Double-arm clamping claw bracket

A claw cow and double-arm technology, applied in the field of double-arm claw corbels, can solve the problems of small space, small variety, high utilization rate of warehouse space, etc., and achieve the effect of meeting storage requirements, strong carrying capacity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

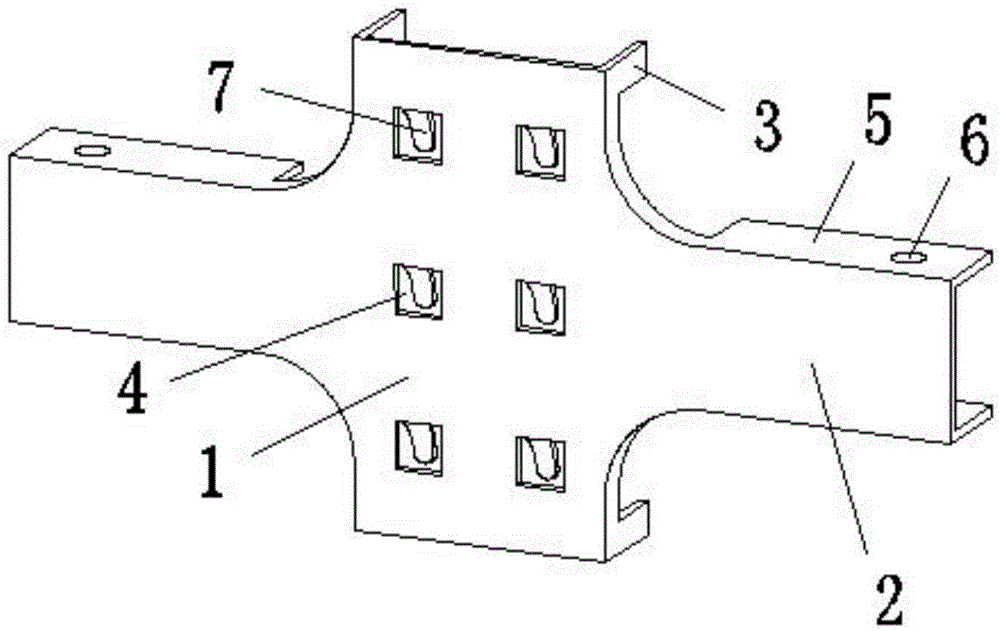

[0012] as attached figure 1 As shown, a double-arm claw bracket according to the present invention includes a vertically arranged column connecting plate 1 and two horizontally arranged beam connecting plates 2, and the two beam connecting plates 2 are respectively arranged on the column connecting plate 1 The left and right sides of the column connecting plate 1 and the two beam connecting plates 2 are located on the same vertical plane, and the column connecting plate 1 and the beam connecting plate 2 are connected by arc surfaces; the four corners of the column connecting plate 1 are all provided with There are column clamping arms 3, and a plurality of symmetrical column connecting grooves 4 are arranged on the column connecting plate 1, and column claws 7 are arranged on each column connecting groove 4; the upper and lower ends of the beam connecting plate 2 are provided with Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com