Lithium-based lubricating grease containing nano-particles and preparation method thereof

A technology of lithium-based lubricating grease and nano-particles, which is applied in lubricating compositions, petroleum industry, additives, etc., to achieve the effect of good wear resistance and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

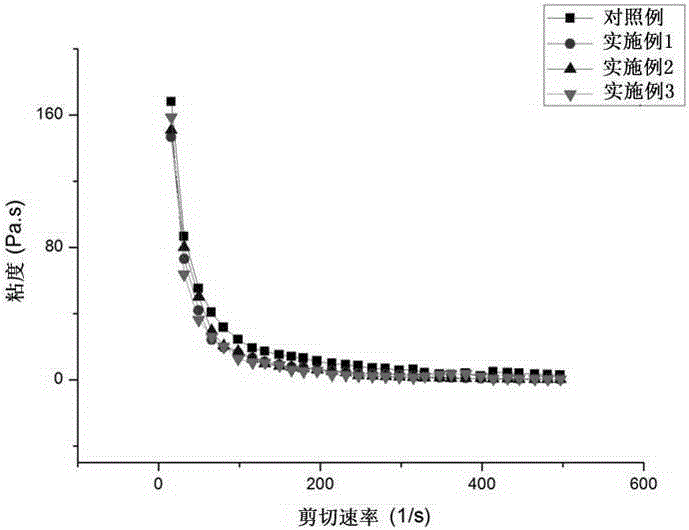

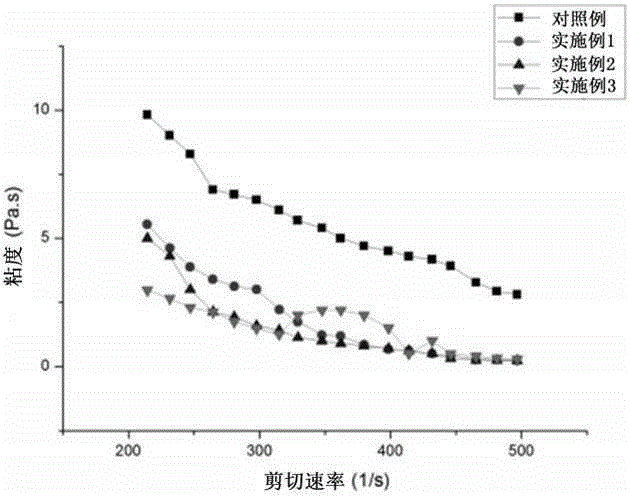

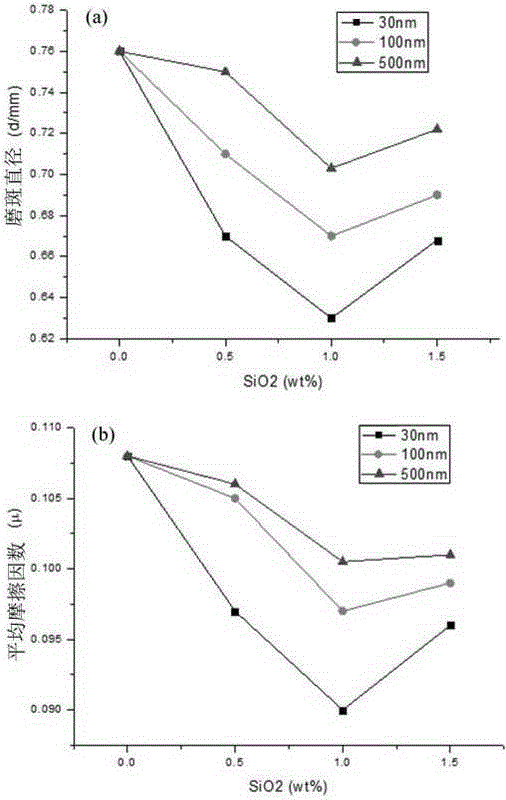

[0018] Embodiment 1-3 and comparative example

[0019] The preparation method of the lithium base lubricating grease containing nanoparticle, concrete steps are as follows:

[0020] (1) Weigh the general-purpose lithium-based grease and nano-SiO with the proportions shown in the table below 2 and nano-MoS 2 ;

[0021]

[0022] (2), additive dispersion treatment

[0023] Nanomaterials will slowly agglomerate after long-term storage, so dispersion treatment should be carried out before use, and nano-SiO 2 and nano-MoS 2 Dispersion treatment: the nano-SiO 2 and nano-MoS 2 Add it into the beaker with absolute ethanol according to the mass ratio of 1:15, stir evenly with a stirring rod, put it into an ultrasonic cleaner for 8min ultrasonic treatment.

[0024] (3), for nano-SiO 2 and nano-MoS 2 After the dispersion treatment, the nano-SiO 2 and nano-MoS 2 Add it together with absolute ethanol to the general-purpose lithium-based grease, first use a mixer to help nano-S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com