Low-cost high-toughness self-lubricating epoxy resin and preparation method thereof

An epoxy resin and high-toughness technology, applied in the field of advanced polymer material science, can solve the problems of unsuitability for large-scale promotion of production and cumbersome preparation steps, and achieve the effects of easy industrial production, simple preparation process, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

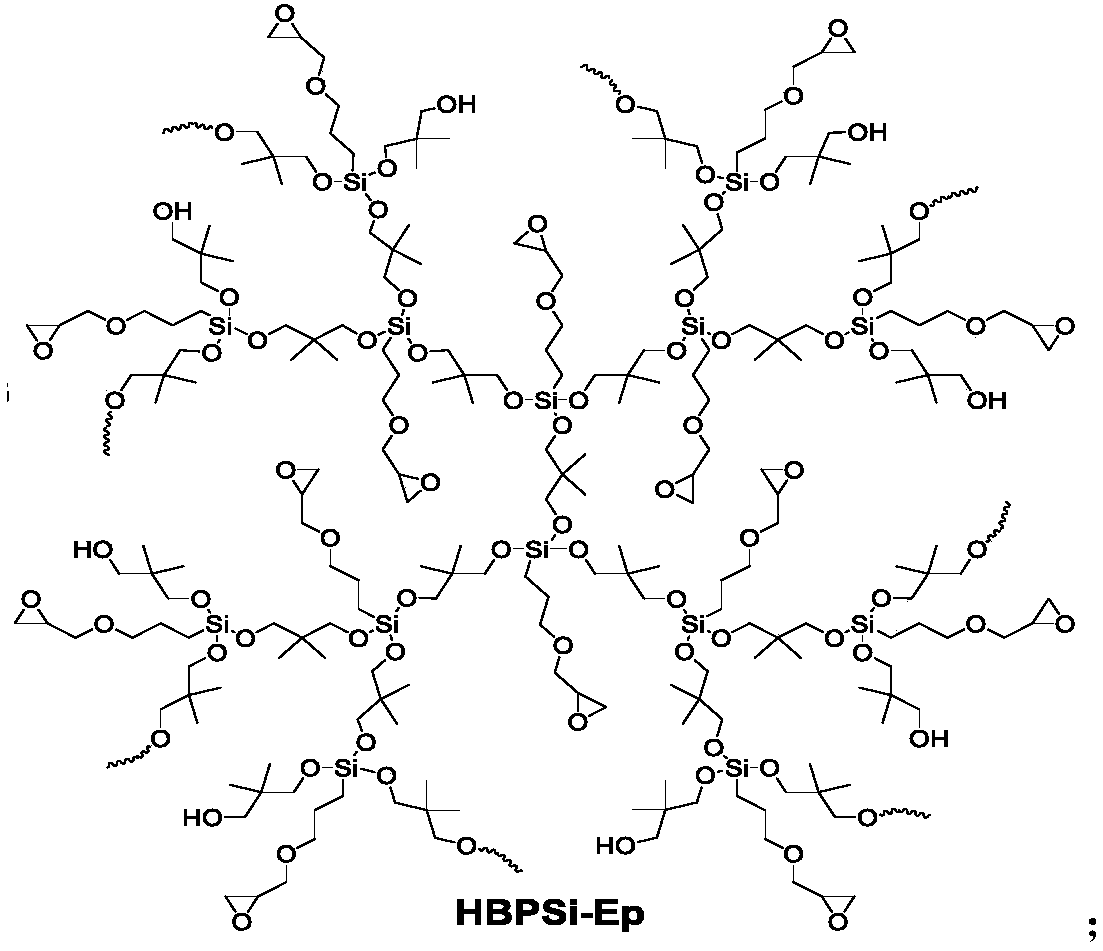

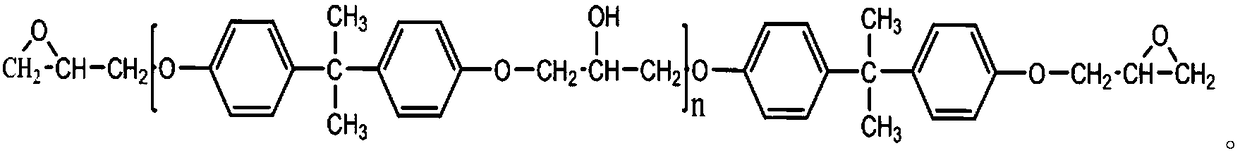

[0030] Mix 10 parts of multifunctional epoxy monomer, 90 parts of bisphenol A epoxy resin, and 25 parts of 4,4'-diaminodiphenyl sulfone, stir at 120°C for 1 hour until it melts, and prepare the resin pre- Polymer. Then, add 3 parts of hyperbranched polysiloxane into the above prepolymer at 120°C, stir for 15 minutes, pour it into a heated mold, and vacuumize to remove air bubbles in a vacuum box at 120-130°C. Blast drying oven for staged temperature rise curing, the curing process is 150 ° C / 2 h + 170 ° C / 2 h, then natural cooling, after demoulding, and then post-treatment at 230 ° C for 2 h.

Embodiment 2

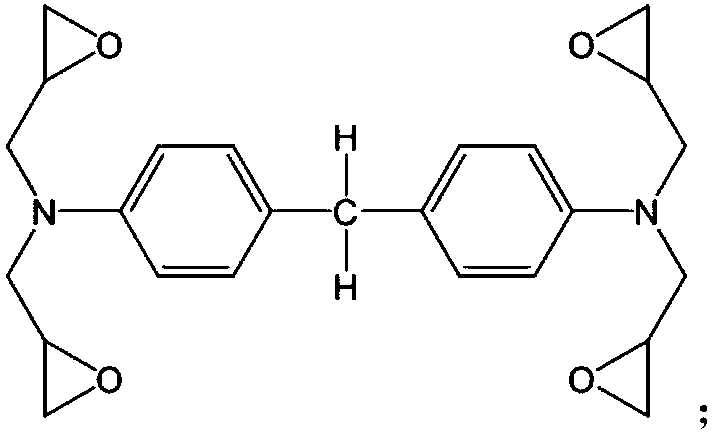

[0032] Mix 20 parts of multifunctional epoxy monomer, 80 parts of bisphenol A epoxy resin, and 30 parts of 4,4'-diaminodiphenylmethane, stir at 130°C for 1 hour until it melts, and prepare the resin pre- Polymer. Then, add 3 parts of hyperbranched polysiloxane to the above prepolymer at 130°C, stir for 10 minutes, pour into a heated mold, vacuumize to remove air bubbles in a vacuum box at 130°C, and put it into the air blast Drying oven for staged heating and curing, the curing process is 150°C / 2 h+170°C / 2h, then naturally cooled, after demoulding, and post-treatment at 230°C for 2 hours.

Embodiment 3

[0034] Mix 30 parts of multifunctional epoxy monomer, 70 parts of bisphenol A epoxy resin, and 35 parts of 4,4'-diaminodiphenyl sulfone, stir at 110°C for 2 hours until it melts, and prepare the resin pre- Polymer. Then, add 3 parts of hyperbranched polysiloxane to the above prepolymer at 110°C, stir for 30 minutes, pour it into a heated mold, vacuumize in a vacuum box at 130°C to remove air bubbles, and put it into the air blast Drying oven for staged heating and curing, the curing process is 150°C / 2 h+170°C / 2h, then naturally cooled, after demoulding, and post-treatment at 230°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com