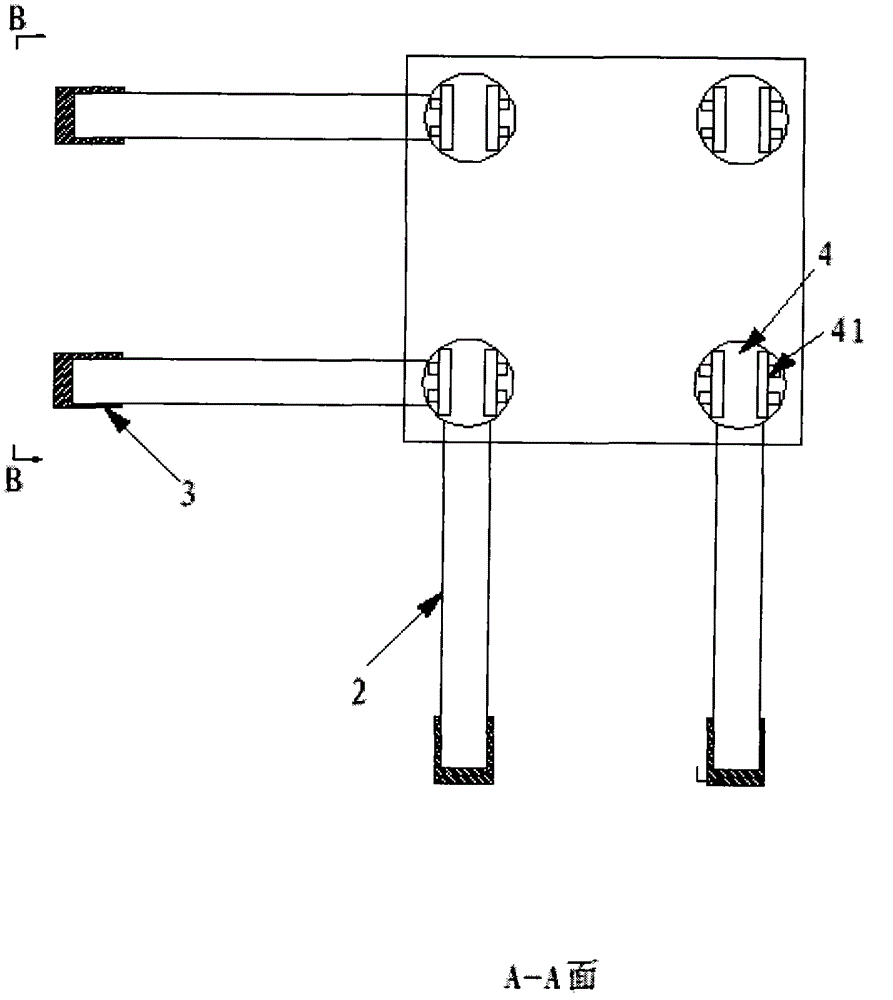

Around synchronization hydraumatic jacking process of upper module of ultra-large marine oil platform

ActiveCN102561289ALower lifting heightReduce site resource allocation requirementsArtificial islandsUnderwater structuresButt jointEngineering

The invention discloses an around synchronization hydraumatic jacking process of upper module of an ultra-large marine oil platform. The around synchronization hydraumatic jacking process comprises the following steps of: step 1, arranging a jacking and supporting mechanism at the bottom of each landing leg; step 2, controlling a jacking device to jack a set height journey, supporting an upper structure by virtue of a radial arm, and enabling a jacking device to retract; step 3, enabling a support beam slippage rail to enter a position below the upper structure; step 4, the jacking device supports jacking the set height journey by virtue of the jacking device, rotating the radial arm to support the upper structure, and enabling the jacking device to retract; step 5, enabling a next group of support beam slippage rails to enter the lower part of the support beam, enabling the jacking device to retract, and jacking the upper module for a set height; step 6, repeating the step 3, the step 4 and the step 5 until jacking the upper module to a preset height; step 7, transporting a lower structure to the bottom of the upper module; step 8, enabling the jacking device to retract, and connecting the upper module and the lower structure in a butt joint manner; and step 9, unloading and dismantling auxiliary equipment. The jacking process provided by the invention can realize the multipoint and around synchronization jacking of the upper module and can be used for carrying out effective control on the lifting speed and the displacement precision.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Recyclable fracturing fluid used for fracturing construction of sandstone gas reservoir

The invention discloses a recyclable fracturing fluid used for fracturing construction of a sandstone gas reservoir. A primary fracturing fluid comprises the following components in weight percent: 1% to 5% of chloridization stearic acid dimethylamino alcohol ester methyl ammonium, 1% to 5% of potassium chloride and the balance of water. The recyclable fracturing fluid has the advantages of leak-off of the fracturing fluid can be lowered, the pollution to the stratum can be reduced, and flowback liquid is reclaimed on the ground directly, so that earth surface pollution can be avoided; the flowback liquid is reclaimed, so that the water consumption can be lowered; the flowback liquid can be reused after being subjected to ground treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

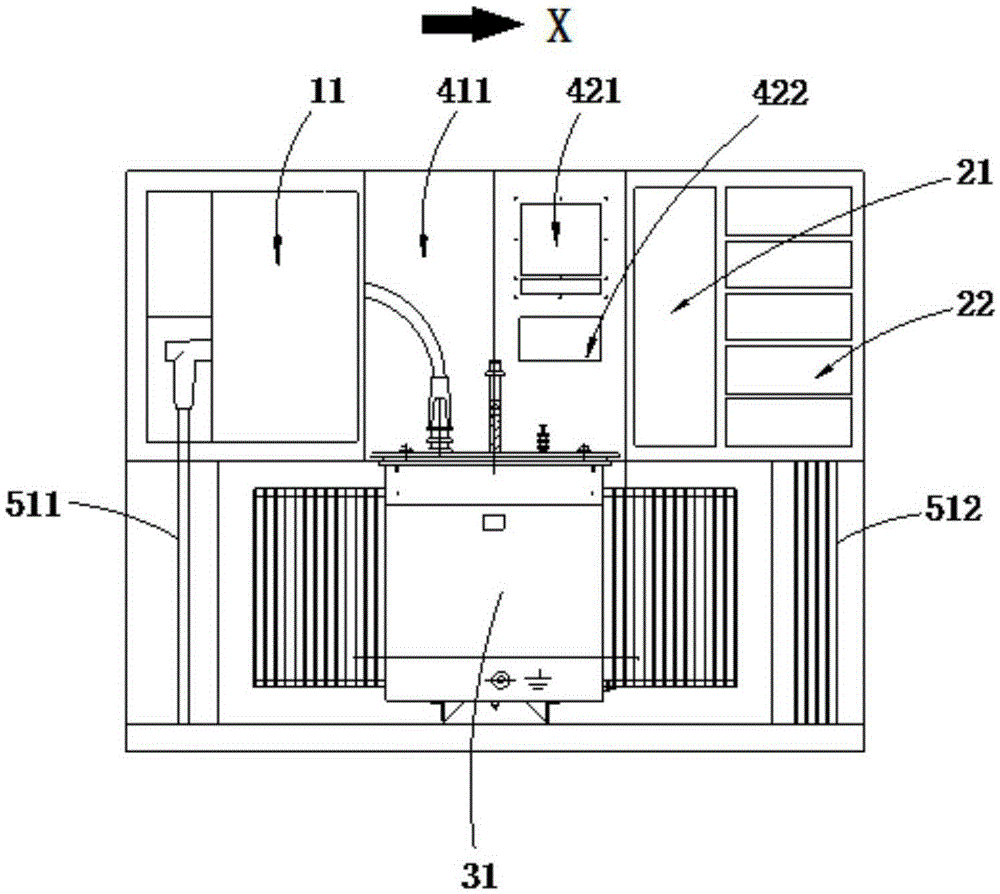

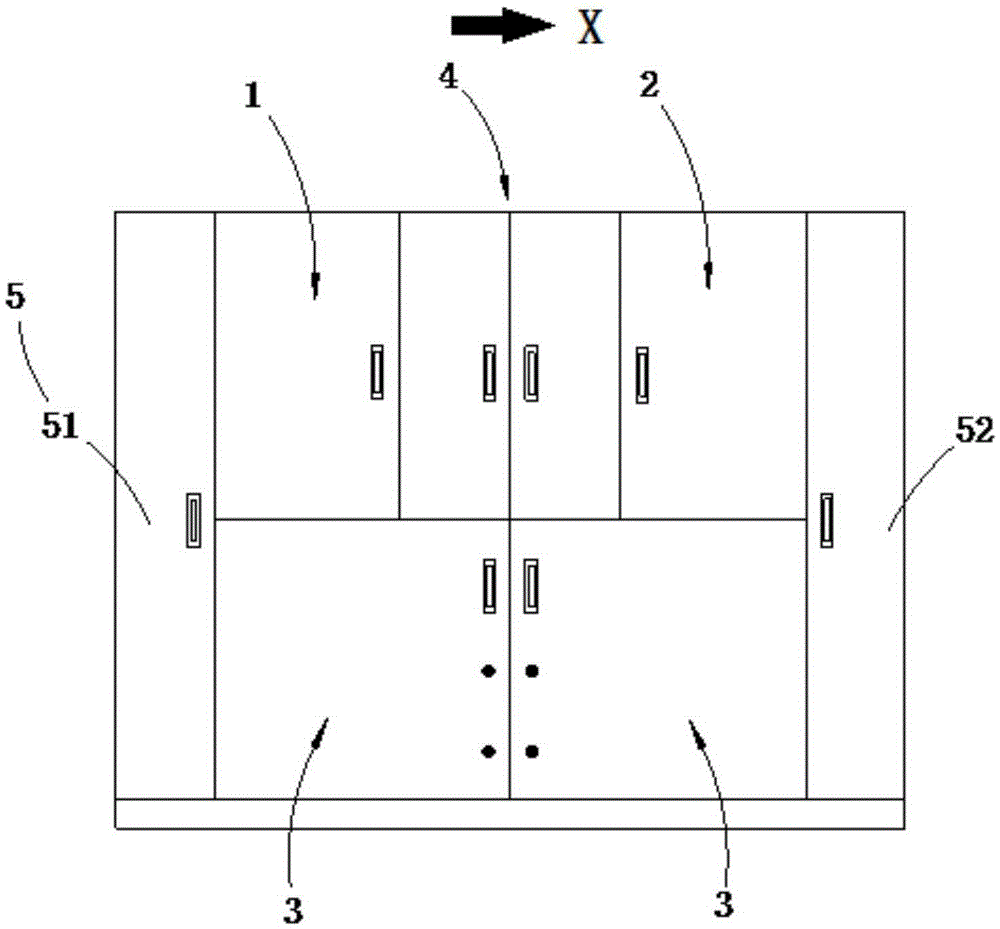

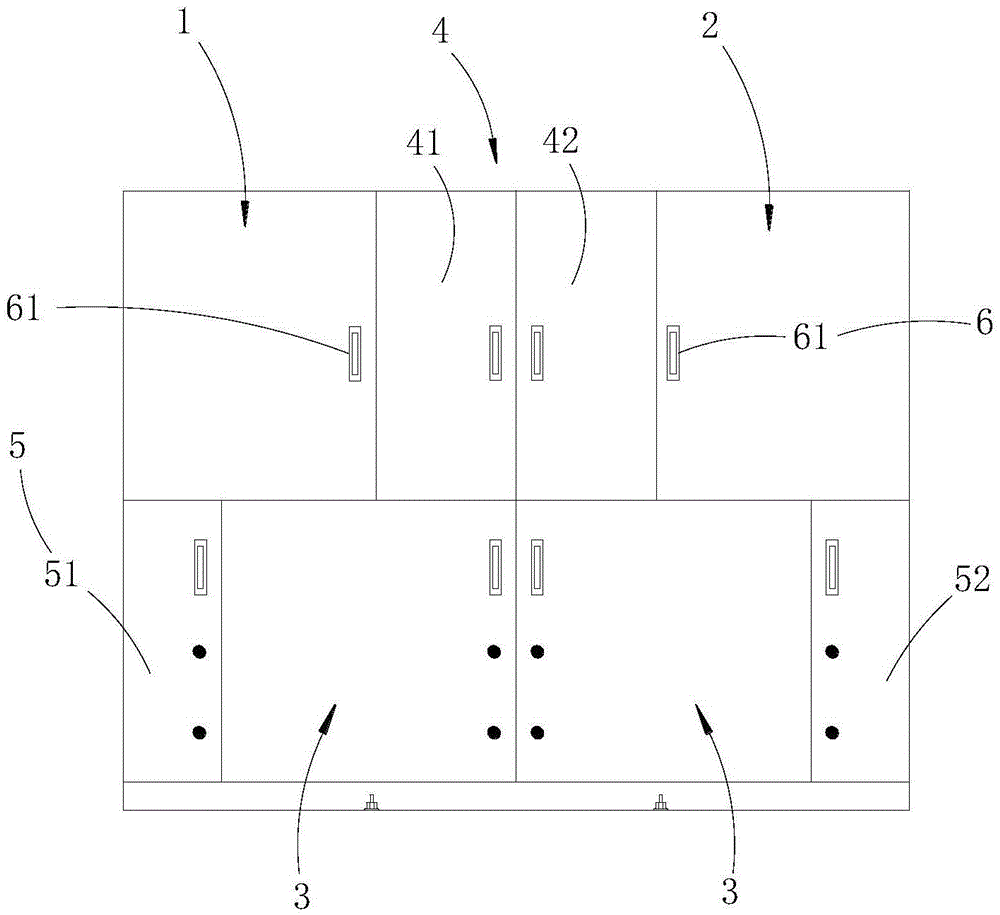

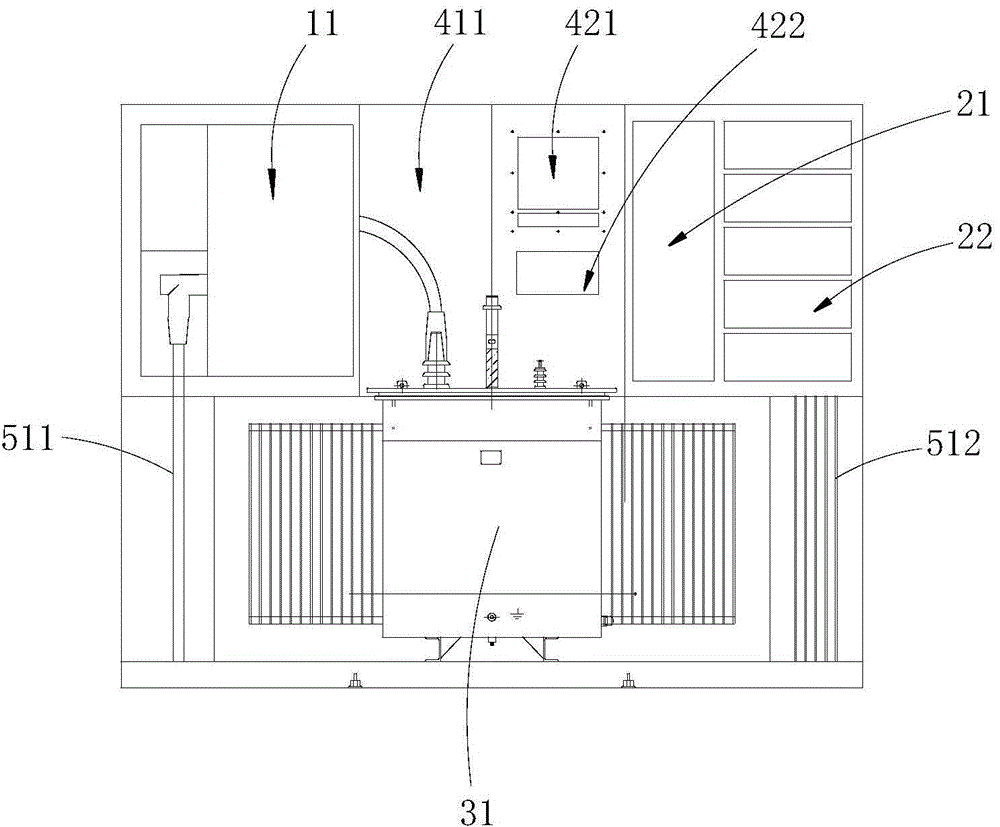

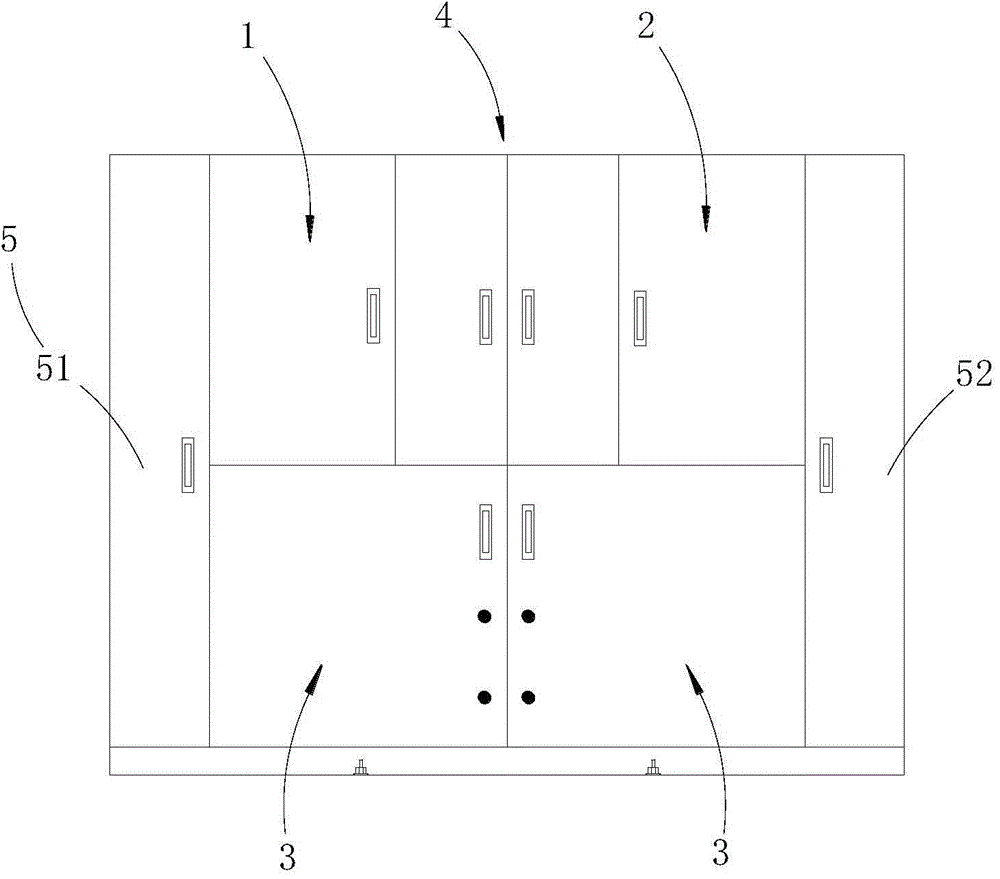

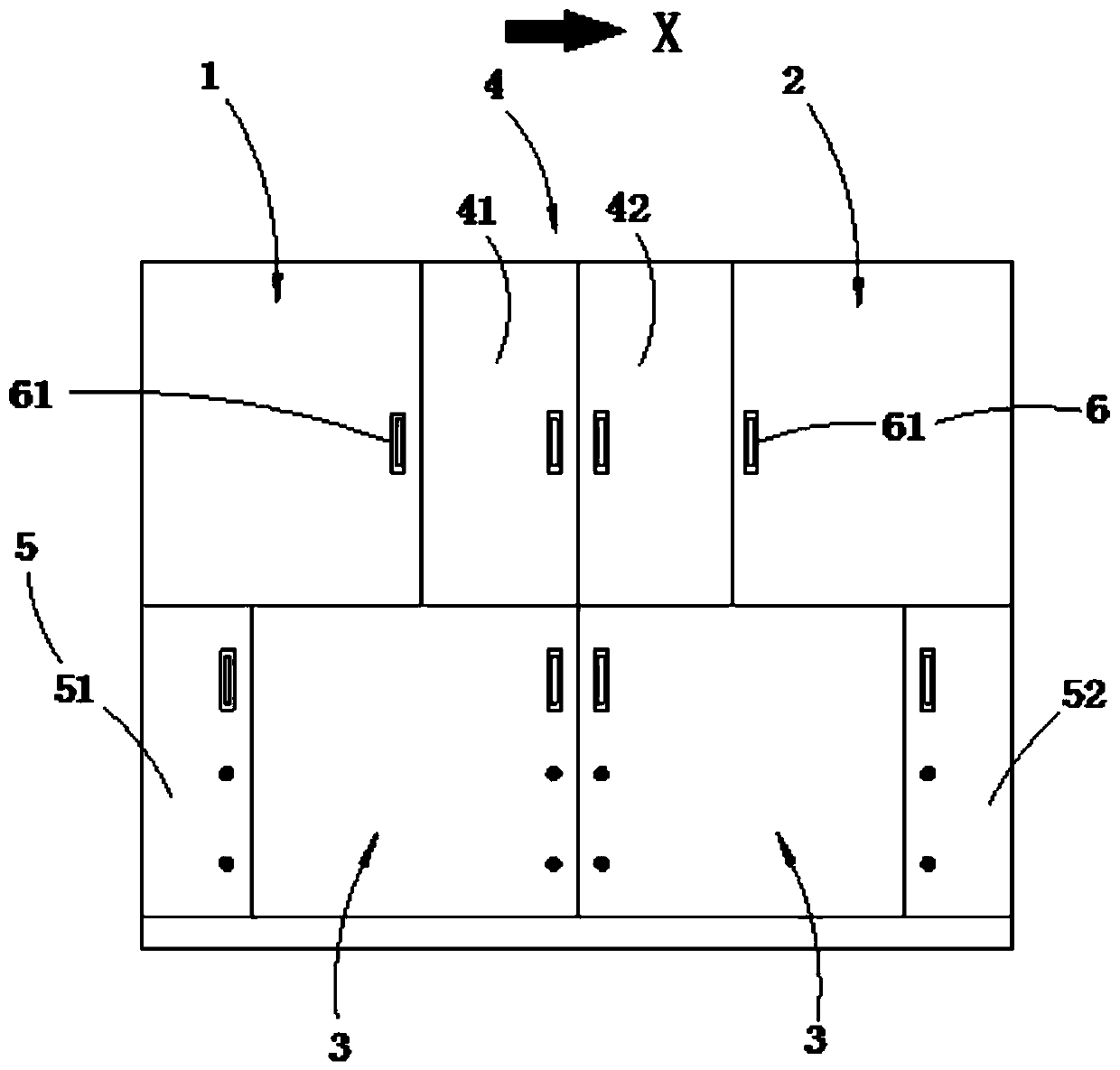

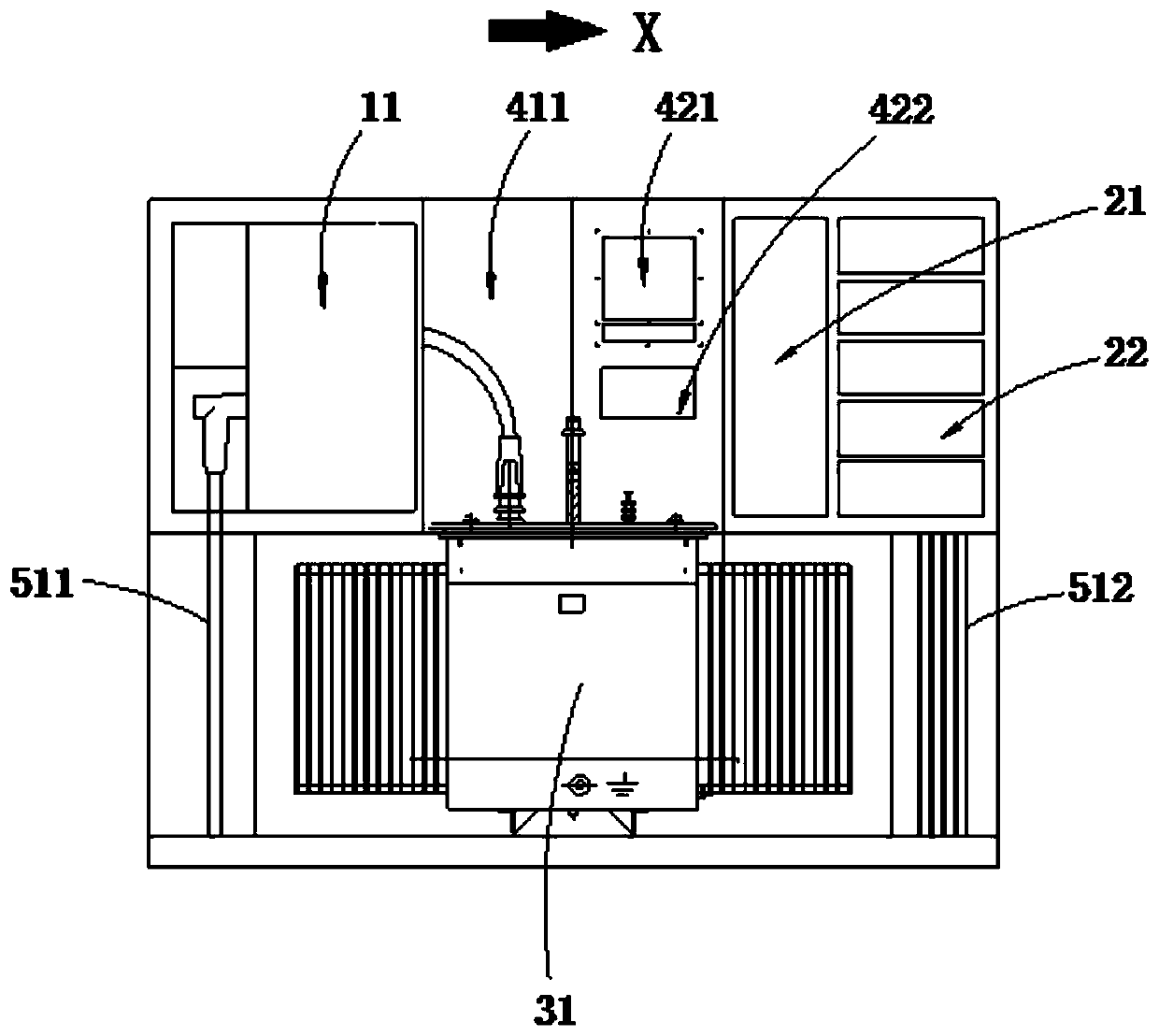

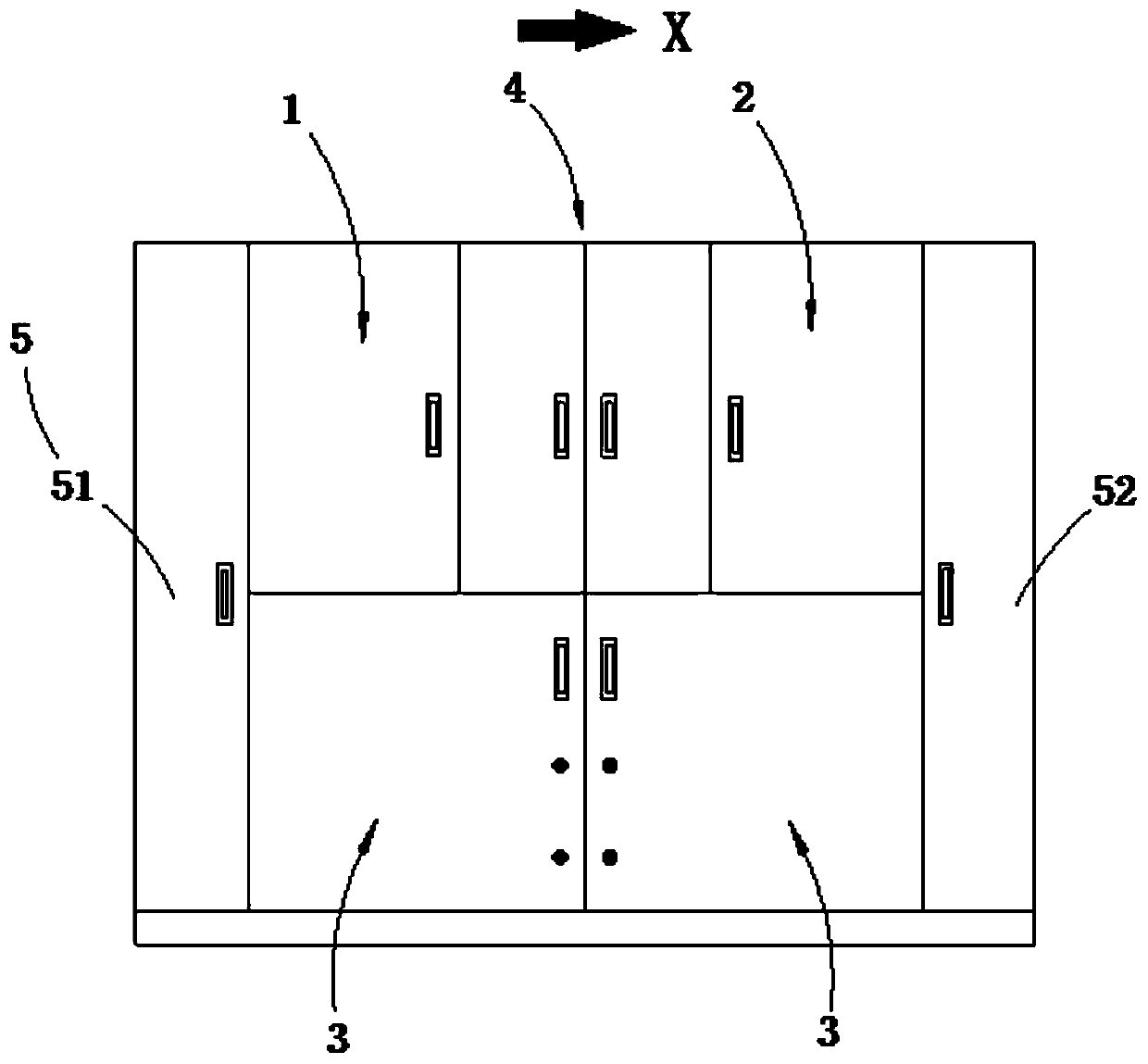

Novel box type transformer station

ActiveCN105762693AReduce difficultySpeed up heat dissipationTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationTransformerLow voltage

The invention discloses a novel box type transformer station. The novel box type transformer station at least comprises a high-voltage switch chamber, a low-voltage switch chamber and a transformer chamber, wherein the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are in echelonment distribution, and equipment lines in the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. Different from the prior art, the novel box-type transformer station enables the volume of the box type transformer station to be reduced by 1 to 3 times compared to a conventional transformer station through innovative adoption of an upper-lower multilayer distribution structure, reduces the area of occupied land, facilitates transportation and decreases the transport cost; and a downward pedestal of the conventional box type transformer station does not have to be manufactured, such that the difficulty of a construction project is reduced, the cost is decreased, and unfavorable influences brought by moisture in the half-embedded pedestal to each device in the box type transformer station can be better avoided.

Owner:袁茂银

Low-friction cleaning fracturing fluid for coal-bed gas

InactiveCN105670595AImprove the transformation effectReduce frictionDrilling compositionFracturing fluidPotassium

The invention provides a low-friction clean fracturing fluid for coalbed methane, comprising the following components: by mass percentage, 0.1-0.5% octadecyl glyceryl dimethyl ammonium chloride, 0.1-0.2 % sodium dibutylnaphthalene sulfonate, 0.2-0.3% potassium chloride and 90.0-96.0% water. The fracturing fluid has a simple preparation method, low viscosity, low friction, no gel breaking, and can be reused, which reduces construction operation costs, low friction, and reduces construction pressure. It is a clean and environmentally friendly fracturing fluid that can be used Achieve large displacement (10m 3 / min) above volume fracturing construction to improve the effect of coal seam stimulation.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Project template engineering management system based on building information model

InactiveCN107784409AReduce construction work costsImprove project management levelResourcesComputer scienceInformation model

The invention provides a project template engineering management system based on a building information model. The system comprises a network server which is used for storing and sending data information, a central control computer which is connected with the network server, and branch computers which are connected with the network server. The use method of the management system comprises the steps that a basic project document is collected, and the central control computer carries out basic model creation by relying on BIM software; the basic building information of a template project is collected, and the central control computer creates a template project information model by relying on BIM software; model safety stress calculation is carried out to generate a template project construction management file, and the file is uploaded to the network server; and each branch computer accesses the network server to view the template project construction management file, so that related personnel can inspect the file and guide on-site construction. The management system can visually and accurately understand the layout of the template before on-site template project construction, whichreduces the construction cost and improves the project management level.

Owner:SHANGHAI BAOYE GRP CORP

Construction method for pore forming in artificial rockfill layer

ActiveCN109385992AGuaranteed to proceed normallyReduce construction work costsExcavationsBulkheads/pilesSteel platesExcavator

The invention discloses a construction method for pore forming in an artificial rockfill layer. The construction method includes the steps that superficial-layer dimension stones are screened and removed through an excavator at a position of a pile position, cohesive soil is backfilled and compacted, and then steel plates are laid; a protection cylinder is embedded, and the center of the protection cylinder is coincided with the center of the pile position; according to the diameter of the dimension stones and the layer thickness of the rockfill layer, a rotary drilling rig and a punching drilling rig are used and are positioned on the laid steel plates for conducting pore-forming construction, and meanwhile slurry with the certain relative density is prepared for grouting pore forming; after pore forming, the pore depth is measured and inspected through a measuring line, and after verification, pores are cleaned. By means of the construction method for pore forming in the artificial rockfill layer, the aim that pore forming construction of the cast-in-place pile is conducted is achieved, normal operating of construction operation is guaranteed, the cost of the construction operation is reduced, and the efficiency of the construction operation is improved.

Owner:SHANGHAI BAOYE GRP CORP

Anchoring ball type casing truing unit and truing method thereof

ActiveCN101942979BAvoid damageSimple structureBorehole/well accessoriesHydraulic cylinderWork performance

The invention relates to an anchoring ball type casing truing unit and a truing method thereof, and overcomes the defects that during the repairing casing operation, the existing roll type truing unit is easy to damage a drilling rig, and the unstable state of a tubular column enables the time for repairing the operation and the operation cost to be increased. In the invention, an upper joint (1), an aerial drainage assembly (32), an anchoring assembly (33), a hydraulic cylinder assembly (34) and a lower joint (17) are arranged on an anchoring device (30) and fixedly connected in sequence; a lower joint (17) is internally provided with a check valve (35); the lower joint (17) of the anchoring device (30) is fixedly connected with the upper end of the ball truing unit (31), or the lower joint (17), a drill collar and the ball truing device (31) are fixedly connected from up to down. The invention has the following benefit effects of simple structure and reasonable design, is convenientto operate, is safe and reliable, avoids the damage to the drill, reduces the construction period, has high working performance and reduces the field operation cost.

Owner:DAGANG OIL FIELD GRP +2

Slurry shield split launching construction method for water-rich sandy gravel stratum

ActiveCN112302670AImprove efficiencyFace stabilityUnderground chambersTunnel liningSoil scienceSlurry

The invention discloses a slurry shield split launching construction method for a water-rich sandy gravel stratum. The method comprises the following steps that A, a tunnel portal is sealed to build abin, grease is smeared on a tunnel portal brush, the tunnel portal is broken, a shield cutter head is jacked into a tunnel face, the grease is injected into a short sleeve and a muddy water bin, mudis injected into the muddy water bin, and the pressure is gradually increased to calculated incision pressure; B, shield tunneling and trolley transfer construction are conducted, a trolley is arranged before shield launching, the trolley is straightened, the tunnel portal is sealed, and the trolley is lowered into a well; and C, secondary switching of the trolley is conducted, outage and pressuremaintaining are conducted, slurry with the viscosity of 35-50s and the density of 1.1-1.3g / cm<3> is used, and permeation is conducted on the tunnel face in a large circulation mode; and slurry with the viscosity of 90-120s is injected into the muddy water bin from a central rotation standby uppermost flushing pipeline to replace the slurry in the muddy water bin, and the pressure of the muddy water bin is maintained. The method has the beneficial effects that the process is reasonable, the stability of the tunnel face of the water-rich sandy gravel stratum is guaranteed under the condition ofoutage, the high efficiency of slurry shield split launching is realized, and the cost is reduced.

Owner:CCCC TUNNEL ENG +1

Box-type substation

InactiveCN104638555AReduce volumeReduce difficultyBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationTransformerLow voltage

The invention discloses a box-type substation. The box-type substation at least comprises a high-voltage switchgear chamber, a low-voltage switchgear chamber and a transformer chamber, which are distributed in the shape of steps, wherein equipment circuits in the high-voltage switchgear chamber, the low-voltage switchgear chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. The box-type substation is different from the prior art on the aspect that a structure that a plurality of layers are distributed up and down is creatively adopted, so that the size of the box-type substation is 1 to 3 times smaller than that of the traditional substation, the occupation area is reduced, the box-type substation is convenient to transport, and the transportation cost is reduced; a downward foundation of the traditional box-type substation is not required to be manufactured, the difficulty for constructing a project is reduced, the cost is reduced, and adverse influence to each piece of equipment in the box-type substation by humidity in the semi-buried foundation can be better avoided.

Owner:袁茂银

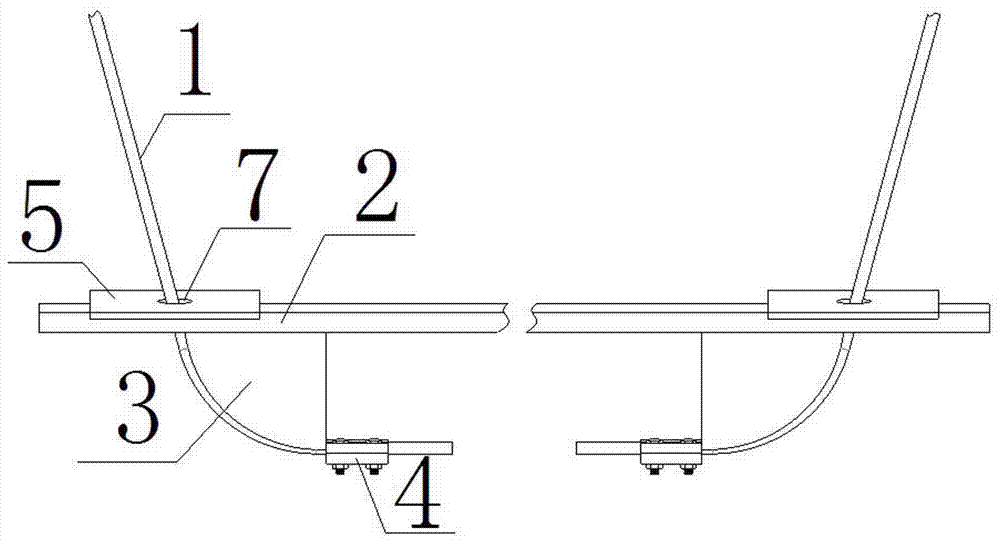

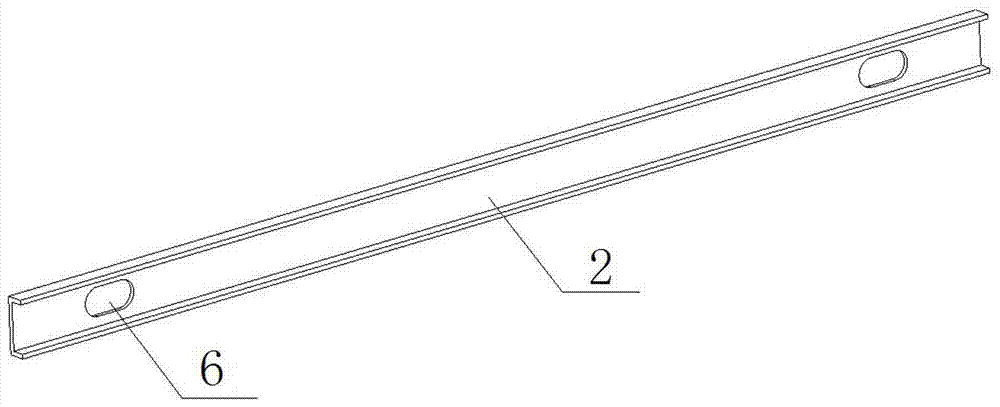

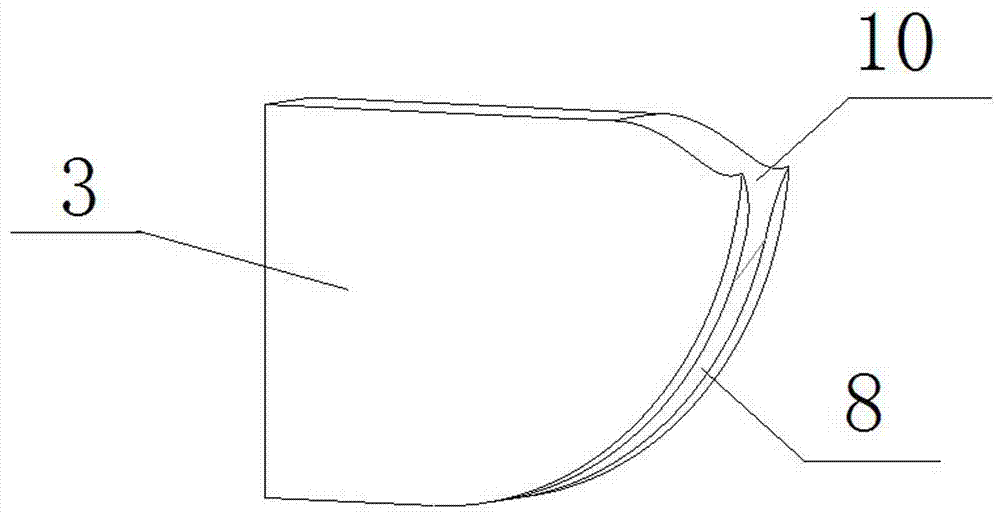

Bent anchor cable yielding top beam and construction method

PendingCN107355245AStrong carrying capacityImprove bearing capacityMine roof capsEngineeringWork ability

The invention relates to a bending anchor cable pressure top beam, which includes a cable body, a beam, an anchor cable guide plate, a friction fastening device and a tray. The fastening device is connected to the lower end surface of the beam, and the upper end surface of the beam and the cable body are connected to each other through the tray and the cable body. The friction fastening device includes a load-bearing base plate, a pressure plate, a guide groove and a pressure regulating bolt; the construction method includes anchoring the cable body, installing Channel steel and pallets and fastening in stages. On the one hand, the present invention can effectively improve the load-bearing and positioning operation capacity of the rock formation at the top of the roadway, has strong bearing capacity, constant bearing capacity and stable output of bearing capacity; , automatically adjust the positioning structure of the equipment, so as to effectively improve the stability and reliability of the positioning equipment while improving the bearing positioning capacity of the roadway.

Owner:HENAN POLYTECHNIC UNIV

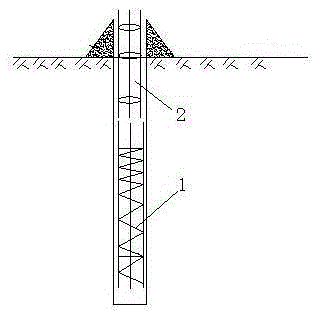

Water gushing sand breaking disturbance deep loose stratum ground grouting hole-forming method

The invention provides a water gushing sand breaking disturbance deep loose stratum ground grouting hole-forming method. The method comprises the following steps that S1, the stratum is divided into three sections, wherein the three sections are respectively a conventional section, a stratum alternate section and a water gushing sand breaking section; S2, levelness correction and cement table pouring are carried out on a drilling tower, a drilling machine is installed, and levelness and verticality of the drilling machine are calibrated; S3, a drilling tool is improved, a pagoda type drillingtool consisting of multiple stages of sleeves is used for combined drilling, and the ways of sleeve ring sleeving and multi-stage hole shrinkage are used for drilling and hole protection; S4, the three sections of stratum in step S1 are drilled layer by layer to form a drilled hole; and S5, the fracture condition and the cementing characteristic of the drilled hole formed in the step S4 are detected, and the drilled hole is cleaned. Normal treatment and repair of a vertical shaft of a coal mine are ensured, the construction operation efficiency is improved, and the construction operation costis reduced.

Owner:ANHUI UNIV OF SCI & TECH

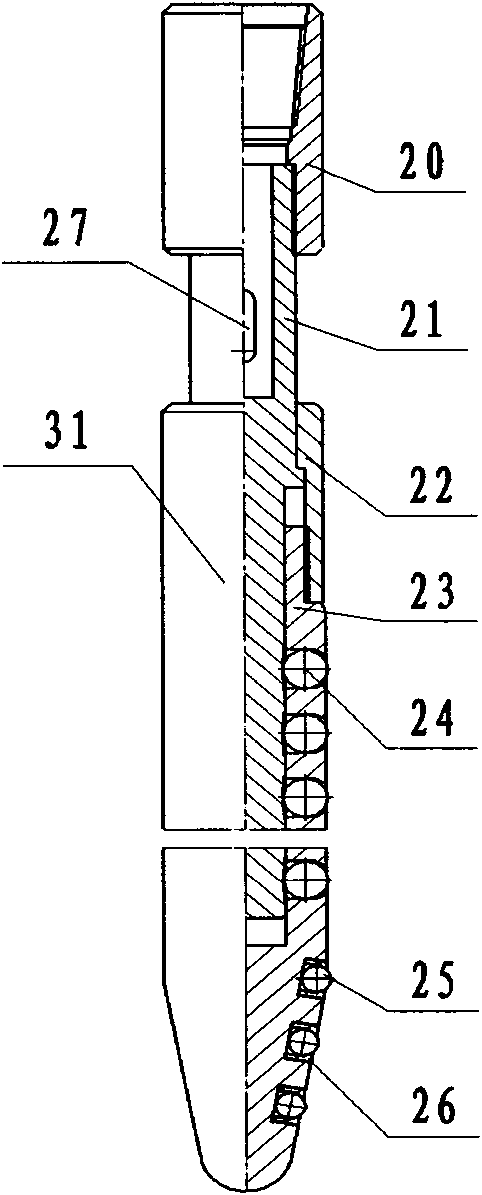

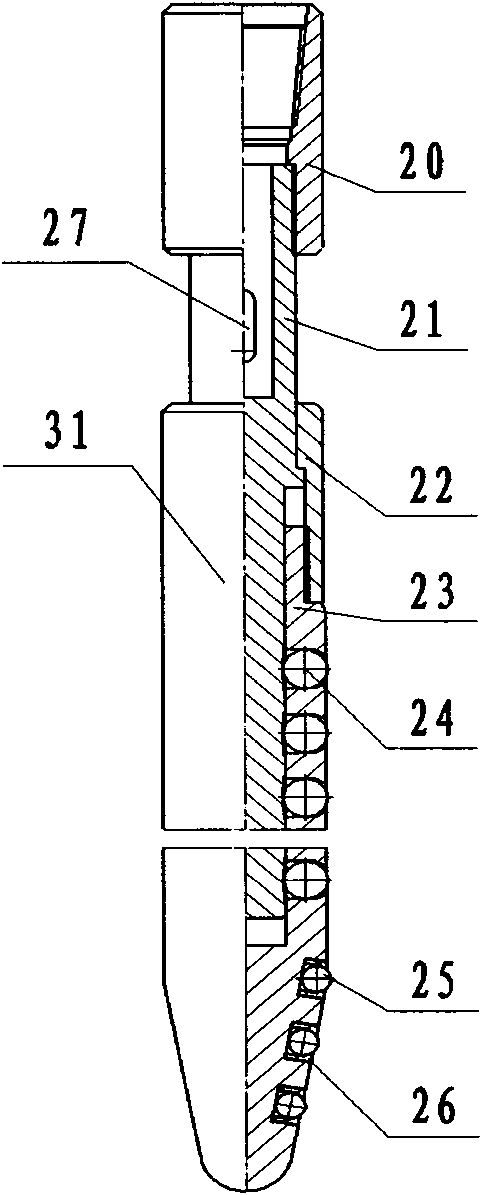

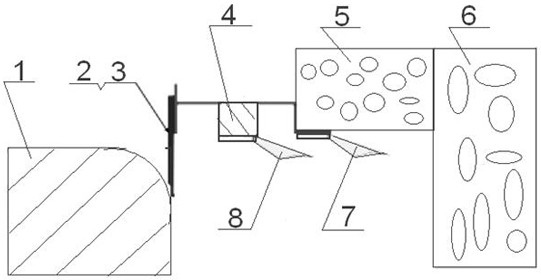

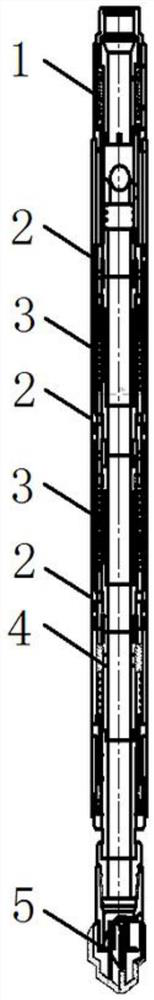

Drilling tool for down-hole string

ActiveCN107893640AEnsure construction safetyReduce construction work costsBorehole/well accessoriesCoiled tubingEngineering

The invention discloses a drilling tool for a down-hole string. A piston of the drilling tool for the down-hole string is located at the upper portion of a main body in a sealed mode in the axial direction by a shear pin; the upper portion of a cone and a concave platform inside the main body are sealed slidably in the axial direction; a drilling block is fixed on the lower portion of the main body by a pin; the main body, the piston, and the cone form a sealed cavity; the main body is provided with a pressure guiding hole and a drilling hole block groove, a bearing working face of the lower portion of the cone is of a wedge-shaped body or a conical structure, and the drilling block rotates in the axial direction when the pin moves in the radial direction of the main body; and the pin is mounted in the axial direction, and the drilling block can rotate in the radical direction. After the drilling tool for the down-hole string is put into the string or the drilling tool for the down-hole string is downwards placed into the down-hole string by a certain depth adopting cable and steel wire operation and coiled tubing operation, drilling or cutting on the down-hole string can be achieved through pressurization in the down-hole string; compared with the cable operation and the coiled tubing operation, construction is simple and safe, operating cost of the construction is reduced, and the drilling tool for the down-hole string is a breakthrough in drilling or cutting of the down-hole string.

Owner:孙伟峰 +1

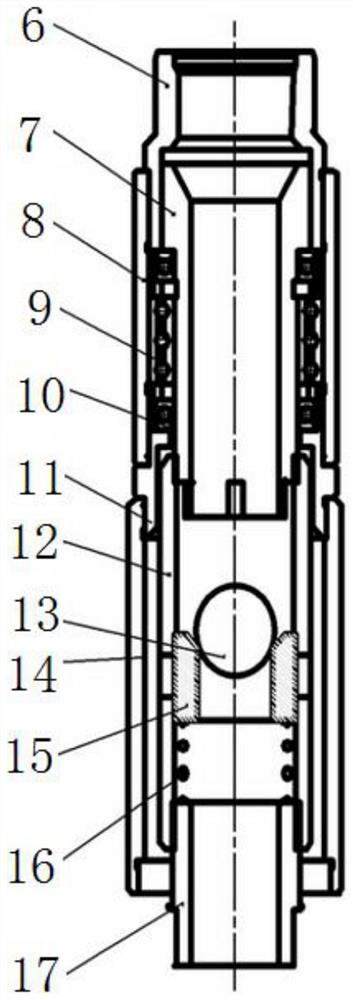

Sand washing drilling and milling integrated device for workover operations in oil field

PendingCN111706274AIt has the function of rotary drilling and milling of turbo drillImprove construction progressDrill bitsFlushingThermodynamicsOil field

The invention relates to an oil well matching device, in particular to a sand washing drilling and milling integrated device for workover operations in an oil field. According to the technical schemeof the invention, the sand washing drilling and milling integrated device for the workover operations in the oil field comprises an upper support body assembly, a turbine assembly(turbine assemblies),a lower support body assembly, multiple connecting cylinders and a sand washing drill bit; the turbine assembly is arranged by one or more; the upper support body assembly, the turbine assembly(turbine assemblies) and the lower support body assembly are sequentially connected into a whole by the multiple connecting cylinders; the upper support body assembly is connected with the lower end of a drill pipe or oil pipe; and the sand washing drill bit is installed at the lower end of the lower support body assembly. The sand washing drilling and milling integrated device for the workover operations in the oil field provided by the invention not only has rotary drilling and milling functions of a turbodrill, but also can realize two functions of direct circulation sand washing and reverse circulation sand washing; and one-time pipe string construction operation can complete sand washing drilling and milling operations of an oil well, thereby speeding up the construction progress, and reducing the construction operation cost.

Owner:鞍山宏景石油机械有限公司 +1

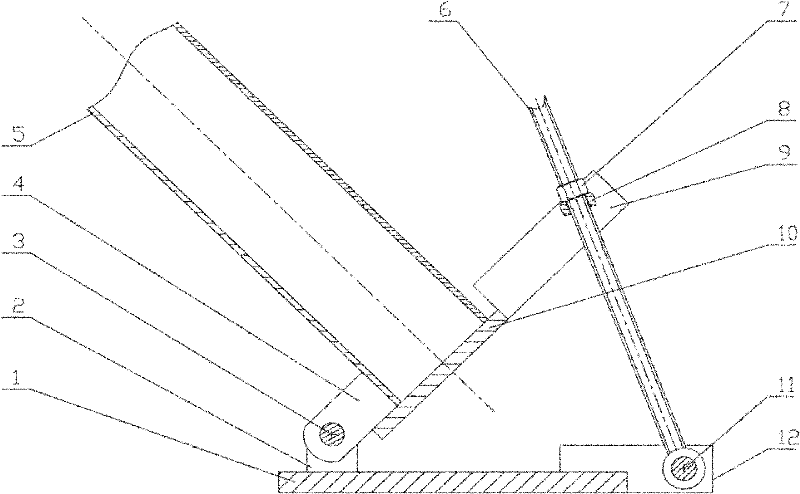

Upright rod capable of being erected and lowered depending on manpower

InactiveCN102052552BSimple structureLow machining accuracy requirementsLifting devicesStands/trestlesEngineering

Owner:SICHUAN UNIV

Pipeline spraying device for air conditioner production

PendingCN113399153AEasy to spray and transportReduce collisionSpraying apparatusSpray nozzleElectric machinery

The invention discloses a pipeline spraying device for air conditioner production. The pipeline spraying device for air conditioner production comprises a supporting frame, a conveying assembly is arranged on the supporting frame and comprises a plurality of conveying rollers connected with the supporting frame, the conveying rollers are in transmission connection with two conveying belts, the supporting frame is connected with a clamping control conveying mechanism, and the clamping control conveying mechanism comprises a first motor fixedly connected with the supporting frame; the first motor is connected with a first cam through a first rotary shaft, a connecting frame connected through a first rotating shaft is arranged above the first cam, the upper right end of the connecting frame is connected with an upper limiting plate, the lower end of the upper limiting plate is connected with an upper dividing strip, the upper limiting plate is located above the conveying assembly, the lower right end of the connecting frame is connected with a lower limiting plate, and the upper end of the lower limiting plate is connected with a lower dividing strip; and the lower limiting plate is located below the conveying assembly, a spraying nozzle is arranged above the conveying assembly, and the spraying nozzle is located between the lower limiting plate and the upper limiting plate. By means of the pipeline spraying device, spraying and transporting of pipelines can be achieved conveniently, and collision between the sprayed pipelines is reduced.

Owner:安徽美博智能科技有限公司

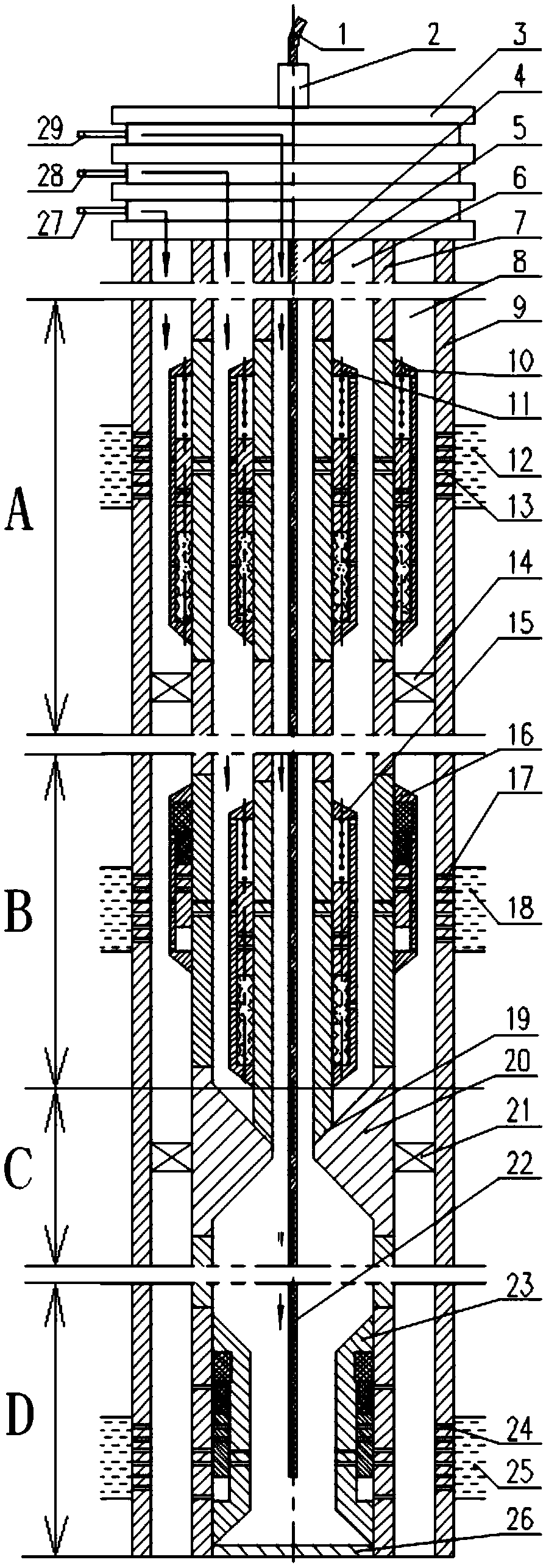

A layered ignition gas injection string

ActiveCN106640011BReduce construction work costsImprove work efficiencyFluid removalWell/borehole valve arrangementsTemperature controlOil well

The invention provides a layered ignition and gas injection pipe column which comprises an inner pipe column (5) and an outer pipe column (7), wherein the outer pipe column (7) comprises a first gas injection valve (10), a fourth gas injection valve (16) and a fifth gas injection valve (23) which are sequentially arranged from top to bottom, the inner pipe column (5) comprises a second gas injection valve (11) and a third gas injection valve (15) which are sequentially arranged from top to bottom, the first gas injection valve (10), the second gas injection valve (11) and the third gas injection valve (15) are all temperature control gas injection valves capable of being switched by multiple times, and the fourth gas injection valve (16) and the fifth gas injection valve (23) are both temperature control gas injection valves capable of being switched by only one time, so that the temperature control gas injection valves capable of being switched by only one time can be opened when the temperature in the valves is greater than or equal to a preset value. According to the layered ignition and gas injection pipe column provided by the invention, multi-layer ignition and gas injection can be realized, the requirement of ignition of an oil well is meet, and the operation efficiency of igniting the well is improved.

Owner:PETROCHINA CO LTD

New box type substation

ActiveCN105762693BReduce difficultySpeed up heat dissipationTransformers/inductances coolingSubstation/switching arrangement cooling/ventilationTransformerControl theory

The invention discloses a novel box type transformer station. The novel box type transformer station at least comprises a high-voltage switch chamber, a low-voltage switch chamber and a transformer chamber, wherein the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are in echelonment distribution, and equipment lines in the high-voltage switch chamber, the low-voltage switch chamber and the transformer chamber are M-shaped, U-shaped or V-shaped. Different from the prior art, the novel box-type transformer station enables the volume of the box type transformer station to be reduced by 1 to 3 times compared to a conventional transformer station through innovative adoption of an upper-lower multilayer distribution structure, reduces the area of occupied land, facilitates transportation and decreases the transport cost; and a downward pedestal of the conventional box type transformer station does not have to be manufactured, such that the difficulty of a construction project is reduced, the cost is decreased, and unfavorable influences brought by moisture in the half-embedded pedestal to each device in the box type transformer station can be better avoided.

Owner:袁茂银

Fracturing method for recyclable fracturing fluid used in fracturing construction of sandstone gas reservoirs

ActiveCN103603644BLow costImprove scalabilityFluid removalDrilling compositionFiltrationFracturing fluid

The invention discloses a fracturing method of recyclable fracturing liquid for sandstone gas reservoir fracturing construction. The fracturing method includes the steps that a filtrate reducer and the recyclable fracturing liquid are evenly mixed on the ground, and the mixture is filled into the stratum for crack forming; sand fracturing operation is performed; after sand adding in the fracturing operation is ended, open flow is controlled after the cracks are closed; flow-back liquid enters a liquid storage tank after sand removal and gas-liquid separation; viscosity detection is performed on the liquid in the liquid storage tank, if a design requirement is not met, a thickening agent is added continuously until the viscosity meets the requirement, and a filtrate reducer is replenished until the specified concentration requirement is met; secondary fracturing construction is performed; the steps are repeated until cyclic utilization of the liquid is achieved. According to the fracturing method, filtration of the fracturing liquid is lowered, pollution to the stratum is reduced, and due to the fact that the flow-back liquid is directly recycled into the liquid storage tank on the ground, ground surface pollution is avoided; the flow-back liquid is recycled, and therefore water consumption is lowered; after the flow-back liquid is processed on the ground and a small number of the thickening agent is added, the flow-back liquid can be reused, the construction cost is reduced, and infinite fracturing operation is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

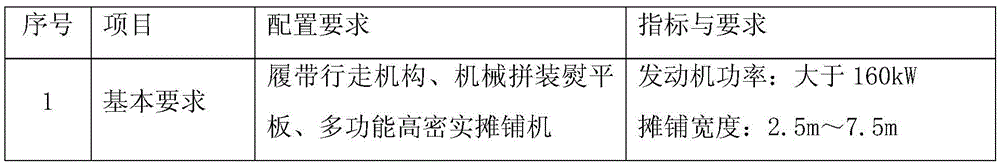

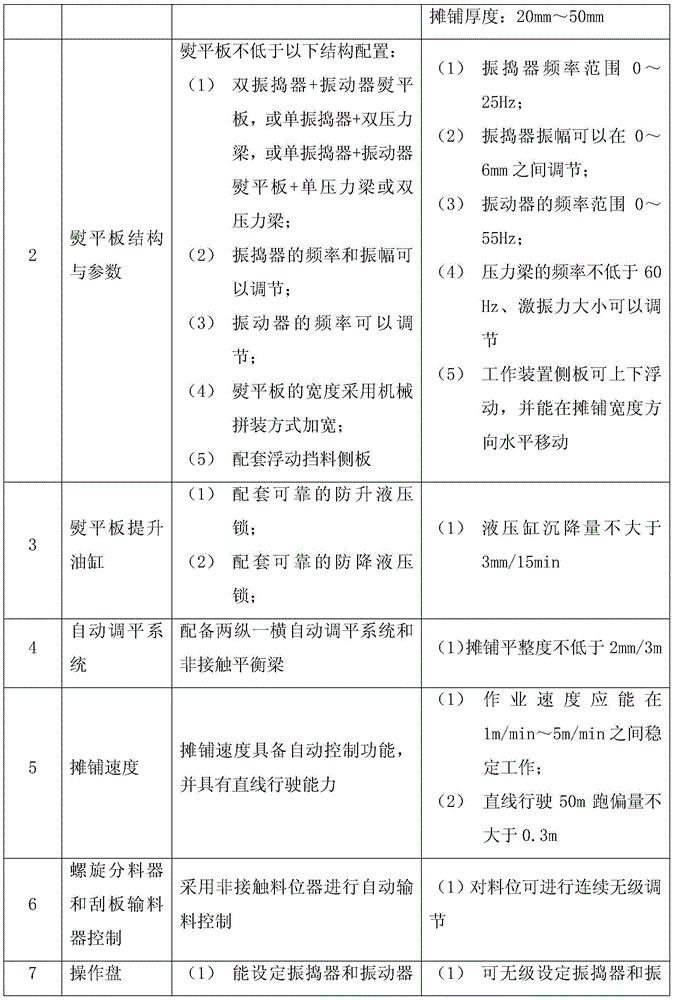

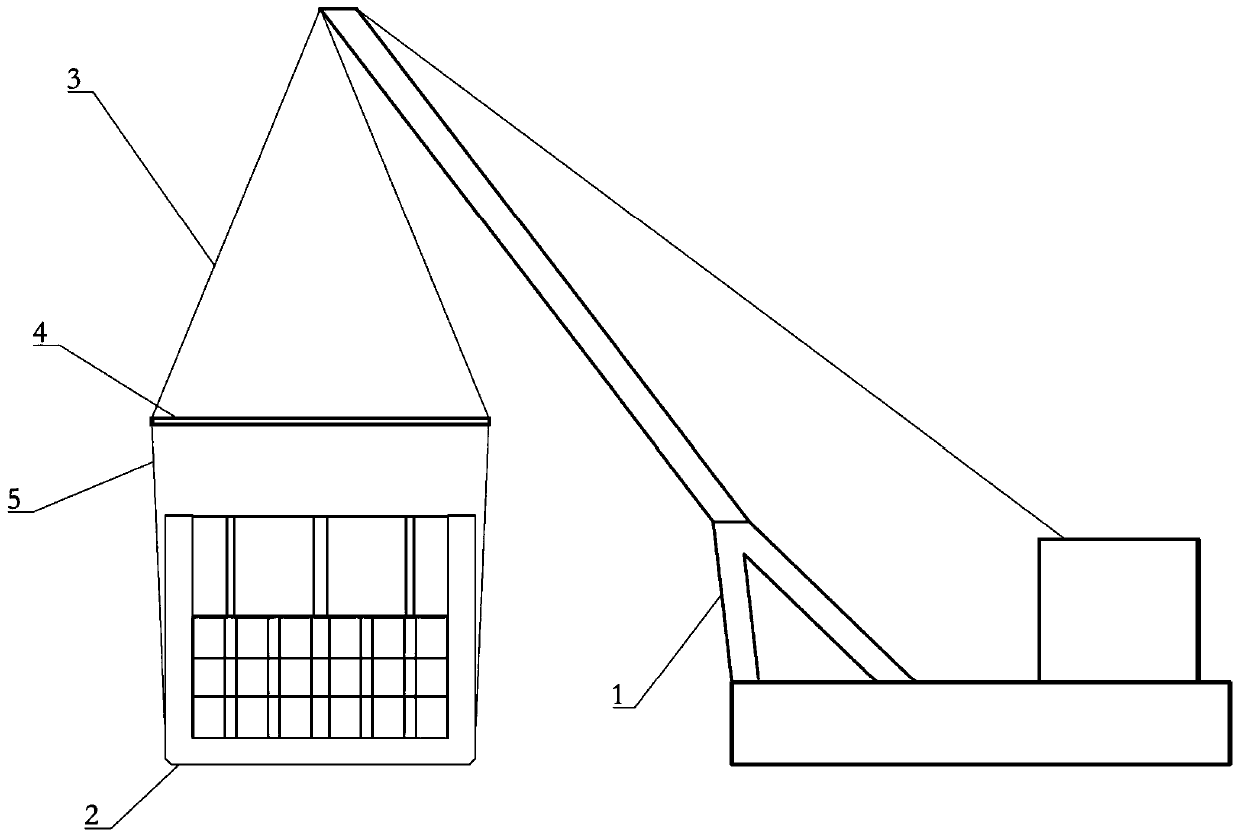

One-time paving forming method of polymer modified cement concrete

InactiveCN103643617BSimple construction processImprove construction efficiencyIn situ pavingsRoads maintainenceRough surfacePolymer modified

The invention discloses a polymer-modified cement concrete one-time paving forming method, which is characterized in that an asphalt paver with a high-density screed structure is used to make the thin-layer polymer modified cement concrete one-time paving and forming; The thickness of the polymer modified cement concrete thin layer is less than 40mm. The invention utilizes an asphalt paver to pave the polymer-modified cement concrete, and realizes one-time molding, without subsequent vibrating compaction by a vibrating bar or rolling compaction by a road roller, directly paving to form a smooth and rough surface.

Owner:CHANGAN UNIV

Method for checking leakage of abalone culture platform

ActiveCN110132495AAvoid wastingImprove work efficiencyFluid-tightness measurement using fluid/vacuumWater resourcesReliability engineering

The invention provides a method for checking leakage of an abalone culture platform. The method comprises the steps of integrally hoisting the whole abalone culture platform by using a floating crane;soaking a part to be checked in water; and after a specified time is up, enabling check personnel to enter cabins through channels in the platform to perform cabin leakage check. According to the method, the problems of low efficiency and water resource waste in the prior art can be effectively solved.

Owner:SHANGHAI ZHENHUA PORT MACHINARY HEAVY IND CO LTD

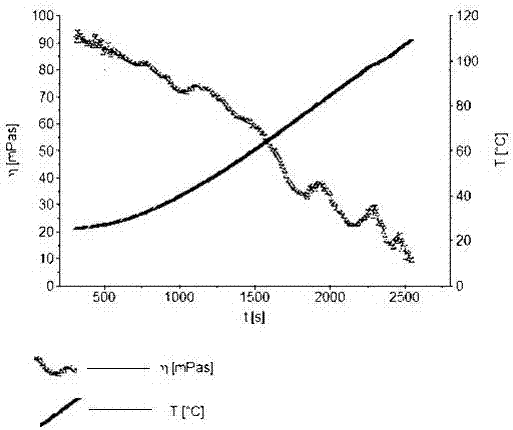

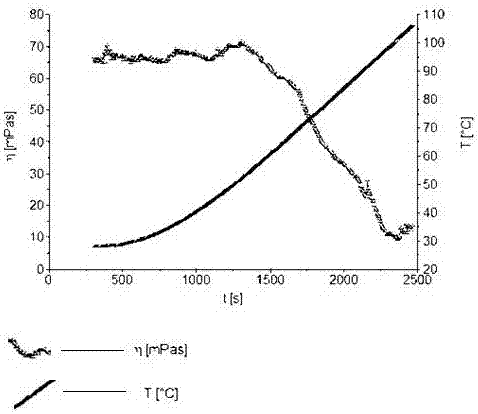

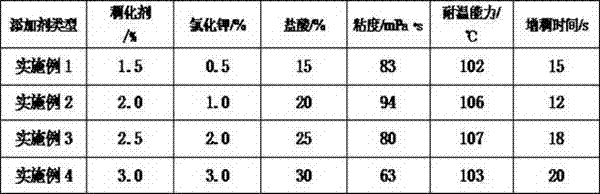

A kind of acidification method of recoverable instant thickening acid

The invention relates to an acidification method of recoverable quick-dissolving viscous acid. The method comprises the following steps of: uniformly mixing thickening agents, potassium chlorides and a hydrochloric acid solution on the ground; then pumping and injecting the mixture into the formation for acidification; closing a well for 30 minutes for controlling blow off after the acidification completion; entering flow-back fluid subjected to gas-liquid separation into an acid tank and performing still standing for 2 hours for delamination; respectively collecting a residual acid solution and the thickening agents; performing detection; if the design requirement is not reached, adding a certain amount of hydrochloric acid and thickening agents until the concentration of the acid solution conforms to the requirement; then, adding a certain number of potassium chlorides to reach the design requirement; performing the acidification construction again; repeating the steps; and completing the liquid repeated utilization. The acidification method has the advantages that the acid liquid filtration loss is reduced; the pollution on the formation is reduced; the flow-back fluid is directly recovered to the acid tank, so that the earth surface pollution is reduced; the flow-back fluid is recovered, so that the consumption of the thickening agents, water and the hydrochloric acid is reduced; after the flow-back fluid is treated on the ground, the flow-back fluid can be reused after the supplementary addition of a small number of the thickening agents, the hydrochloric acid and the potassium chloride; the construction operation cost is reduced; and the multi-time repeated utilization can be realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

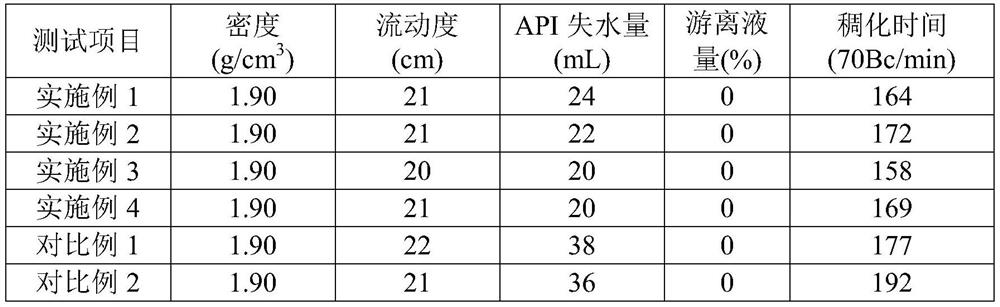

A kind of high temperature resistant Portland cement slurry and preparation method thereof

ActiveCN108298902BGood settlement stabilityRapid development of strengthDrilling compositionPortland cementPhysical chemistry

The invention provides a high temperature resistant portland cement slurry and a preparation method thereof. The high temperature Portland cement slurry comprises the following components by weight: 100 parts of oil well portland cement, 60-85 parts of high-temperature reinforcing materials, 68-80 parts of fresh water, 1-200 parts of density regulator, 0.1-1.5 parts Suspension stabilizer, 0.8-1.5 parts of dispersant, 3-4 parts of fluid loss reducer, 0-3 parts of retarder and 0.2-0.8 parts of defoamer. The high-temperature resistant portland cement slurry has good settlement stability at room temperature, and its strength develops rapidly at low temperature, and its compressive strength is as high as 40MPa or more at 350°C. It meets the field application requirements of heavy oil thermal recovery wells and reaches the level of Portland G grade cement for oil and gas well cementing.

Owner:CHINA NAT PETROLEUM CORP +2

Around synchronization hydraumatic jacking process of upper module of ultra-large marine oil platform

ActiveCN102561289BLower lifting heightReduce site resource allocation requirementsArtificial islandsUnderwater structuresButt jointEngineering

Owner:CHINA NAT OFFSHORE OIL CORP +2

Dual-camera monitoring welding quality device for ultra-thick-walled high-alloy steel pipelines

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

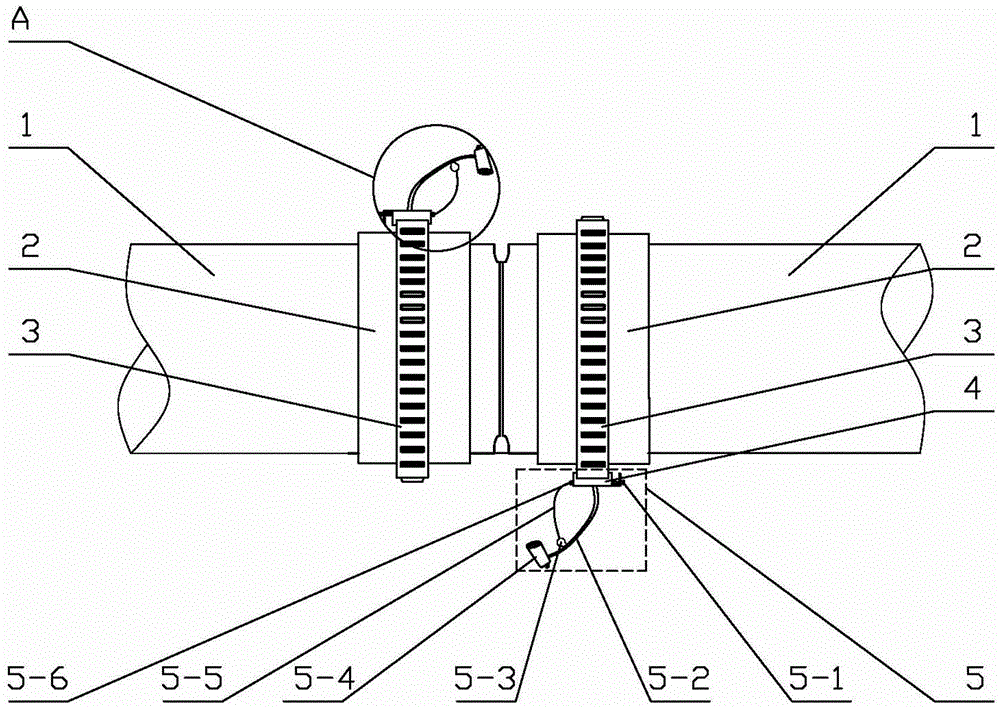

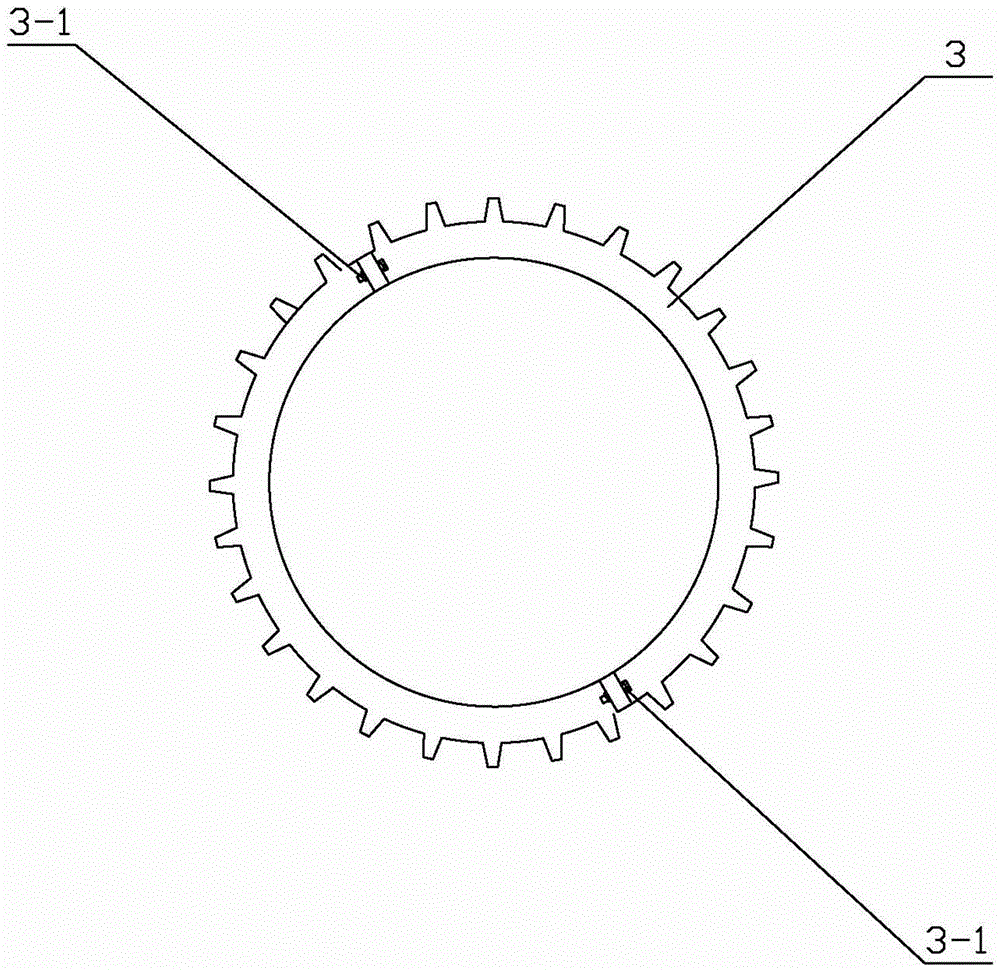

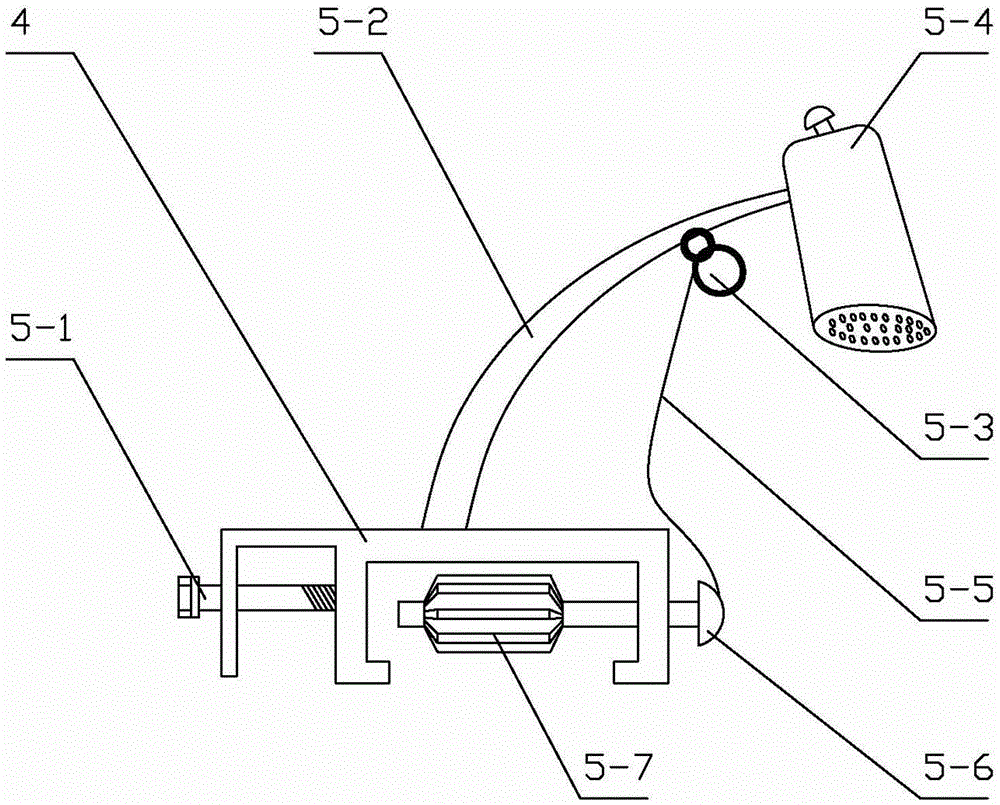

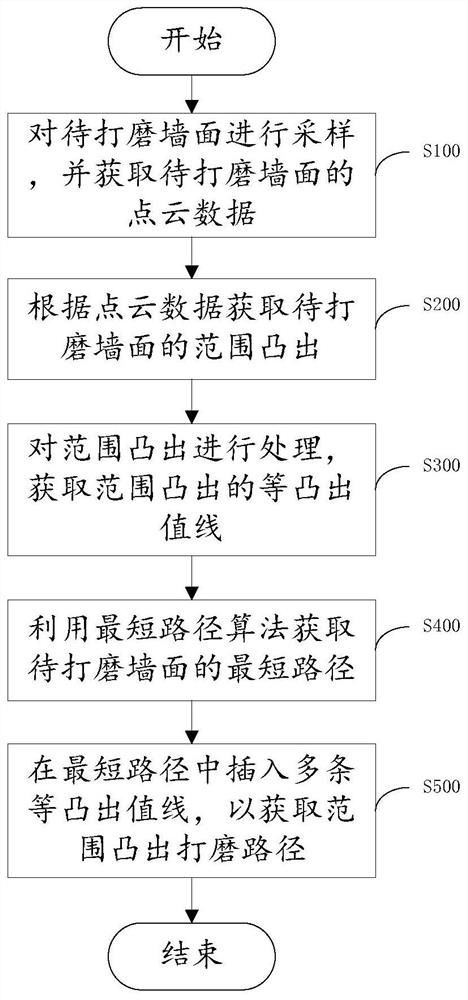

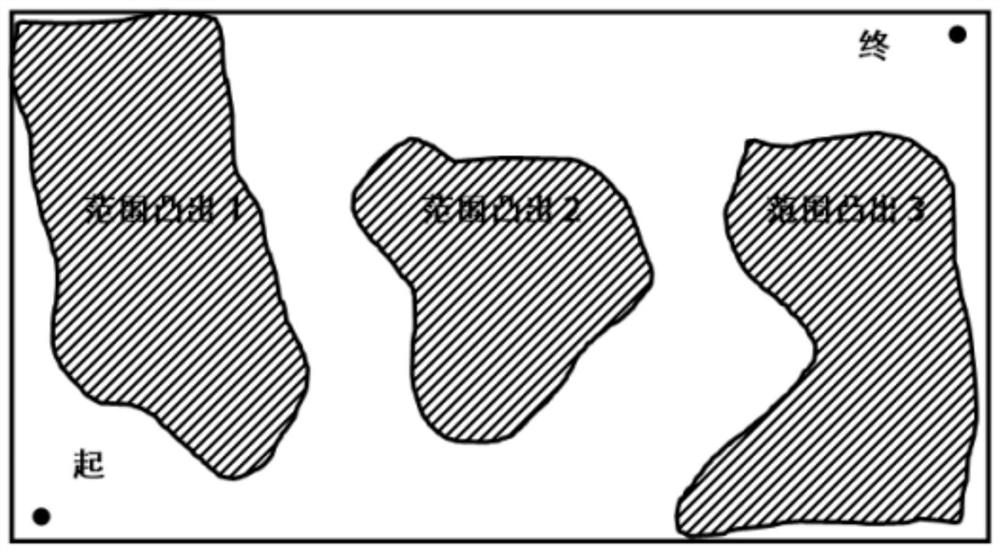

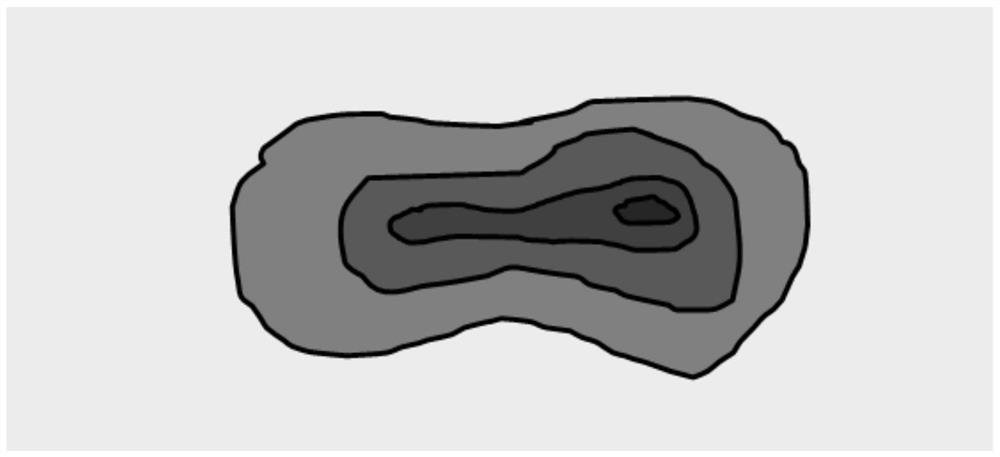

A wall grinding path planning method, device, electronic equipment and storage medium

ActiveCN111438578BImprove efficiencyImprove working accuracyAutomatic grinding controlPlane surface grinding machinesPathPingShort path algorithm

Embodiments of the present application provide a route planning method, device, electronic equipment, and storage medium, which relate to the technical field of operating equipment route planning. The method includes: sampling the wall surface to be polished, and obtaining point cloud data of the wall surface to be polished; obtaining the range projection of the wall surface to be polished according to the point cloud data; Processing, obtaining the isobulging value lines protruding in the range; using the shortest path algorithm to obtain the shortest path of the wall surface to be polished; inserting the plurality of isobulging value lines in the shortest path to obtain the range Convex sanding paths. The method effectively grinds the protruding area by optimizing the grinding path, and solves the problems of low grinding efficiency, poor grinding effect and easy damage to the grinding head in the existing method.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

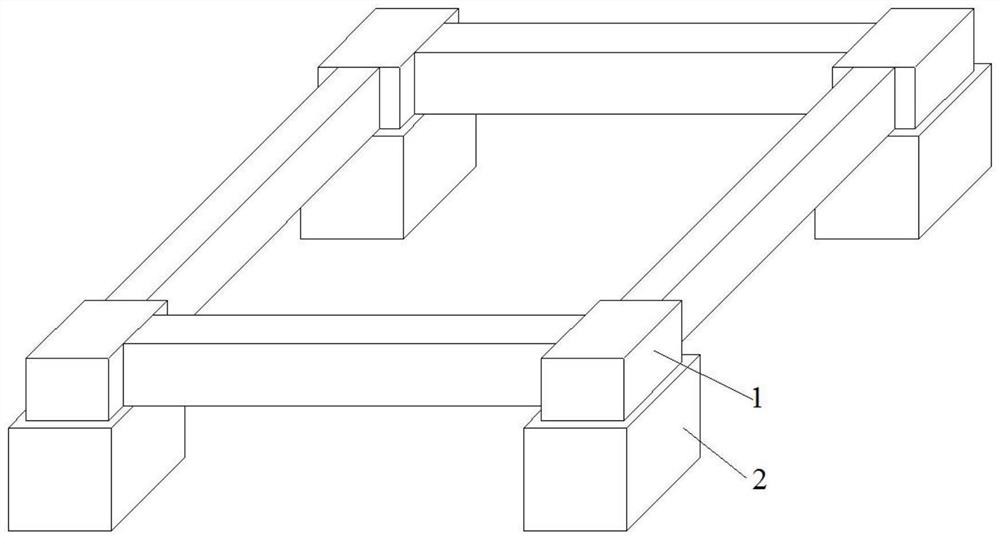

Reinforcement cage feeding method of long auger drilling press-grouting pile

The invention relates to the field of building construction, in particular to a reinforcement cage feeding method of a long auger drilling press-grouting pile. The reinforcement cage feeding method of the long auger drilling press-grouting pile is characterized by comprising the following steps that 1, a pushing device is manufactured according to hole diameters, and the pushing device comprises a plurality of vertical rods and a plurality of hoops which surround the vertical rods to form cage-shaped columns; 2, concrete is poured into a pile hole to reach a standard height; 3, a reinforcement cage is inserted into the pile hole; 4, the cage-shaped columns are lifted, and the bottoms of the cage-shaped columns align to and abut against the tail end of the reinforcement cage; 5, a vibrating tamper is started to convey the reinforcement cage to the designed standard height position of a pile bottom through the cage-shaped columns; and 6, the device and the vibrating tamper are together lifted out of the pile hole. According to the reinforcement cage feeding method, the adopted cage-shaped columns are easy to manufacture and convenient to use so as to effectively accelerate the feeding operation of the reinforcement cage, and the cage-shaped columns can be recycled and reused, so that the cost of construction operation is lowered, and the operation efficiency is improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

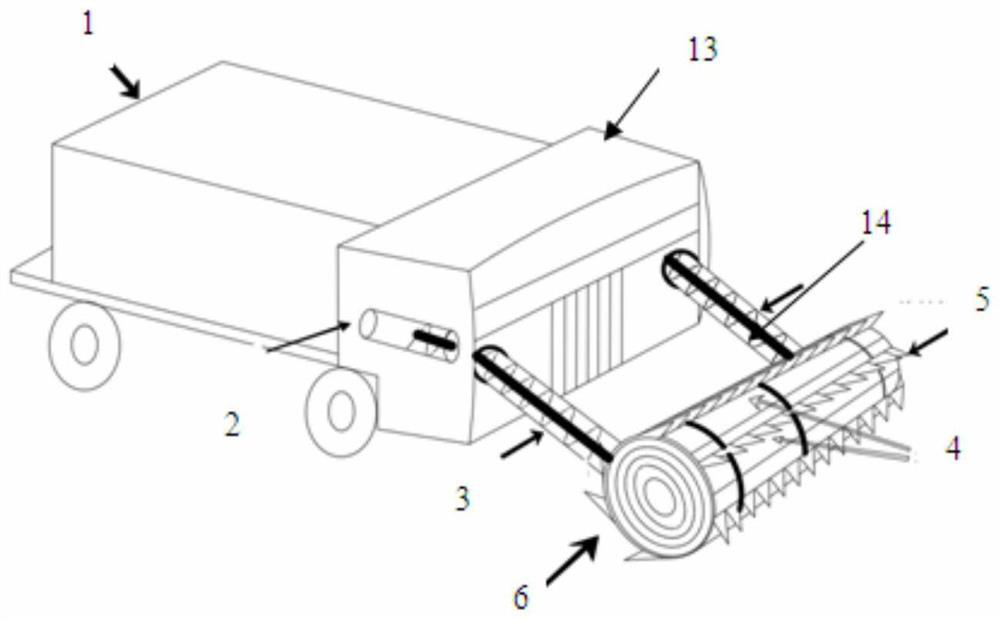

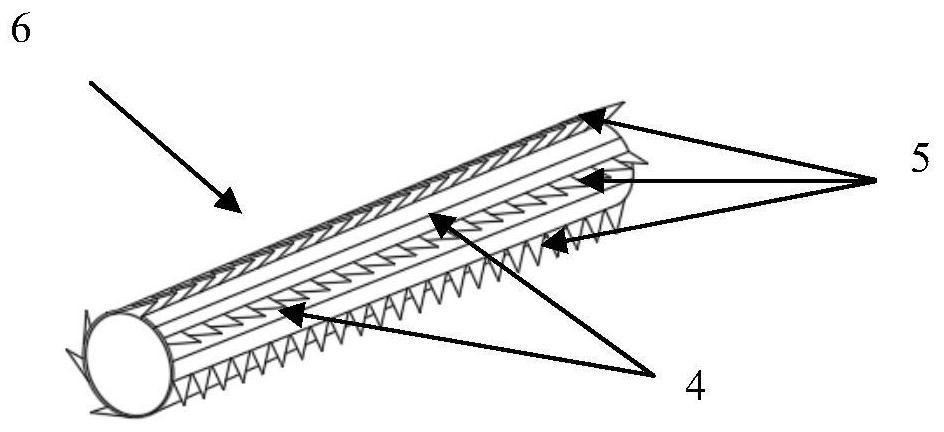

Multipurpose excavating and cleaning machine

PendingCN113123288AWork fasterImprove engineering efficiencyRoad cleaningSnow cleaningSnowpackRoad surface

The invention relates to a multipurpose excavating and cleaning machine which is composed of a wheel type chassis, a garbage compressing and storing bin and a supporting structure. An excavation cleaner is arranged at the front end of the machine and is of a transverse drum-type structure; the two ends of the excavation cleaner are fixed to a supporting structure through garbage drainage pipes; and the excavation cleaner is communicated with the interior of a garbage feeding hole. Along with forward pushing of the wheel type chassis, the roller of the excavation cleaner rotates, accumulated snow or garbage is sucked into the roller and then enters the garbage compressing and storing bin through the garbage drainage pipes, and accumulated snow cleaning and excavating operation is completed. The accumulated snow cleaning operation speed is increased, meanwhile, various construction operation tasks can be completed, the working efficiency and quality are improved, the construction operation cost is reduced, the machine can be used for multiple construction operation tasks such as road surface accumulated snow or garbage cleaning and ditch topsoil gravel cleaning or digging, and the equipment adaptation efficiency is improved.

Owner:陈云桥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com