Patents

Literature

116results about How to "Strong carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

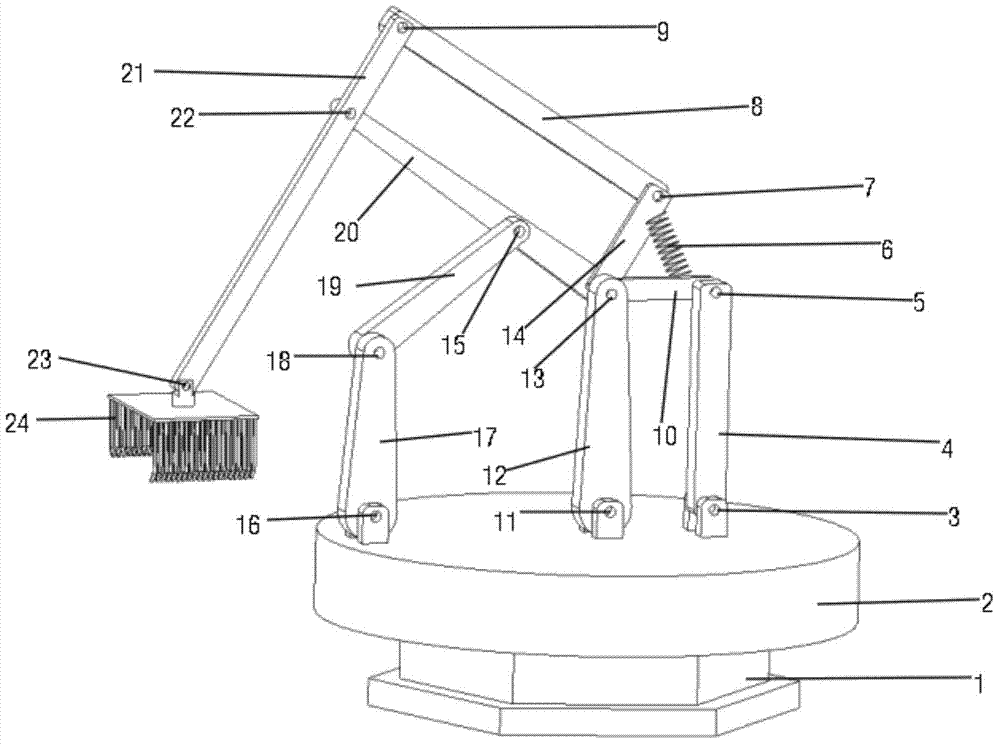

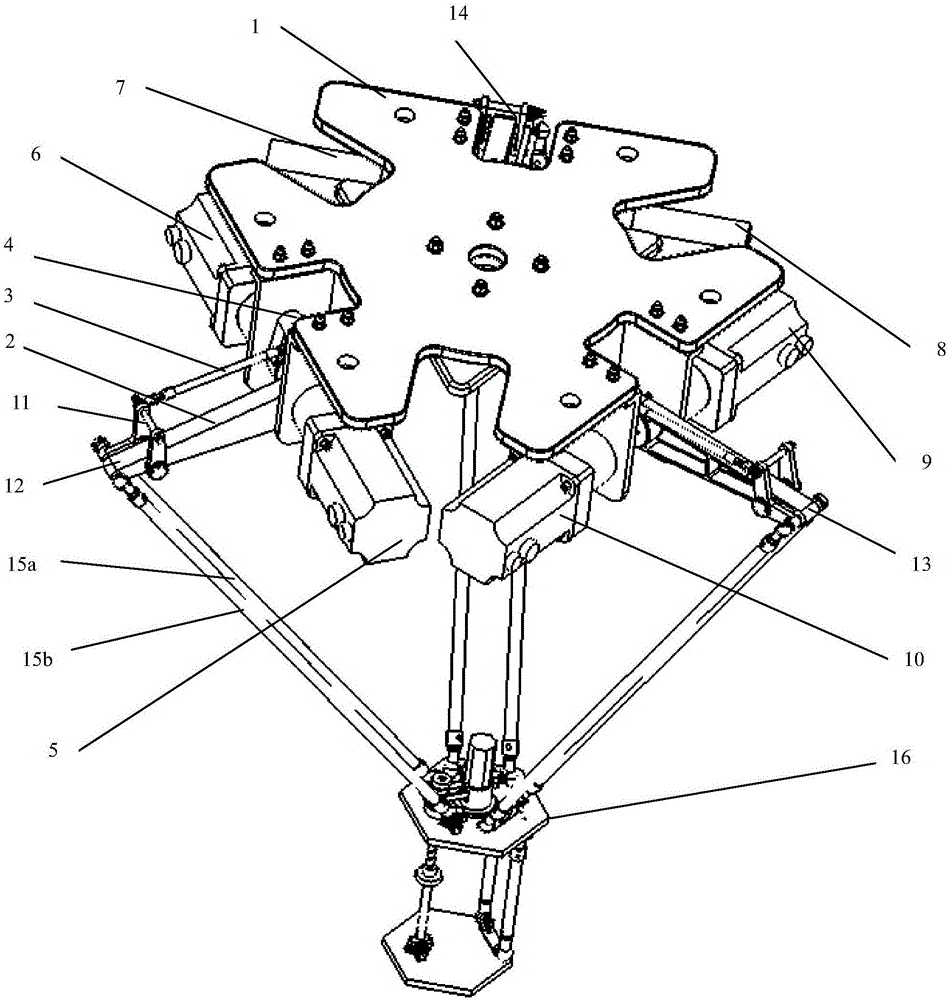

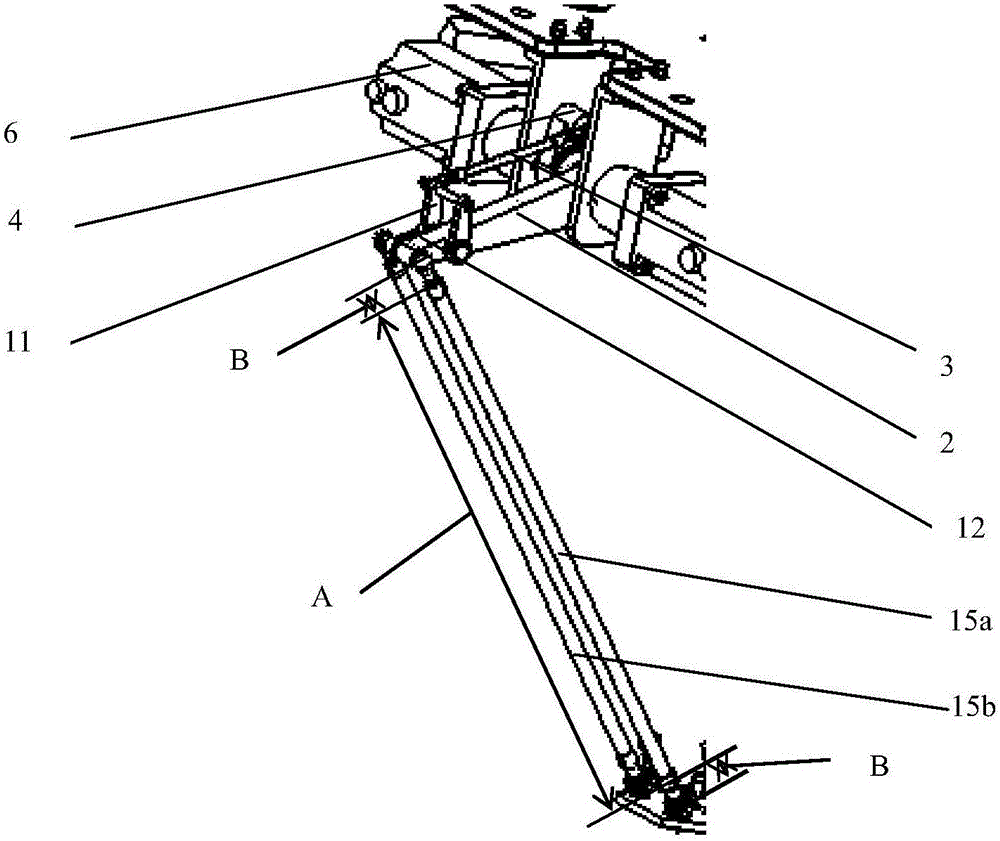

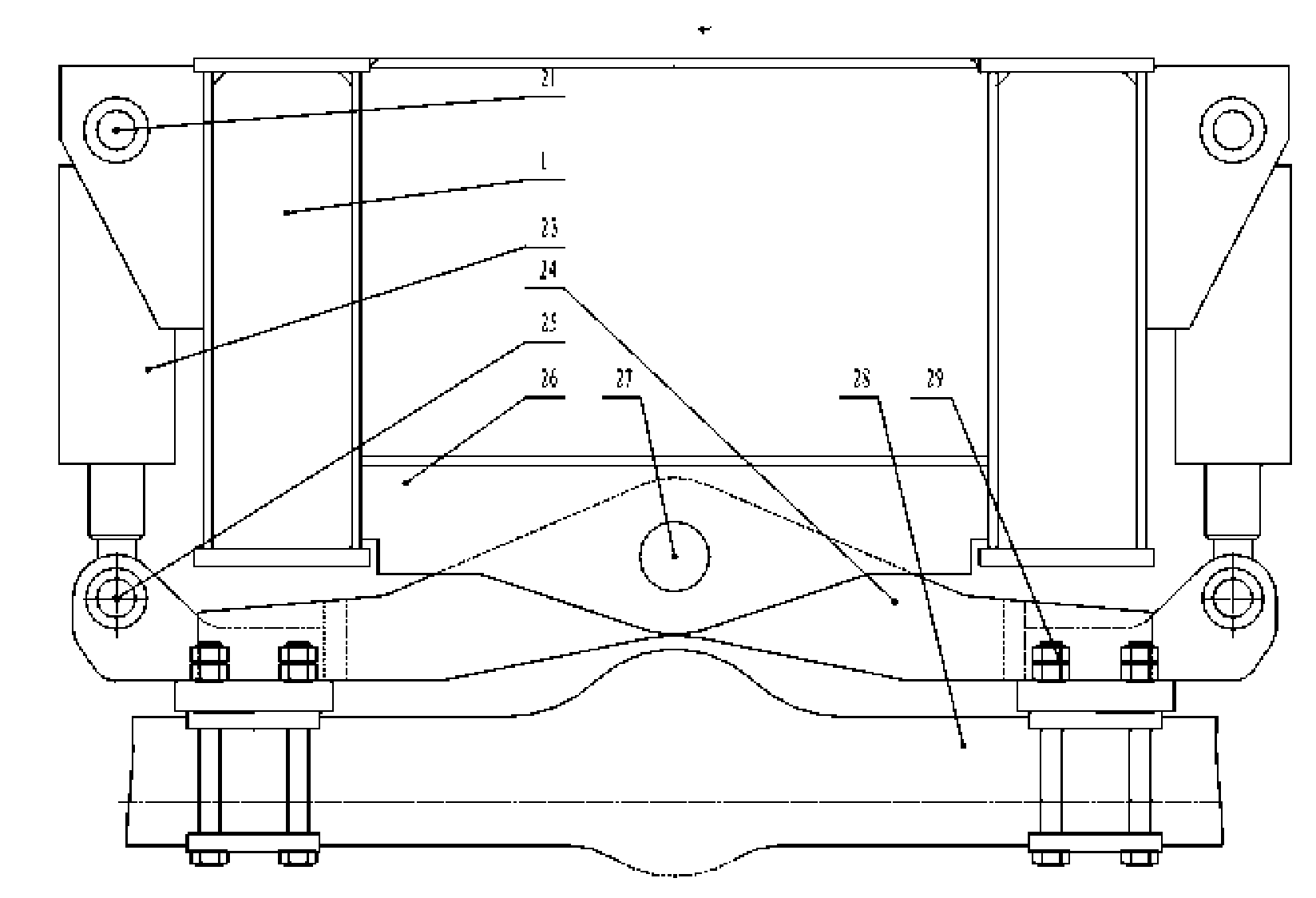

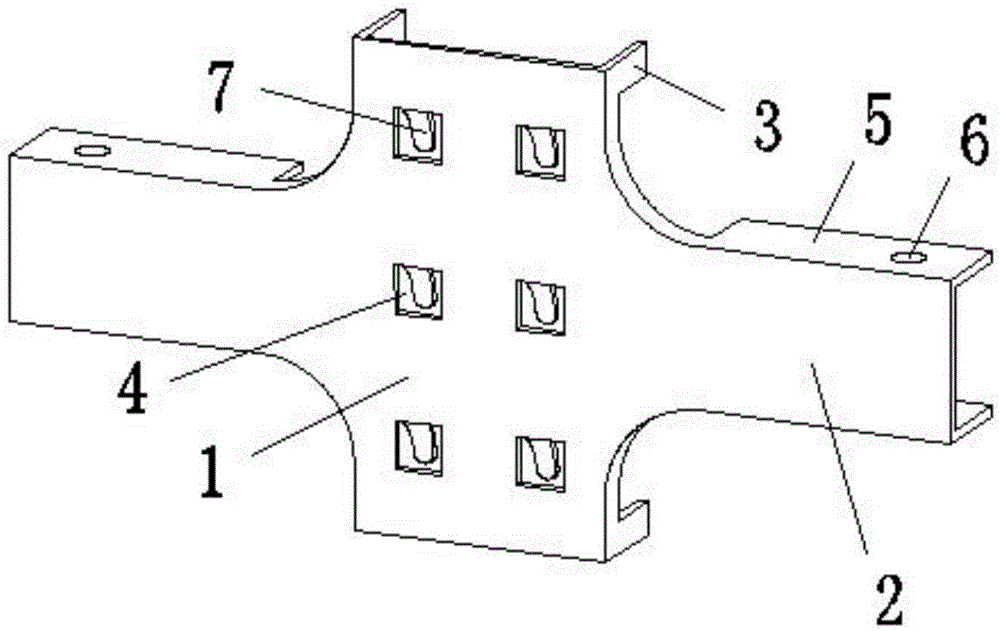

Metamorphic parallel-connection robot palletizer mechanism

ActiveCN104493816AIncrease stiffnessStrong carrying capacityProgramme-controlled manipulatorStacking articlesChain typeEngineering

The invention discloses a metamorphic parallel-connection robot palletizer mechanism. One end of a first driving rod of the metamorphic parallel-connection robot palletizer mechanism is connected with a rack; the other end of the first driving rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected with a seventh connecting rod; one end of a second driving rod is connected with the other end of the rack; the other end of the second driving rod is connected with one end of a fifth connecting rod; the other end of the fifth connecting rod is connected with the fourth connecting rod; one end of a first connecting rod is connected with the rack; the other end of the first connecting rod is connected with one end of a second connecting rod and is also connected with the first driving rod, the fourth connecting rod and a third connecting rod; one end of the third connecting rod is connected with the first driving rod, the fourth connecting rod and the second connecting rod simultaneously; the other end of the third connecting rod is connected with one end of a sixth connecting rod; the other end of the sixth connecting rod is connected with one end of the seventh connecting rod; the other end of the seventh connecting rod is connected with a tail end implanter; one end of a spring is connected with the second connecting rod; the other end of the spring is connected with the third connecting rod. Compared with a conventional open-chain type parallel-connection robot palletizer, the metamorphic parallel-connection robot palletizer mechanism has the advantages of high rigidity, high bearing property, small error accumulation, and the like.

Owner:GUANGXI UNIV

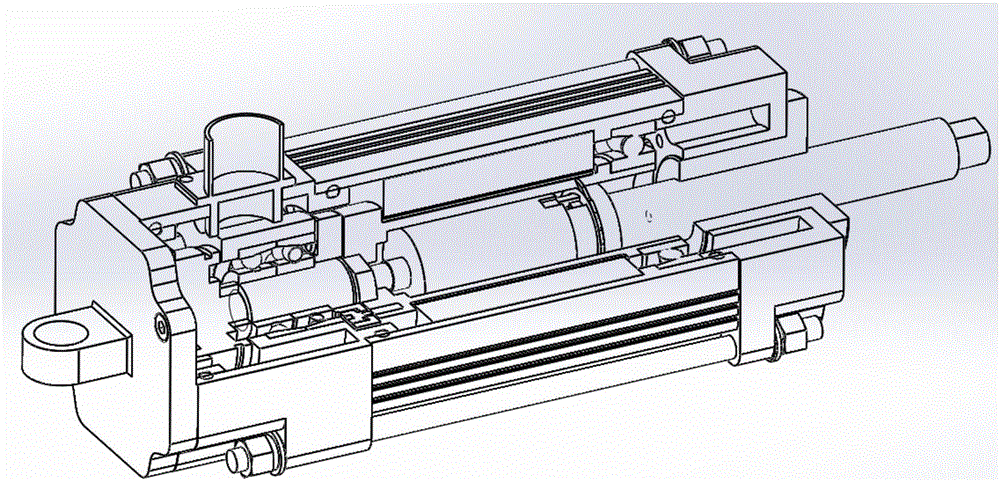

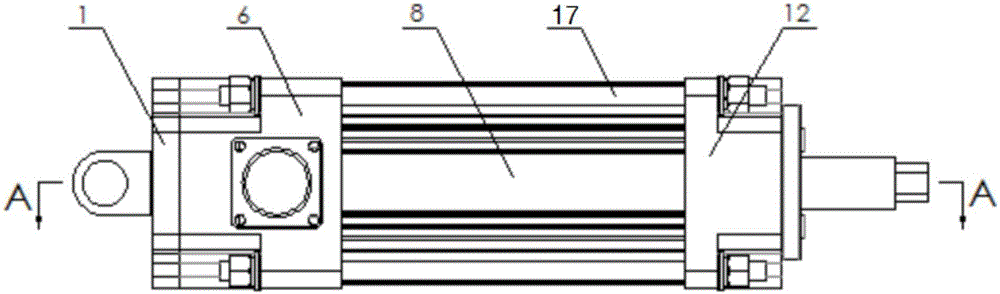

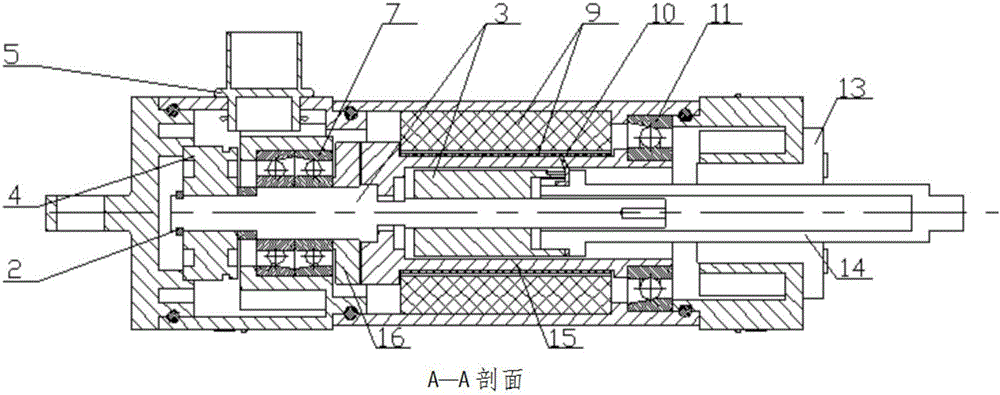

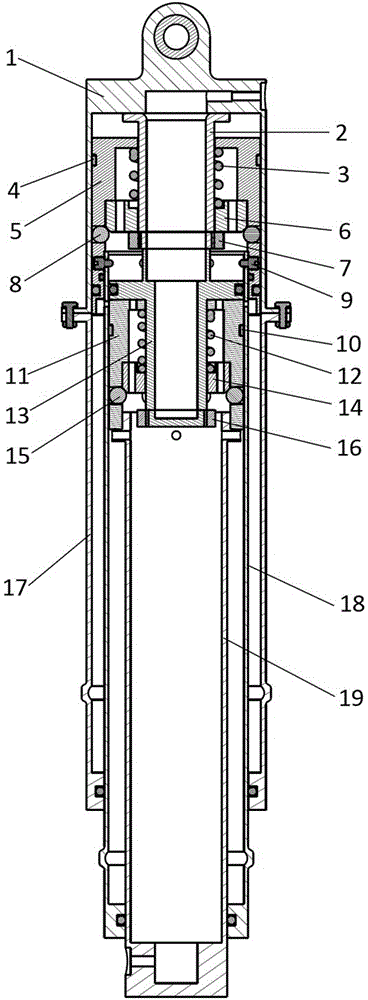

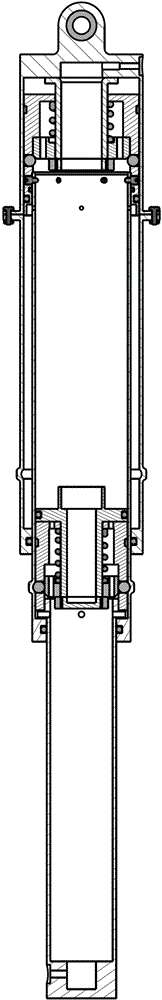

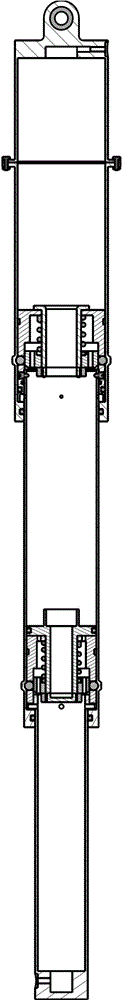

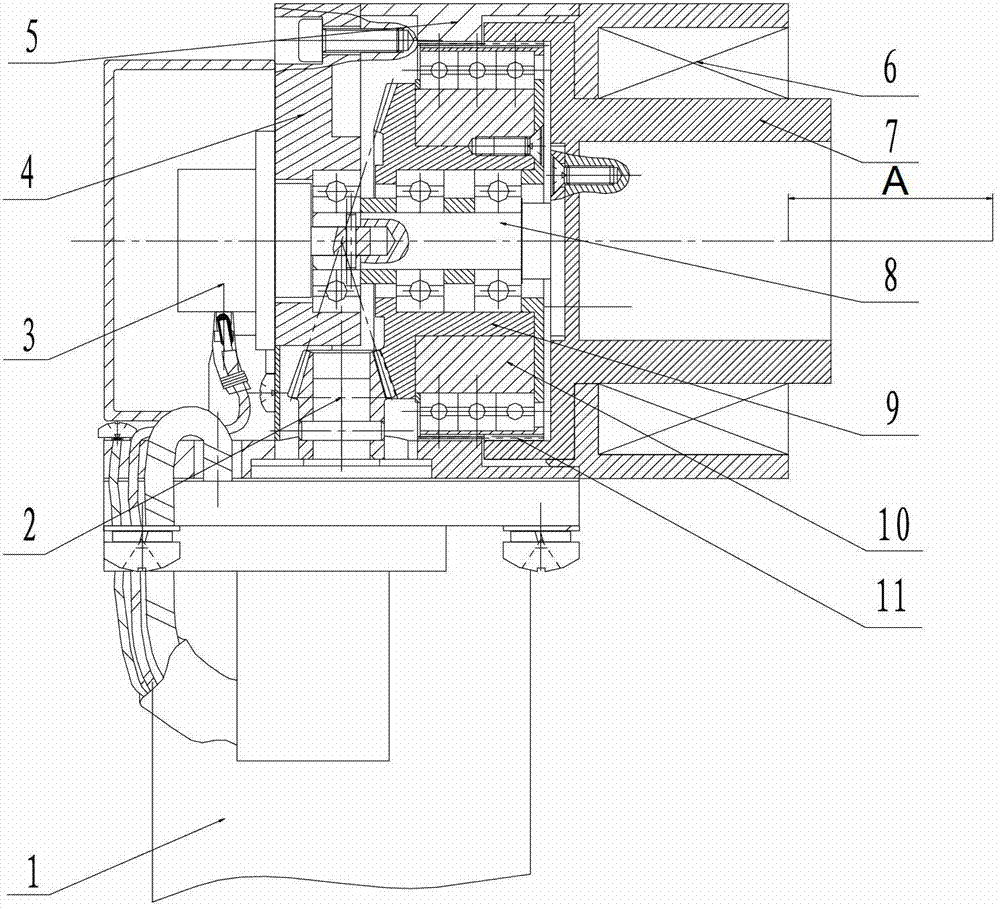

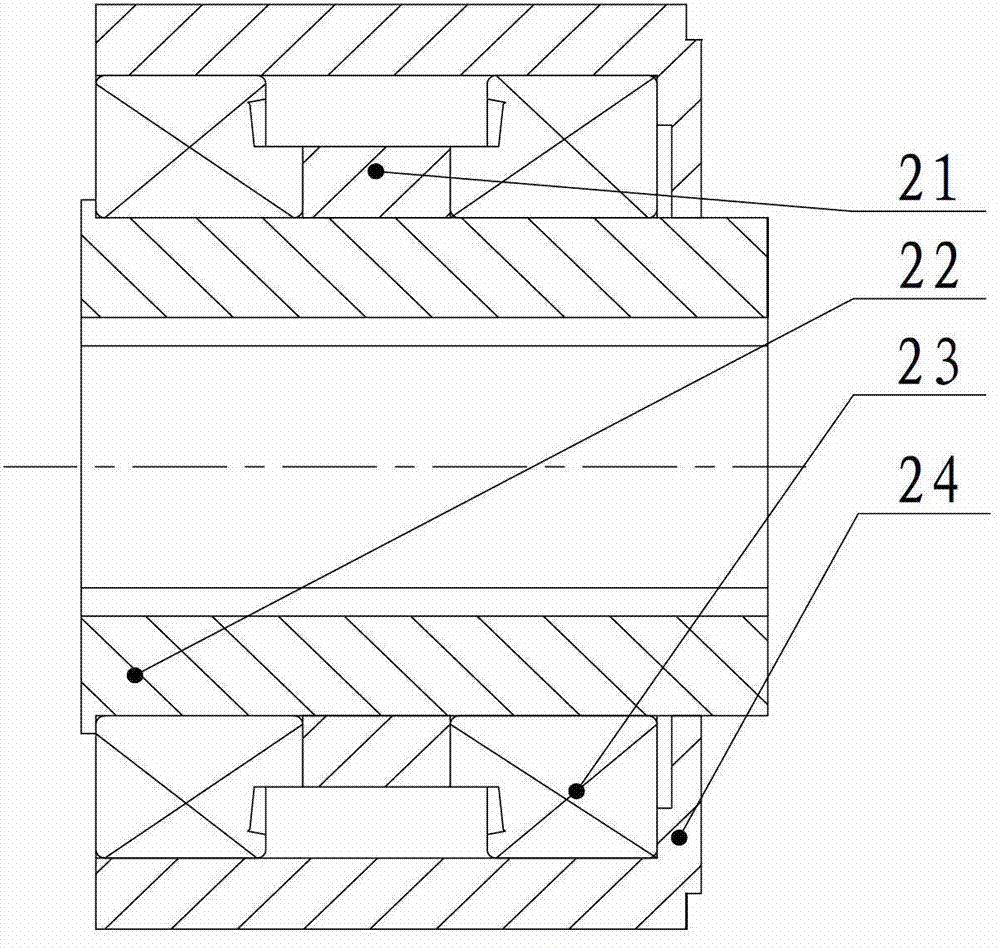

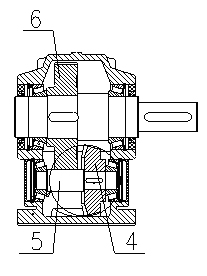

High-power-density integrated electromechanical servo actuating device

InactiveCN106787414ACompact structureStrong carrying capacityMechanical energy handlingTechnical supportHigh power density

The invention provides a high-power-density integrated electromechanical servo actuating device. The high-power-density integrated electromechanical servo actuating device comprises an integrated permanent magnet synchronous motor, a rotor sleeve, a planet roller lead screw pair, a bearing and matched devices such as a sensor. A motor stator is embedded into the inner side of a cylinder body, forms the integrated motor together with a permanent magnet patch attached to the rotor sleeve and drives the rotor sleeve to do rotating motion; the rotor sleeve is fixedly connected to a flange plate through a screw and then drive a lead screw to generate synchronous rotating motion through a key structure arranged on the roller lead screw; the planet roller lead screw pair converts rotating motion of the lead screw into linear motion of a nut; finally, the nut pushes an output rod to do linear motion by taking the liner bearing as a guide of the output rod through a thread formed in the output rod and a lock washer device. According to the high-power-density integrated electromechanical servo actuating device, the problem that an existing electromechanical actuating device is large in size and weight is solved, then the power to weight ratio and loading capacity of the electromechanical actuating device are increased, and a technical support is provided for promoting development of future multi-electrochemical / full-electrochemical air vehicles.

Owner:BEIHANG UNIV

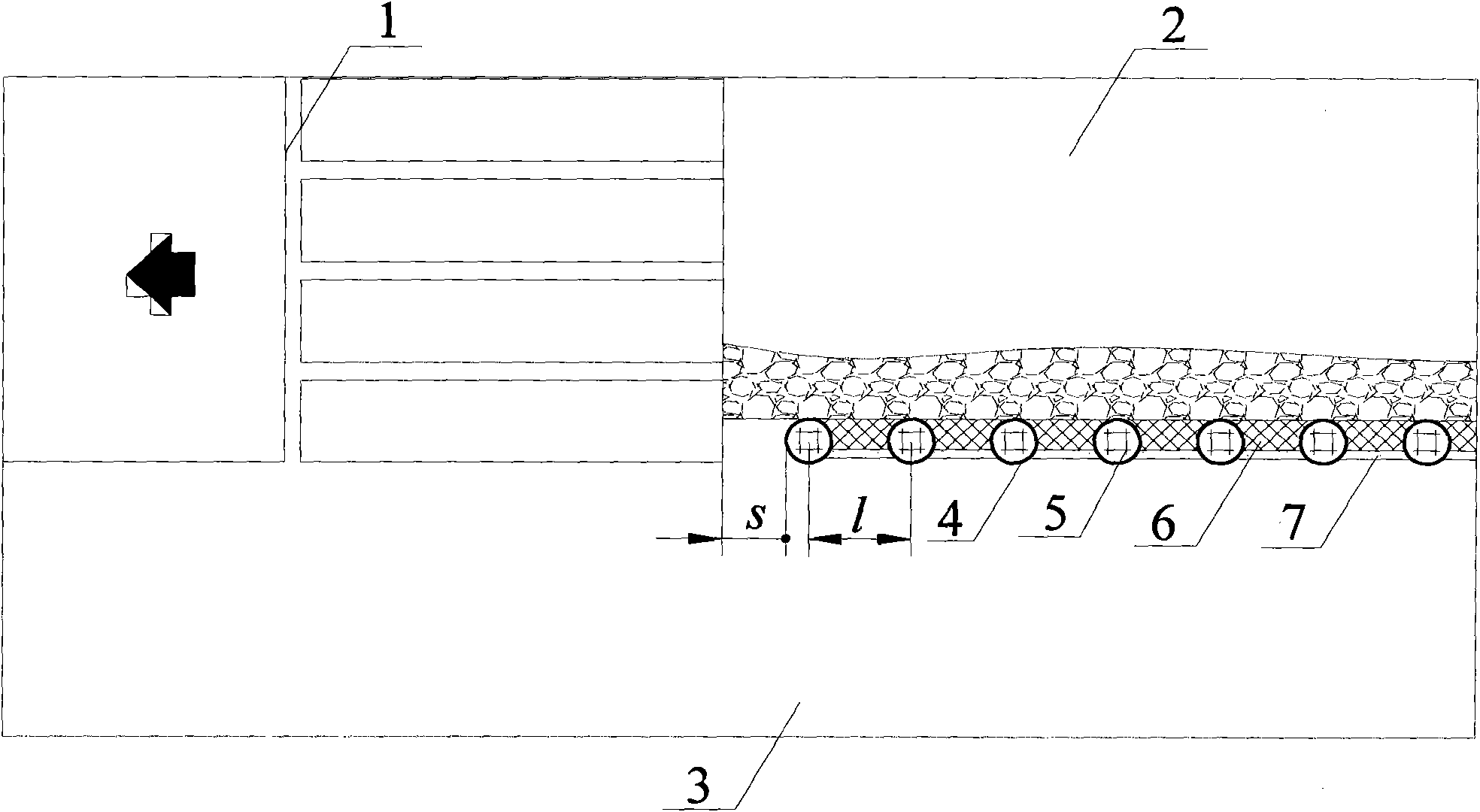

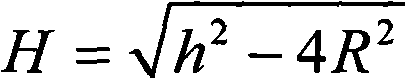

Method for entry retaining for walling at sides of road in steel cylinder support mode

InactiveCN101892860AStrong carrying capacityHigh compressive strengthMaterial fill-upProps/chocksRebarCoal

The invention relates to a method for entry retaining for walling at sides of a road in a steel cylinder support mode, which is applicable to the construction of gob-side entry retaining for a coal mine stope. The method comprises the steps of: after stopping a coal face, arranging a steel cylinder support at the edge of a gob by lagging 1-2m, and arranging a steel grid frame structure in the steel cylinder; then, pouring concrete in the steel cylinder; firmly piling the edge of the gob with waste rocks, coal cinder and the like after an overhead plate of the god collapses; spraying slurry to close the gob; and jointly forming a support wall at the sides of the road with the high-strength steel cylinder support and a waste rock wall. The restriction of the high-strength steel cylinder can obviously enhance the strength and the carrying capacity of the concrete structure. The method has the advantages of simple construction process and high adaptability, and also can save materials, reduce labor intensity and improve the construction environment.

Owner:CHINA UNIV OF MINING & TECH

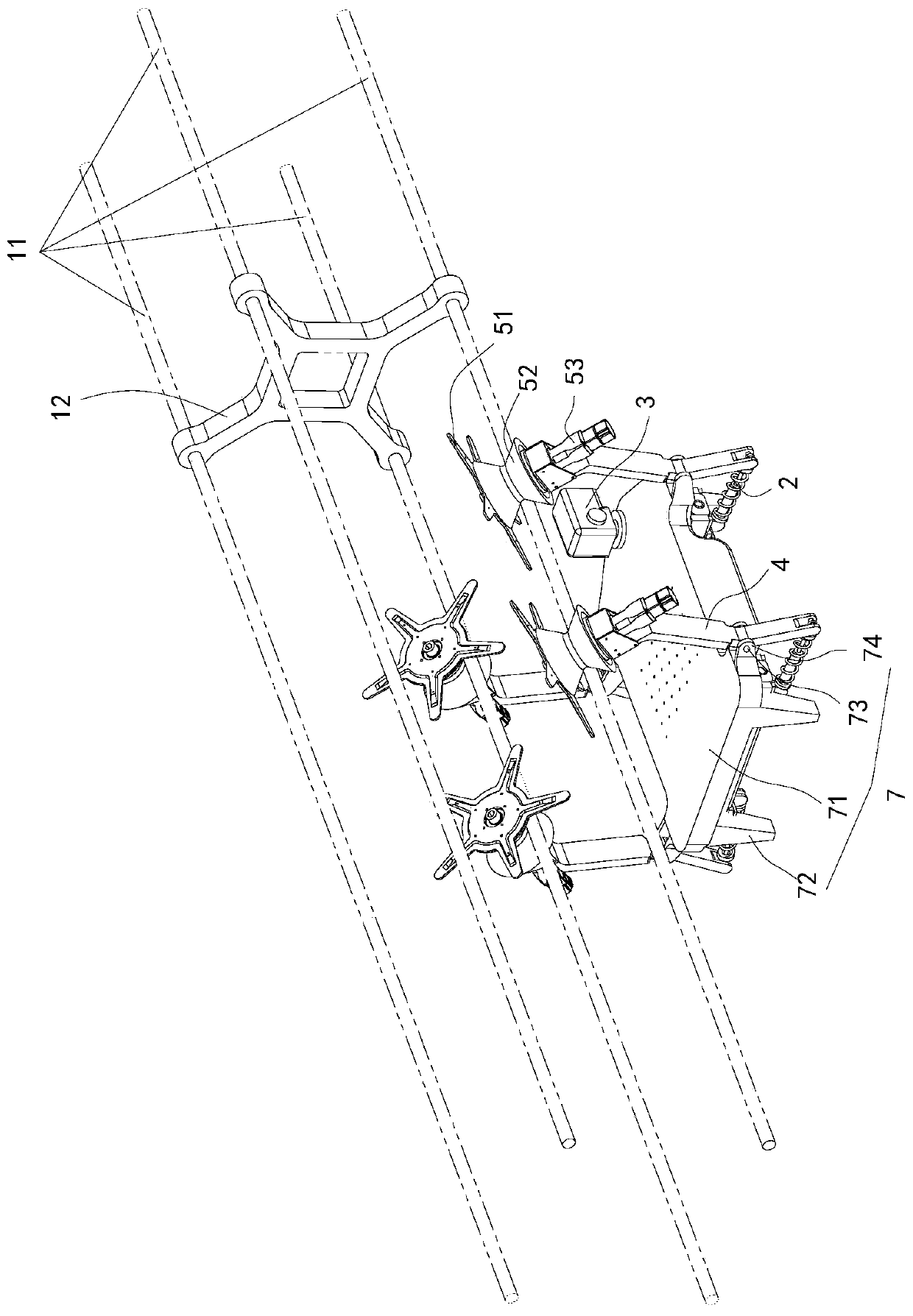

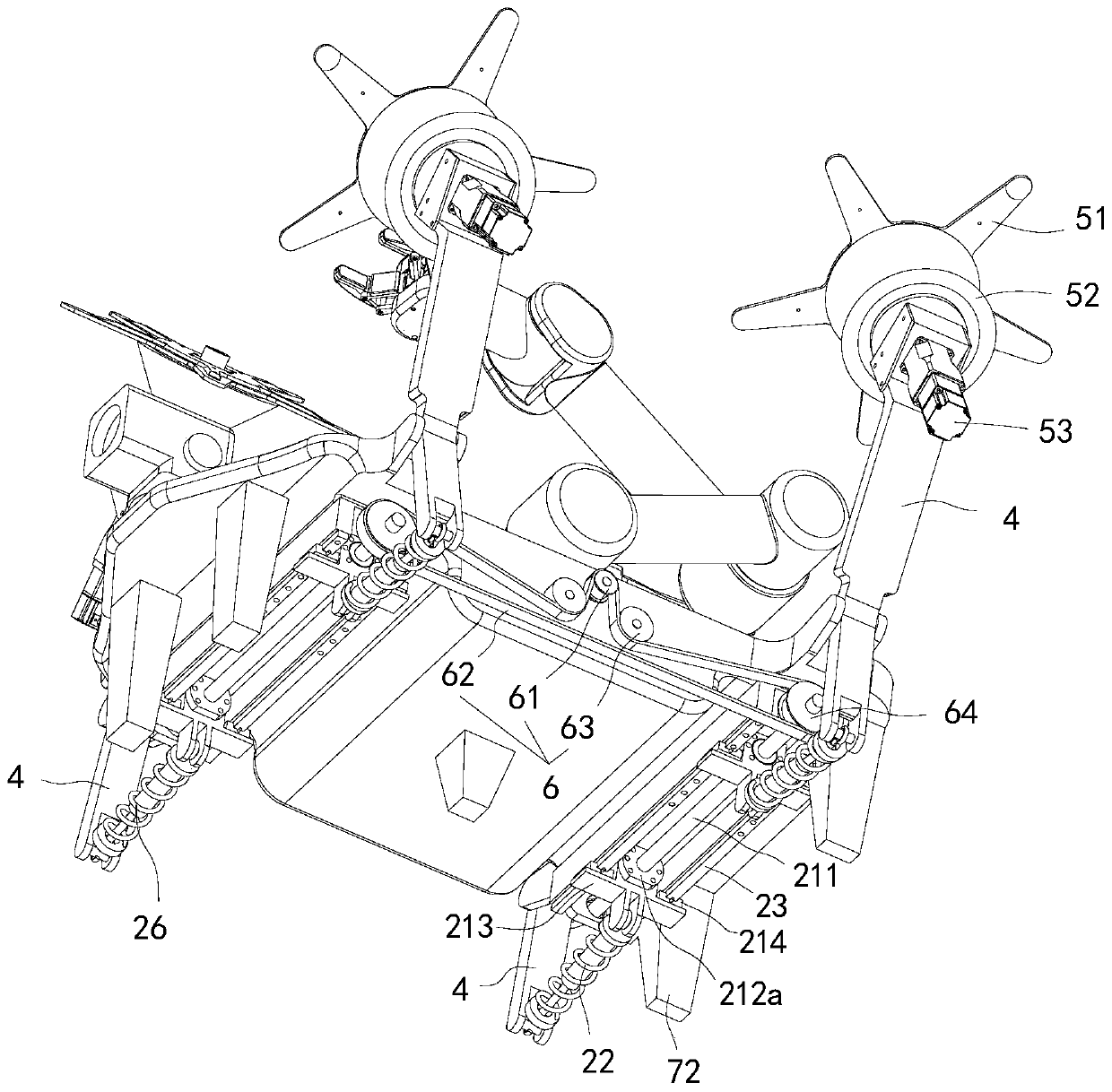

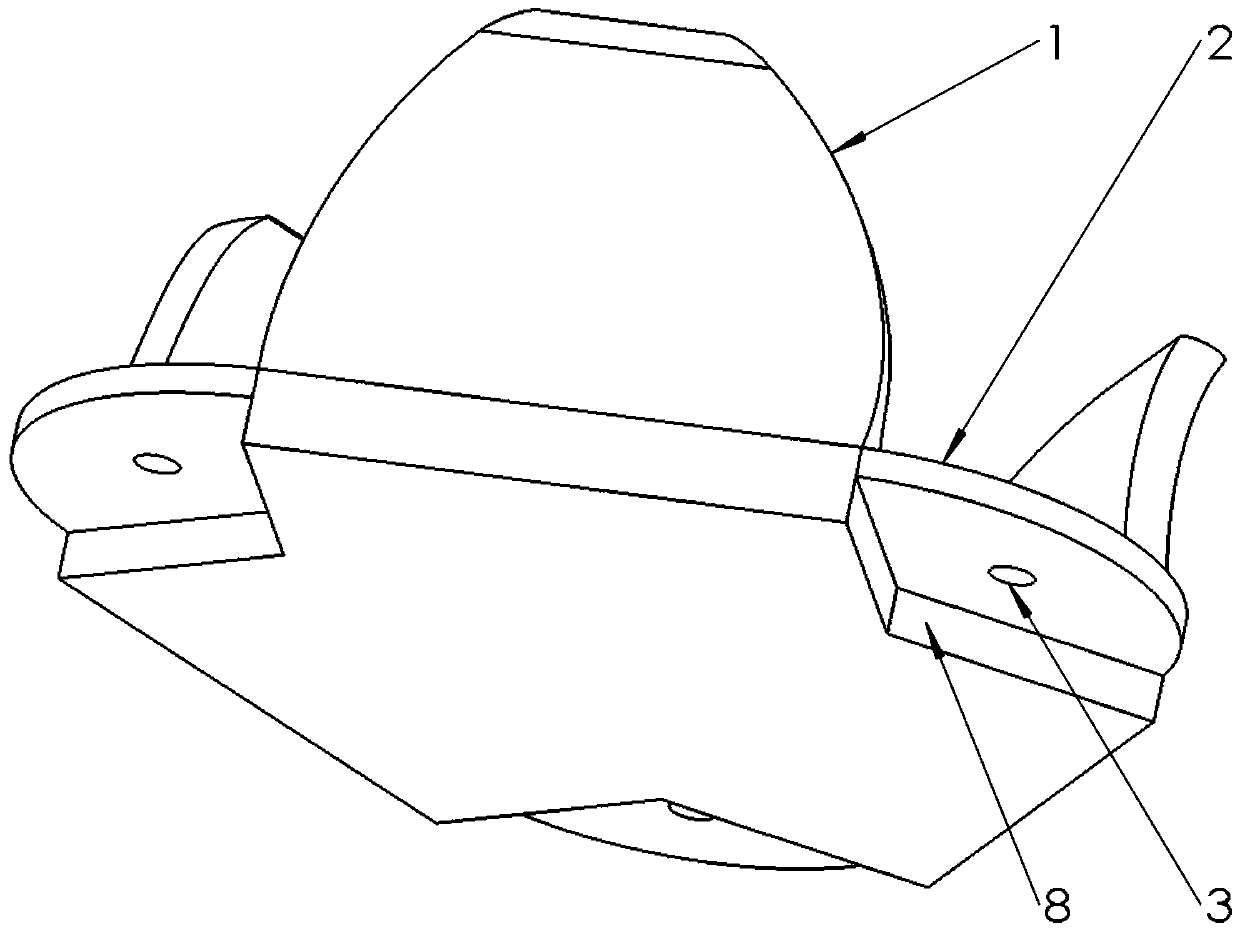

High-voltage power transmission line robot

PendingCN110480597AEasy to hang and hangImprove reliabilityArmsApparatus for overhead lines/cablesActuatorHigh pressure

The invention provides a high-voltage power transmission line robot. The high-voltage power transmission line robot comprises flexible power wheels which are arranged in pairs and can move along powertransmission cables, power wheel supporting arms and a supporting seat, wherein one end of each power wheel supporting arm is connected with each flexible power wheel; walking arm flexible driving mechanisms are correspondingly arranged on the supporting seat; the other end of each power wheel supporting arm is connected with each walking arm flexible driving mechanism and is hinged on the supporting seat in a swinging state; and an actuator which can be replaced according to operation tasks is also arranged on the supporting seat. The high-voltage power transmission line robot is designed for divided conductors with voltage being higher than 500kv, is capable of ensuring that the flexible power wheels are tightly close to an inspection line during moving, can be adapted to complicated situations of the line, can be better applied to line hardware, has a function of easily lifting and hanging the line, and also naturally has a falling prevention function, is capable of avoiding crossing failure caused by leaving from the line when crossing over poles and towers; the reliability and the stability of a robot platform in use are improved; the inspection efficiency and the safety aregreatly improved; and the equipment reliability is high.

Owner:克诺机器人(深圳)有限公司

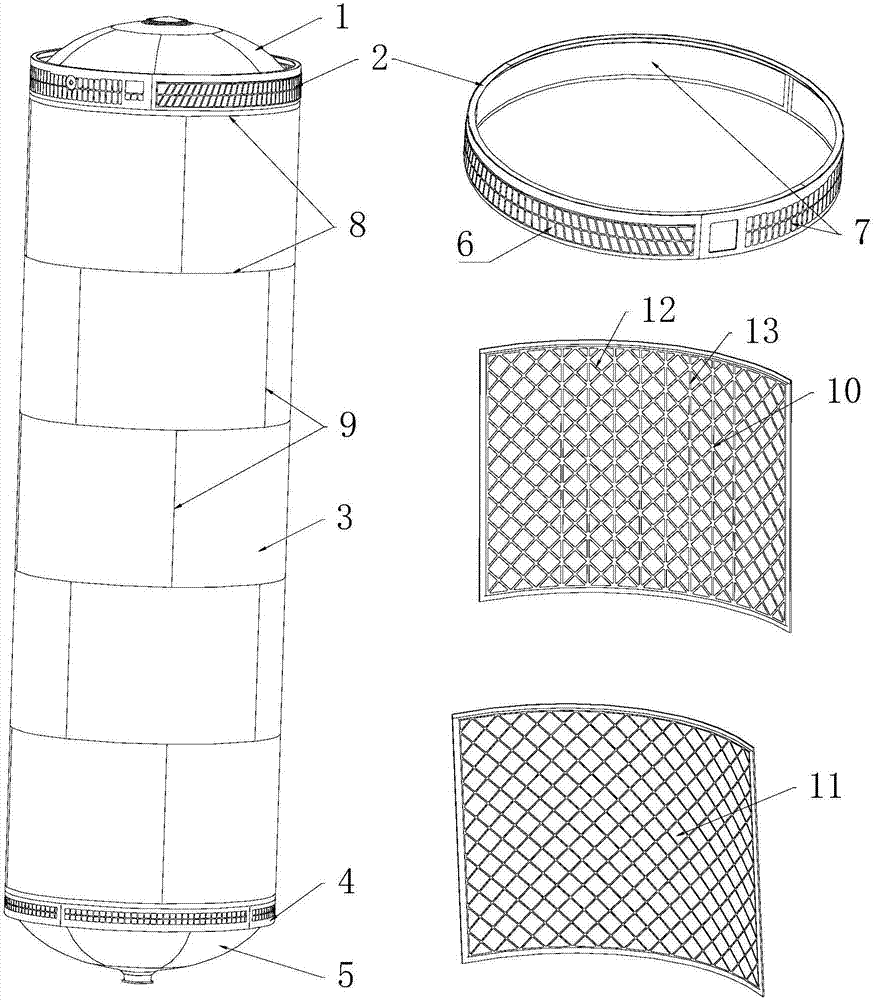

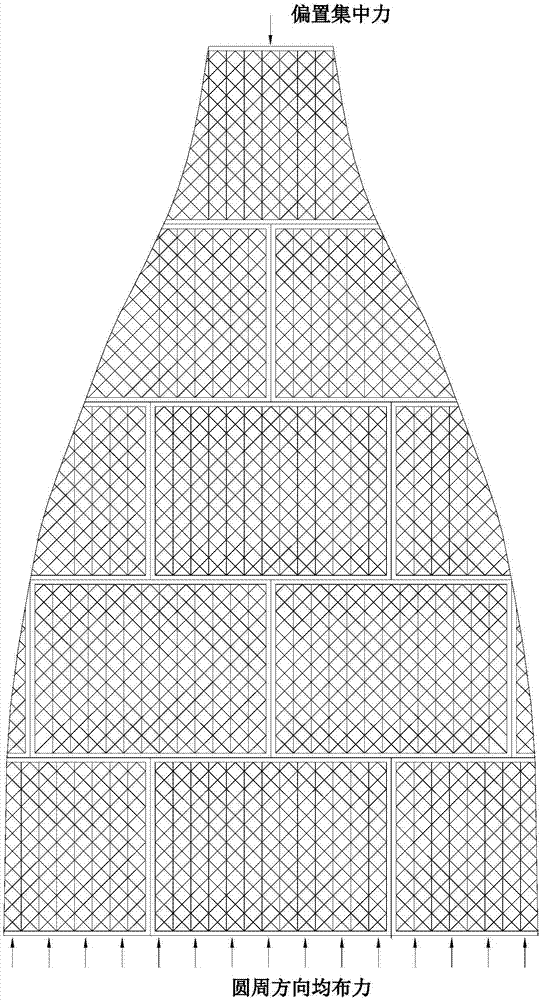

Carrier rocket booster tank structure for biased concentrated force

InactiveCN107063007AStrong carrying capacityHigh structural efficiencySelf-propelled projectilesWeld seamDiffusion function

The invention provides a carrier rocket booster tank structure for biased concentrated force. The structure comprises a front short shell, a front tank bottom, a cylinder segment, a rear tank bottom and a rear short shell, wherein the five parts form the whole tank structure through circumferential welded seams and form a sealed container which can store a propellant and bear various loads; the front short shell is welded into a whole by a radial outer reinforced wall plate and two positive outer reinforced wall plates, and the cylinder segment is composed of a mixed inner reinforced wall plate with a concentrated force diffusion function and an oblique inner reinforced wall plate. The carrier rocket booster tank structure solves the bearing and diffusion problem of the biased concentrated force, the biased concentrated force is diffused through the tank structure to become uniformly distributed force, and a good mechanical environment is provided for a cabin behind a tank. The tank structure has the characteristics of high bearing capacity, high structure efficiency, good concentrated force diffusion effect, etc.

Owner:SHANGHAI AEROSPACE SYST ENG INST

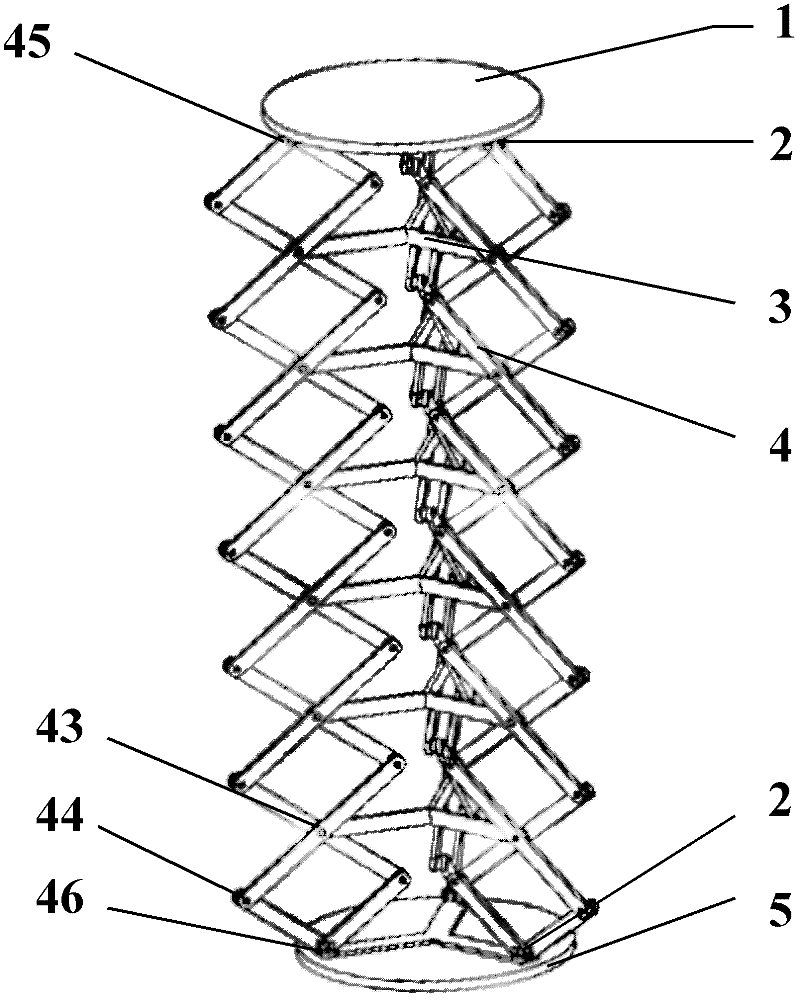

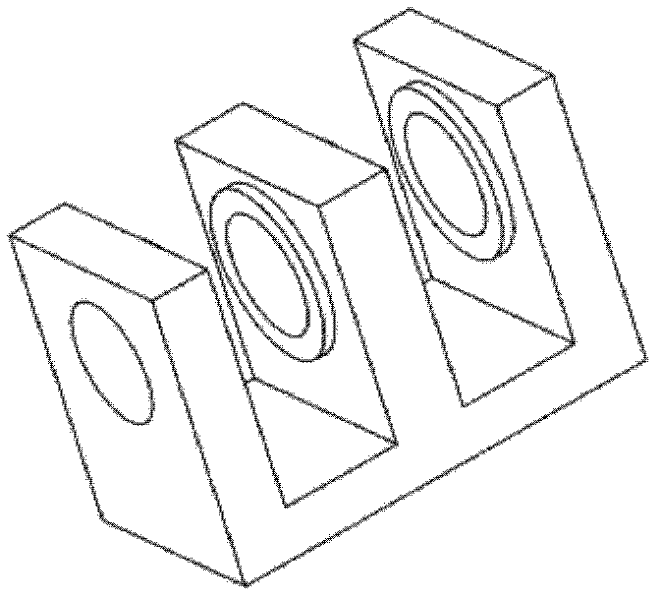

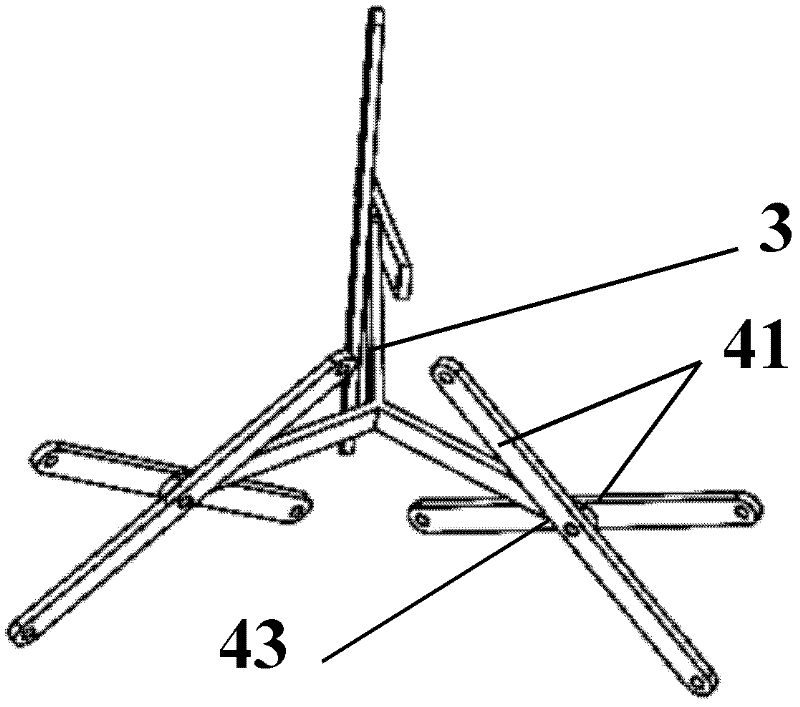

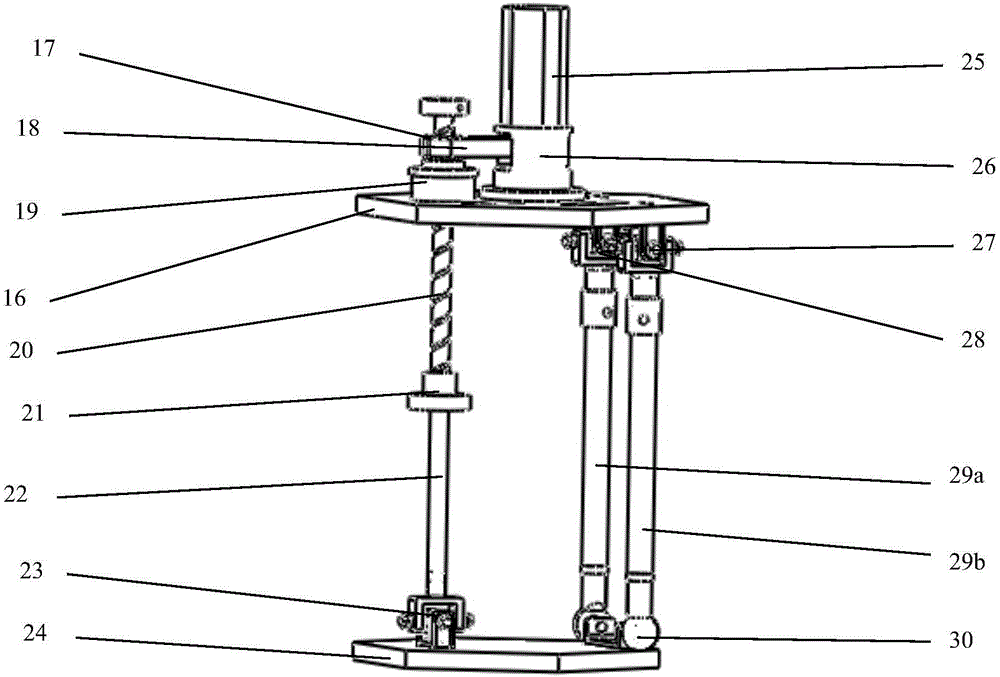

Fulcrum fixed multi-surface over-constrained radial scissor type lifting mechanism

The invention belongs to the field of lifting equipment, and in particular relates to a fulcrum fixed multi-surface over-constrained radial scissor type lifting mechanism. W-shaped connecting pieces are respectively fixed on the upper plane of a base and the lower surface of a bearing platform according to vertex positions of regular triangles; three groups of scissor type trusses are vertical to the base; the bottom ends and the top ends of the scissor type trusses are connected with the W-shaped connecting pieces through a bottom rotation pair respectively; an inclined angle of 120 DEG is formed by planes where every two groups of scissor type trusses are positioned; star-shaped connecting pieces are arranged among the three groups of scissor type trusses and among connecting rods with the same height on each layer; and a driving device is arranged at the central position of the base. Compared with a parallel type scissoring machine in the prior art, the invention has the advantages that: the mechanism has a stable structure, the weight of the mechanism can be reduced without the variation of intensity, the rigidity is improved, and high loads can be born, so that the maximum operation height of a lifting platform is increased; and the mechanism has the characteristics of high foldable ratio, compact structure, low dead weight, high bearing capacity, high throughput capacity and high operability.

Owner:TSINGHUA UNIV

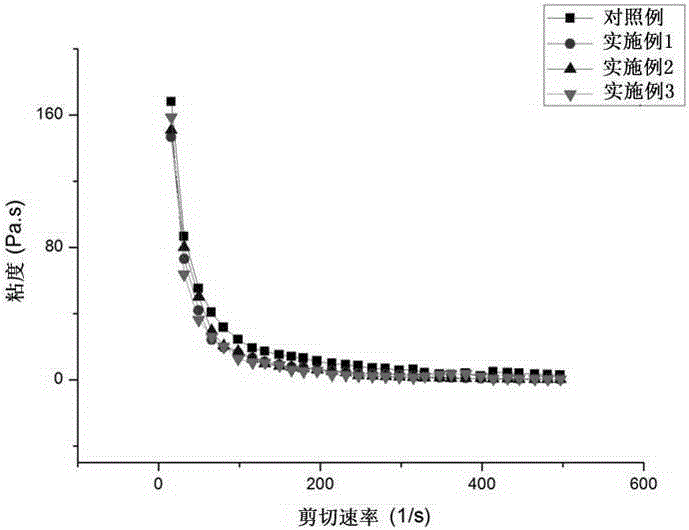

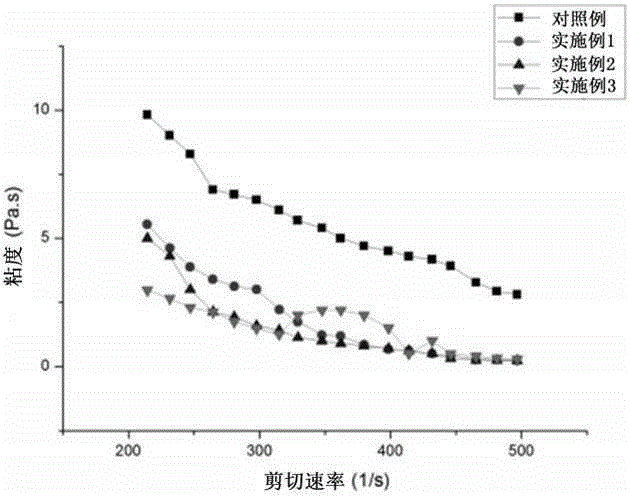

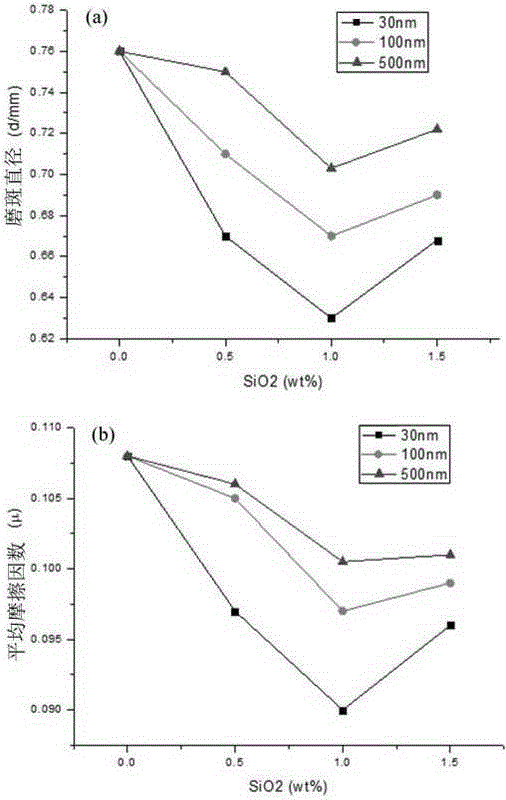

Lithium-based lubricating grease containing nano-particles and preparation method thereof

The invention belongs to the technical field of lubricant preparation, and particularly relates to lithium-based lubricating grease containing nano-particles and a preparation method thereof. The lithium-based lubricating grease containing the nano-particles is prepared from, by weight, 97%-99% of general lithium-based lubricating grease, 0.5%-1.5% of nano SiO2 and 0.5%-1.5% of nano MoS2. The preparation method comprises the steps that the general lithium-based lubricating grease, the nano SiO2 and the nano MoS2 are weighed by weight; the nano SiO2 and the nano MoS2 are ultrasonically dispersed into ethyl alcohol; the dispersed nano SiO2 and nano MoS2 and the ethyl alcohol are together added into the general lithium-based lubricating grease, even mixing is performed, and then the finished product is obtained. According to the lithium-based lubricating grease containing the nano-particles and the preparation method thereof, the general lithium-based lubricating grease serves as a criterion, the nano SiO2 and the nano MoS2 particles are added, and therefore the lubricating grease obtained through modification is better in wear resistance and higher in carrying capacity.

Owner:HUANGHE S & T COLLEGE

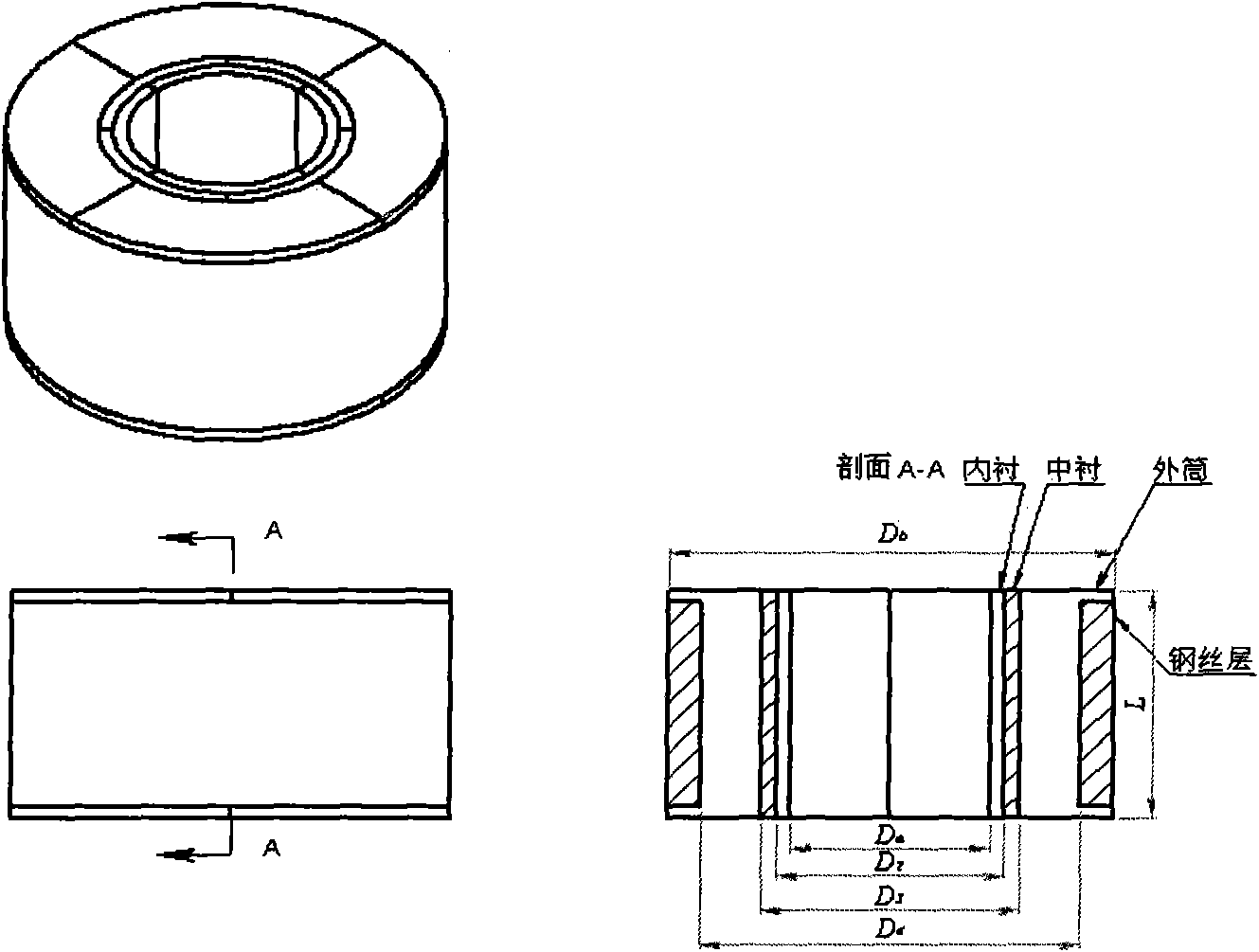

Design method of subdivision-combination recipient under full prestressing field and structure thereof

InactiveCN101879535AStrong carrying capacityImprove fatigue lifeExtrusion profiling toolsCarrying capacityEngineering

The invention relates to a subdivision-combination recipient wound by prestressed steel wire, a novel design method of a recipient and a novel structure thereof in metal extrusion process. The method comprises the following steps: adopting a steel wire wrapping layer outside a recipient body to form a full presressing field so as to enable an ouster cylinder, a middle lining and an inner lining to be in stress state during both prestressing and operation to separate the prestressed cylinder layer into a plurality of blocks, then winding the steel wires into a whole, and enabling the stressing condition of the wound cylinder to be the same as that of the whole cylinder. Compared with the traditional multilayer combination recipient, the subdivision-combination recipient wound by prestressed steel wire has higher carrying capacity and longer fatigue life, the subdivision-combination structure obviously reduces the manufacturing difficulty and cost of the recipient, and the invention has excellent application prospect in the recipient manufacturing of large-tonnage extruders.

Owner:TSINGHUA UNIV

Seven-degree-of-freedom transfer robot provided with ball screw movable platform

ActiveCN106737600AIncrease stiffnessStrong carrying capacityProgramme-controlled manipulatorDeflection angleEngineering

The invention discloses a seven-degree-of-freedom transfer robot provided with a ball screw movable platform and belongs to the technical field of robots. The robot comprises a machine frame, an upper movable platform, a lower movable platform, a ball screw, a synchronous belt and three branches. Each branch comprises a large driving arm, a small driving arm, a driving arm connecting rod, a lining frame and a driven arm, wherein the upper end of the driven arm is connected with the lower end of the lining frame; the lower end of the driven arm is connected with the upper movable platform; a screw nut is fixedly connected to the upper movable platform; a synchronous pulley is installed at the upper end of a screw shaft; and the lower end of the screw shaft is connected with the lower movable platform. The robot is based on a six-axis transfer parallel robot, one degree of freedom is additionally added by transforming and upgrading the movable platforms, the lower movable platform deflects by a certain angle based on the upper movable platform, thus, the deflection angle of a tail end execution mechanism is increased, and the problem that the robot is limited in the actual motion process, and accordingly the deflection angle of the tail end execution mechanism is small is solved. The robot provided by the invention is larger in application range and better meets the practical requirements.

Owner:杭州千岛湖瑞淳机器人研究院有限公司

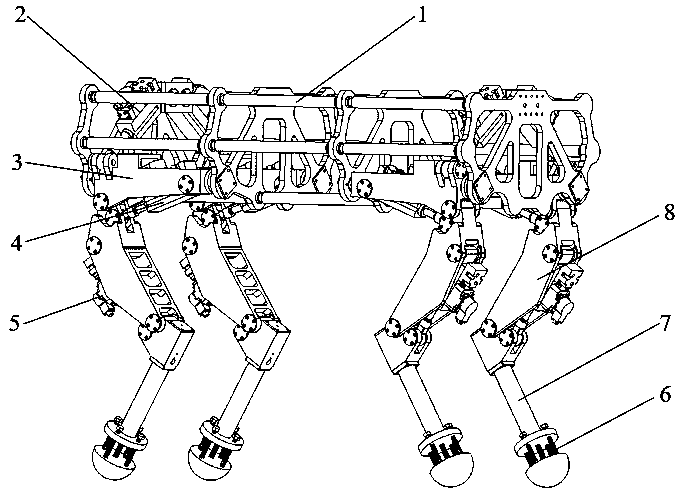

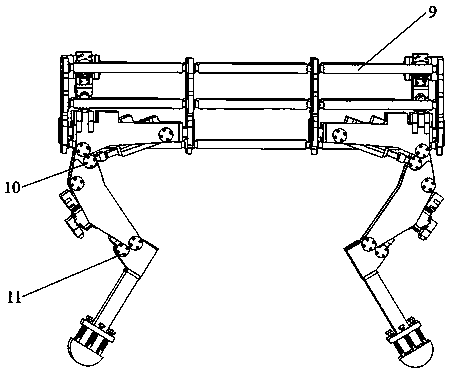

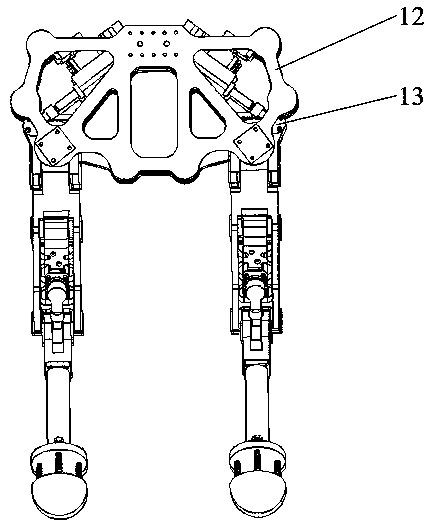

Foot-end adaptive hydraulic quadruped robot

PendingCN109760762AImprove adaptabilityStrong carrying capacityVehiclesStability of motionSelf adaptive

The invention discloses a foot-end adaptive hydraulic quadruped robot. The foot-end adaptive hydraulic quadruped robot comprises a machine body and four mechanical legs, wherein the machine body consists of end plates and connecting rods which have hollow structures; the self-weight of the robot can be effectively reduced; structures of the four legs are the same, and are uniformly and symmetrically distributed on the periphery of the machine body; each leg has three active degrees of freedom; and a servo actuator controls a hydraulic cylinder to realize movement of the robot. Each foot end consists of a bolt, a spring and hemispherical solid rubber, the pre-tightening bolt on each foot end can adjust the rigidity of the corresponding spring, and the circumstance that the stability of movement of the robot is affected due to over large force of contact between each foot end and the ground is avoided.

Owner:HARBIN UNIV OF SCI & TECH

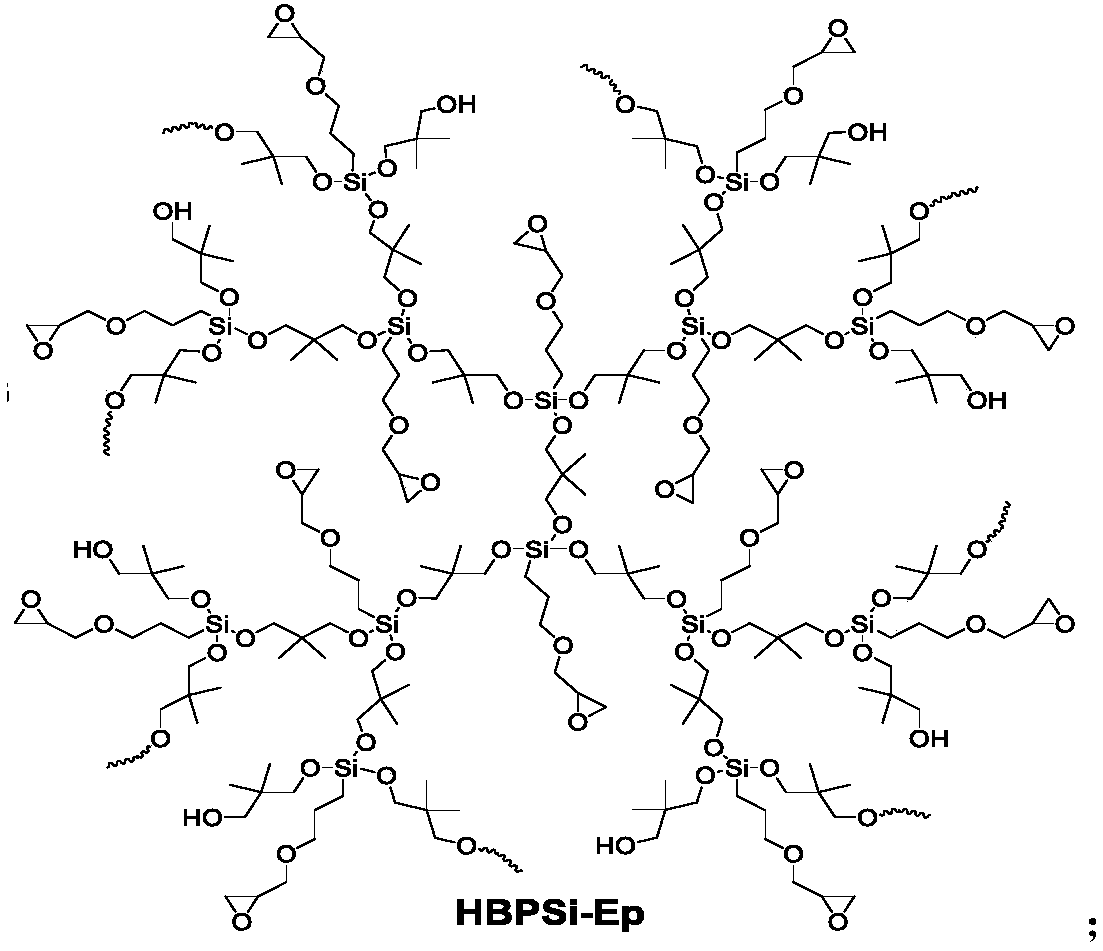

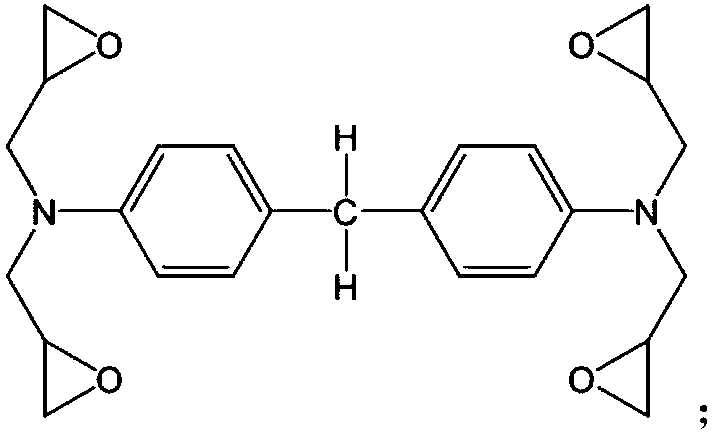

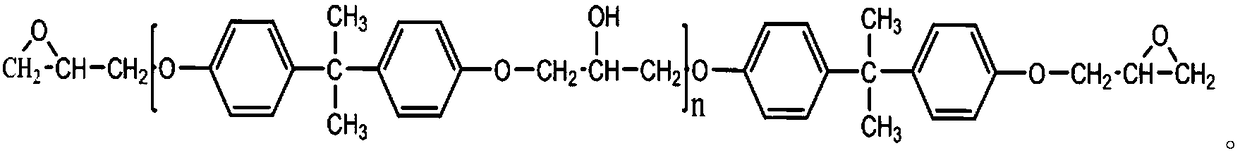

Low-cost high-toughness self-lubricating epoxy resin and preparation method thereof

InactiveCN109265930AReduce coefficient of frictionStrong carrying capacityChemistryFlexural strength

The invention relates to a low-cost high-toughness self-lubricating epoxy resin and a preparation method thereof, wherein the low-cost high-toughness self-lubricating epoxy resin comprises, by mass, 3-15 parts of epoxy-based hyper-branched polysiloxane, 10-40 parts of polyfunctional epoxy resin, 60-90 parts of a bisphenol A type epoxy resin, and 25-40 parts of an amine-based curing agent. According to the present invention, the low-cost high-toughness self-lubricating epoxy resin has characteristics of low friction coefficient, strong bearing capacity, good toughness and the like, can be usedas the resin matrix of electronic packaging materials, wear-resistant coatings, structural composite materials and the like in the fields of aerospace, electronic machinery, nuclear industry and the like, and can be widely used, wherein the casting body of the low-cost high-toughness self-lubricating epoxy resin has an impact strength of more than 33.0 KJ / m<2>, a bending strength of more than 150MPa, a friction coefficient of less than 0.25, and a glass transition temperature of more than 220 DEG C.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

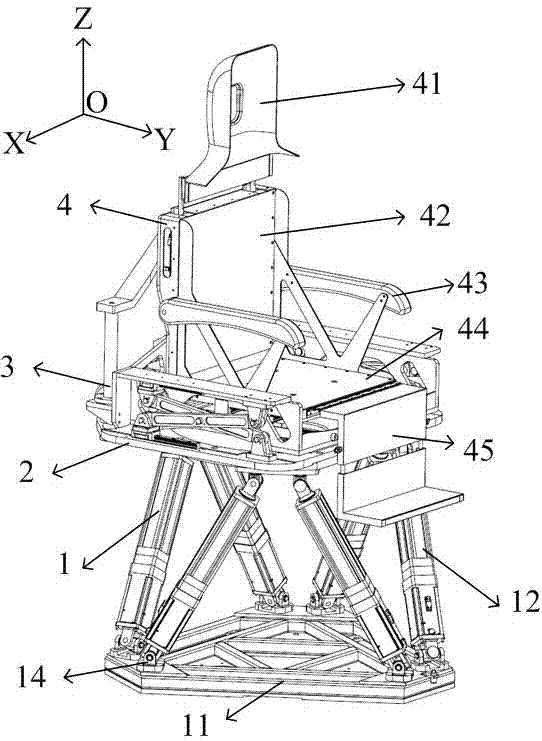

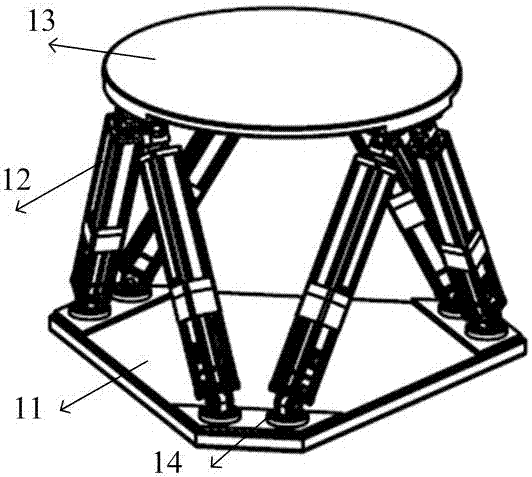

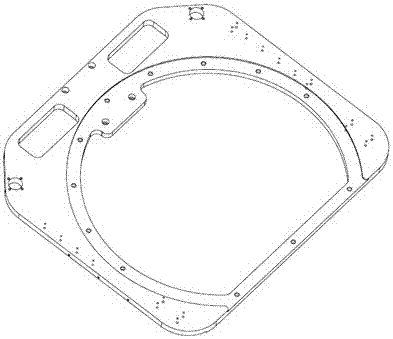

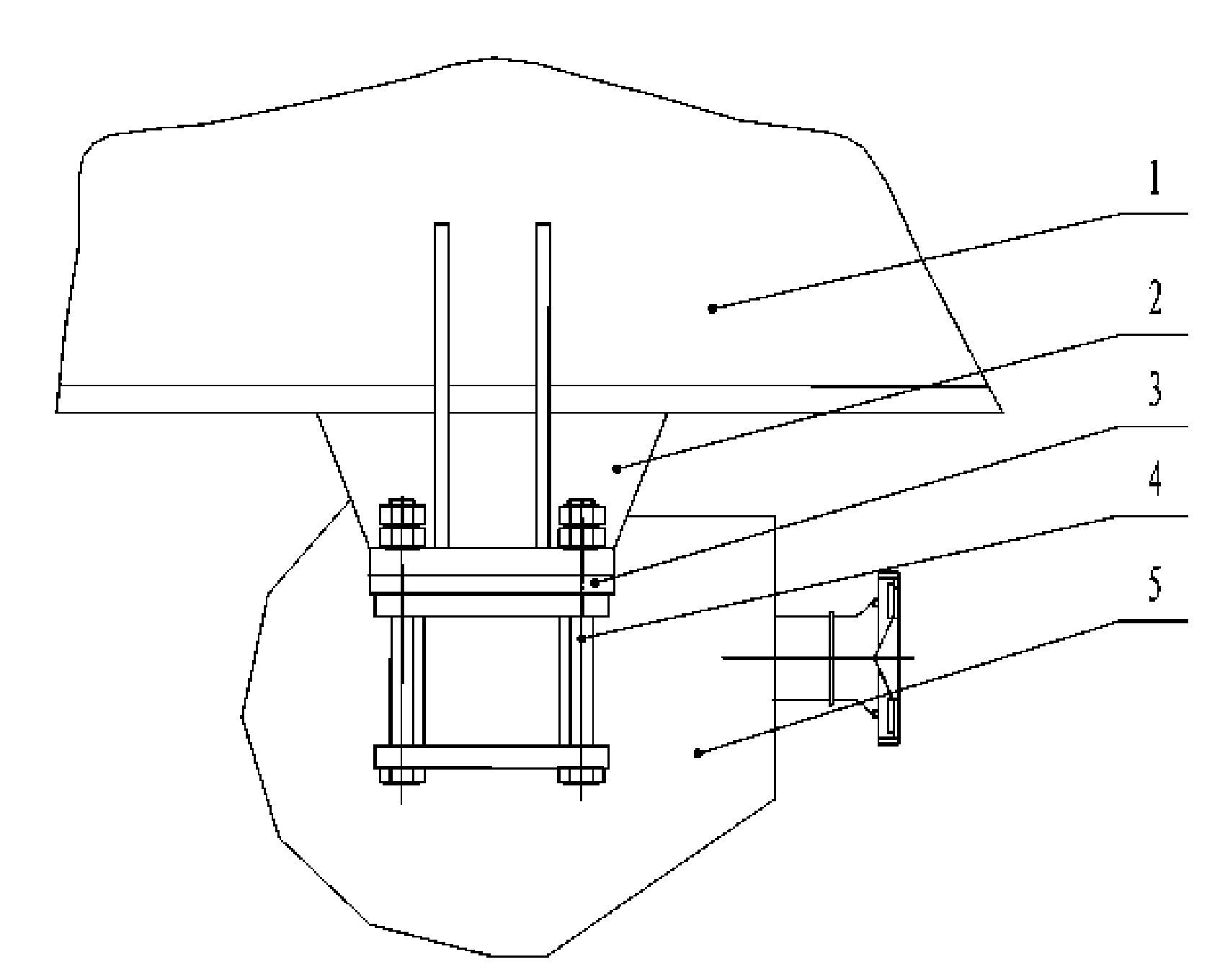

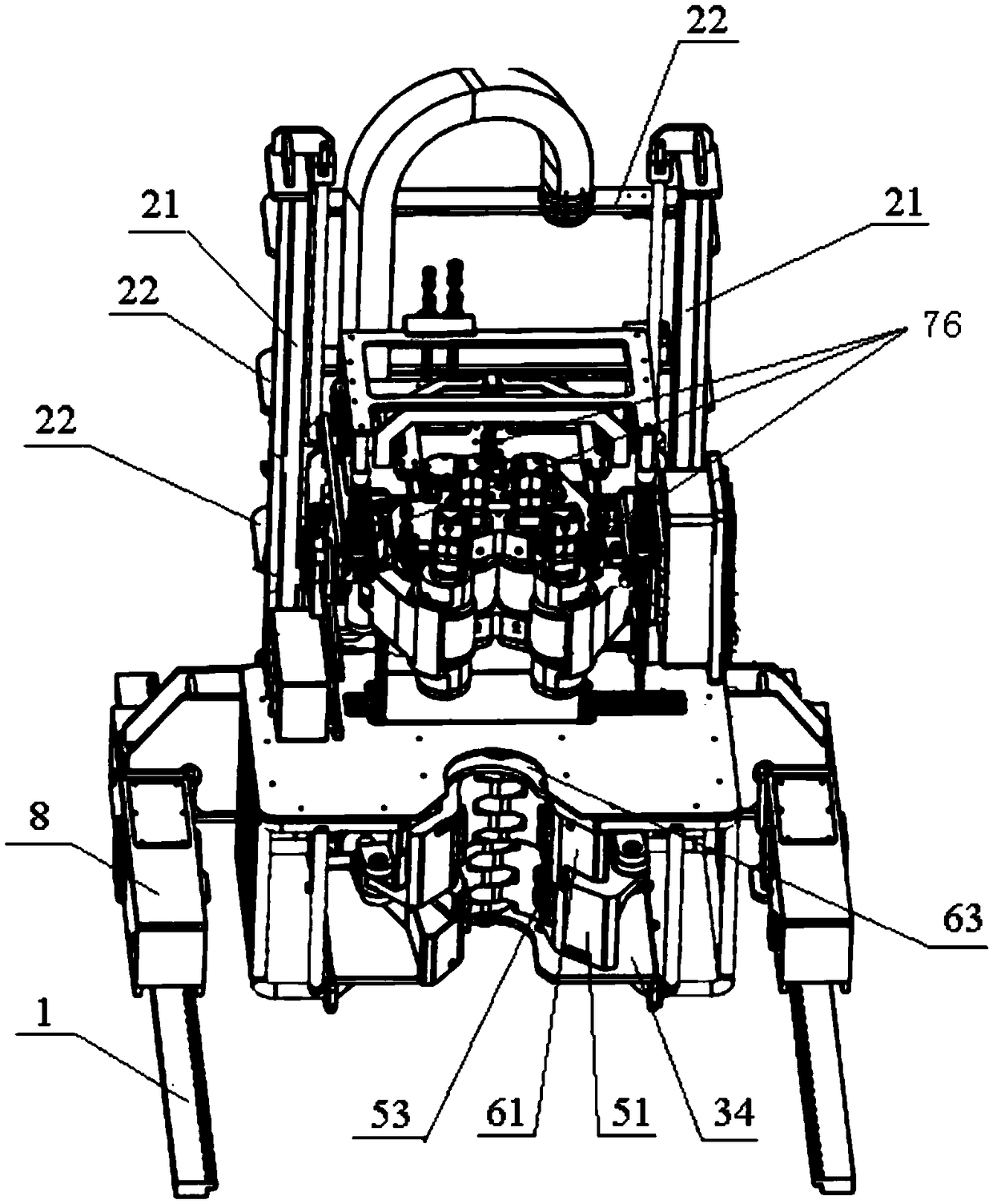

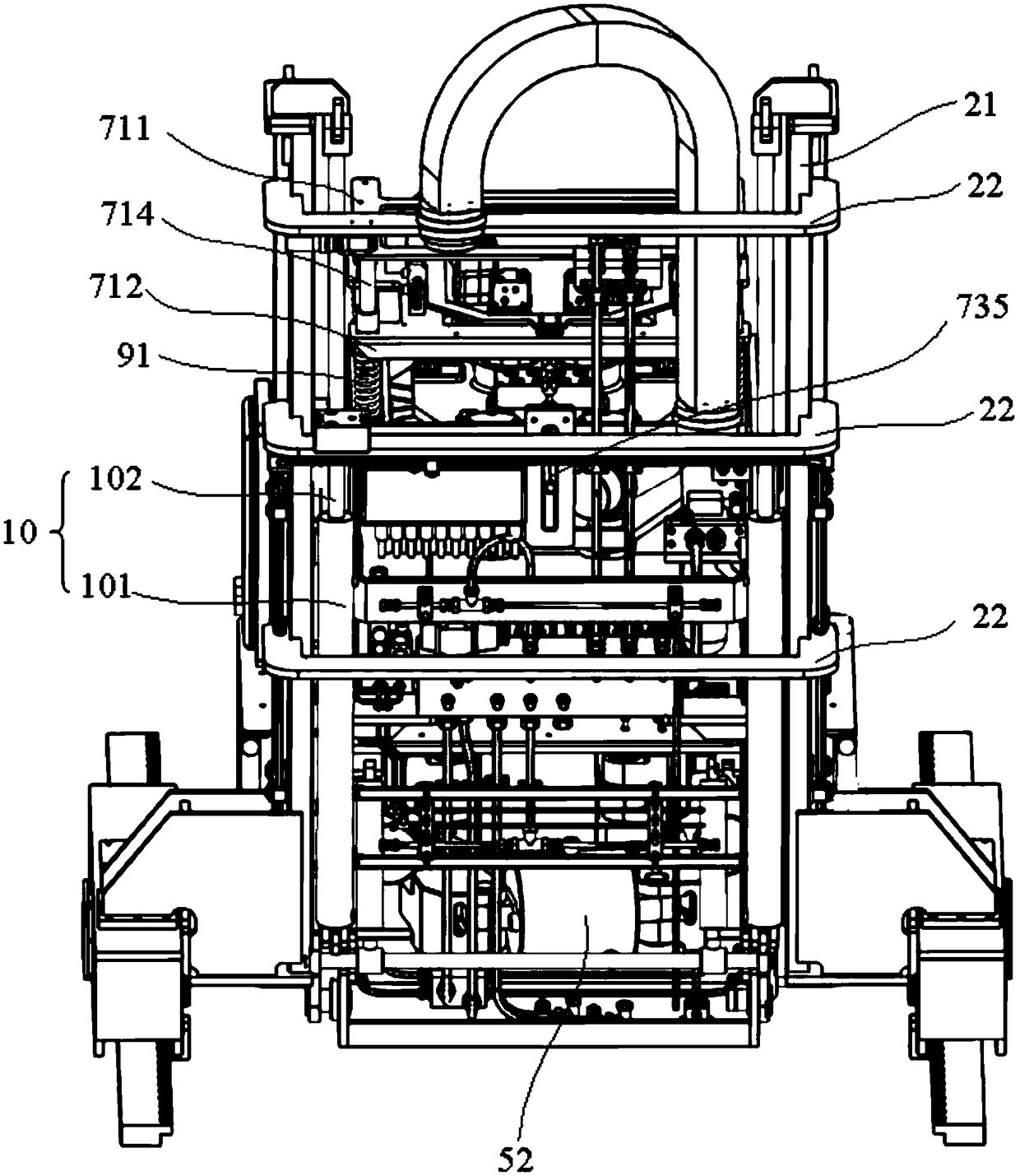

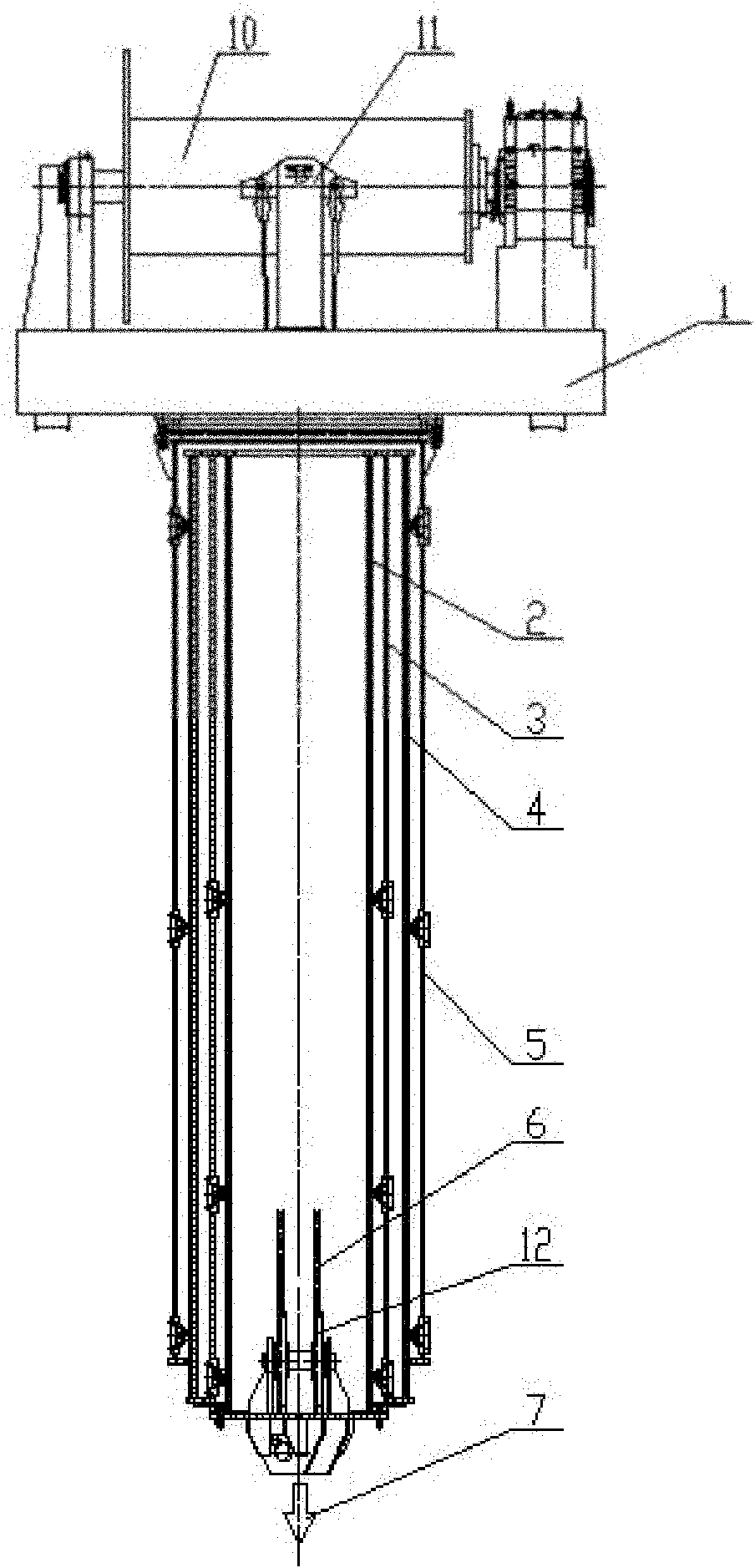

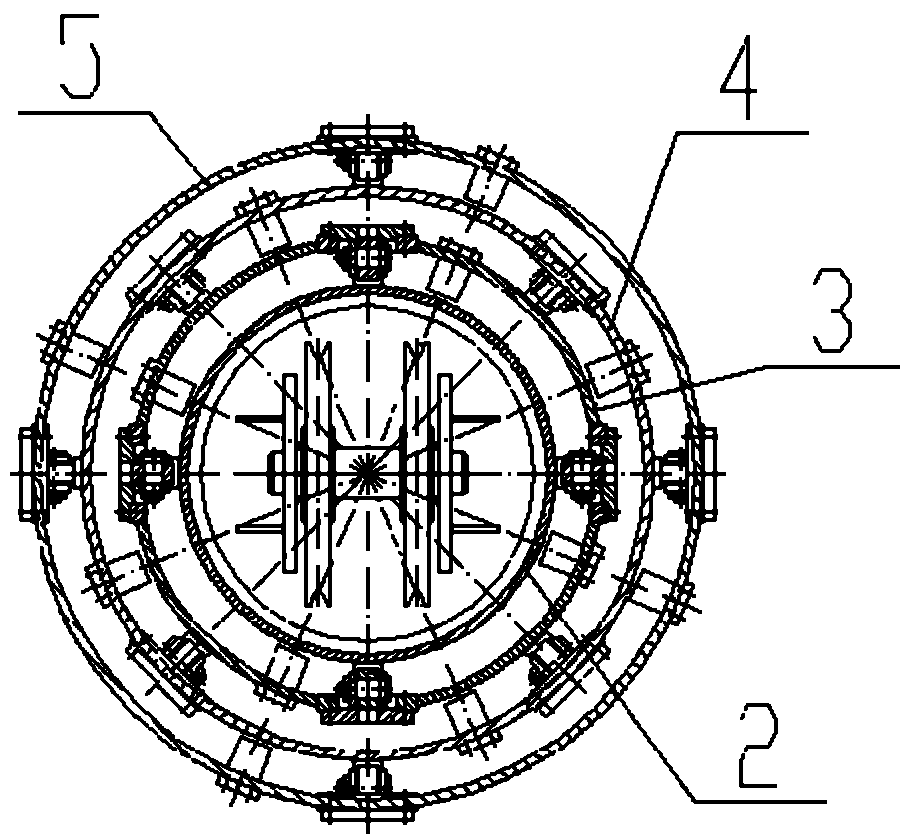

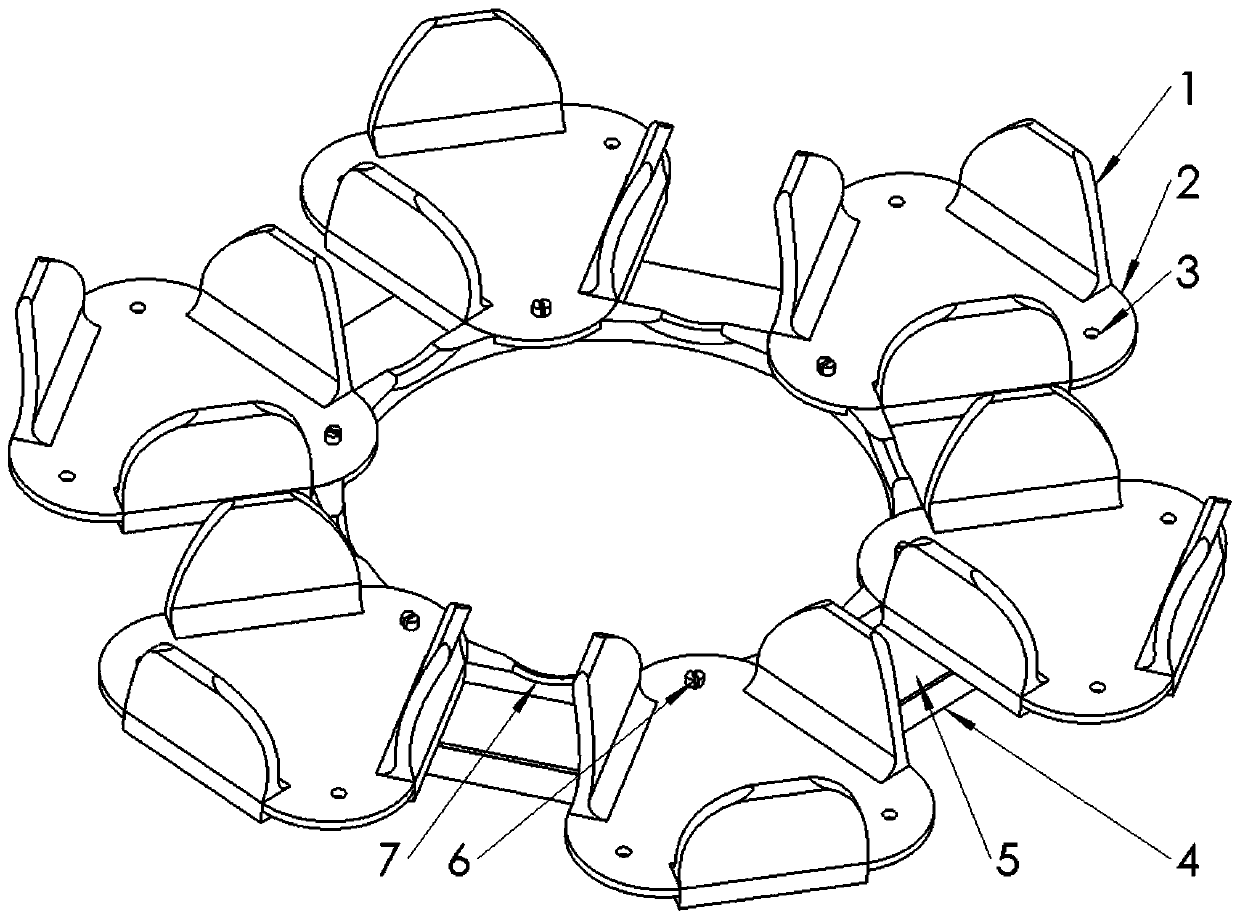

Automatic chair for treating cancers at heads and necks by using protons and heavy ions

PendingCN107007946ACompact structureStrong carrying capacityX-ray/gamma-ray/particle-irradiation therapyHandrailSix degrees of freedom

The present invention relates to an automatic chair for treating cancers at heads and necks by using protons and heavy ions and belongs to the medical apparatus and instrument field. The automatic chair comprises a six-degree-of-freedom parallel platform, a mounting plate, a three-dimensional translation platform and a chair; the mounting plate is square; the three-dimensional translation platform is fixed on the upper platform of the six-degree-of-freedom parallel platform through the mounting plate; and the chair includes a backrest, armrests, a seat and a footrest, wherein the seat is fixed on the three-dimensional translation platform by bolts. According to the automatic chair of the invention, the three-dimensional translation platform is adopted, so that the motion range of the automatic chair can be extended, and the problem of the stroke range coupling of various directions of an automatic chair using a six-degree-of-freedom parallel platform scheme can be solved.

Owner:成都博士科技有限公司

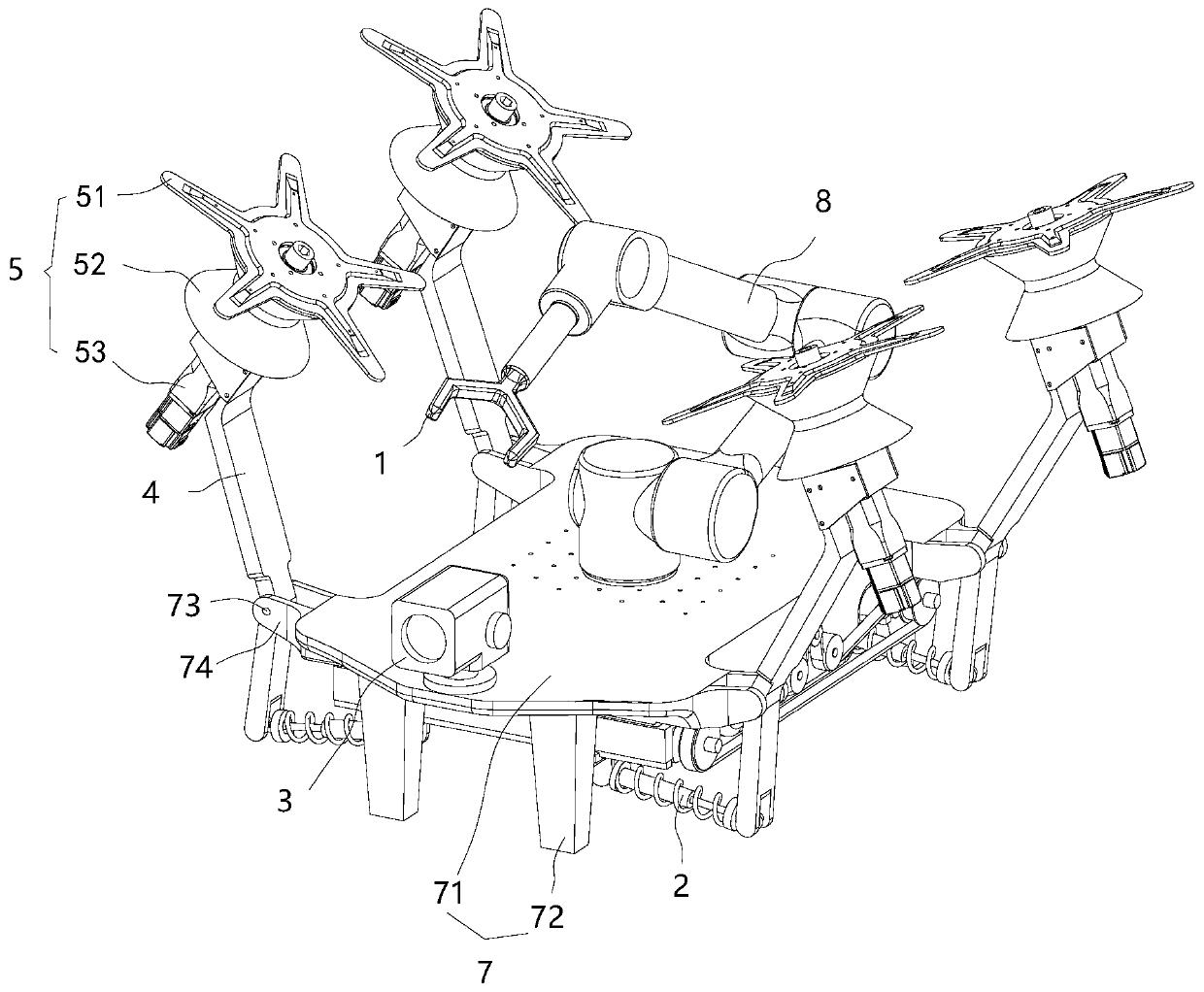

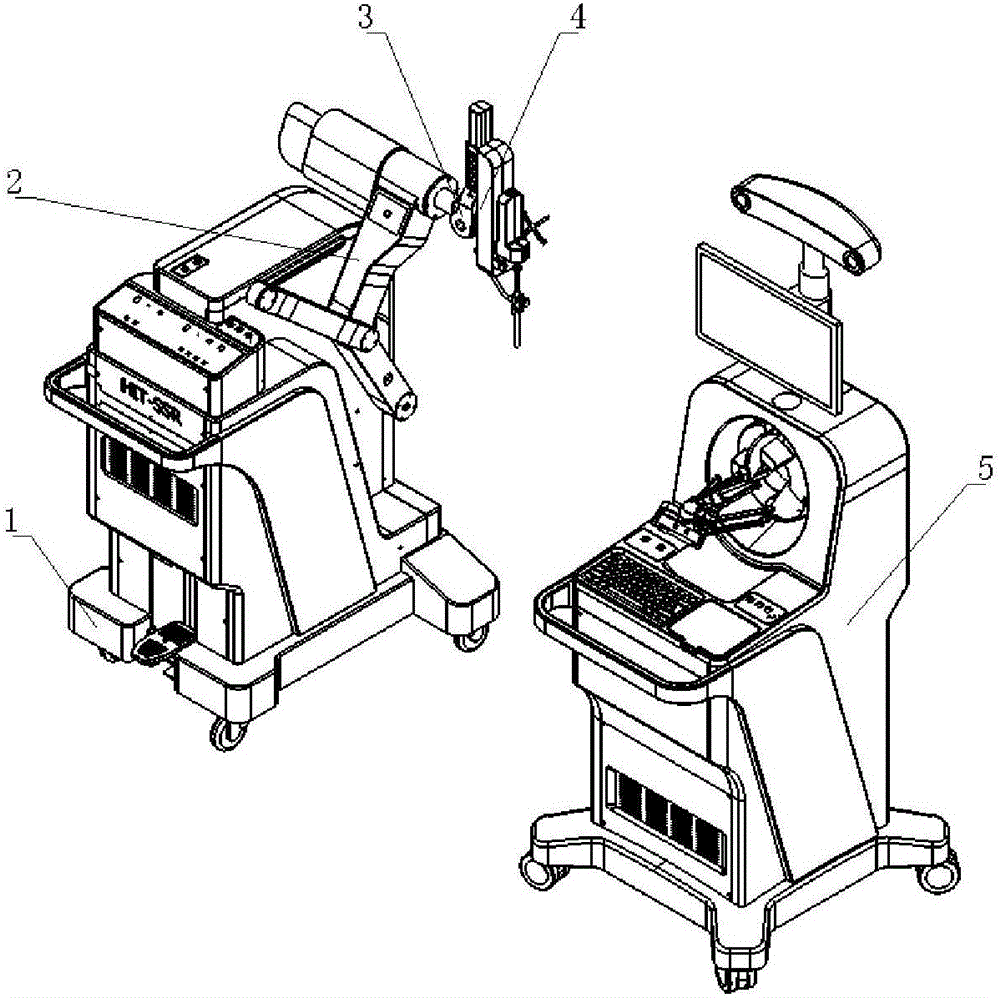

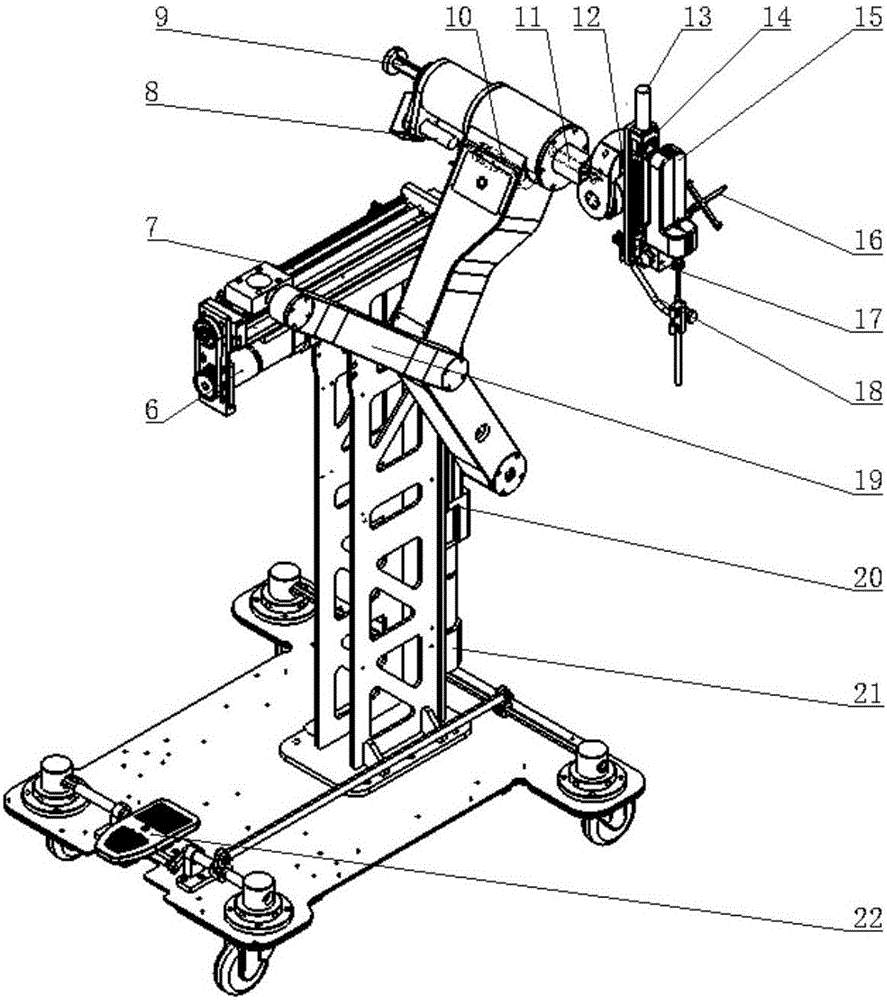

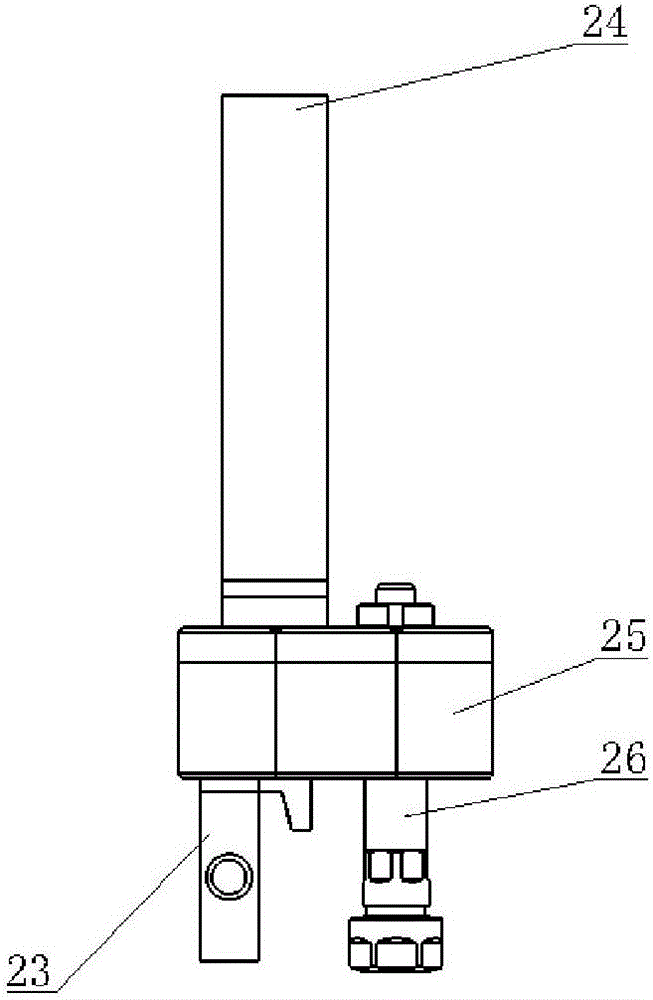

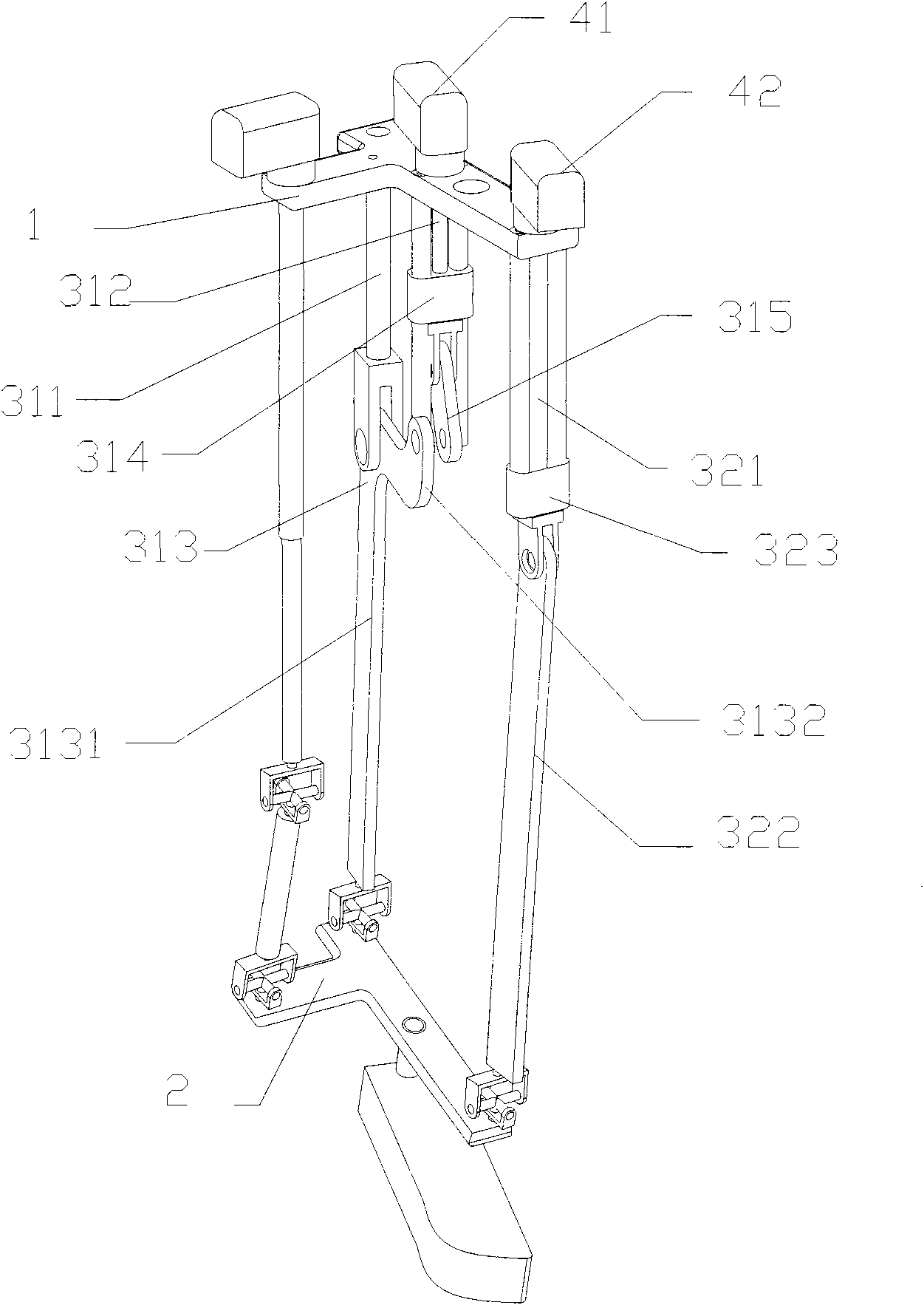

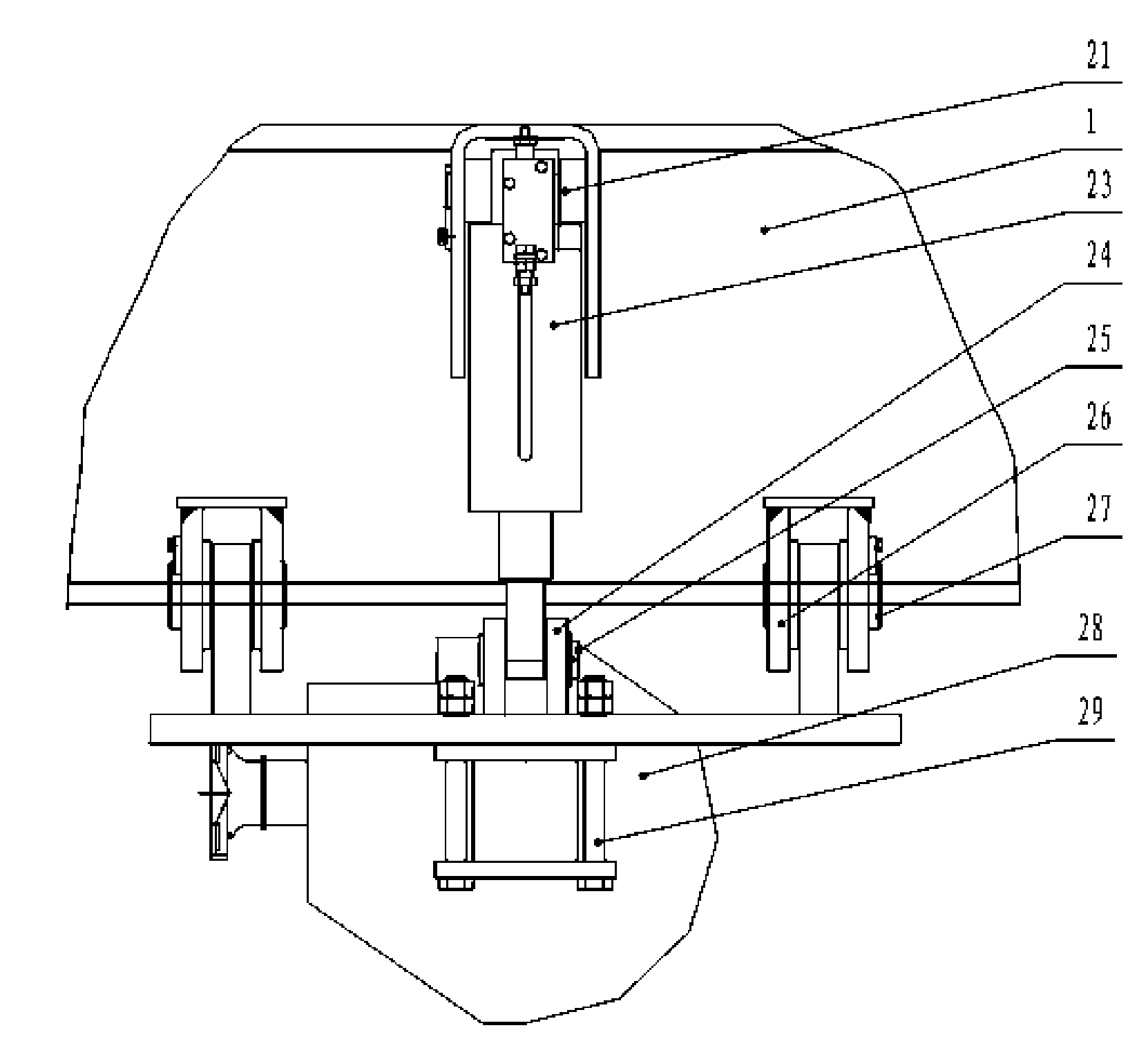

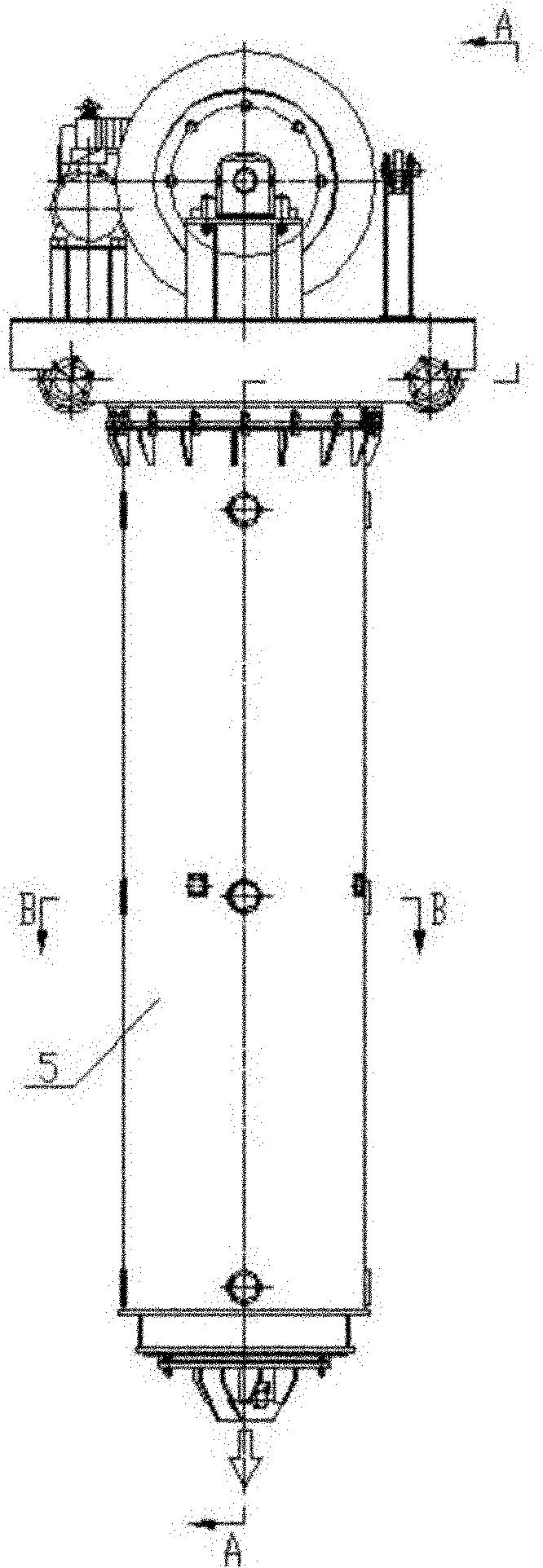

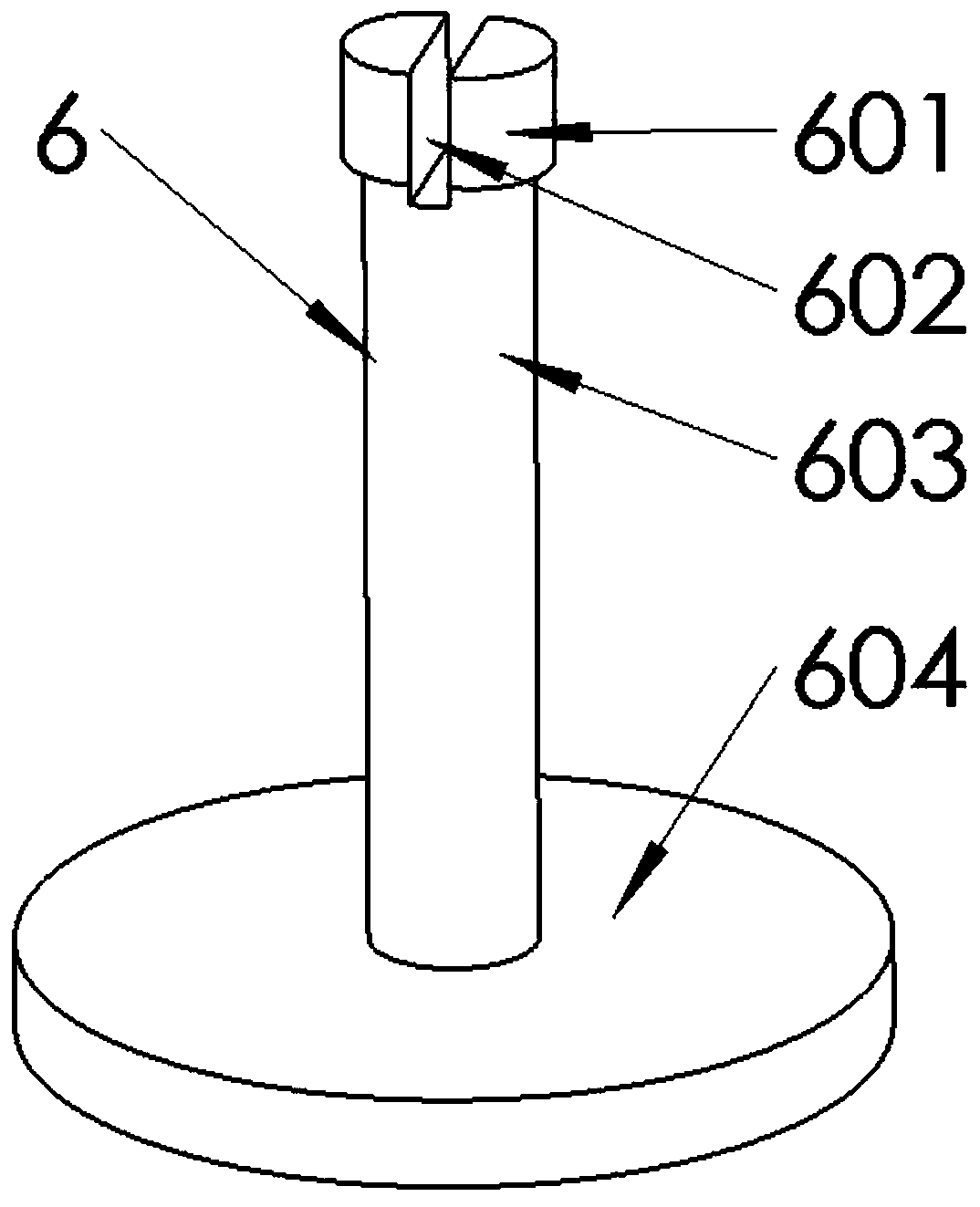

Minimally-invasive spine surgery robot

ActiveCN106344162ALarge working spaceStrong carrying capacitySurgical robotsOsteosynthesis devicesSacroiliac jointInvasive surgery

The invention relates to a minimally-invasive surgery robot, in particular to a minimally-invasive spine surgery robot. The problem that an existing minimally-invasive spine surgery robot is high in requirement for operation accuracy is solved. The minimally-invasive spine surgery robot comprises a base, a main mechanical arm, a sliding table, a support, a horizontal linear moving mechanism, a vertical linear moving mechanism, a movable joint assembly and a needle retaining mechanism; the middle of the main mechanical arm is installed at the upper end of the support through the horizontal linear moving mechanism, the support is installed on the base, the vertical linear moving mechanism is installed at one side of the support, the lower end of the main mechanical arm is connected with the vertical linear moving mechanism, the sliding table is installed at the upper end of the main mechanical arm through the movable joint assembly, and the needle retaining mechanism is installed on the movable joint assembly. The minimally-invasive spine surgery robot belongs to the field of medical machines.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

Locking device for multistage actuating cylinder

ActiveCN106275392AStrong carrying capacityExpand stroke lengthUndercarriagesEngineeringLaunch vehicle

The invention provides a locking device for a multistage actuating cylinder. The locking device comprises an end cover, an outer barrel, a middle barrel, an inner barrel, upper and lower sliding sleeves, upper and lower unlocking sleeves, upper and lower locking clamp rings, upper and lower limiting clamp rings, connecting screws, upper and lower elastic elements as well as upper and lower steel balls. A highly bearing steel ball locking mechanism is combined with the multistage actuating cylinder, so that the mechanism has high bearing capacity in a locked state, guarantees long unfolding travel of the actuating cylinder, realizes a reusable function on the basis of reliable locking and unlocking, and is applicable to landing support legs of reusable launch vehicles; meanwhile, the mechanism is simple to machine, convenient to mount, capable of realizing automatic collection and release and long in service life.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

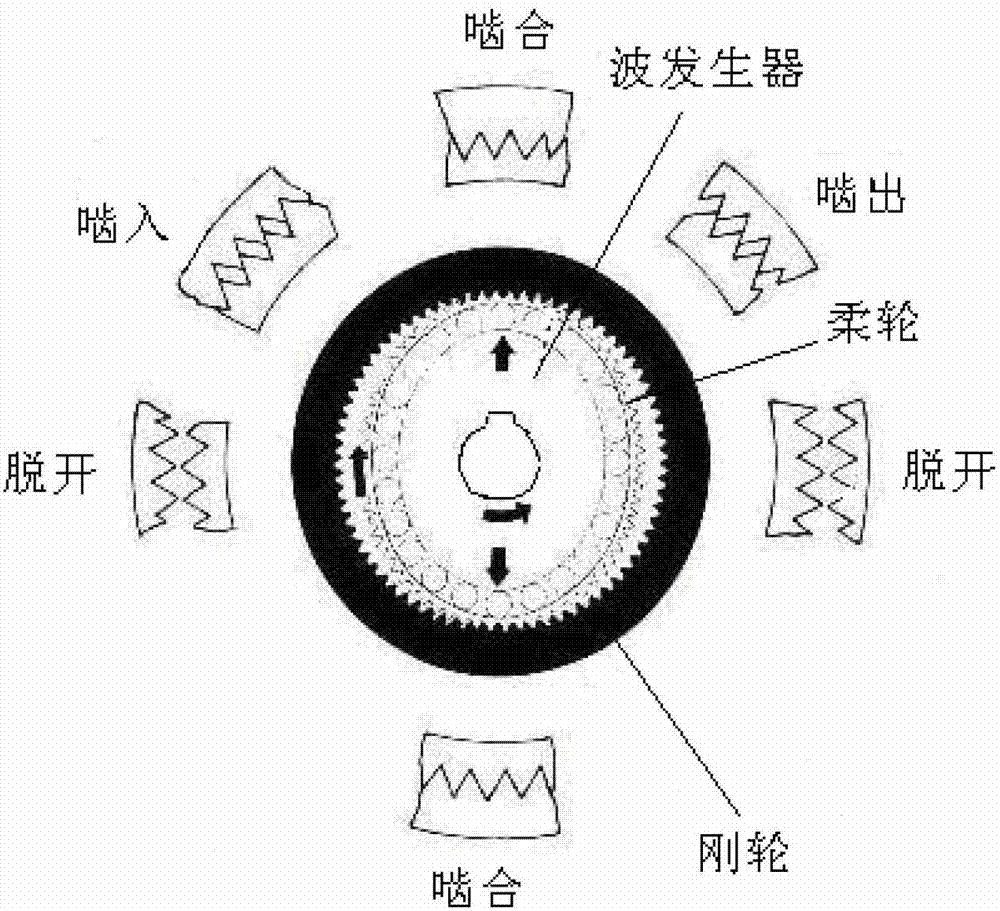

Air vehicle and electric steering engine capable of resisting large bending torque thereof

ActiveCN102765475AStrong carrying capacityPrevent radial displacementWith power amplificationFlight vehicleBending moment

The invention discloses an electric steering engine capable of resisting large bending torque. The electric steering engine capable of resisting the large bending torque comprises a harmonic speed reducer, an output shaft and a connection assembly, wherein the output shaft is fixedly connected with an output steel wheel of the harmonic speed reducer, and the connection assembly is arranged between the output shaft and a load, used for transmitting torque and fixedly connected onto an elastic body. According to the electric steering engine, the connection assembly additionally arranged between the output shaft and the load is used for transmitting the torque and fixedly connected onto the elastic body, so that the connection assembly bears the bending torque from the output shaft. By utilizing the elastic body to unload the bending torque, separation of a carrying object of the bending torque of the electric steering engine is achieved, and the output shaft is only responsible for transmitting the torque. Therefore, the electric steering engine has the advantages of being resistant to the large bending torque, high in reliability and strong in bearing capability, avoids radial displacement of the output shaft under the effect of the being torque, and meets the requirement for long service life of middle-long distance high-altitude air vehicles. The invention further discloses an air vehicle applying the electric steering engine capable of resisting the large bending torque. The air vehicle is high in reliability, long in service life and especially suitable for middle-long distance flight.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

Robot leg mechanism

A robot leg mechanism comprises a base and a moving platform, wherein the base is connected with the moving platform by a transmission mechanism; the transmission mechanism comprises a motor fixed on the base and a moving unit connected with the motor; the moving unit comprises a first moving unit which can lead the robot leg mechanism to swing backwards and a second moving unit which can lead the moving platform to be pressed downwards or lifted; the first moving unit comprises a supporting rod with the top end fixed on the base, a first screw rod mechanism connected with a first motor, and a first rod with constant length hinged with the moving platform; the first rod with constant length comprises a straight-rod part and a lug part protruding outwards, the supporting rod is hinged with the straight-rod part, and the first screw rod mechanism is hinged with the lug part; the second moving unit comprises a second screw rod mechanism connected with a second motor, and a second rod with constant length hinged with the moving platform, and the second screw rod mechanism is hinged with the second rod with constant length. The robot leg mechanism has the advantages of simple structure, strong bearing capability, small volume, and good processing and assembling technology.

Owner:ZHEJIANG UNIV OF TECH

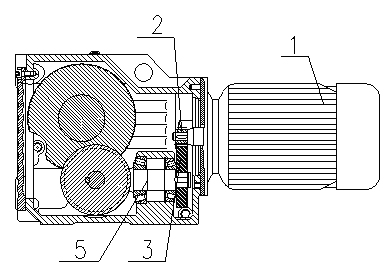

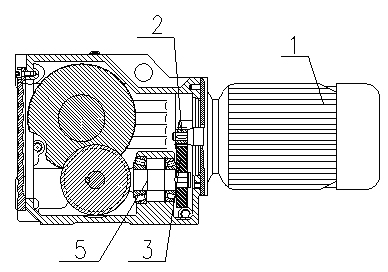

Spiral wheel-spiral bevel gear retarder

InactiveCN102062173AStrong carrying capacityLarge transmission torqueGearboxesToothed gearingsThree levelFastener

The invention discloses a spiral wheel-spiral bevel gear retarder, which comprises a motor for supplying power, a flange cover, fasteners and various transmission gears, wherein the flange cover and the fasteners are used for installing and fixing the motor. The flange cover of the motor is fixedly installed on an input surface of a box body via a positioning spigot and the fasteners, an output shaft of the motor is fixedly provided with first level small spiral wheels via bonds and a stop ring, and the first level small spiral wheels are meshed with first level large spiral wheels which are fixedly installed on a shaft table at one end of a cone-shaped gear wheel shaft via bonds and a stop ring. The small cone-shaped gears at both ends of the cone-shaped gear wheel shaft are meshed with the large spiral wheel gears. The large spiral wheel gears are fixedly installed on a three level gear shaft via keys and the three level gear shaft is meshed with the output large spiral wheel which is fixedly installed on the output shaft via keys. The invention has the advantages of strong bearing capacity, large transmission torque, good wear-resisting property and long service life, thereby alleviating the axial load of a bearing and prolonging the service life of the whole machine and greatly reducing the quantity of gear pairs and the production cost.

Owner:SHANGHAI LONGXIE ELECTRONICS TECH

Oscillating suspension system of crane

InactiveCN101585490ASimple structureStrong carrying capacityResilient suspensionsCranesAutomotive engineeringEngineering

This invention discloses an oscillating suspension system of crane, including a chassis of vehicle, front and rear suspensions. It is characterized that the front suspension includes a front suspension support fixed to the chassis. The front suspension support is rigidly connected with a front drive bridge. The rear suspension is articulated with the support via a pin shaft. The direction of the pin shaft is perpendicular to the direction of a wheel shaft. Two locking oil tanks are symmetrically mounted at two sides of the pin shaft and between the rear suspension and the chassis. A connecting conduit of a chamber with rod and a chamber without rod of the locking oil tank is provided with a control valve set controlled by an electric control system. The rear suspension is rigidly connected with a rear drive bridge. The oscillating suspension system of crane provided by this invention is characterized that it can be flexibly applied to the crane to work at different pavements and under different bearing changes and it has simple structure, strong bearing ability, convenient distribution and low manufacturing cost.

Owner:四川长起起重设备有限公司

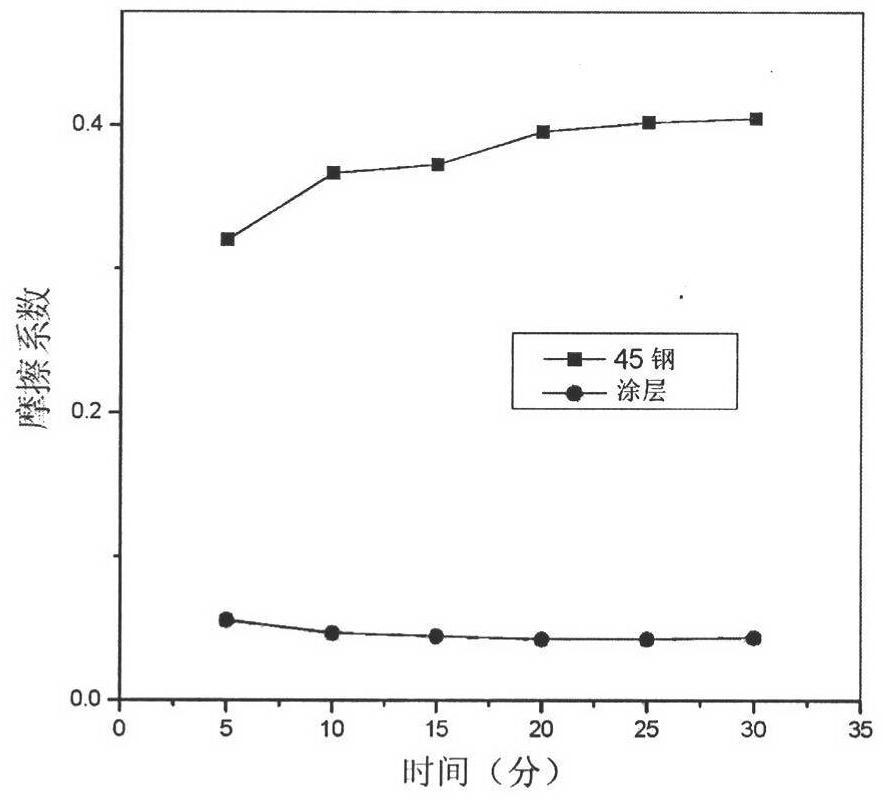

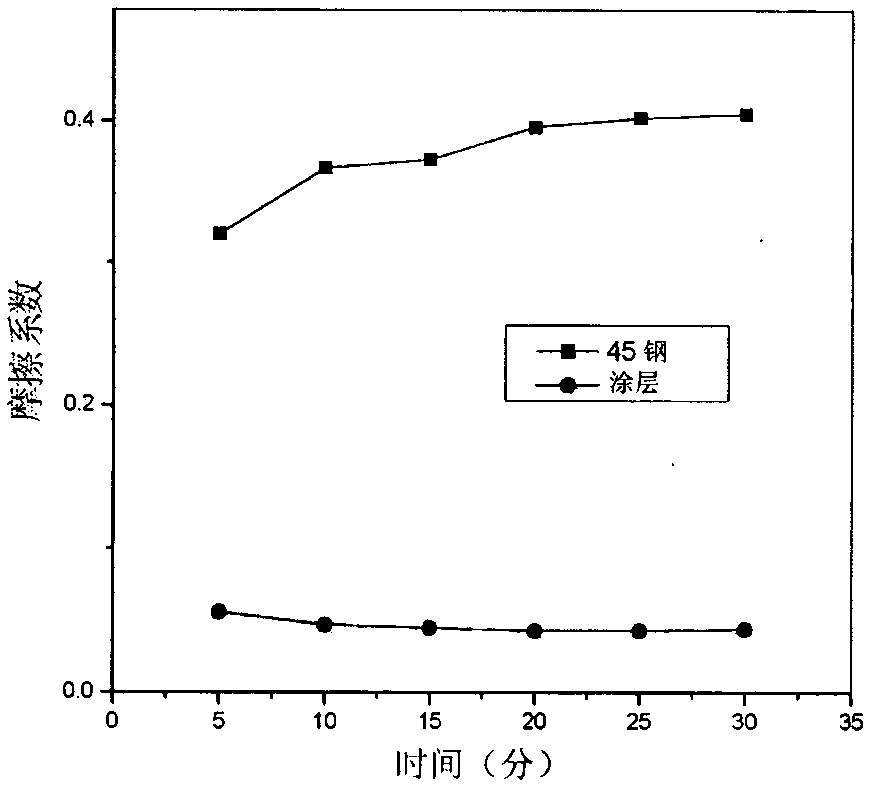

Anti-friction self-lubrication complex paint

InactiveCN102408761AReduce coefficient of frictionStrong carrying capacityAlkali metal silicate coatingsLubricationAdhesive

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

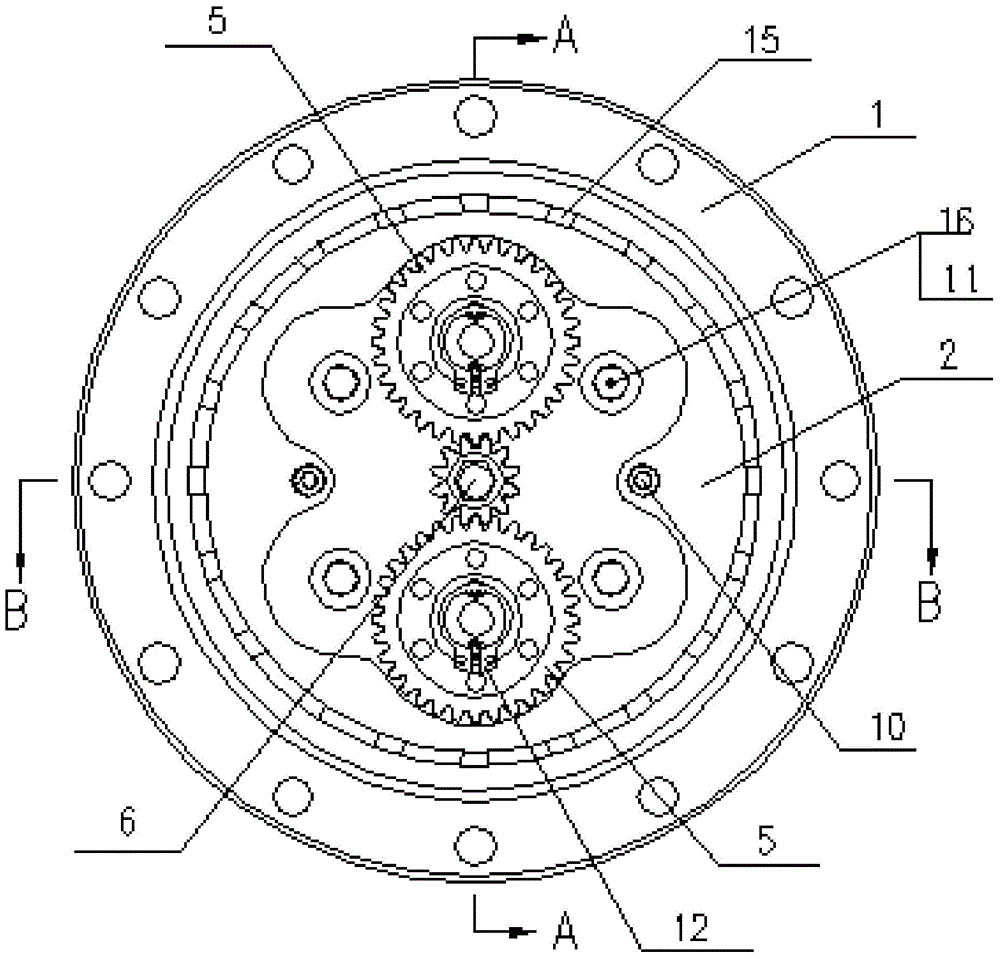

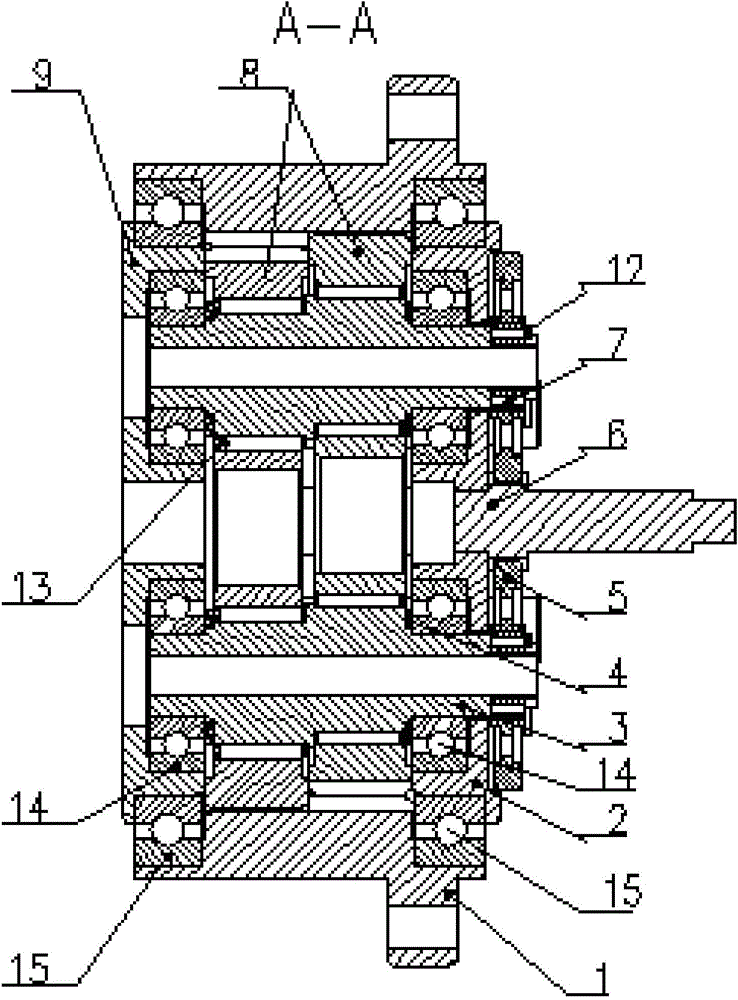

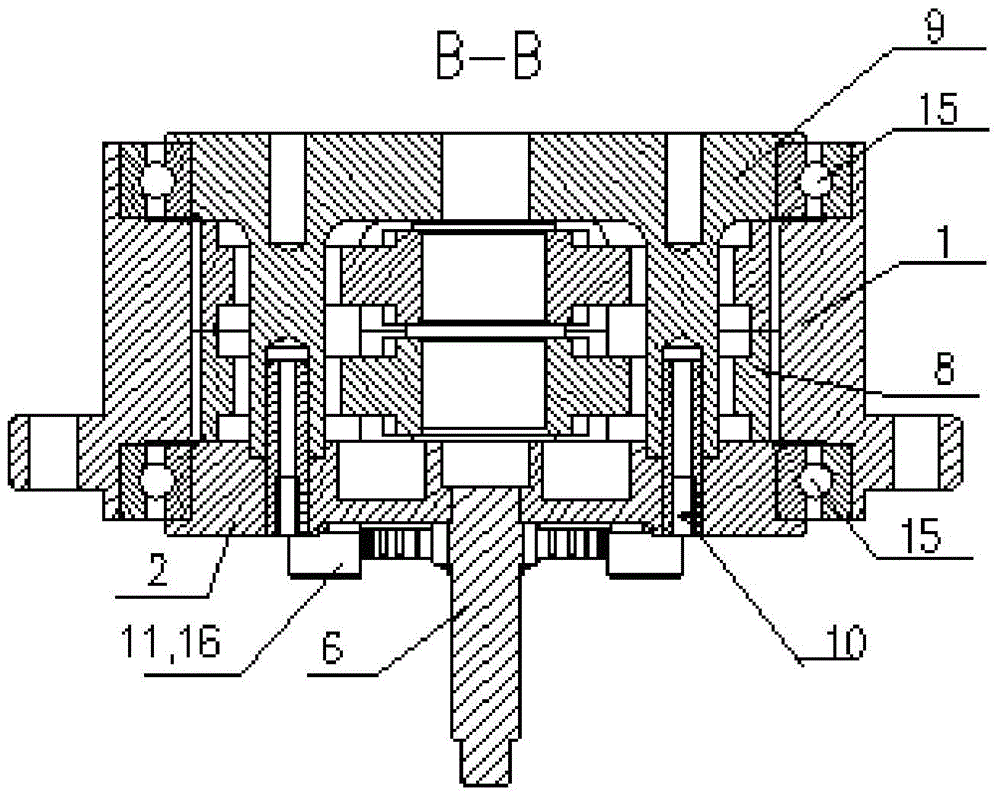

RV speed reducer based on CTC (Centralized Traffic Control) circular arc and single circular arc few tooth difference planetary transmission

InactiveCN104565218AStrong carrying capacityHigh precisionToothed gearingsGearing detailsEngineeringMachining process

The invention belongs to a speed reducer, and particularly discloses an RV speed reducer based on CTC (Centralized Traffic Control) circular arc and single circular arc few tooth difference planetary transmission. The speed reducer comprises a fixing seat, input end flanges, eccentric shafts, planetary wheels, a gear shaft, outer gears and output end flanges, wherein the middle parts of the eccentric shafts are sleeved with the outer gears; the outer gears are arranged on the fixing seat in a sleeving way; one end of each eccentric shaft is sleeved with one planetary wheel; the input end flanges are arranged between the eccentric shafts and the planetary wheels; the planetary wheels are meshed with the gear shaft arranged in the input end flanges through gears; the output end flanges are arranged between the other ends of the eccentric shafts and the fixing seat. The speed reducer has the advantages of compact structure, simple machining process, high transmission accuracy, high carrying capability, large torsion rigidity and stable transmission, and can meet the severe working condition requirements of aerospace servo mechanisms.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

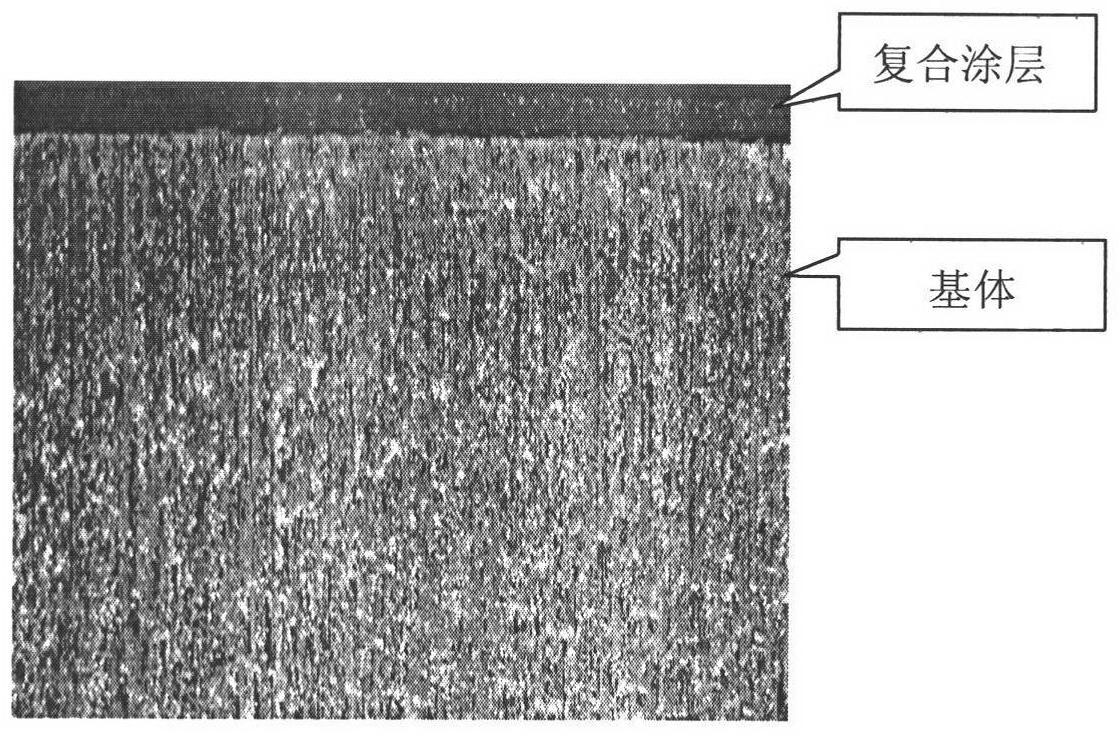

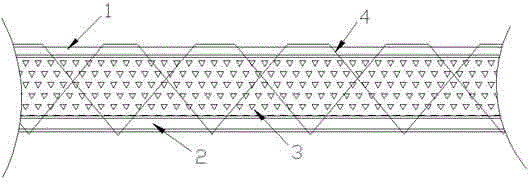

Three-dimensional reticular texture structure composite coating and preparation method thereof

InactiveCN105624668AStrong carrying capacityImprove wear resistanceMetallic material coating processesMetal substrateDiffusion effect

The invention provides a three-dimensional reticular texture structure composite coating and a preparation method thereof. The three-dimensional reticular texture structure composite coating is composed of a texture structure composite layer region (1), a transition region (2), and a diffusion effect region (3); an effective metallurgical bonding is formed between the coating and a substrate; fine hard particles in the composite region (1) are uniformly distributed between spherical granular alloys to form a three-dimensional reticular texture; the width of the reticular texture between the particles is 20-30 microns, and a space between the hard particles is about 5-10 microns. The preparation method of the three-dimensional reticular texture structure composite coating comprises the following steps: (1) metal substrate treatment; (2) coating powder mixing; (3) preparation of a prefabricated layer, in which the substrate is coated with a 1-2mm thick nickel-based alloy powder in advance to serve as a transition layer before a composite powder partially added with WC is applied; and (4) sintering of a three-dimensional texture coating: naturally drying the product produced through the step (3) in the shade, and then drying the same again, followed by sintering, increasing the temperature, and preserving heat in a vacuum environment, and then carrying out cooling along with a furnace to 150 DEG C, discharging the product from the furnace, and cooling the product to a room temperature, thereby obtaining the product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

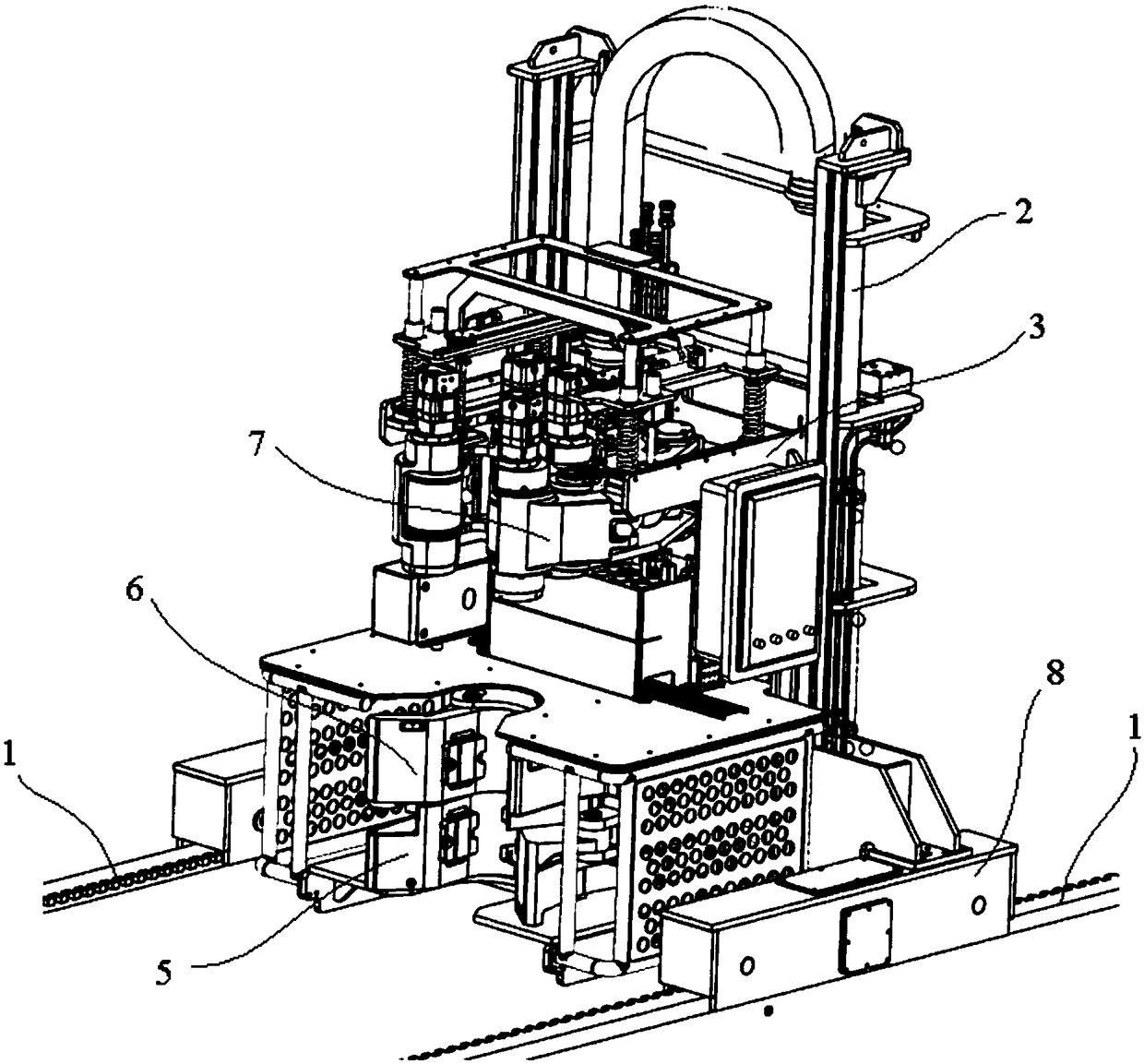

Iron roughneck

PendingCN108643850AGreat practicabilityStrong carrying capacityDrilling rodsDrilling casingsWellheadWrench

The invention discloses an iron roughneck, and belongs to the technical field of oil drilling and well workover. The iron roughneck comprises a track, a walking frame, a lifting frame, a tilting mechanism, a back-up wrench, a punching and buckling wrench and a spinning wrench. The walking frame can move forwards, stop or return along the track through a walking mechanism. The lifting frame can belifted relative to the walking frame through a lifting mechanism, and the lifting frame can tilt relative to the walking frame through a tilting mechanism. The lifting frame comprises a tilting oil cylinder and a rotating frame, wherein the rotating frame is rotatably connected with the lifting frame, one of a cylinder body and a piston rod of the tilting oil cylinder is rotatably connected with the lifting frame, and the other of the cylinder body and the piston rod of the tilting oil cylinder is rotatably connected with the rotating frame. The back-up wrench, the punching and buckling wrenchand the spinning wrench are sequentially arranged on the lifting frame from bottom to top. According to the iron roughneck, the lifting frame of the iron roughneck can be tilted, after the track crosses a wellhead and a mouse hole, the iron roughneck can walk to two places for direct operation, and the practicability is wide.

Owner:荆州市明德科技有限公司

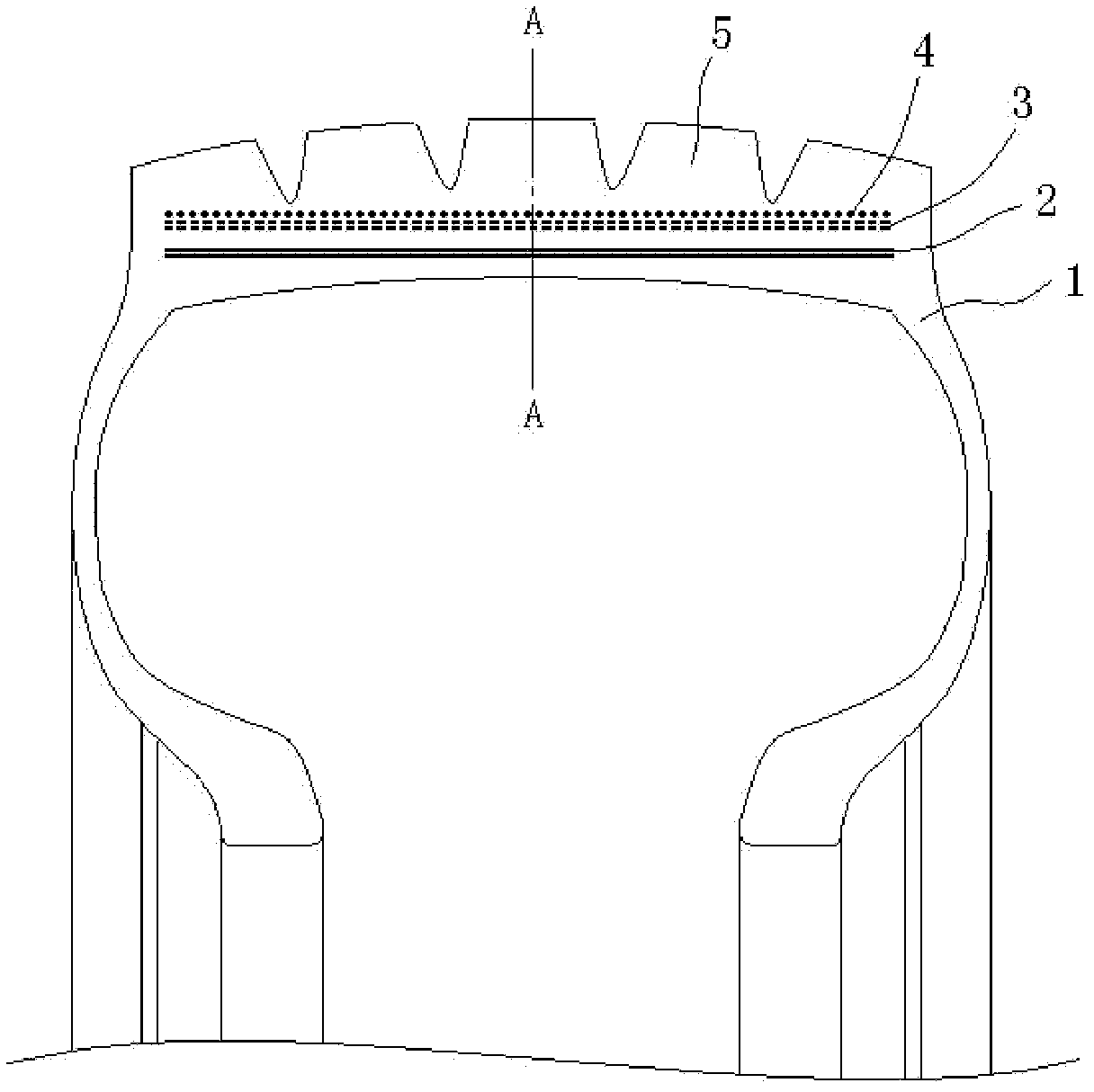

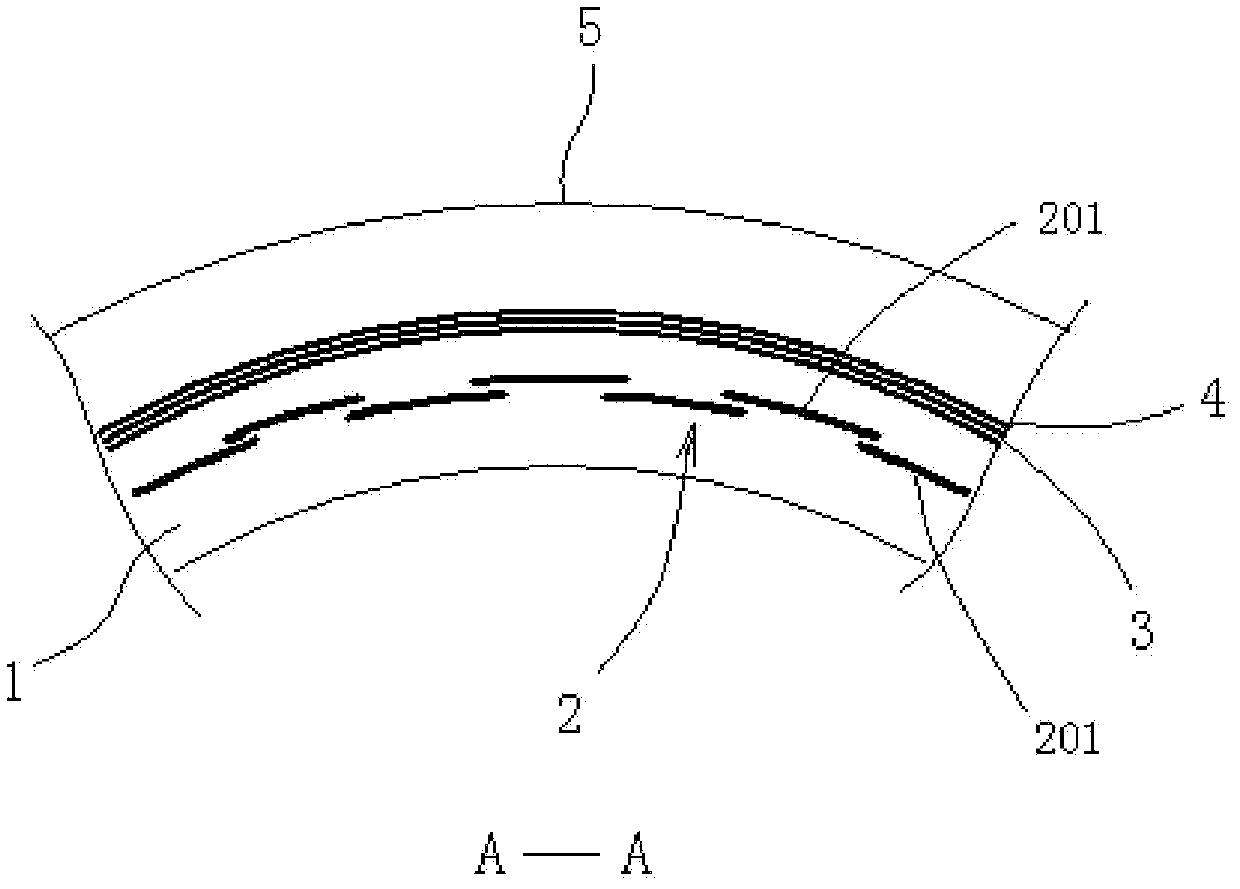

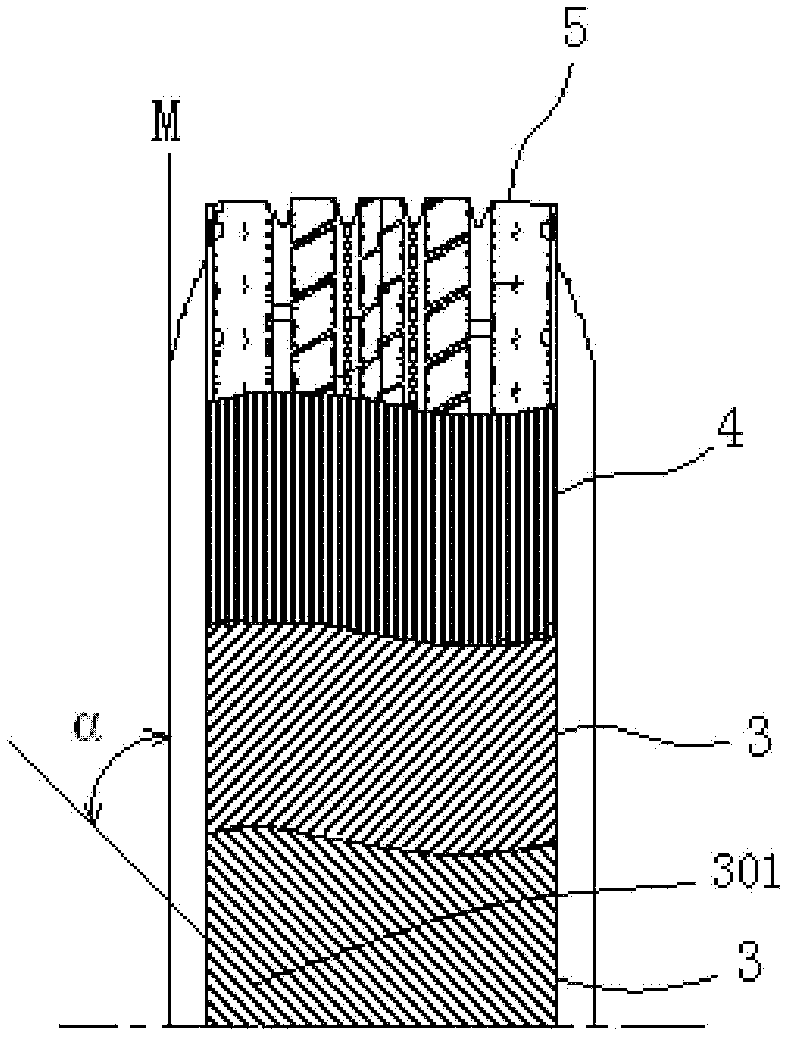

Anti-pricking tire

ActiveCN102602248AStrong carrying capacityTread balancePneumatic tyre reinforcementsAutomotive engineeringTire rotation

The invention discloses an anti-pricking tire, comprising a tire body, a tire tread integrally vulcanized with the tire body, or a tire tread matched with teeth and grooves on the tire body, wherein belted layers are arranged in the tire tread; and at least one of the belted layers is a spiral belted layer wound by steel wires along the rotary direction of the tire. According to the anti-pricking tire disclosed by the invention, the anti-pricking performance can be improved, and the service life can be prolonged.

Owner:罗茂湘

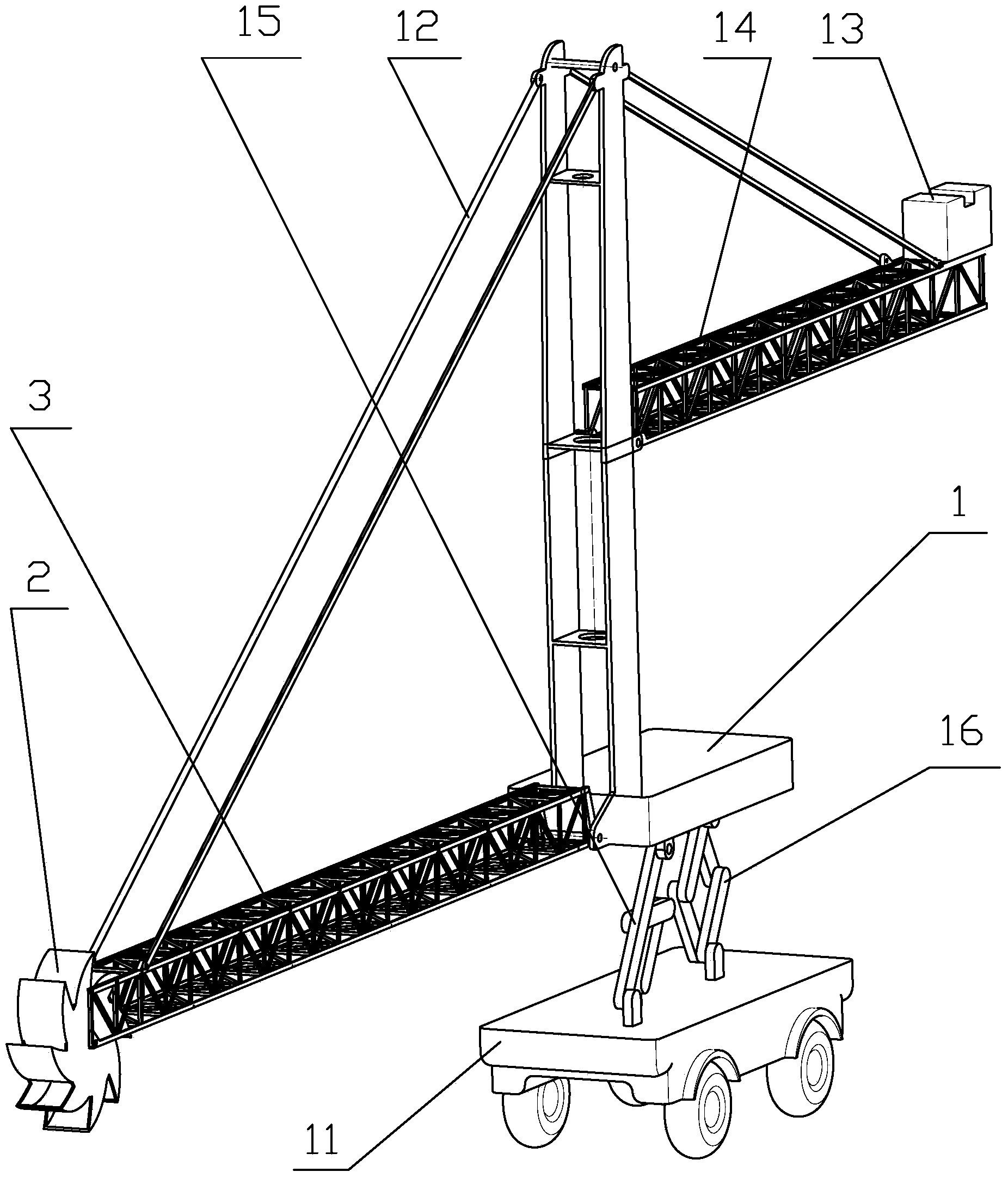

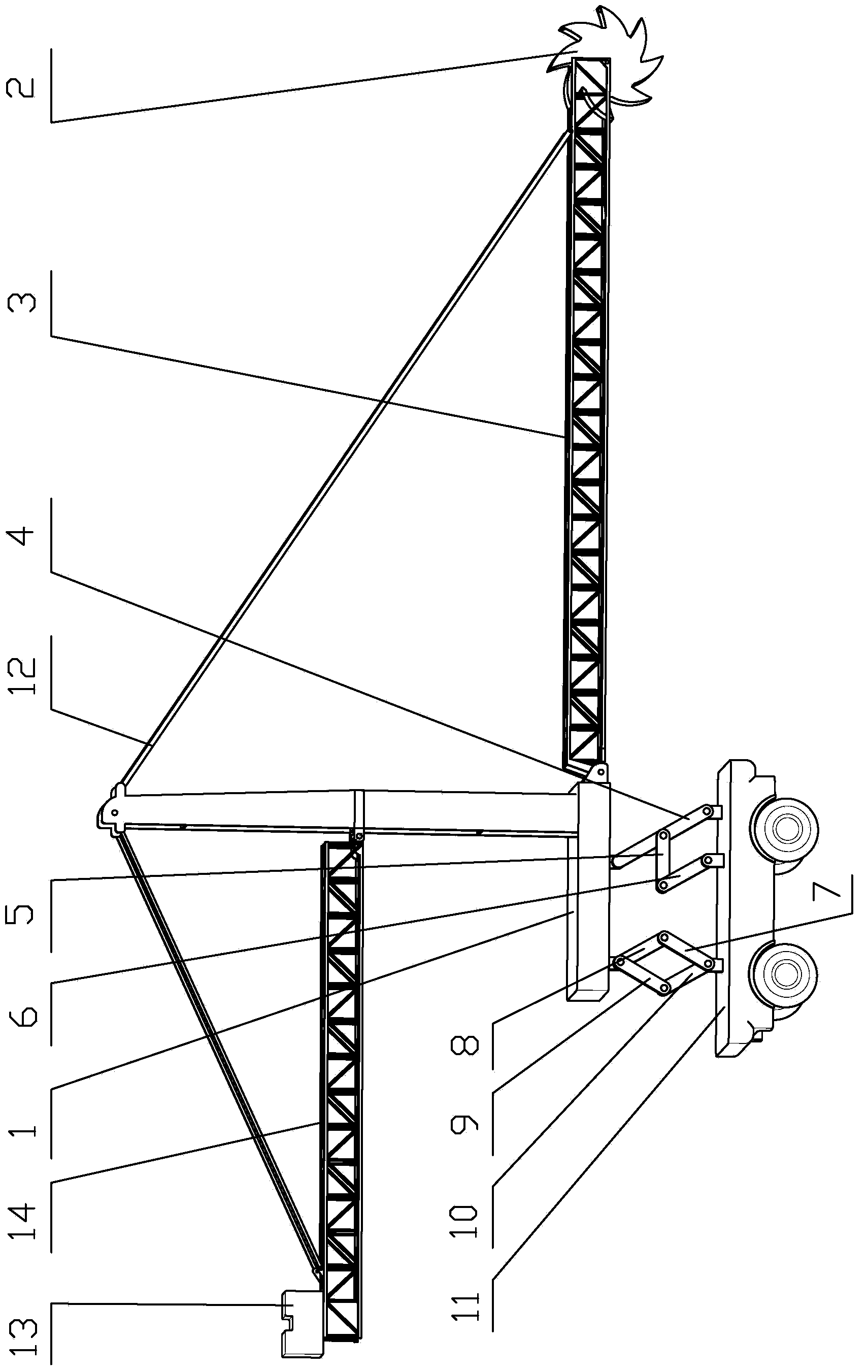

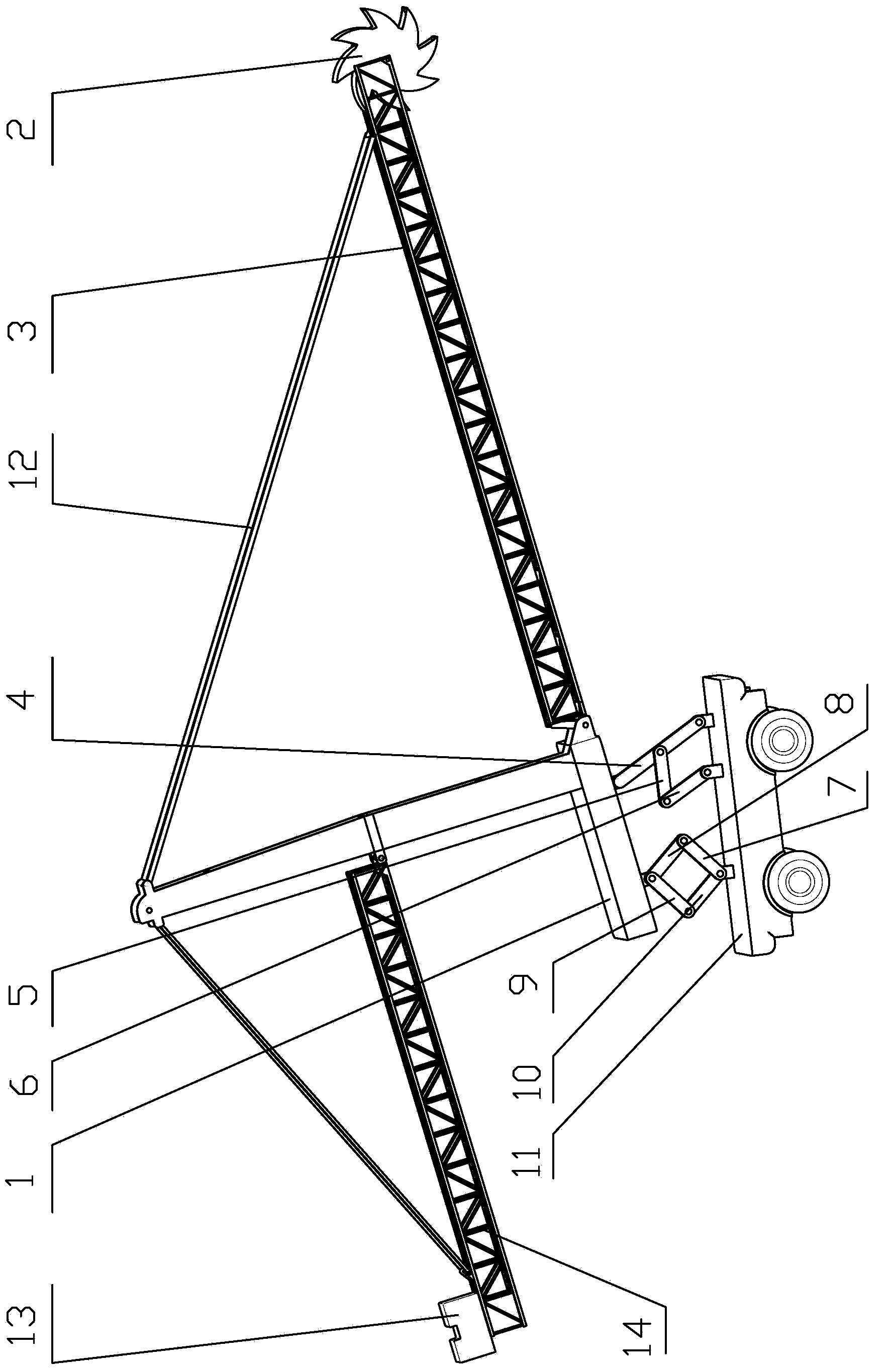

Hybrid-driven type bucket-wheel material stacking and taking machine

InactiveCN103950735AOutput flexibilityStrong carrying capacityLoading/unloadingVehicle frameHybrid drive

The invention discloses a hybrid-driven type bucket-wheel material stacking and taking machine. A bucket-wheel overhanging arm pitching device comprises a first stander pitching mechanism arranged at the front part of a frame and a second stander pitching mechanism arranged at the rear part of the frame, wherein the first stander pitching mechanism is a four-connecting-rod mechanism and comprises a first pitching rocker, a first pitching connecting rod and a first pitching swing rod; the second stander pitching mechanism is a parallelogram connecting rod mechanism which comprises a second front rocker and a second rear rocker which are positioned on the lower side and a second front connecting rod and a second rear connecting rod which are positioned on the upper side; hinge points of the rear bottom of a stander and the second front connecting rod and the second rear connecting rod form a composite hinge; the front bottom of the stander is hinged to the upper end of the first pitching swing rod; a bucket wheel is mounted at the front end of a bucket-wheel overhanging arm; the rear end of the bucket-wheel overhanging arm is hinged to the front part of the stander; an arm body at the front part of the bucket-wheel overhanging arm is pulled to the top of the stander through a traction rope in an inclined manner. By the adoption of motor hybrid driving, the hybrid-driven type bucket-wheel material stacking and taking machine has the advantages of output flexibility, high bearing capacity and the like.

Owner:QINZHOU UNIV

Suture technique enhanced foam sandwich hat stiffened wall panel structure and forming method thereof

ActiveCN104554701AHigh strengthStrong carrying capacityFuselage bulkheadsFibrous compositesSurface plate

The invention relates to an improved suture technique enhanced foam sandwich hat stiffened wall panel structure and a forming method thereof, belonging to the technical field of fiber composite enhancement. The foam sandwich hat stiffened wall panel structure is characterized in that the suture technique is used for the foam sandwich hat stiffened wall panel and is used for improving the strength and stiffness of the hat stiffened wall panel. The method comprises the following steps: firstly, laying hat ribs and skin on a stiffened wall panel mould; secondly, perforating a foam core material along the thickness direction according to the pre-designed perforation pattern (the perforation directions of front and rear rows are symmetric along the vertical foam centerline) in a foam sandwich; thirdly, suturing upper and lower panels and the core material with a suture together; finally, combining and packaging the hat ribs, and solidifying. The strength, stiffness and stability of the composite hat stiffened wall panel structure are obviously improved. According to the bearing capacity required by the enhanced hat stiffened wall panel, the suture parameter meeting the requirement can be designed. The suture foam sandwich structure provided by the invention has the advantages of strong bearing capacity, simple manufacturing process, high structural efficiency and low manufacturing and maintenance cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Crane hoisting mechanism with extension sleeve

ActiveCN102009913AStrong carrying capacityReduce the processing surfaceLoad-engaging elementsEngineeringFlange

The invention discloses a crane hoisting mechanism with an extension sleeve, comprising a trolley frame, a steel wire rope, a winding drum, a balance arm and a movable pulley block. The crane hoisting mechanism is characterized in that the extension sleeve is composed of an extension sleeve assembly IV, an extension sleeve assembly III, an extension sleeve assembly II and an extension sleeve assembly I, wherein the extension sleeve assembly IV is sequentially sheathed with the extension sleeve assembly III, the extension sleeve assembly II and the extension sleeve assembly I. The circumferences of the extension sleeve assemblies IV, III, II are respectively equipped with four stop blocks and four roller wheel assemblies which are alternately and uniformly distributed, wherein the installation phase difference of the stop block and the roller wheel between the extension sleeve assembly IV and extension sleeve assembly III is 45 DEG, and the installation phase difference of the stop block and the roller wheel between the extension sleeve assembly III and extension sleeve assembly II is zero. The extension sleeve assemblies I, II, III are respectively equipped with four guide rails I, II, III, which are uniformly distributed on the circumferences of the extension sleeve assemblies and are respectively and freely connected with the roller wheels on the extension sleeve assemblies II, III, IV. The upper flange of the extension sleeve assembly IV is fixedly connected with the trolley frame; and the lower flange of the extension sleeve assembly I is fixedly connected with a pulley assembly, and the steel wire rope is wound on the lower flange which is fixedly connected with the balance arm by virtue of the movable pulley block.

Owner:DALIAN HUARUI HEAVY IND GROUP

Production method for constant-section composite-material section material

InactiveCN103991227AStrong carrying capacityRealize automatic continuous productionWoven fabricsElectric heatingEngineering

A disclosed production method for a constant-section composite-material section material comprises the following technological steps: 1) weaving, specifically employing a large-size 2.5D stereo weaving machine to finish weaving of 2.5D prefabricated fabric on-line stereo fabric; 2) pre-setting, specifically conveying the stereo fabric to a pre-setting apparatus for continuous setting by employing a conveying apparatus; 3) performing gum dipping, specifically connecting an injection apparatus controllable in pressure and metering and a backflow apparatus with a gum-dipping apparatus, injecting resin into the gum-dipping apparatus with designed pressure and flow velocity, and matching the injected resin amount with the designed pressure, the thickness of the prefabricated fabric and the drawing extrusion speed; 4) performing curing molding, specifically sending the prefabricated fabric subjected to gum dipping to a metal mold, performing curing molding under the effect of an electric heating plate of drawing extrusion equipment, employing a three-zone heating curing technology, and controlling the curing temperature at a scope of 100 DEG C-180 DEG C; and 5) cutting to obtain finished products, specifically utilizing a tracking cutting machine, and cutting according to demanded length to obtain finished products of the composite-material section material.

Owner:TIANJIN POLYTECHNIC UNIV

Rubber tube material and preparation method thereof

InactiveCN106279798AStrong carrying capacityGood wear resistanceFlexible pipesMagnesiumButadiene-styrene rubber

The invention discloses a rubber tube material that is prepared from the following raw materials in parts by weight: 30-60 parts of butadiene styrene rubber, 45-80 parts of natural rubber, 15-35 parts of nitrile rubber, 10-22 parts of polyurethane, 0.8-3.6 parts of vulcanizing agent, 1-3 parts of accelerant, 3-7 parts of anti-aging agent, 1-4 parts of dispersant, 2-10 parts of nano-calcium oxide, 3-12 parts of zinc oxide, 1-6 parts of magnesium oxide, 2-8 parts of amine benzoate, 1-4 parts of decabromodiphenyl ethane, 1-6 parts of ammonium fatty alcohol polyoxyethylene ether sulfate, 8-16 parts of quartz powder, and 8-20 parts of trimethylsiloxane. The rubber tube material of the invention has favorable abrasive resistance and compressive capacity, and long service life with greatly reduced use cost.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

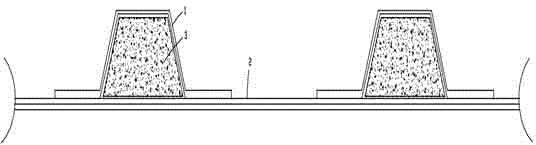

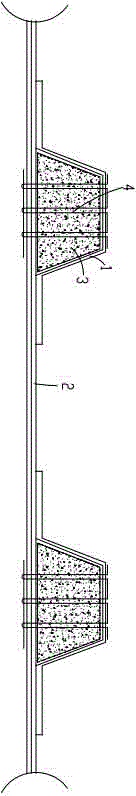

Floor heating laying device for fabricated building

ActiveCN110821087AStrong carrying capacityImprove construction efficiencyLighting and heating apparatusSpace heating and ventilation detailsStructural engineeringMechanical engineering

The invention discloses a floor heating laying device for a fabricated building. The floor heating laying device for the fabricated building comprises insulation boards and reflective film. Each insulation board is provided with reflective film to form a laying module. Each laying module is of a regular hexagon blocky structure, and a sleeving connection column block is arranged at each of the sixcorners from bottom to top in a penetration manner. A reinforcing connection ring is arranged between every two adjacent sleeving connection column blocks on the same laying module in a nested manner, each sleeving connection column block extends out of the upper end of the corresponding reinforcing connection ring and is provided with a sleeving connection linking plate in a nested and clampingmanner, each sleeving connection linking plate is of a regular triangle platy structure with one vertex angle facing the center of the corresponding laying module, an outward curling clamping piece isfixedly arranged at the upper end of the side, opposite to an adjacent one, of each sleeving connection linking plate, and every two opposite outward curling clamping pieces bend oppositely to form apipe channel for a floor heating pipe to penetrate through. According to the floor heating laying device for a fabricated building, two layers of staggered connection structures are formed between each laying module and the corresponding floor heating pipes, so that each laying module and the corresponding floor heating pipes are connected together, the high bearing capacity is achieved, and no steel wire meshes are needed for reinforcement; and because the fabricated floor heating laying measure is taken, the construction efficiency is high.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Double-arm clamping claw bracket

InactiveCN105905495AImprove stabilityStrong carrying capacityStorage devicesEngineeringStructural engineering

Owner:苏州华驰机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com