Method for entry retaining for walling at sides of road in steel cylinder support mode

A pillar-type, steel-cylinder technology, applied in pillars/supports, earth-moving drilling, filling, etc., can solve problems such as restricting the application and development of gob-side entry retention technology, affecting the efficient production of working faces, and gas leakage in goaf areas. , to achieve the effect of strong operability and adaptability, saving materials and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

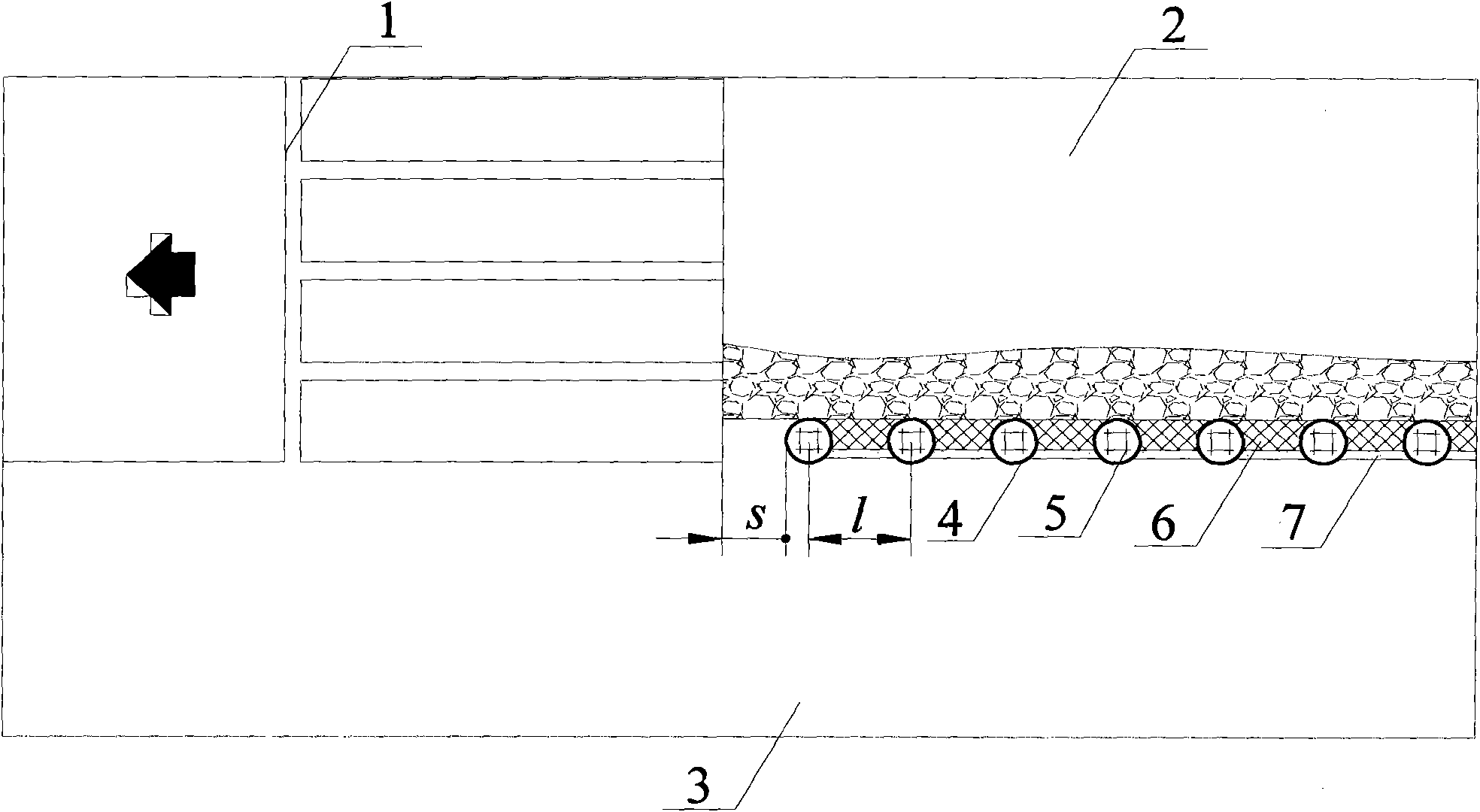

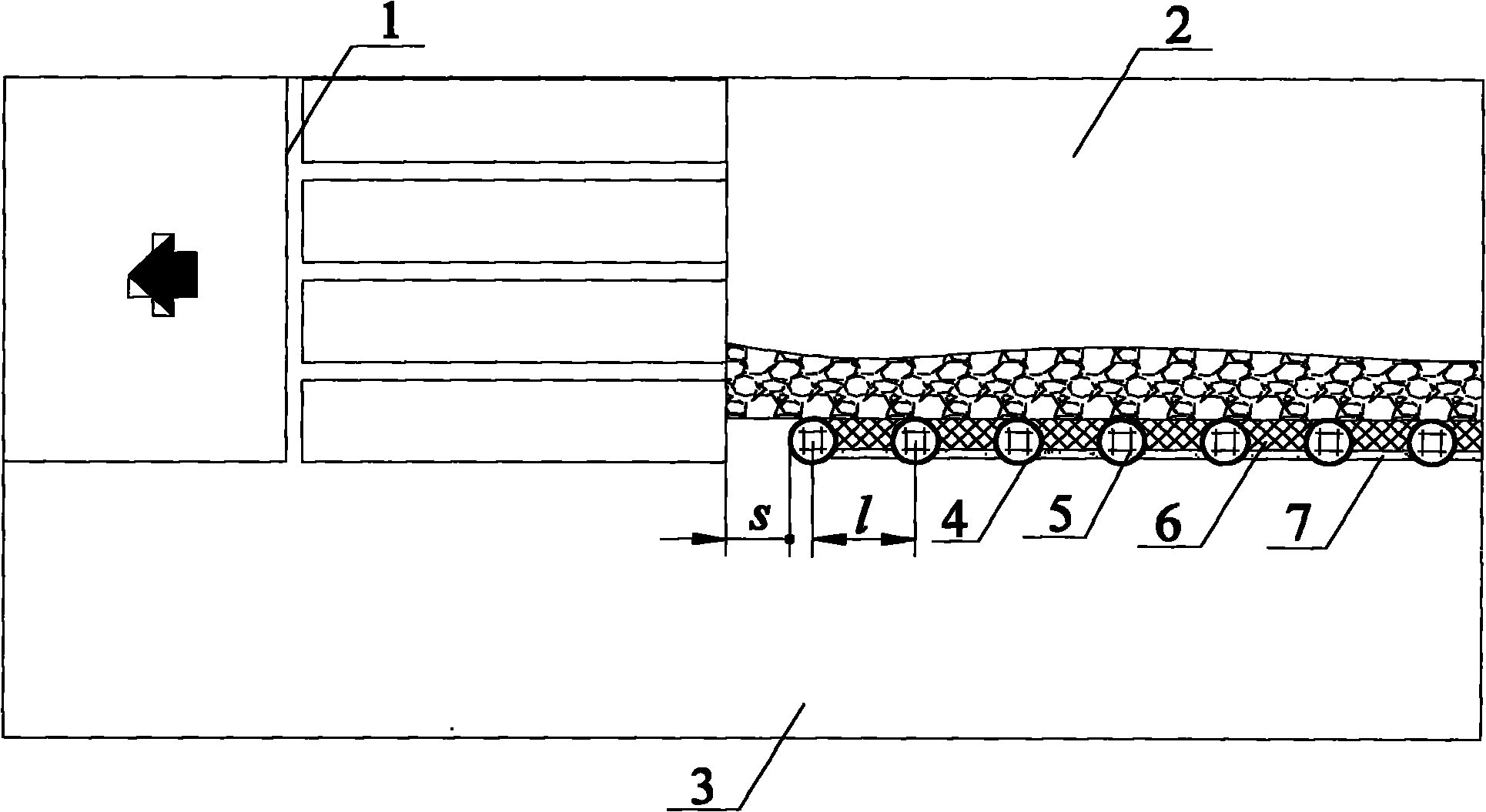

[0022] After the steel cylinder pillar 4 is installed, concrete can be poured into the bucket, and the concrete should be filled to contact the roof. The entire process from the installation of the steel cylinder pillar to the pouring of concrete must be completed within 5m behind the working face, that is, after the steel cylinder pillar is installed The distance s of the lagging working face is not greater than 5m; with the continuous advancement of the working face, the next steel cylinder pillar 4 is arranged at a distance l in sequence, and concrete is poured until the concrete is connected to the top. The distance l between the steel cylinder pillars 4 is about 1.6m~2.0m,;

[0023] Finally, after the goaf has been collapsed and enriched, the gangue wall 6 is piled up with crushed gangue or cinder between the steel cylinder pillars 4 at intervals, and the wall surface of the gangue wall 6 near the goaf side is sprayed with grout. The slurry can completely seal the gaps of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation distance | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com