Anti-friction self-lubrication complex paint

A self-lubricating and coating technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of reducing the safety reliability and service life of mechanical equipment, friction block of friction mechanism parts, vibration and noise, etc., to achieve Reduce friction coefficient, work stably and reliably, reduce noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

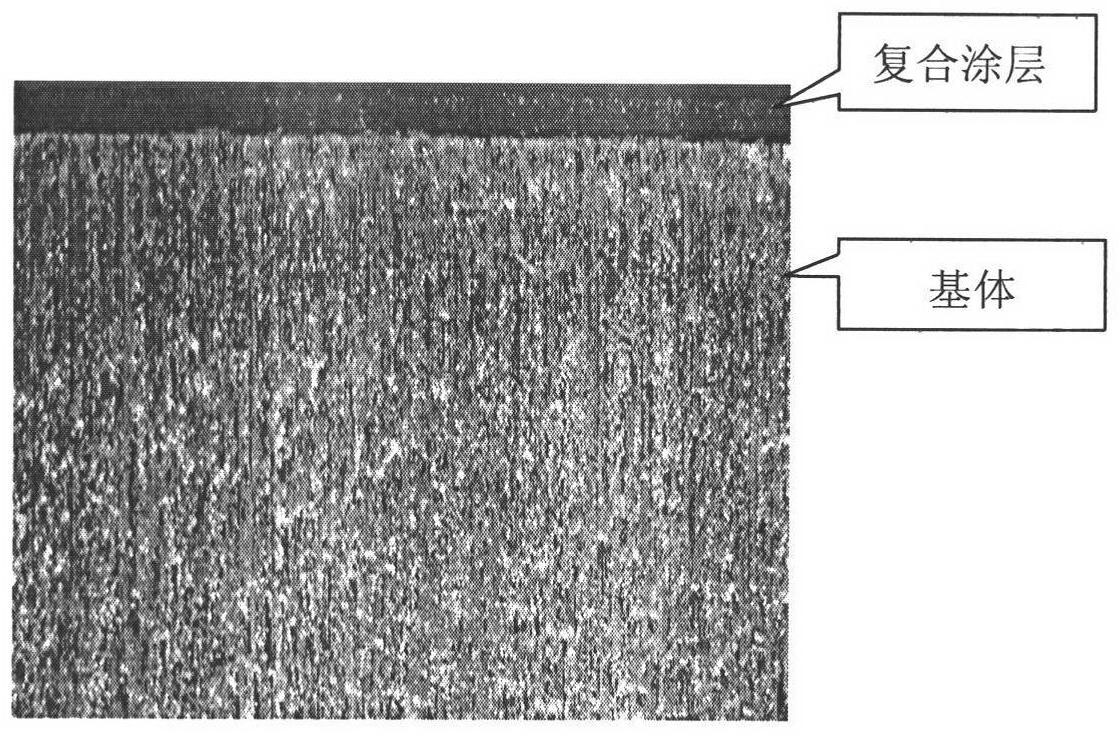

[0011] The preparation of embodiment 1 anti-friction self-lubricating composite coating

[0012] 1. Raw materials

[0013] (1) Graphite: purity 99.5%, particle size 3-5 μm (commercially available, produced by Shanghai Yifan Graphite Co., Ltd.).

[0014] (2) Molybdenum disulfide (MoS 2 ): purity 99.5%, particle size 2-4 μm (commercially available, produced by Shanghai Yifan Graphite Co., Ltd.).

[0015] (3) Zinc (Zn) powder: purity 99.5%, particle size 3-5 μm (commercially available, produced by Beikuang Zinc Industry Co., Ltd.).

[0016] (4) Potassium silicate adhesive (or potassium water glass): modulus 4.5, pH value 11-12, relative density 1.16-1.30, viscosity ≤ 25Pa.s (commercially available, produced by Henan Xinyu Chemical Co., Ltd. ).

[0017] 2. Preparation process

[0018] Coating preparation

[0019] The base material is weighed according to the mass fraction: graphite 40%, molybdenum disulfide 30%, and zinc powder 30%, and then mix and stir evenly; weigh an app...

Embodiment 2

[0021] Example 2 Preparation of Friction-reducing Self-lubricating Composite Coating for Friction Components

[0022] (1) Surface treatment of friction components

[0023] Clean the oil, dust, rust, etc. on the surface of the friction member, and at the same time make the surface have a certain surface roughness (Ra=3.2μm~6.3μm), so as to facilitate the combination of the coating and the friction member matrix. Treatment method: ① use electric hand grinding wheel or 80 # Iron sandpaper is used to polish the surface of friction components to remove rust and stains attached to the surface. ② Scrub the surface with acetone to keep the surface clean.

[0024] (2) Brushing of composite coating materials

[0025] Fix the sample first, and then apply the prepared paint on the surface of the friction member with a special brush for paint. During brushing, the brushing surface should be kept as horizontal as possible, evenly brushed, the coating thickness is about 0.45mm ~ 0.55mm, ...

Embodiment 3

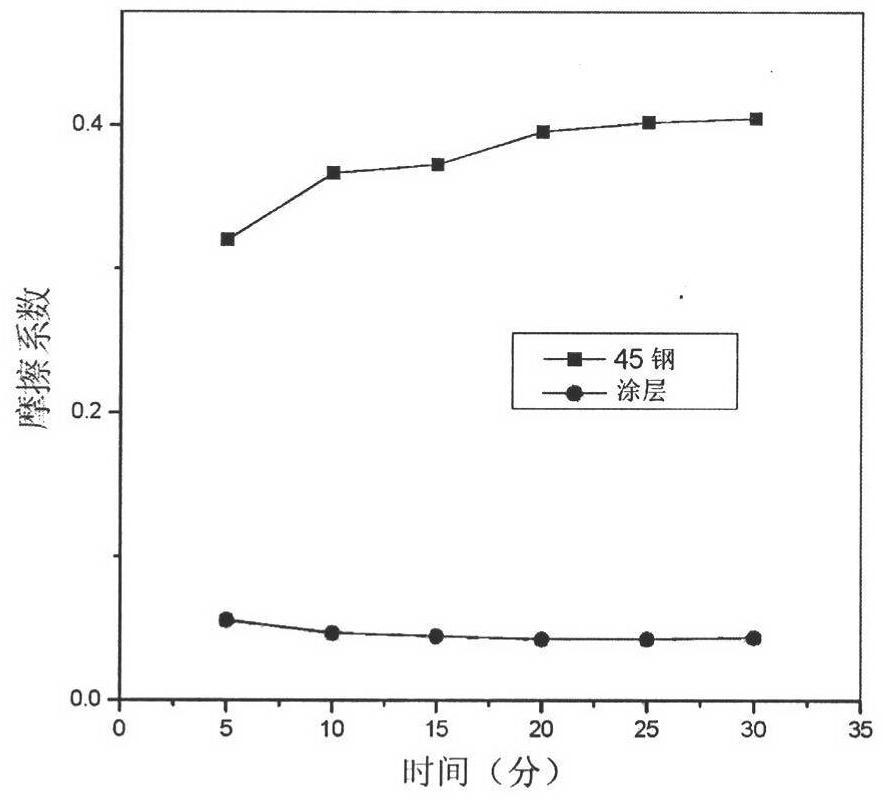

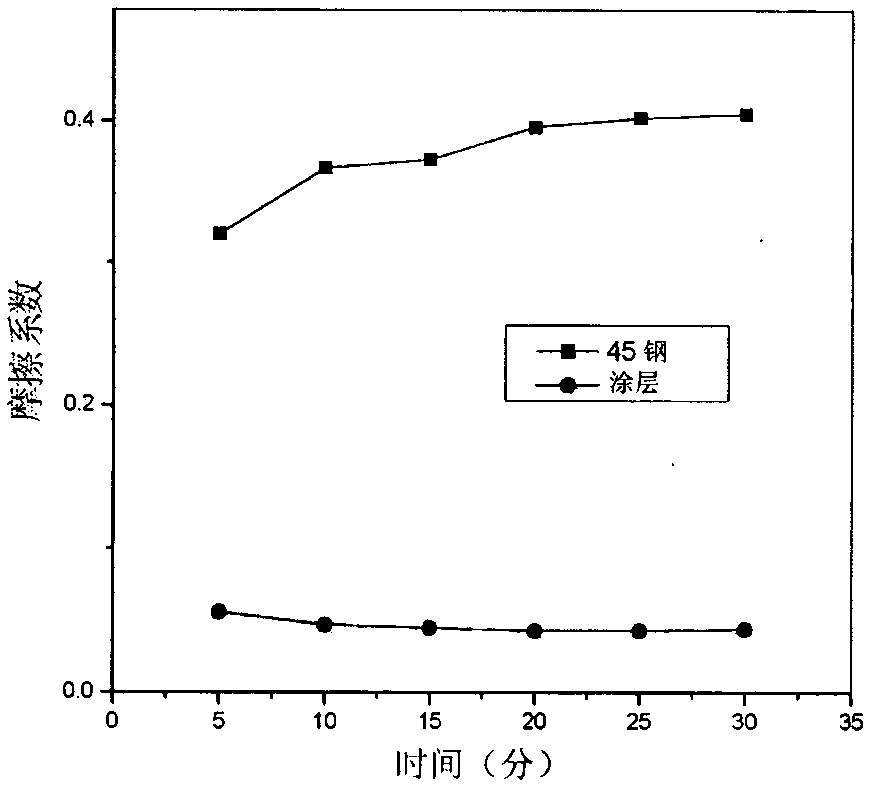

[0026] The friction and wear test of embodiment 3 coating

[0027] Environmental conditions: room temperature 25°C, relative humidity RH60%;

[0028] The friction and wear test is carried out on the ball-disc type HT-500 friction and wear testing machine. The upper sample used is a GCr 15 bearing ball with a diameter of 4 mm, and the lower samples used are 45 # Steel and 45 # The anti-friction and self-lubricating composite coating of the present invention has steel as a matrix. The test load is 6N (the corresponding contact stress is 12.7MPa); the speed is 1m / s; the test running time: 30min.

[0029] The anti-friction self-lubricating composite coating and 45 # For the coefficient of friction of steel see figure 2 . figure 2 middle. The abscissa is the friction reduction time, and the ordinate is the friction coefficient value. It can be seen from the figure that the friction coefficient of the anti-friction self-lubricating composite coating is 0.048-0.051, 45 # Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com