High-power-density integrated electromechanical servo actuating device

A high power density, electromechanical servo technology, applied in the fields of electronics and control, aerospace and marine machinery, can solve the problems of unsatisfactory power-to-weight ratio, large volume and weight, small installation space, etc., achieve compact structure, improve transmission efficiency, Better sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

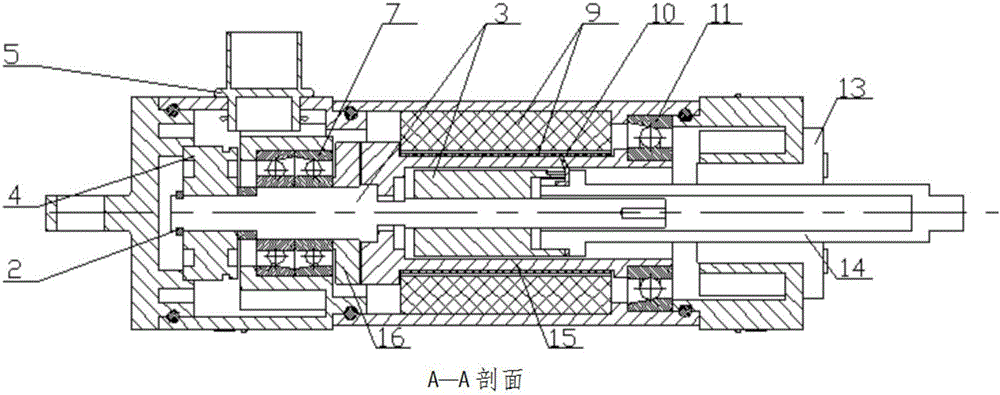

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The purpose of the present invention is to overcome the deficiencies in the prior art and provide a high power density integrated electromechanical servo actuating device with small footprint, high power-to-weight ratio, high transmission efficiency, large bearing capacity and high motion precision.

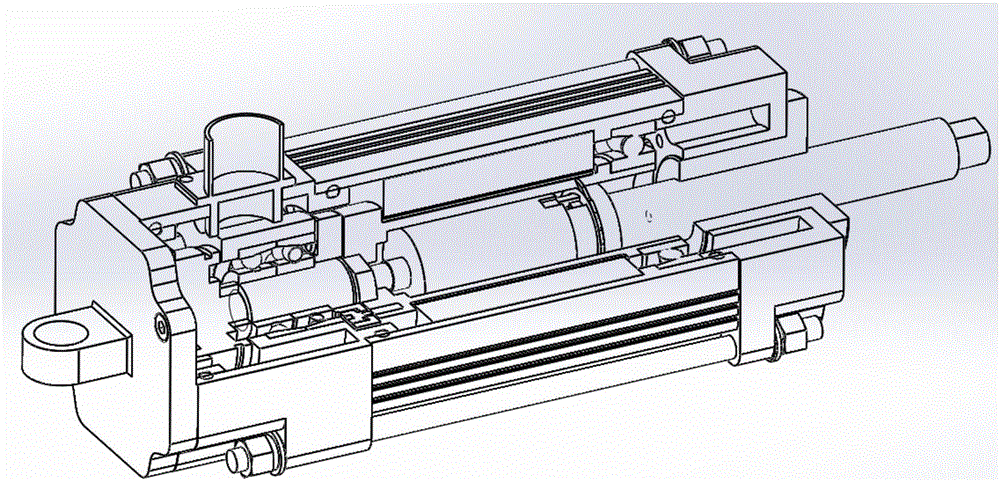

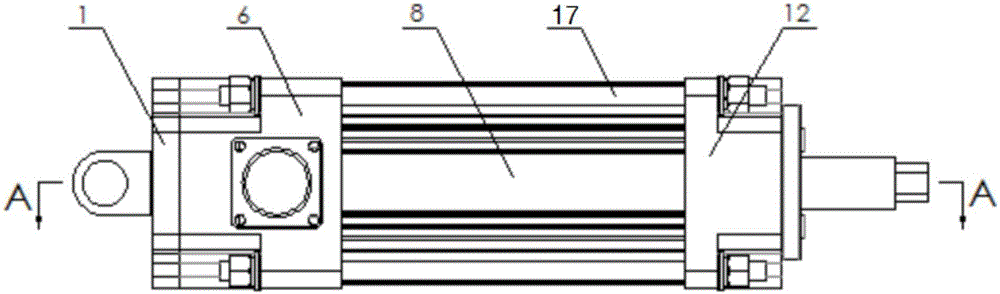

[0029] refer to figure 1 , 3 , a high power density integrated electromechanical servo actuator, including: rear end cover (1); shaft end retaining ring (2); roller screw (3.1); nut (3.2); rotary encoder (4 ); Aviation plug (5); Rear housing (6); Angular contact ball bearing (7); Cylinder block (8); Integrated motor stator (9.1); Integrated motor magnetic patch (9.2); Stop washer (10); Angular Contact Ball Bearing (11); Front Housing (12); Linear Bearing (13); Output Rod (14); Rotor Sleeve (15); Connecting Flange (16); Stud (17) .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com