Spiral wheel-spiral bevel gear retarder

A technology of helical gear and bevel gear, which is applied in the field of helical gear-helical bevel gear reducer, can solve the problems of insufficient transmission torque, small range of speed ratio, single installation type, etc., achieve long service life, reduce quantity, The effect of large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

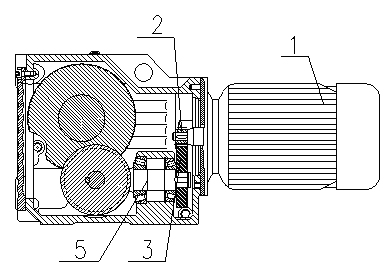

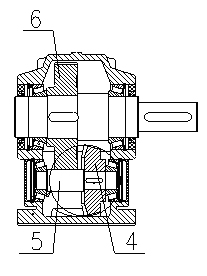

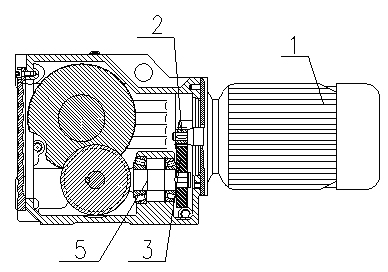

[0013] Further illustrate structural features of the present invention below in conjunction with accompanying drawing.

[0014] like figure 1 and figure 2 As shown, a helical-helical bevel gear reducer includes a motor 1, a first-stage small helical gear 2, a first-stage large helical gear 3, a spiral bevel gear 4, a third-stage gear shaft 5, an output large gear 6, and an output shaft , bearings, oil seals, oil seal covers, keys, retaining rings, adjustment pads and fasteners; the flange cover of the motor 1 is fixed on the input surface of the box through the positioning notches and fasteners, and the motor 1 The output shaft is fixed on the first-stage small helical gear 2 through the key and retaining ring, and the first-stage small helical gear 2 meshes with the first-stage large helical gear 3; the first-stage large helical gear 3 is fixed on the shaft at one end of the bevel gear shaft through the key and retaining ring On the platform, the small bevel gears at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com