Seven-degree-of-freedom transfer robot provided with ball screw movable platform

A technology for handling robots and moving platforms, applied in the field of robotics, can solve the problems of small application range, limited application range, and inflexible movement of the movable platform, and achieve the effects of fast speed, high rigidity, and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

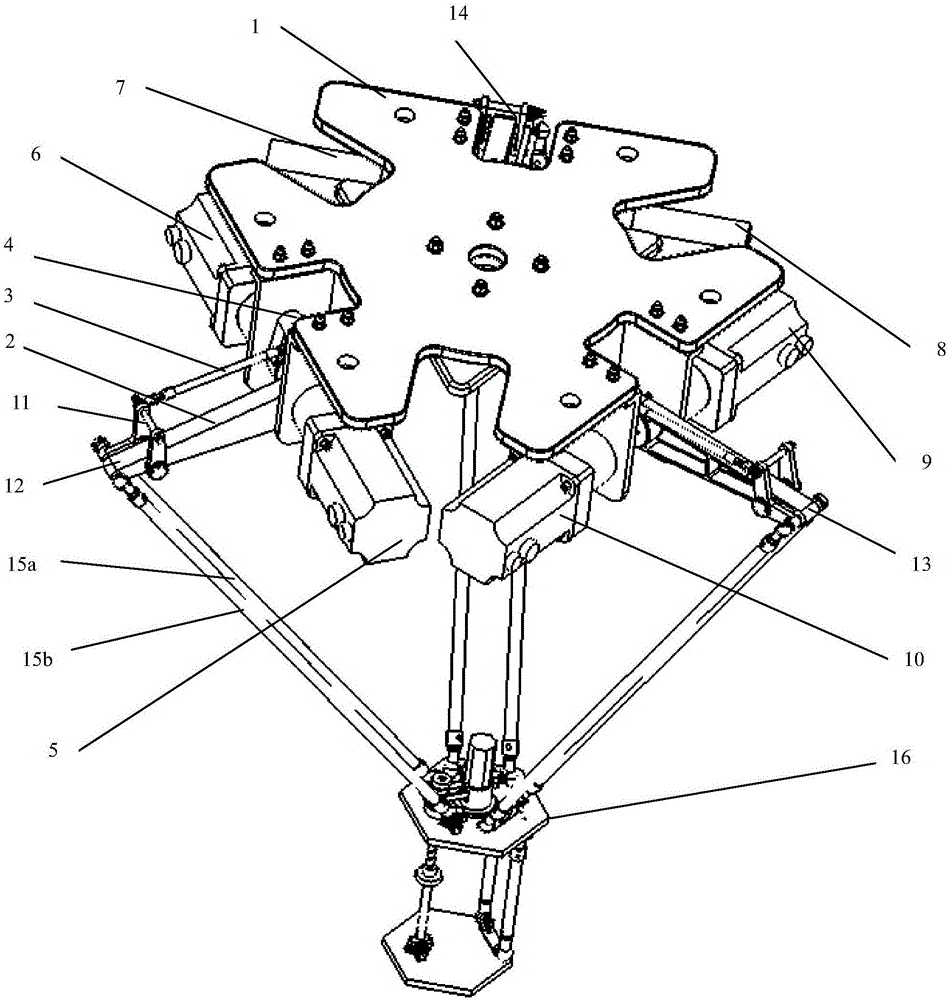

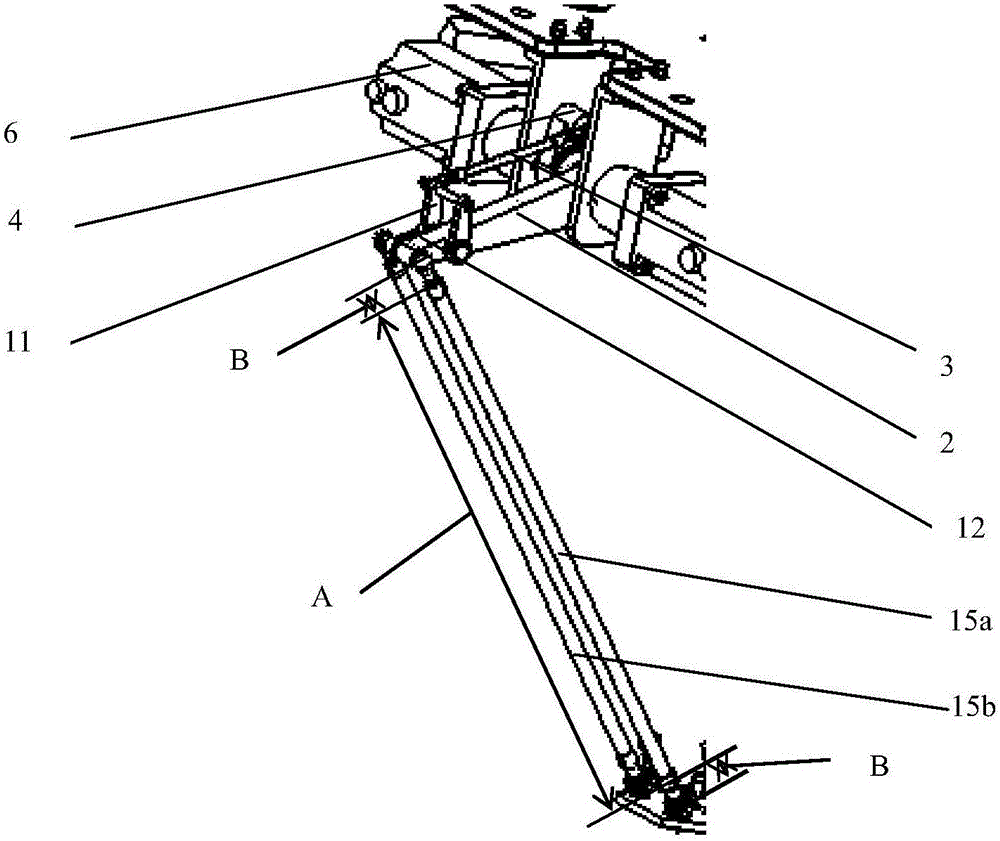

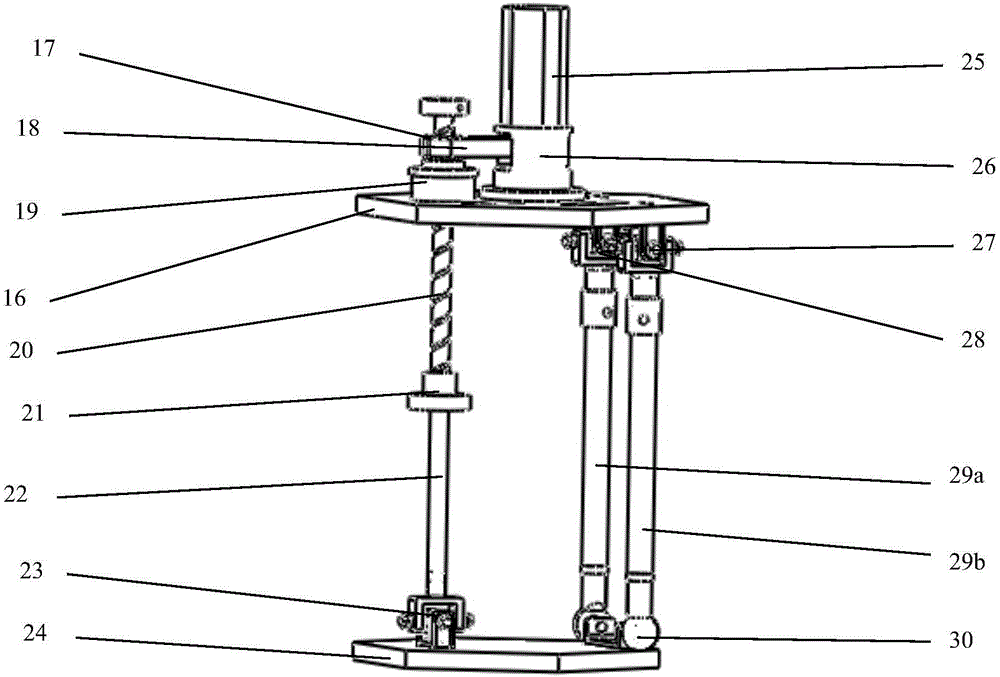

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention contains a seven-degree-of-freedom handling robot with a ball screw moving platform. The robot includes a frame 1, a moving platform mechanism, a driving device and three kinematic branch chains. The driving device is composed of a motor and a speed reducer. The three motion branch chains include a first branch chain 12, a second branch chain 13 and a third branch chain 14, and the three motion branch chains are evenly distributed on the frame 1, and the distance between each branch chain is 120°. The upper moving platform 16 forms a parallel closed-loop structure with the frame 1 through three kinematic branch chains, and the upper moving platform 16 is driven by the three kinematic branch chains. The structure of the second branch chain 13 and the third branch chain 14 is the same as that of the first branch chain 12 .

[0021] Such as figure 2 , image 3 As shown, the large ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com