Sand washing drilling and milling integrated device for workover operations in oil field

A technology for sand washing and well repairing, which is applied in the direction of wellbore/well valve devices, drill bits, drilling equipment, etc., which can solve the problems of poor sand washing effect and inability to perform reverse circulation sand washing, so as to reduce construction operation costs and speed up The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

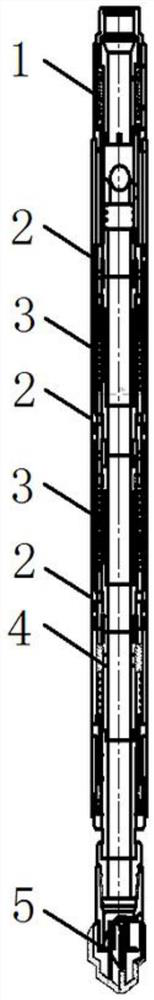

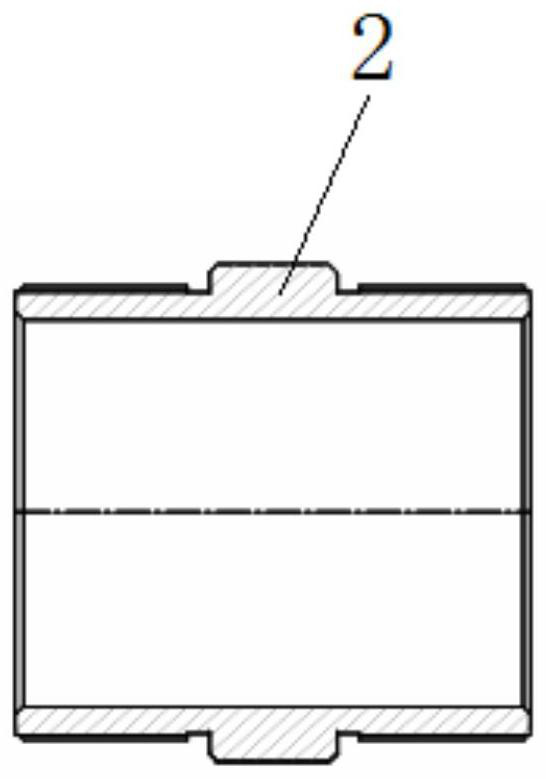

[0021] Such as Figure 1-6 As shown, a sand washing, drilling and milling integrated device for oil field workover operations, including an upper support body assembly 1, two sets of turbine assemblies 3, a lower support body assembly 4, a connecting cylinder 2 and a sand washing drill bit 5, The upper support body assembly 1, two sets of turbine assemblies 3 and the lower support body assembly 4 are sequentially connected through a plurality of connecting cylinders 2 to form a whole;

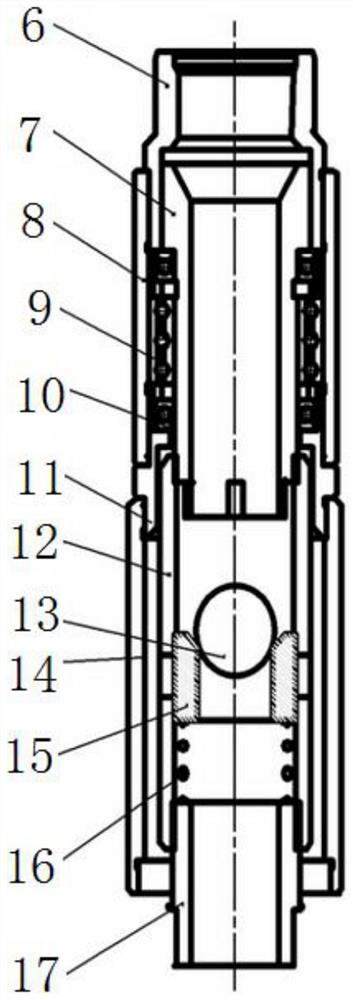

[0022] The upper support body assembly 1 includes an upper joint 6, an upper outer cylinder 8, a lower outer cylinder 14, a connector 11, a central pipe 7, a slide valve cover 12, an insertion head 17, a bearing group, and a slide valve One 15, spring one 16 and steel ball 13, the upper joint 6 is fixedly installed on the front end of the upper outer cylinder one 8, and the rear end of the upper outer cylinder one 8 is fixedly connected with the lower outer cylinder one 14 through the connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com