Hybrid-driven type bucket-wheel material stacking and taking machine

A bucket-wheel stacker-reclaimer and hybrid drive technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high processing and assembly requirements, low carrying capacity, limited working space, etc., and achieve large working space and positioning The effect of high precision and output flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

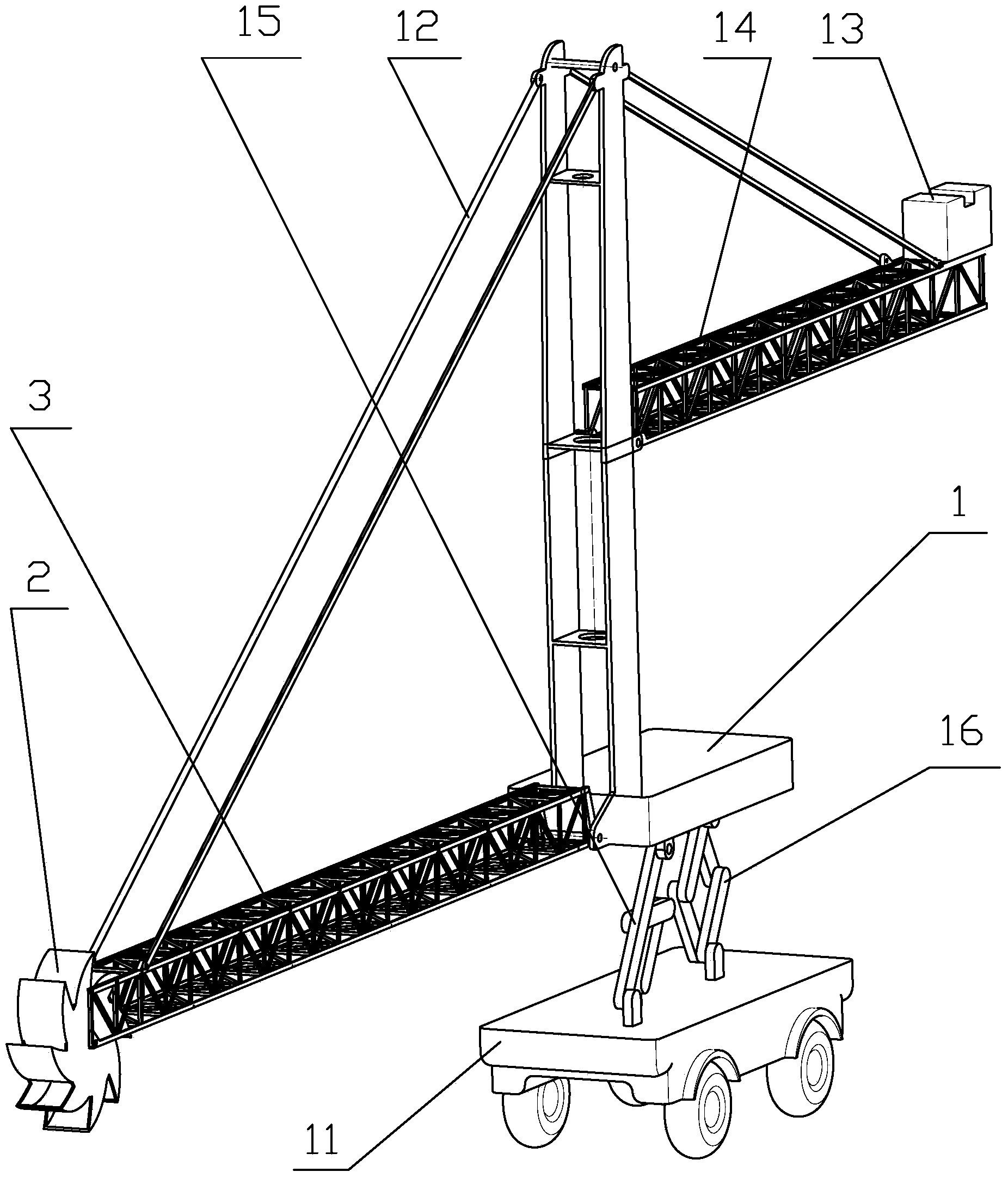

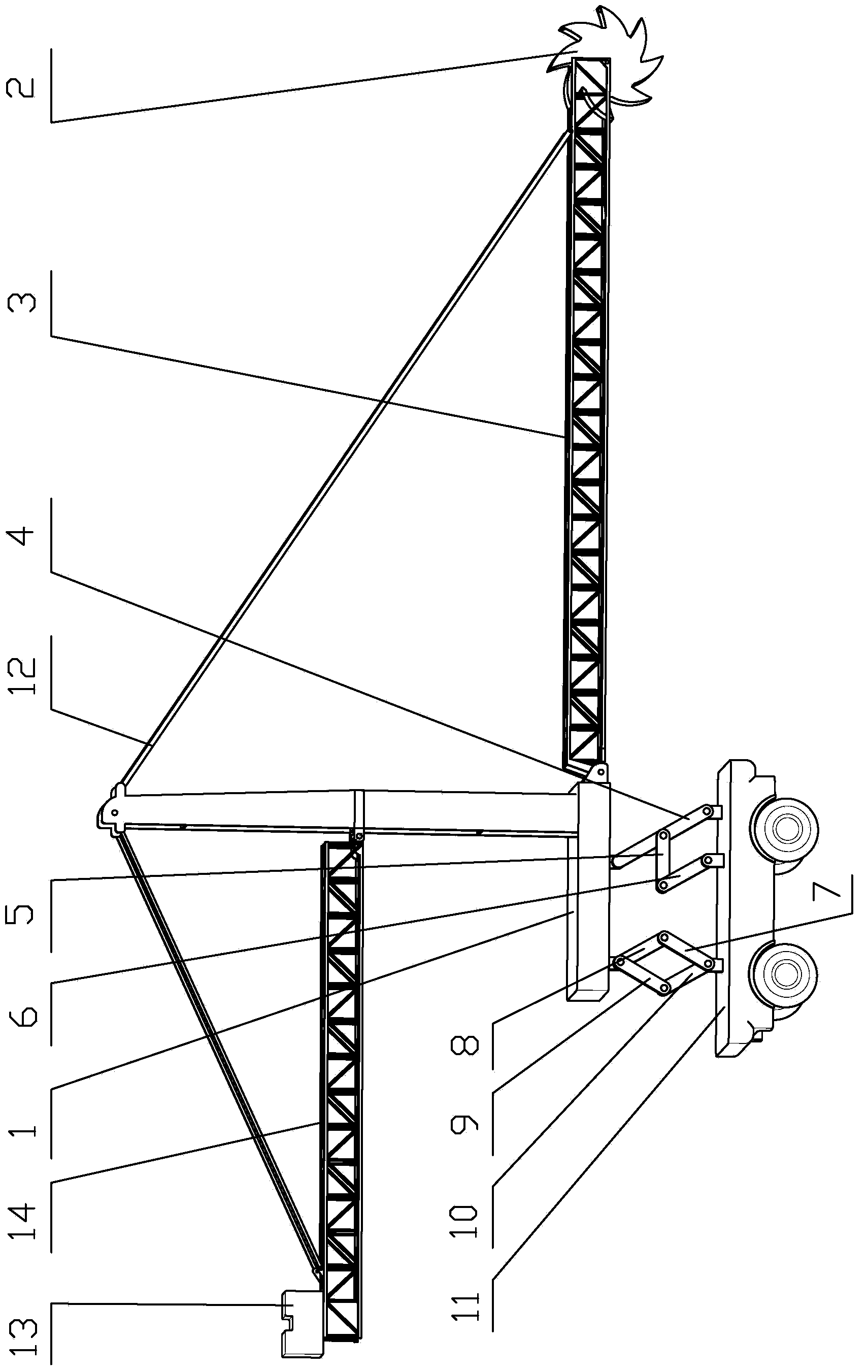

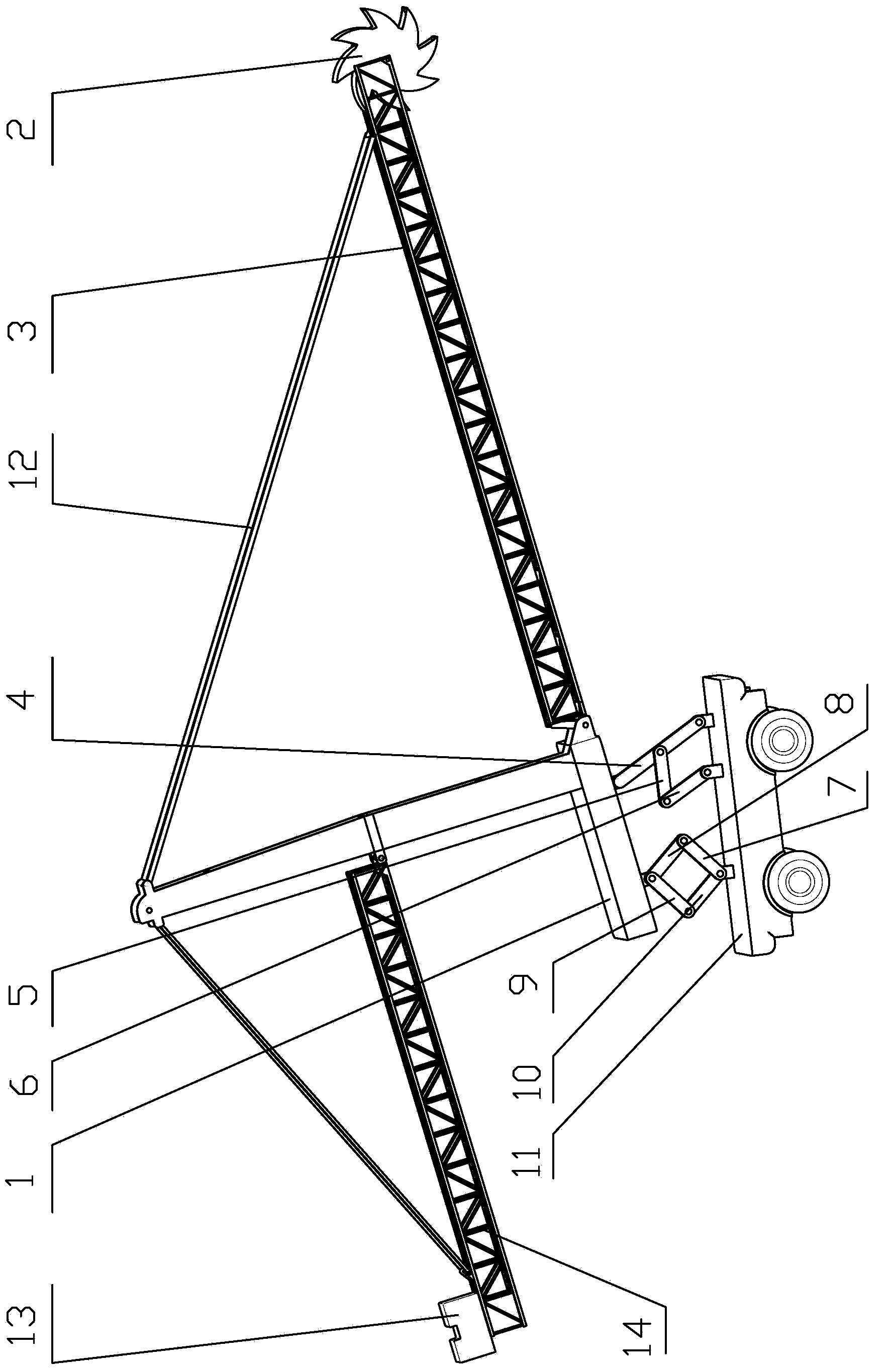

[0014] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0015] The hybrid driving mechanism type bucket wheel stacker and reclaimer of the present invention comprises a vehicle frame 11, a frame 1, a bucket wheel suspension arm 3, a bucket wheel 2, a counterweight suspension arm 14, a counterweight 13 and a bucket wheel suspension arm Pitching device, described cantilever arm pitching device comprises the first frame pitching mechanism 15 that is located at vehicle frame 11 front parts and the second frame pitching mechanism 16 that is located at vehicle frame 11 rear parts, as figure 1 shown.

[0016] The first rack pitching mechanism 15 is a four-bar linkage, and the four-bar linkage includes a first pitch rocker 6, a first pitch link 5, and a first pitch swing 4, and the first pitch swing 4 and the lower end of the first pitching rocker 6 are hinged front and rear on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com