Floor heating laying device for fabricated building

A laying device and prefabricated technology, applied in the directions of building, building structure, heating method, etc., can solve the problems of time-consuming and labor-intensive, restricting floor heating structure paving, low efficiency of thermal insulation board and emission film paving, etc., and achieve strong bearing capacity. , the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

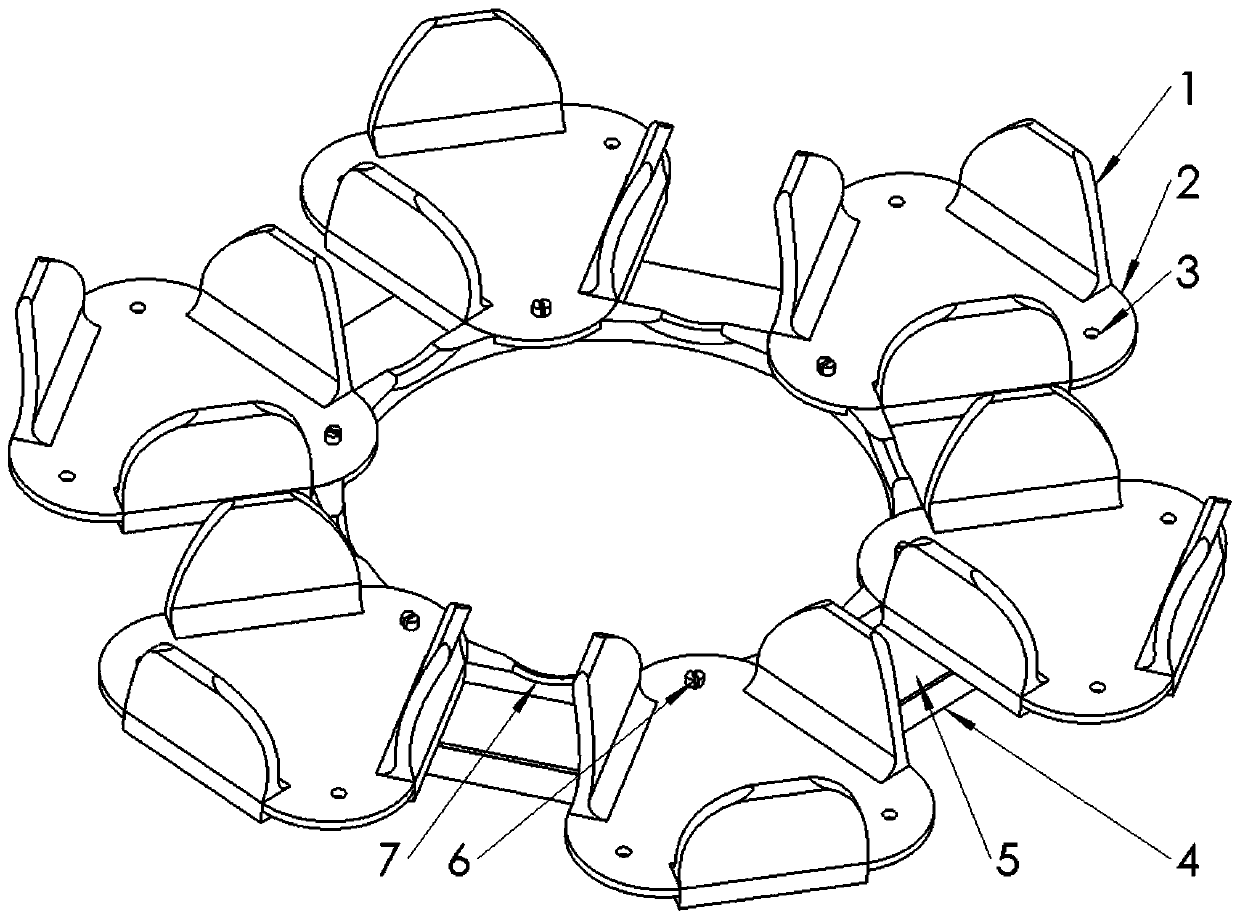

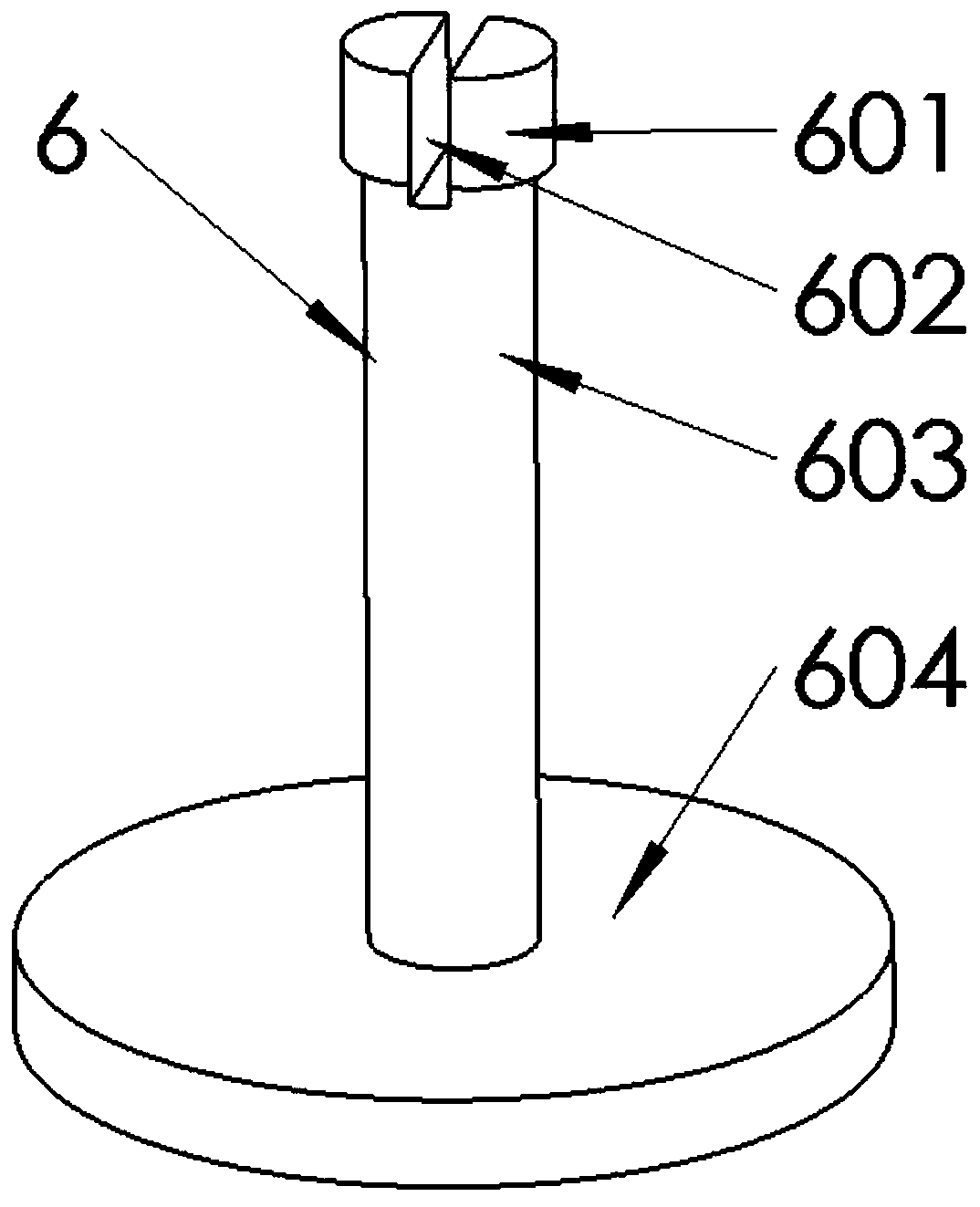

[0024] as attached figure 1 - attached Figure 7 As shown, the present invention provides a prefabricated building floor heating laying device, including a thermal insulation board 4 and a reflective film 5, the thermal insulation board 4 is provided with a reflective film 5 to form a pavement module, and the pavement module has a regular hexagonal block structure And the six corners are penetrated from bottom to top with socketed column blocks 6, and the upper ends of the socketed column blocks 6 on the same pavement module are nested with ring-shaped reinforcements in the shape of an outer regular hexagon and an inner circle. Connecting ring 7, strengthening the bisector of the top angle of the connecting ring 7 is collinear with the top angle bisector of the corresponding paving module;

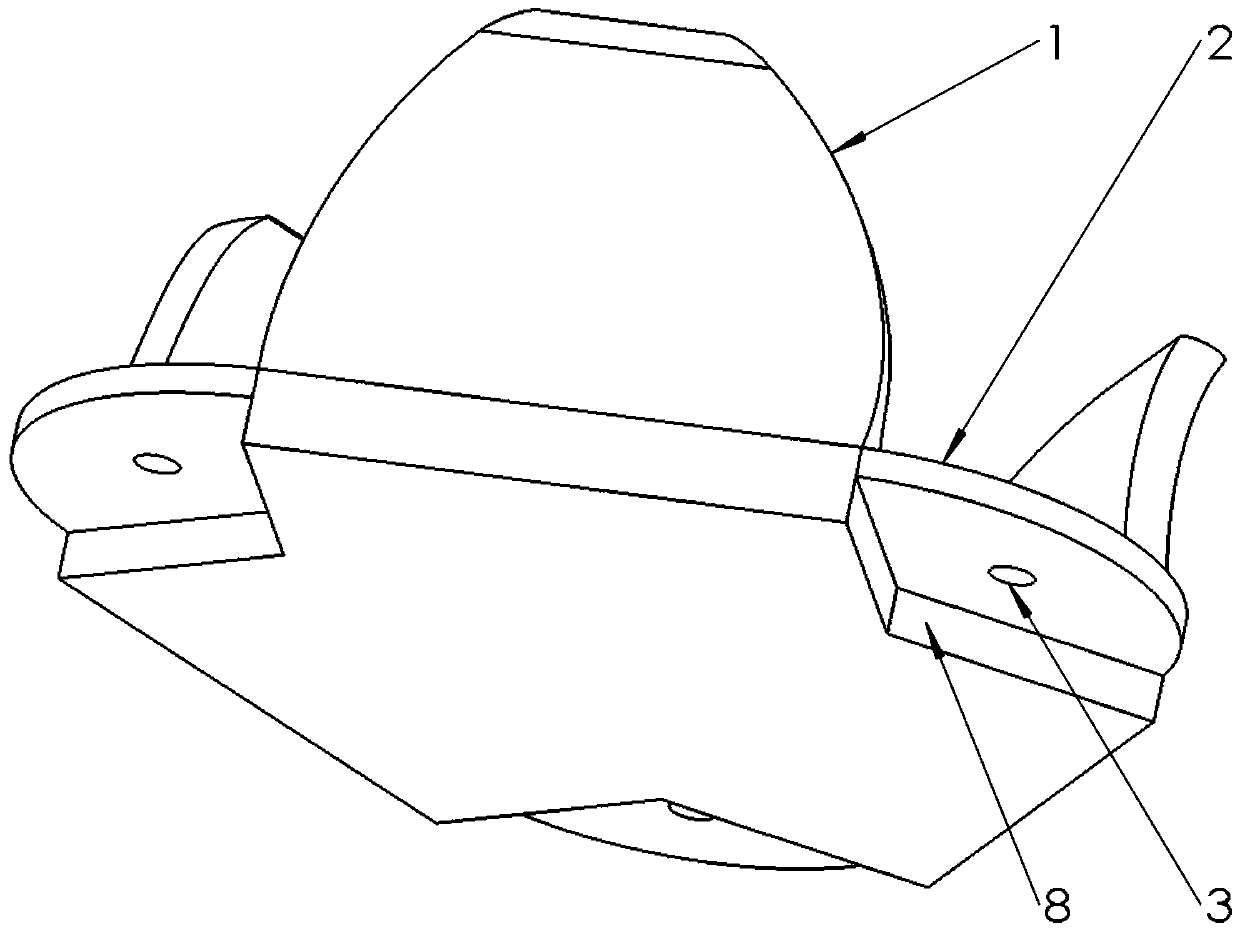

[0025] The upper end of the socket column block 6 protruding from the reinforcing connection ring 7 is nested and engaged with the socket connection plate 2. The socket connection plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com