Crane hoisting mechanism with extension sleeve

A technology of telescopic sleeve and lifting mechanism, which is applied in the direction of load hanging components, transportation and packaging, etc., to achieve the effect of good manufacturability, strong bearing capacity and reduced processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

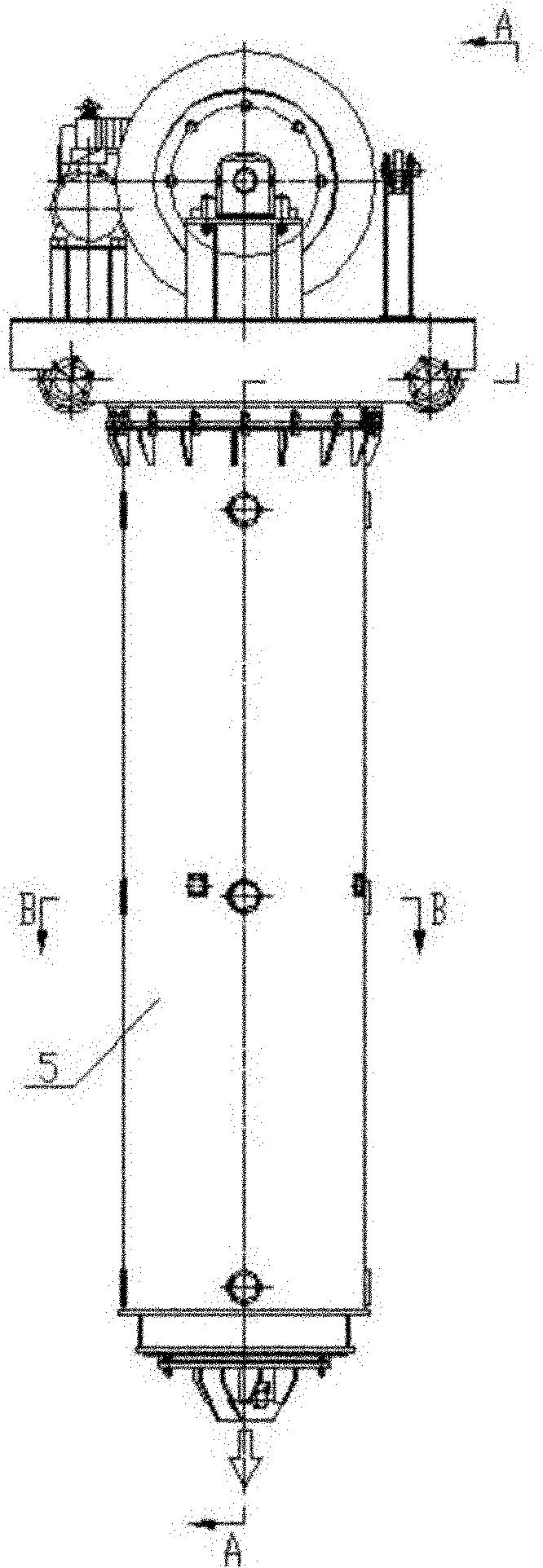

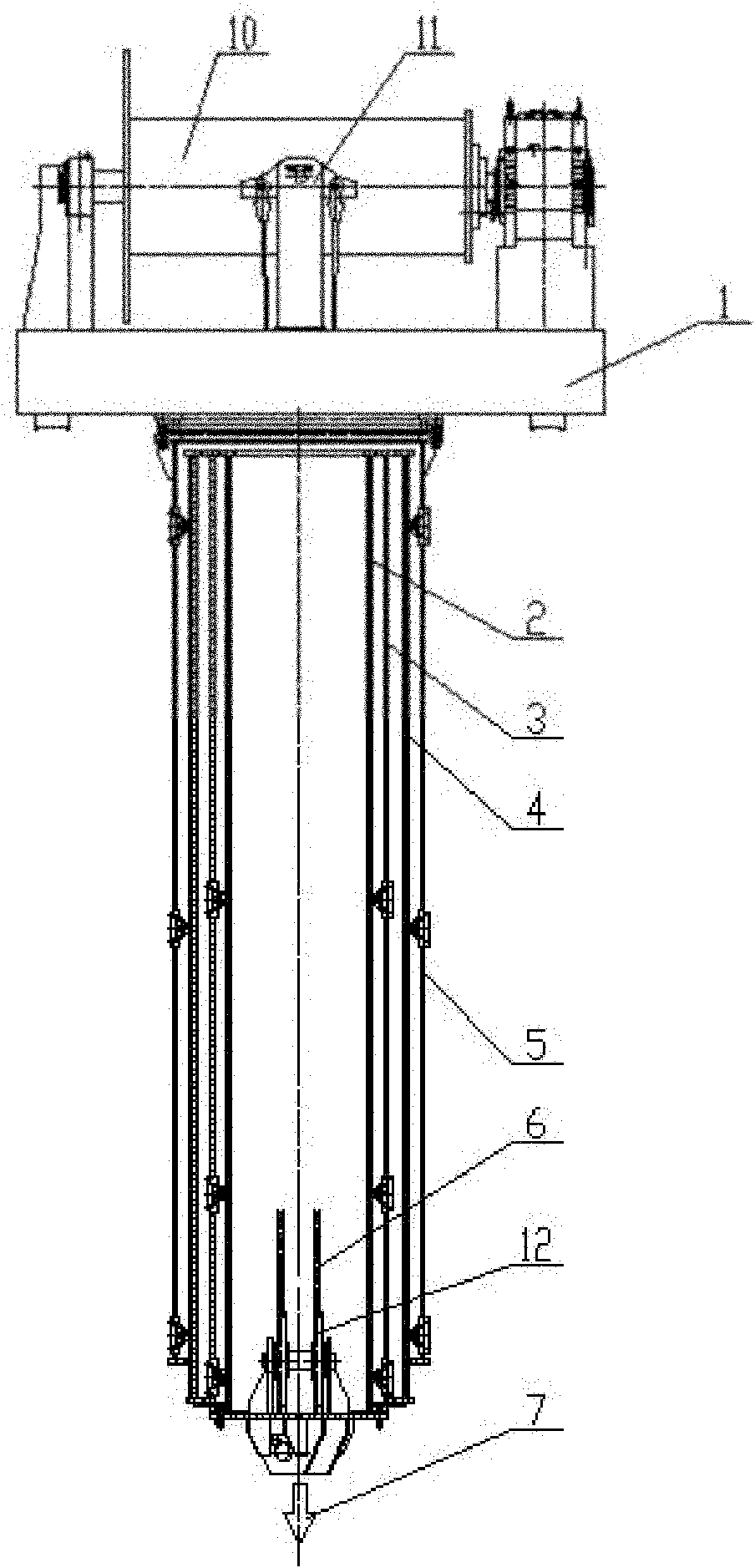

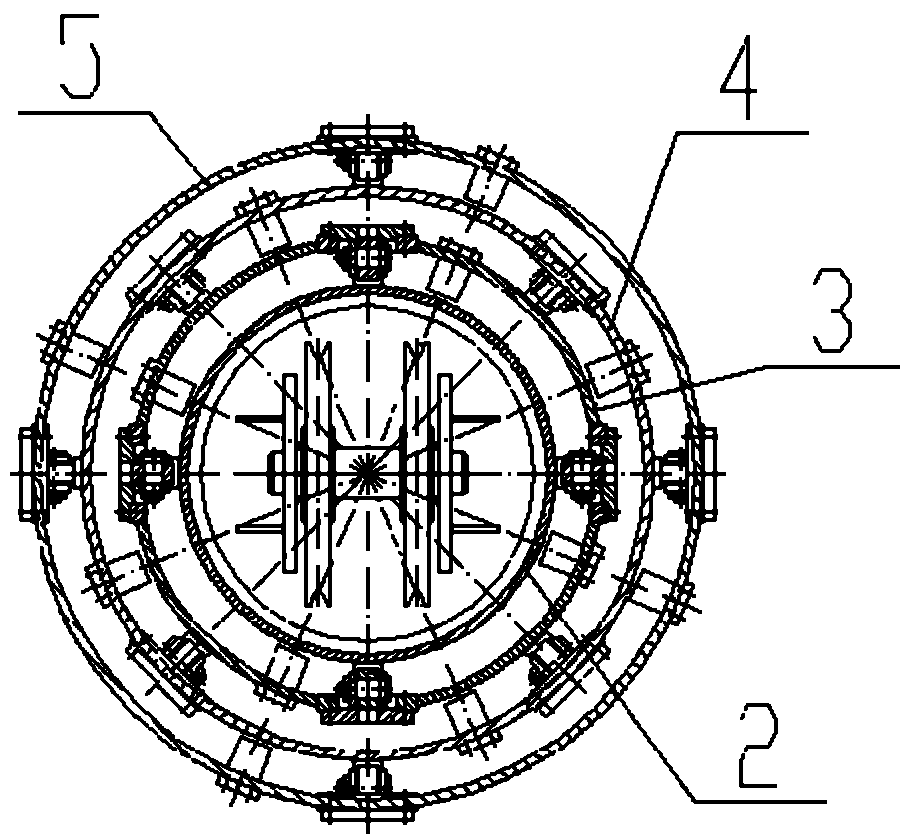

[0027] Such as Figure 1 to Figure 13 The hoisting mechanism of a crane with a telescopic sleeve shown is composed of a telescopic sleeve assembly I2, a telescopic sleeve assembly II3, a telescopic sleeve assembly III4, a telescopic sleeve assembly IV5, a steel wire rope 6, a load 7, a block 8, Roller installation 9, reel 10, balance arm 11 and movable pulley block 12, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 13 .

[0028] Telescopic sleeve assembly IV5 is composed of upper flange IV5.1, telescopic sleeve IV5.2, lower flange IV5.3, stopper 8 and roller installation 9, see Figure 5 and Figure 6 .

[0029] Telescopic sleeve assembly III4 consists of upper flange III4.1, telescopic sleeve III4.2, track III4.3, lower flange III4.4, stopper 8 and roller installation 9, see Figure 7 and Figure 8 .

[0030] The composition of the telescopic sleeve assembly II3 is the same as that of the telescopic sleeve assembly III4, and the outer diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com