Robot leg mechanism

A technology of a robot and a transmission mechanism, applied in the field of leg structure of humanoid robots, can solve the problems of increasing motion inertia, low rigidity, reducing driving capacity, etc., and achieves the effects of good processing and assembly manufacturability, strong bearing capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] With reference to accompanying drawing, further illustrate the present invention:

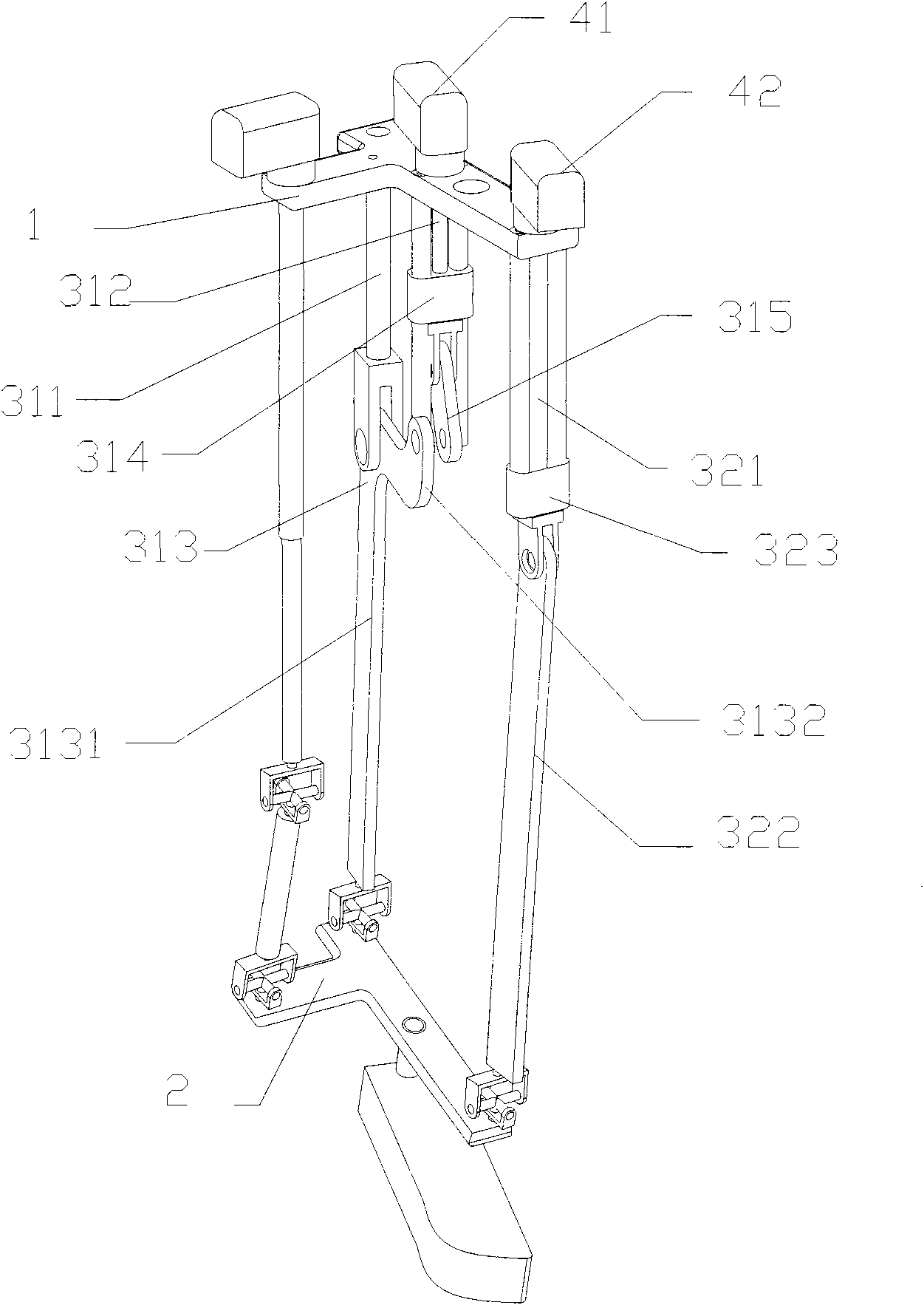

[0019] The robot leg mechanism includes a base 1 and a motion platform 2, and the base 1 is connected with the motion platform 2 through a transmission mechanism; the transmission mechanism includes motors 41, 42 fixed on the base 1 and connected with The motion unit connected with the motors 41 and 42;

[0020] The motion unit includes a first motion unit capable of swinging the robot leg mechanism backward and a second motion unit capable of pressing down or lifting the motion platform;

[0021] The first moving unit includes a support rod 311 whose top end is fixed on the base 1, connected with the first motor 41 to a first screw mechanism 312 and a hinged joint with the moving platform 2. The first fixed length rod 313; the first fixed length rod 313 includes a straight rod part 3131 and an outwardly protruding lug part 3132, and the support rod 311 is hinged with the described stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com