Fulcrum fixed multi-surface over-constrained radial scissor type lifting mechanism

A lifting mechanism, fixed technology, applied in the direction of the lifting frame, lifting device, etc., can solve the problems of inconvenient work for the top staff, structural instability and dumping, and large changes in the force of the mechanism, so as to increase the maximum working height and reduce the The probability of danger, the effect of expanding the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a fulcrum-fixed multi-face over-constrained radial scissor-type lifting mechanism. The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

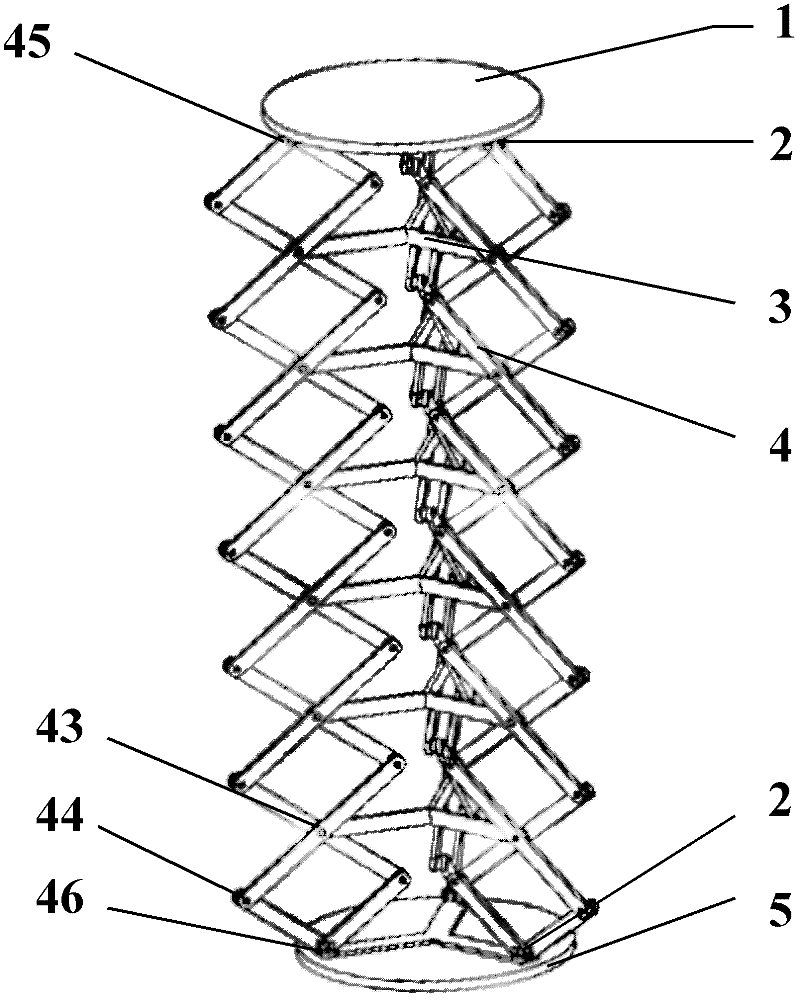

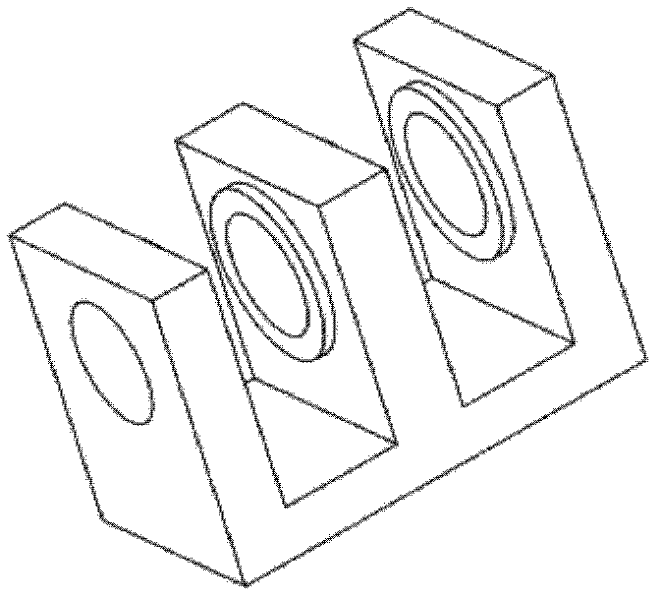

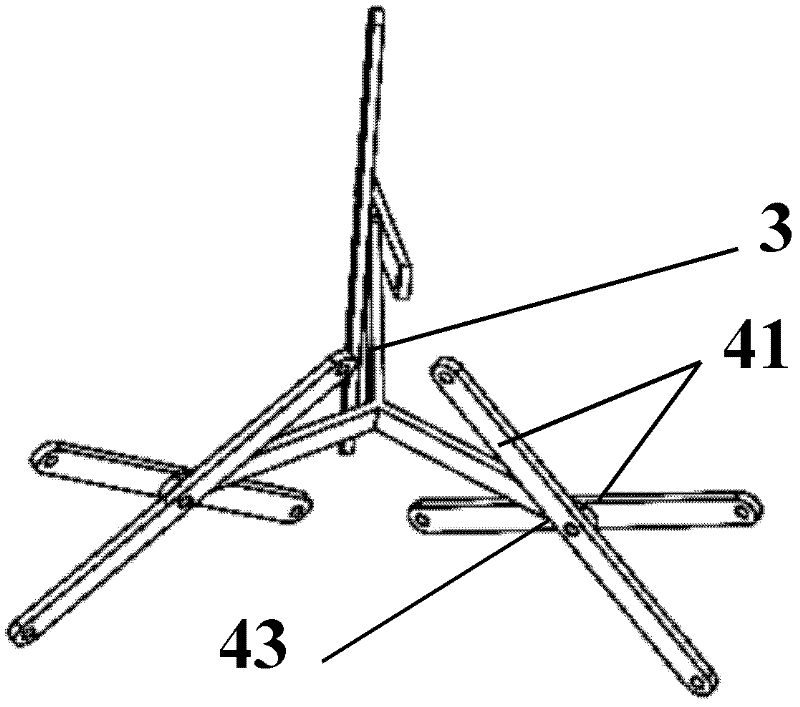

[0028] figure 1 It is a schematic diagram of an embodiment of a fulcrum-fixed multi-sided over-constrained radial scissor lifting mechanism. The lifting mechanism is composed of a supporting platform 1, a mountain-shaped connector 2, a star-shaped connector 3, a scissor truss 4, a base 5 and a driving device. The three mountain-shaped connectors 2 are fixed on the upper plane of the base 5 according to the distribution of the three vertices of the equilateral triangle, and the three sets of scissor trusses 4 are vertical to the base 5, and the bottom ends of the scissor trusses 4 pass through the bottom rotating joint 46 is connected with the mountain-shaped connector 2; 3 mountain-shaped connectors 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com