Drilling tool for down-hole string

A downhole pipe string and tool technology, applied in the field of downhole pipe string drilling tools, can solve the problems of high cost of drilling and draining oil, drilling or cutting construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

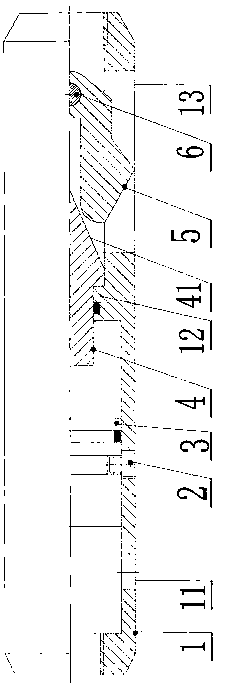

[0015] see figure 1 As shown, a downhole pipe string drilling tool, the piston 3 is axially sealed and positioned on the upper part of the main body 1 through the shear pin 2; the upper part of the cone 4 forms an axial sliding seal with the inner concave platform 12 of the main body 1; The pin 6 is fixed on the lower part of the main body 1; the main body 1, the piston 3 and the cone 4 form a closed cavity;

[0016] The stressed working surface at the lower part of the cone 4 is a wedge-shaped body 41 or a cone-shaped structure.

[0017] The pin 6 is installed radially along the main body 1, and the punching block 5 can rotate axially.

[0018] The pin 6 can be installed axially along the main body 1, and the punching block 5 can rotate radially.

[0019] There are one or two punching blocks 5 and pins 6 respectively.

[0020] Described scissors 2 are shear ring live scissors.

[0021] The use process of this embodiment:

[0022] The upper or lower part of the downhole s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com