Three-dimensional reticular texture structure composite coating and preparation method thereof

A three-dimensional, composite coating technology, applied in the coating, metal material coating process, etc., can solve the problems of high cost, single preparation technology, complex process, etc., and achieve the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

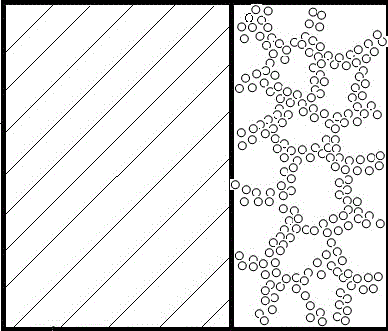

[0019] A preparation method for a three-dimensional network texture composite coating, the steps of which are:

[0020] (1) Metal substrate treatment: After removing the oxide layer on the surface of the substrate with a grinding wheel, polish it with sandpaper until it is smooth and bright, then clean and remove oil stains, and finally dry it for later use;

[0021] (2) Mixing of coating powder: Weigh the nickel-based alloy powder and tungsten carbide powder or nickel-coated graphite powder separately, then place them in a powder mixing bottle and mix them well;

[0022] (3) Preparation of the prefabricated layer: Prepare the powder with an adhesive and evenly coat the surface of the substrate with a thickness of 2-3mm. Part of the composite powder added with WC is pre-coated on the surface of the substrate for a period of time before coating. Nickel-based alloy powder with a layer thickness of 1-2mm is used as a transition layer;

[0023] (4) Sintering of the three-dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com