Patents

Literature

73results about How to "Prevent radial displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

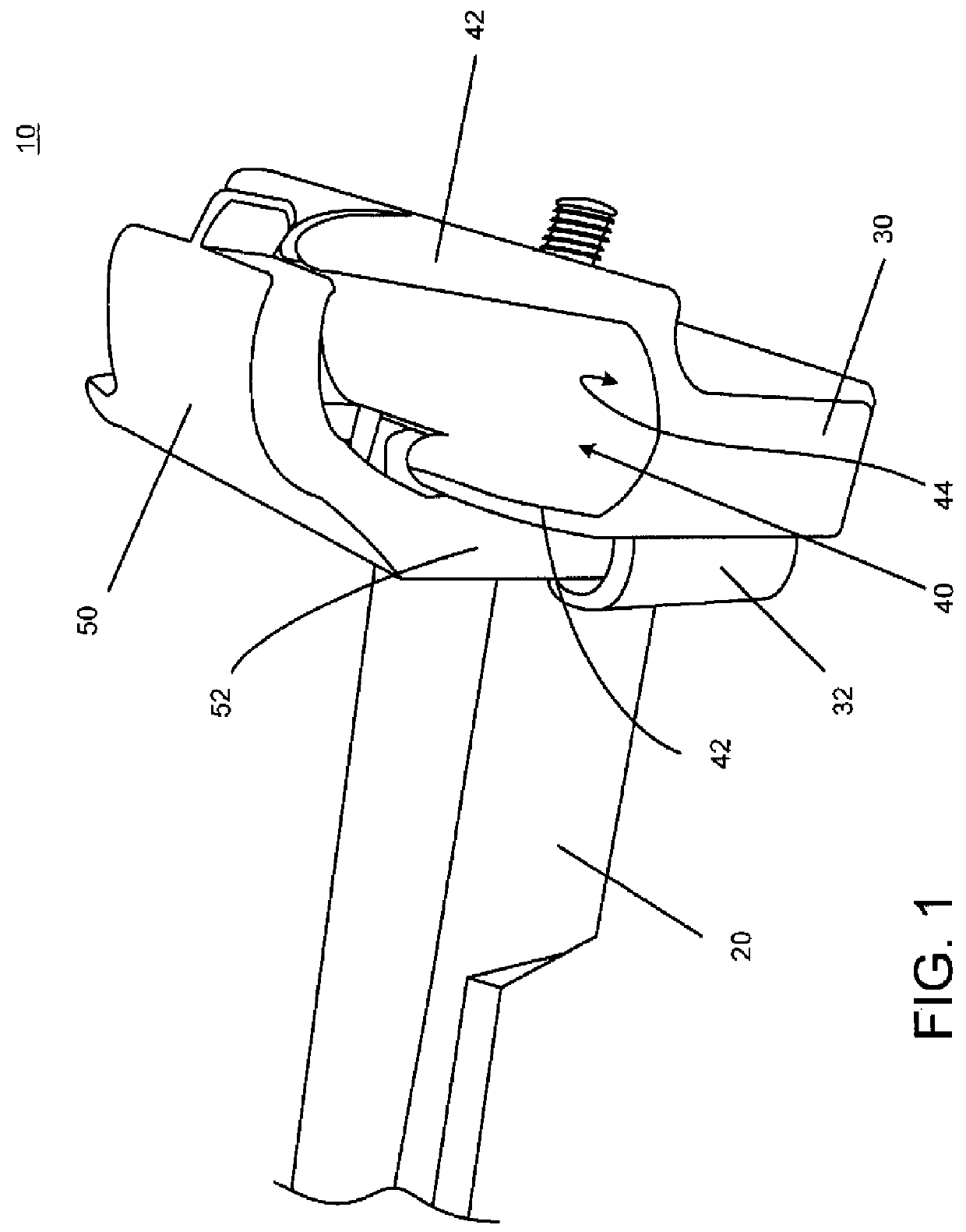

Stringing messenger clamp and methods of using the same

ActiveUS9379527B2Prevent radial displacementFilament handlingInsulatorsDistribution systemEngineering

A stringing messenger clamp for use in overhead transmission and distribution systems and method of installing a messenger cable is provided. The stringing messenger clamp includes a bracket and an assembly body supported by the bracket, wherein the assembly body has a cable channel sized to receive a portion of a messenger cable. An assembly clamp is movable with respect to the assembly body and closable upon the cable channel. When the assembly clamp is in a closed position, it retains in place the portion of the messenger cable within the cable channel.

Owner:MARMON UTILITY

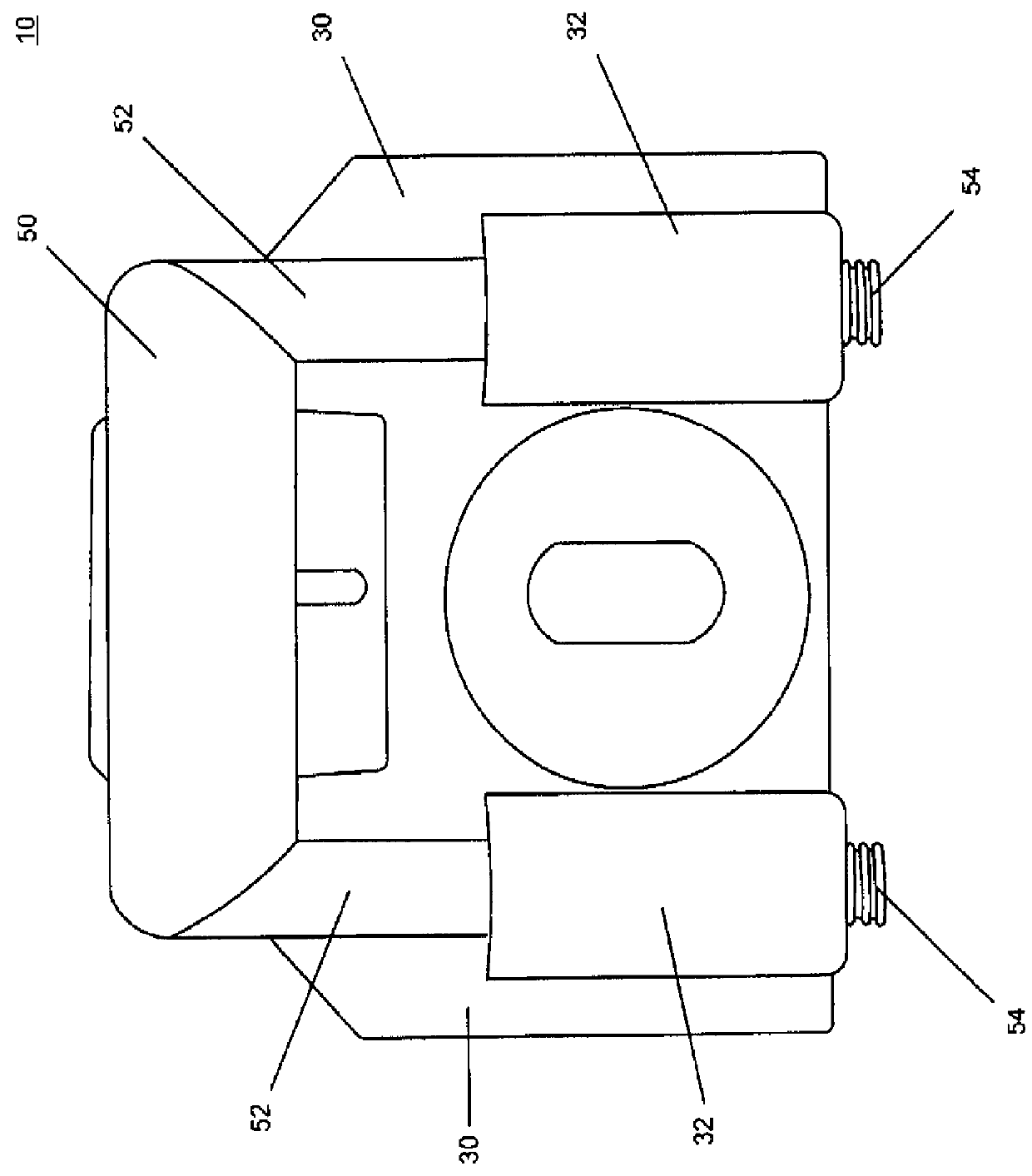

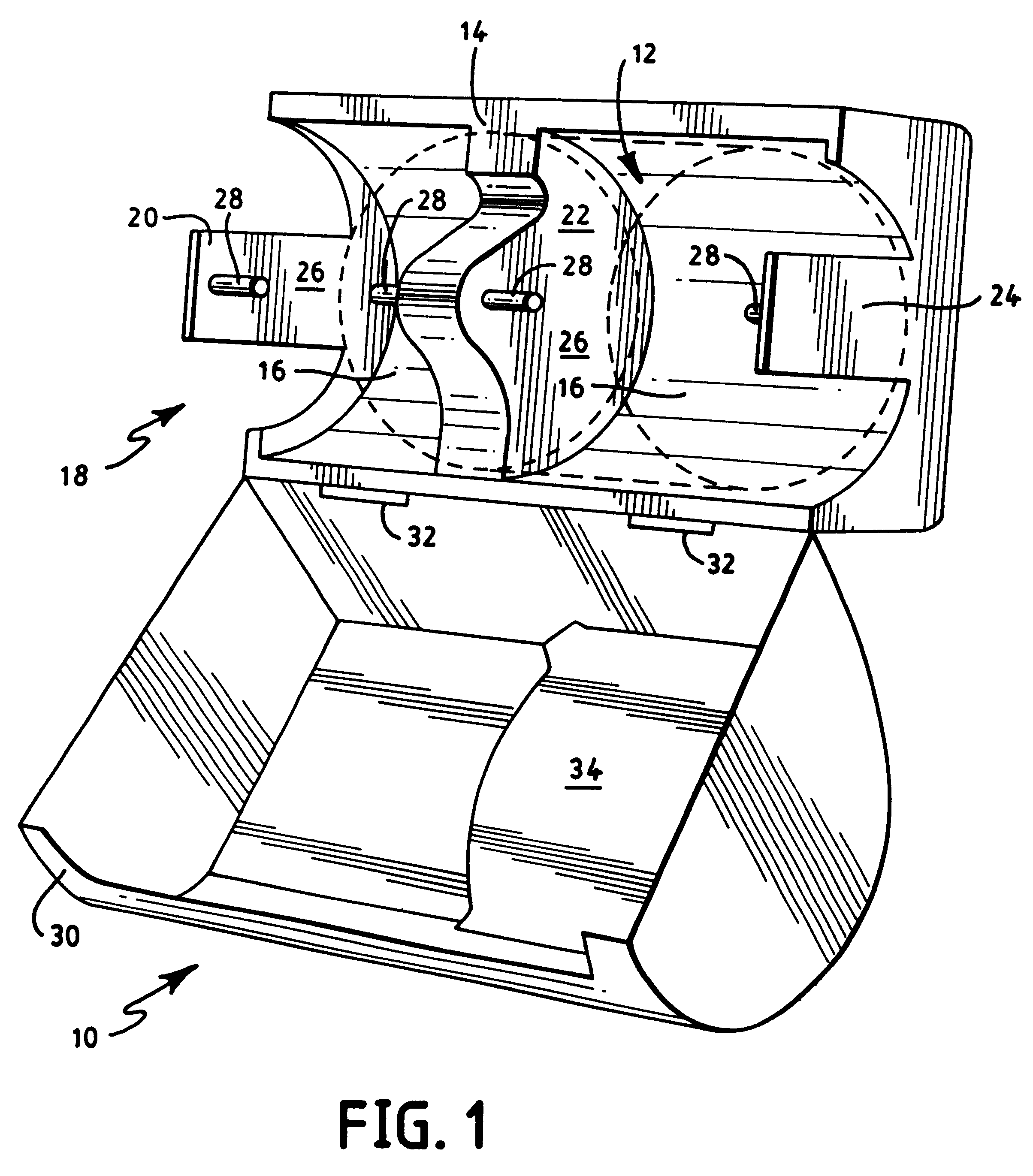

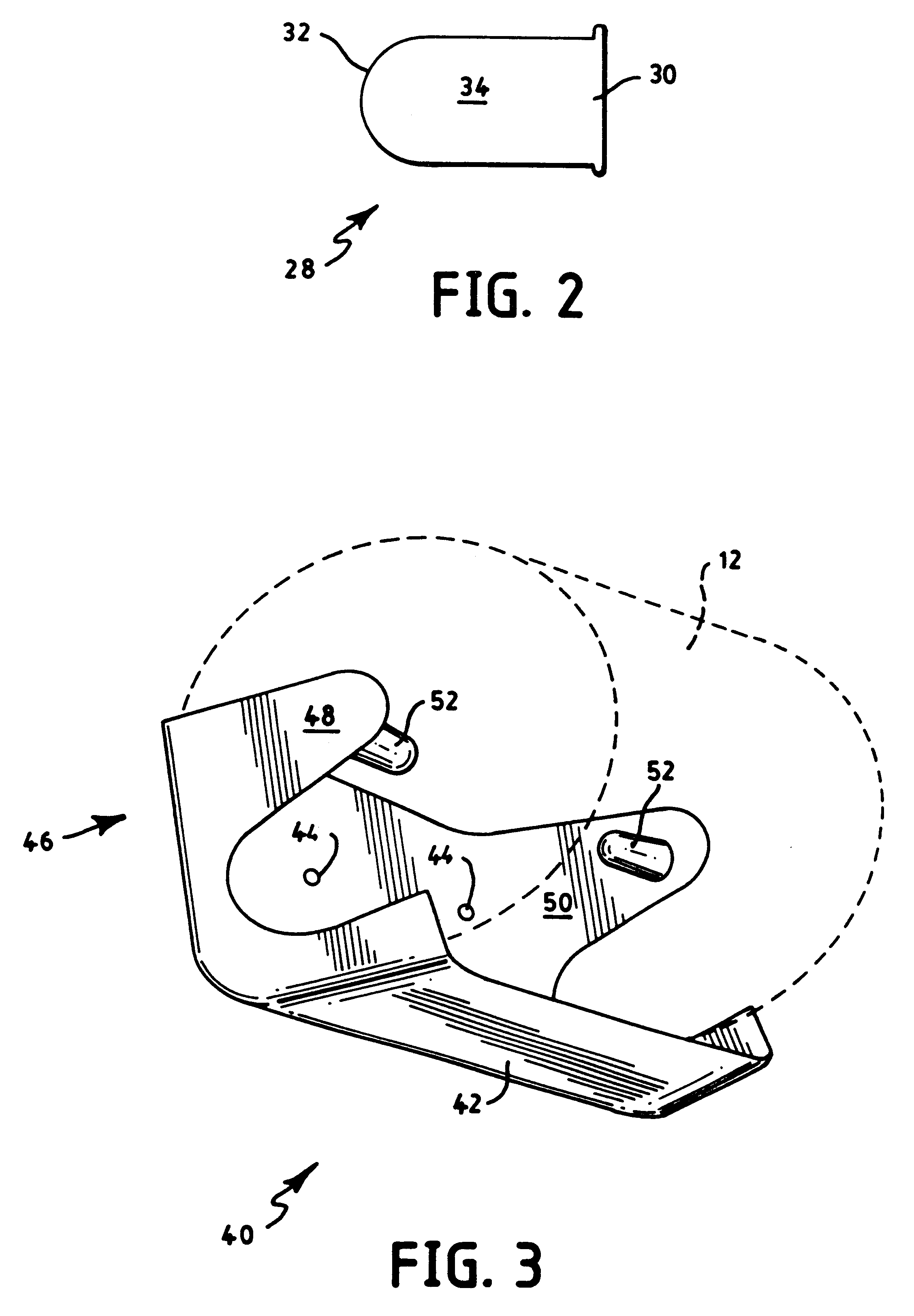

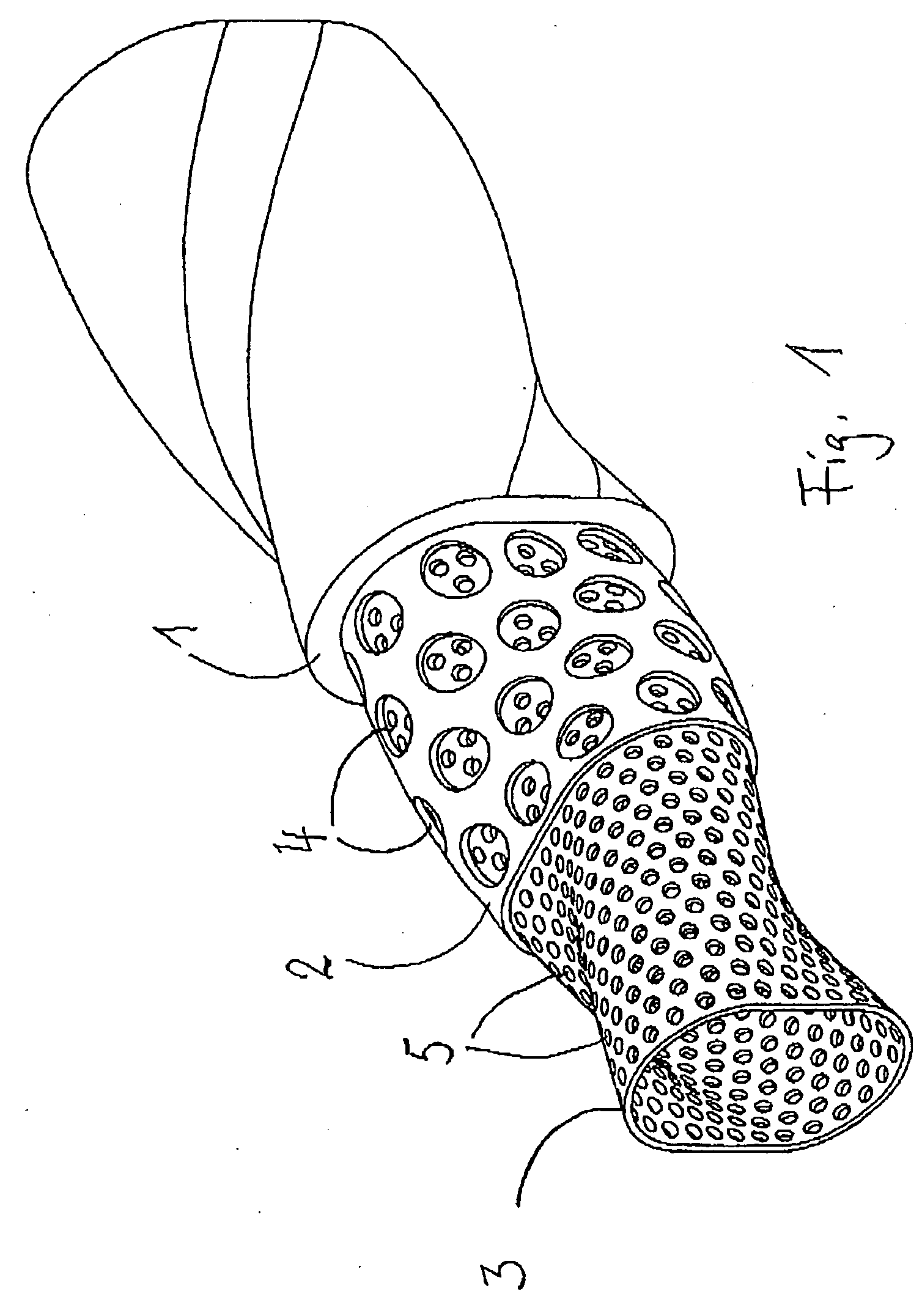

Dispenser for coreless rolls of products

InactiveUS6439502B1Prevent theftPrevent radial displacementFilament handlingDomestic applicationsEngineeringMechanical engineering

A dispenser for a coreless roll product having a pair of depressions defined in the ends of the coreless roll. The dispenser includes: a frame; mounting device for permitting the frame to be mounted to a stationary surface such as a wall; and a coreless roll securing device for securing a coreless roll product for rotation within the frame. The coreless roll securing device includes a pair of cooperating plungers. Each plunger includes: (1) a base, the base being fixed to the frame; (2) a distal end, the distal end having a radius of curvature; and (3) a central shaft, the central shaft connecting the base and the distal end and providing sufficient length so the plunger has a length at least as great as its widest dimension so the plunger is adapted to penetrate a depression defined at an end of a coreless roll product, so radial displacement of the coreless roll with respect to said frame is prevented during use. Also a method for installing a coreless roll of a product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

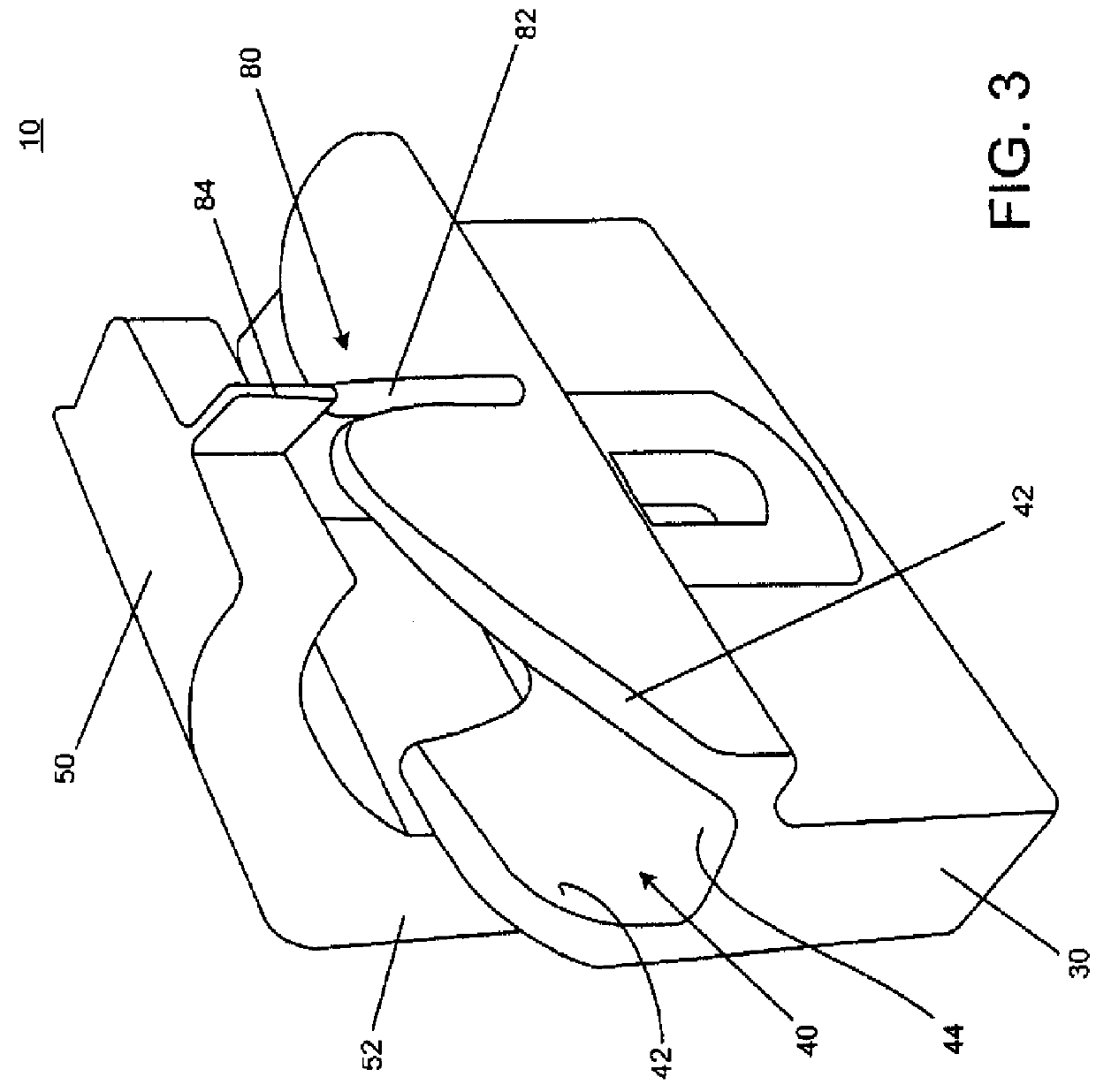

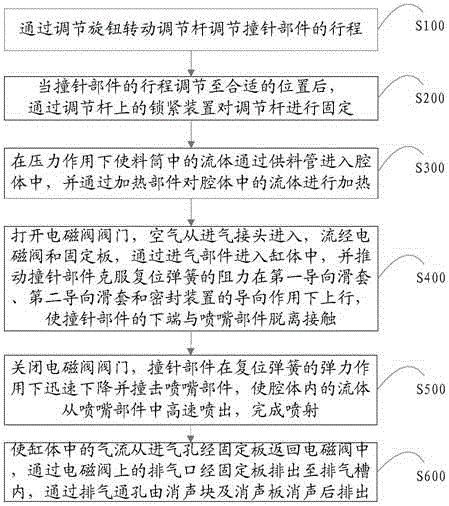

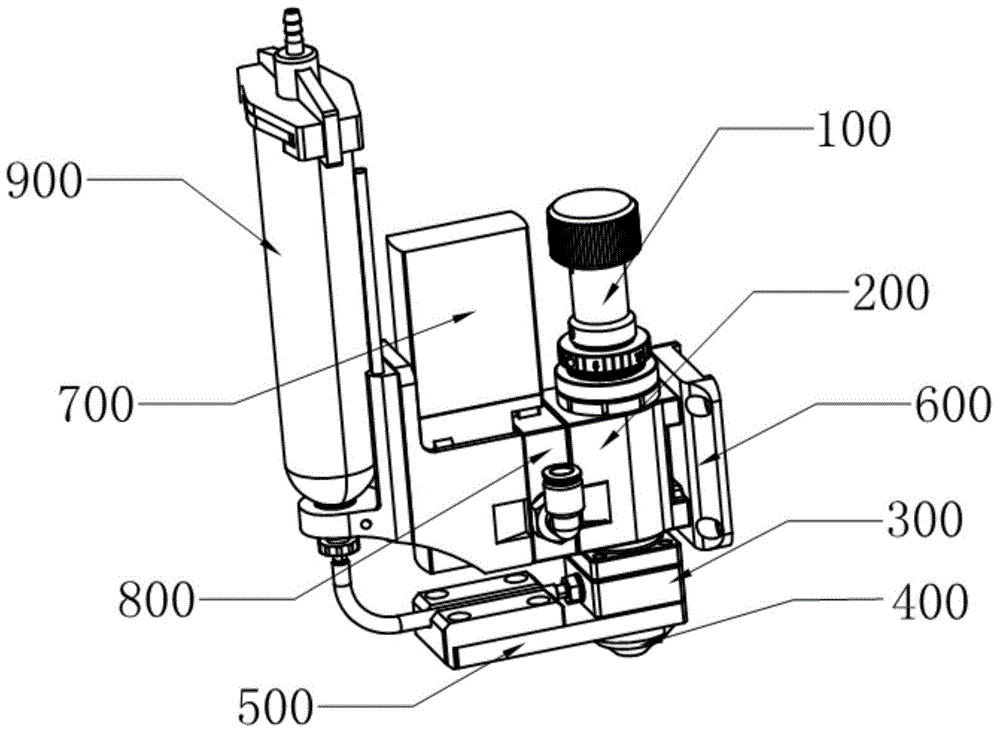

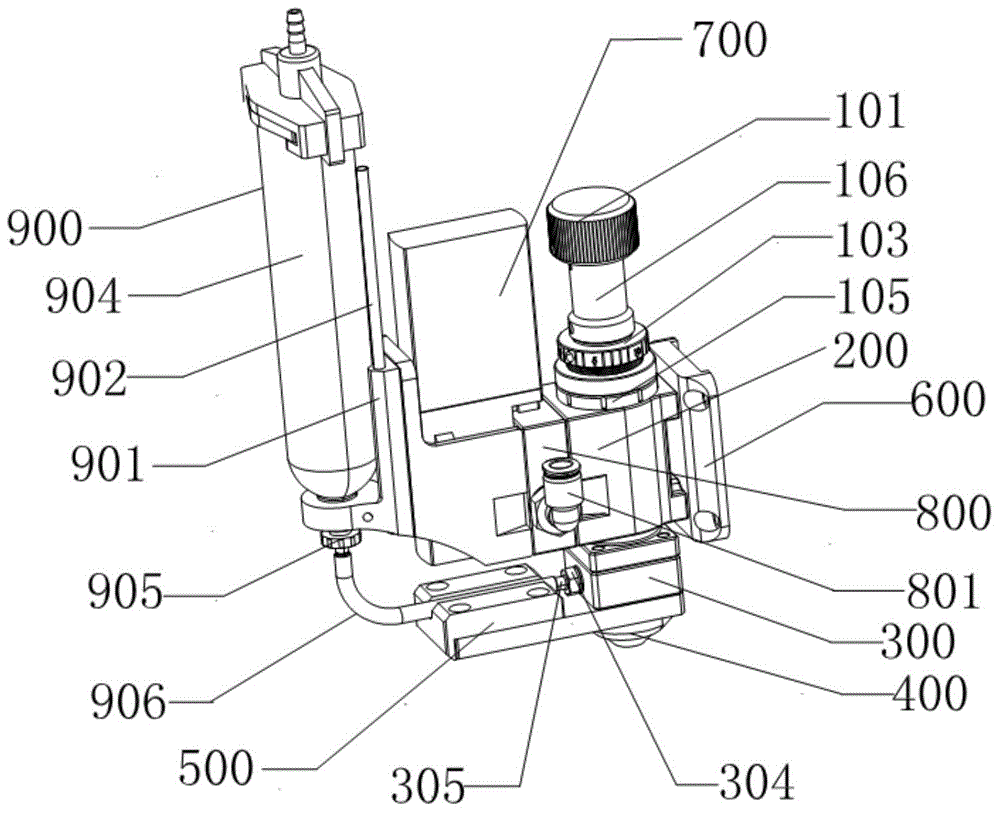

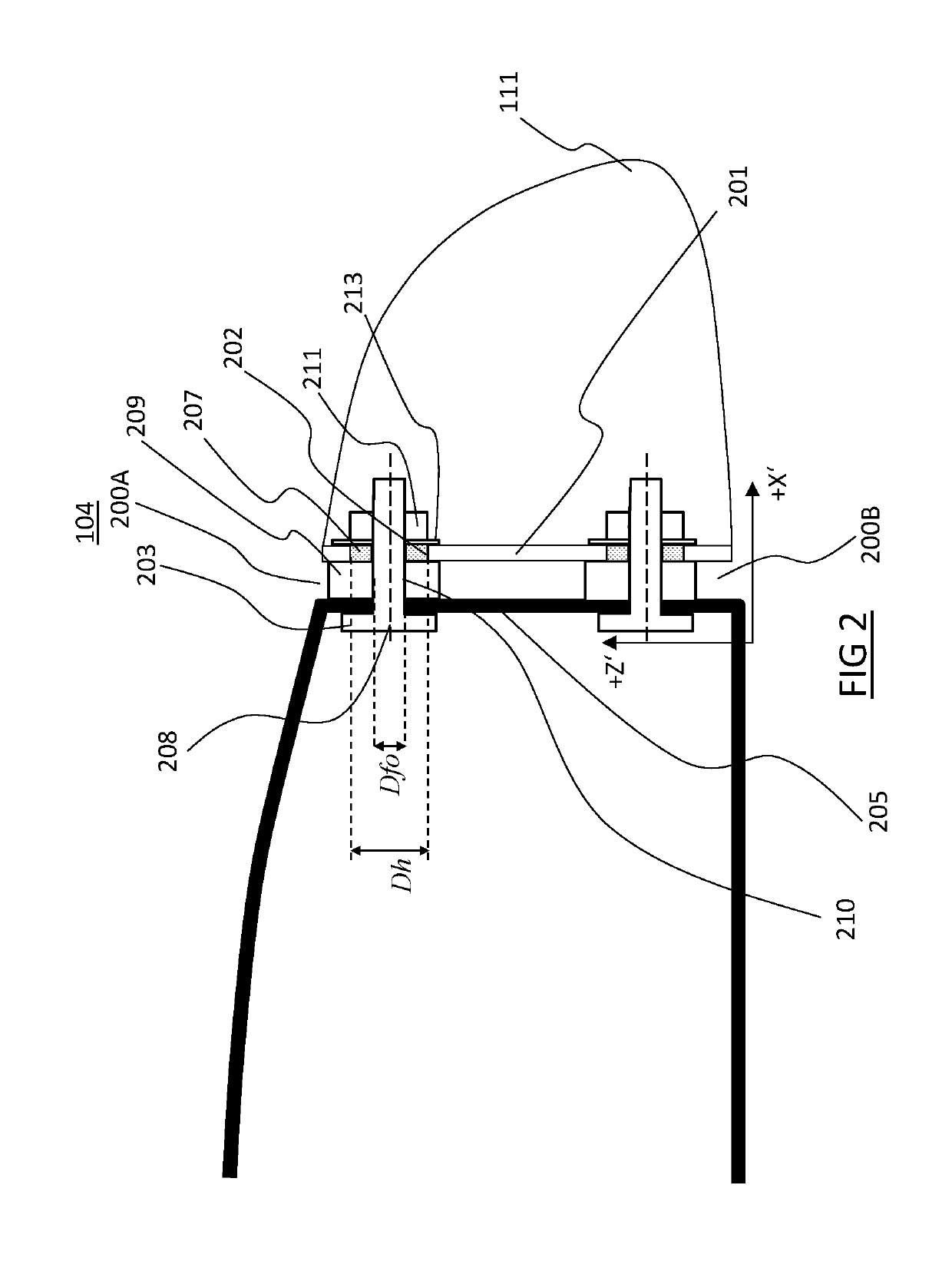

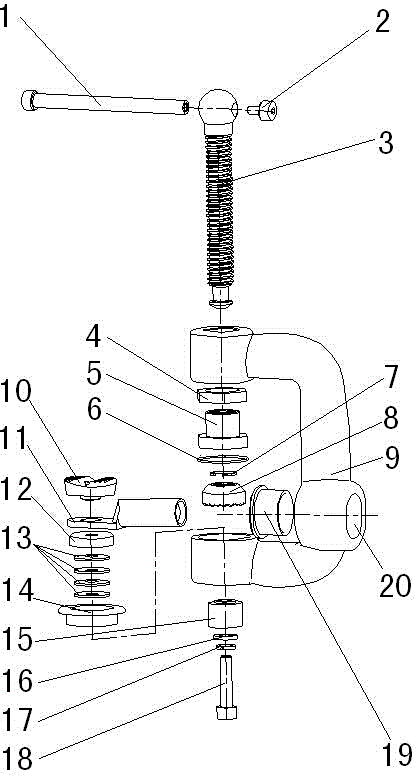

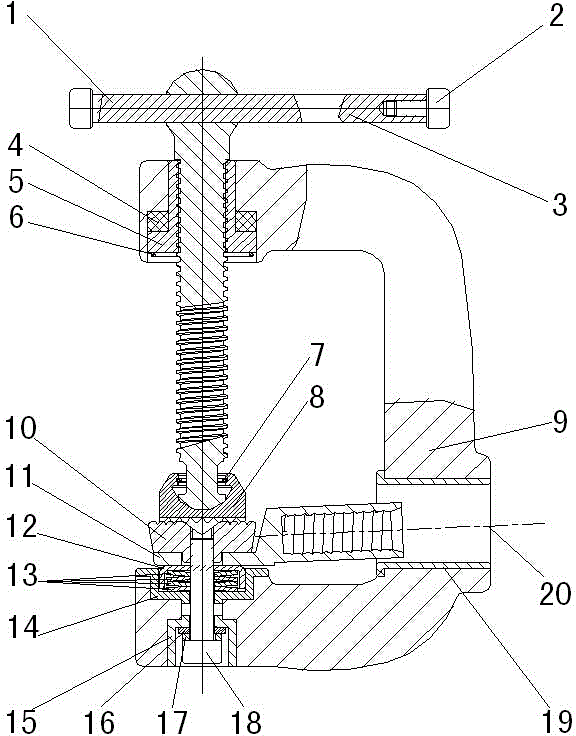

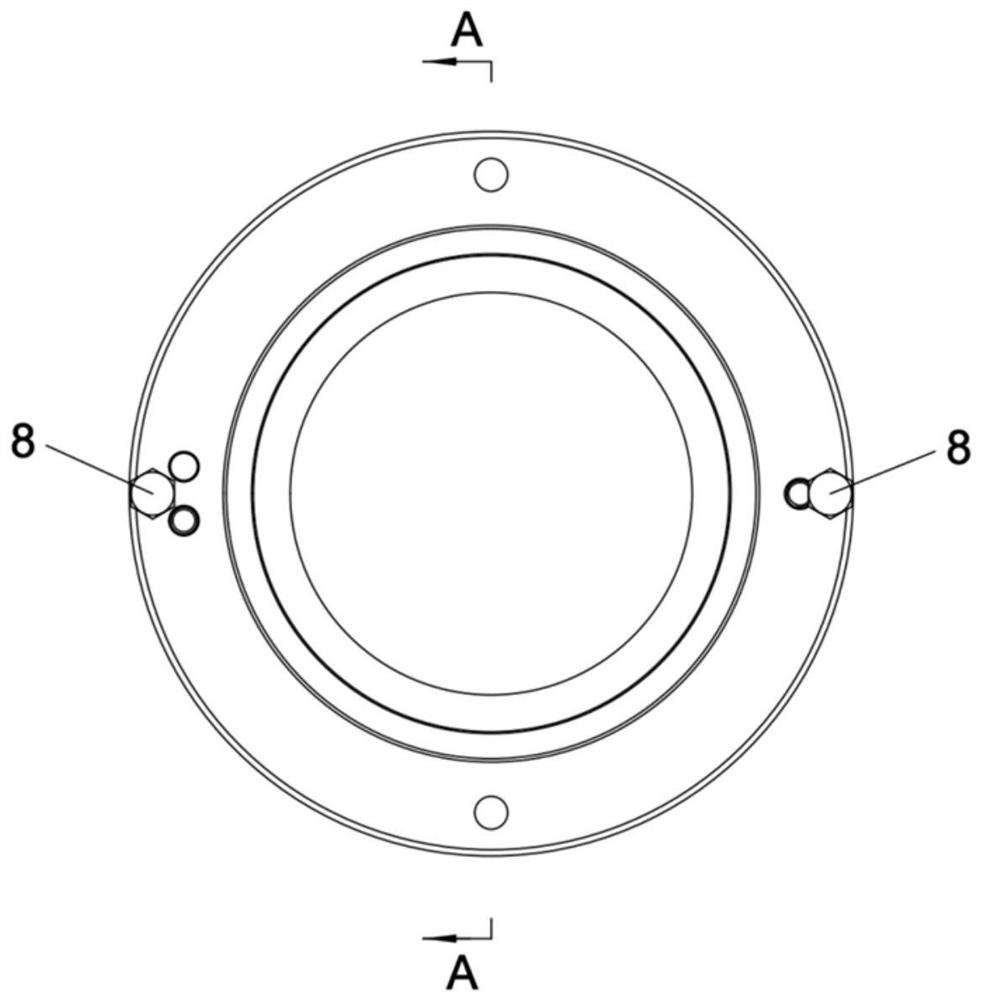

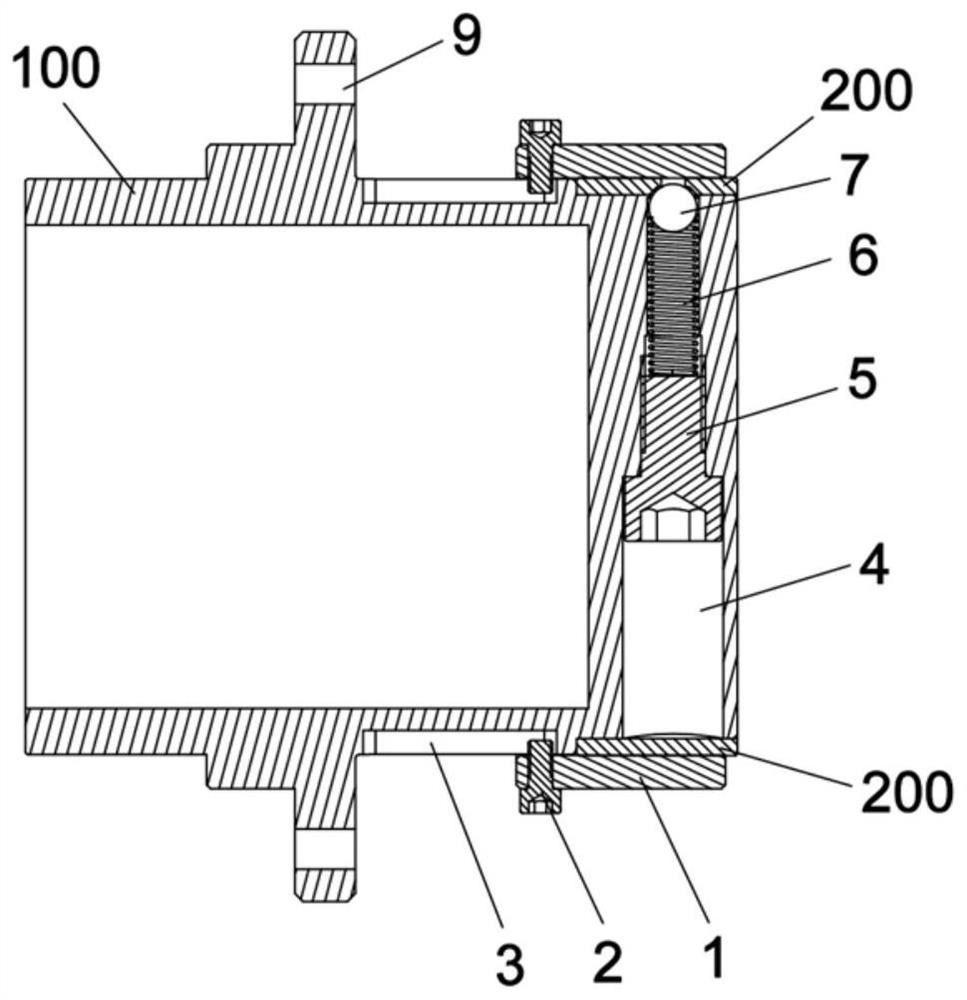

Jet glue dispensing valve and glue dispensing method thereof

ActiveCN104415883APrevent radial displacementMeet exhaust needsLiquid surface applicatorsSpray nozzlesWorking environmentEngineering

A jet dispensing valve and dispensing method thereof, the jet dispensing valve comprising a cylinder (200), a plunger component (201), a cavity (300), a nozzle component (400), an electromagnetic valve (700) and a fixing plate (800); the cylinder (200) and the cavity (300) are fixedly connected; the nozzle component (400) is disposed at the lower end of the cavity (300); one end of the plunger component (201) is located inside the cylinder (200), and the other end is disposed inside the cavity (300) and contacts the nozzle component (400); the electromagnetic valve (700) is fixedly connected to the cylinder (200) via the fixing plate (800); the jet dispensing valve further comprises a vent component (600) disposed at one side of the cylinder (200); the cylinder (200) further comprises a vent groove and a vent through-hole (209); the vent groove is a ring groove structure, and is disposed at the side of the cylinder (200) connected to the fixing plate (800), and communicates with the vent opening of the electromagnetic valve (700) through a tubing of the fixing plate (800); the vent through-hole (209) is disposed inside the cylinder (200); and one end of the vent through-hole (209) communicates with the vent groove, and the other end communicates with the vent component (600). The vent component (600) is disposed to reduce noise and improve working environment; and a guide device is disposed to avoid the radial displacement of the plunger component (201) in the up-and-down movement.

Owner:SHENZHEN TENSUN IND EQUIP

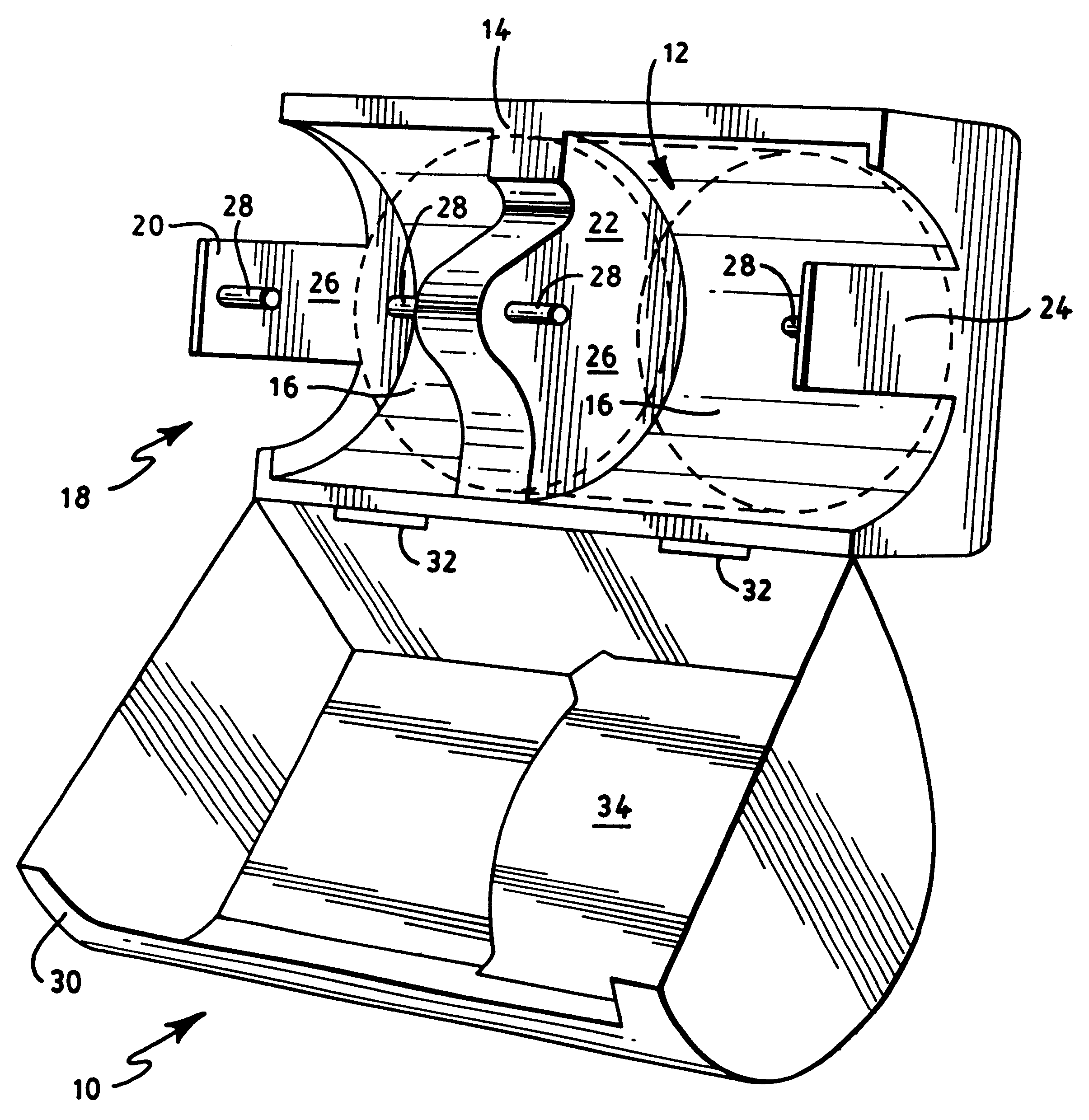

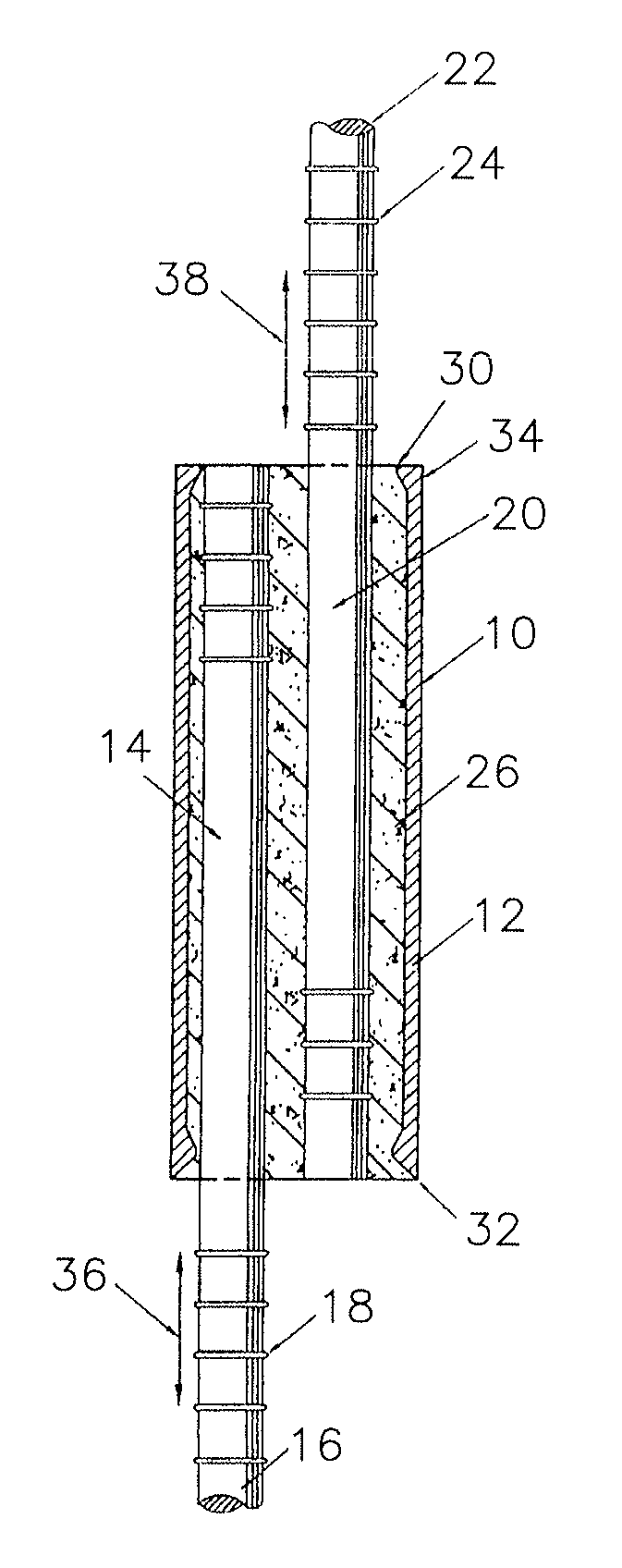

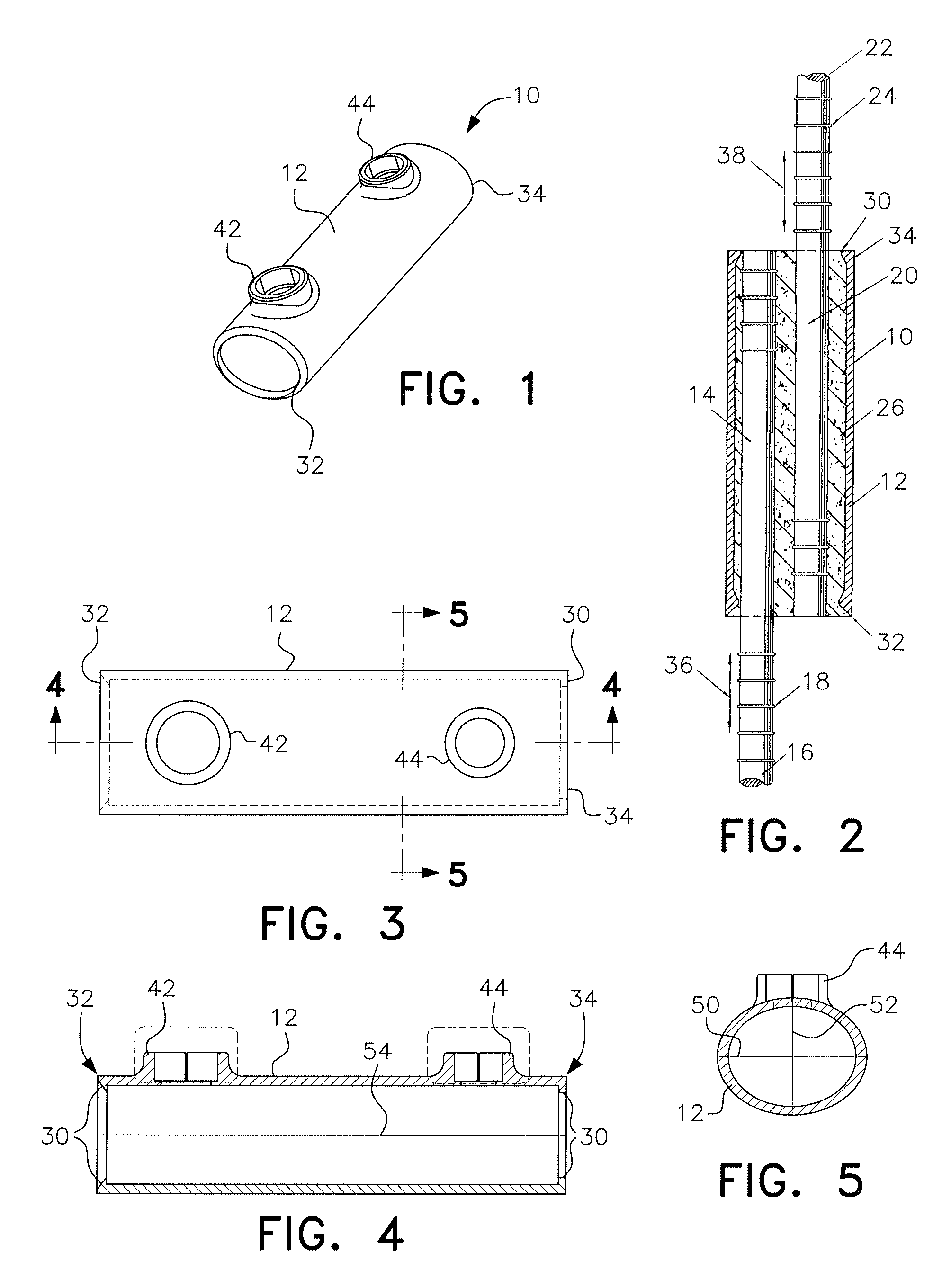

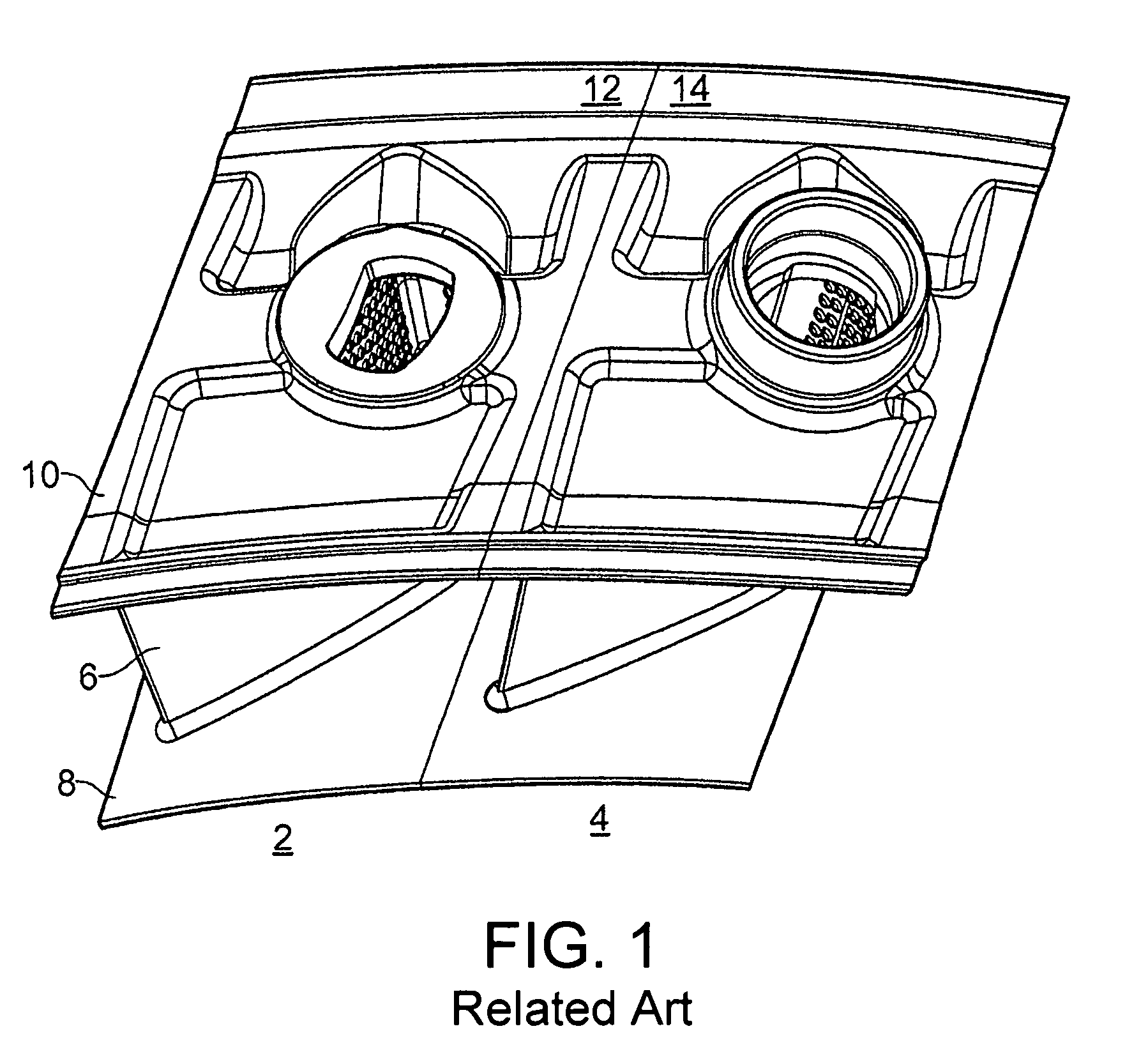

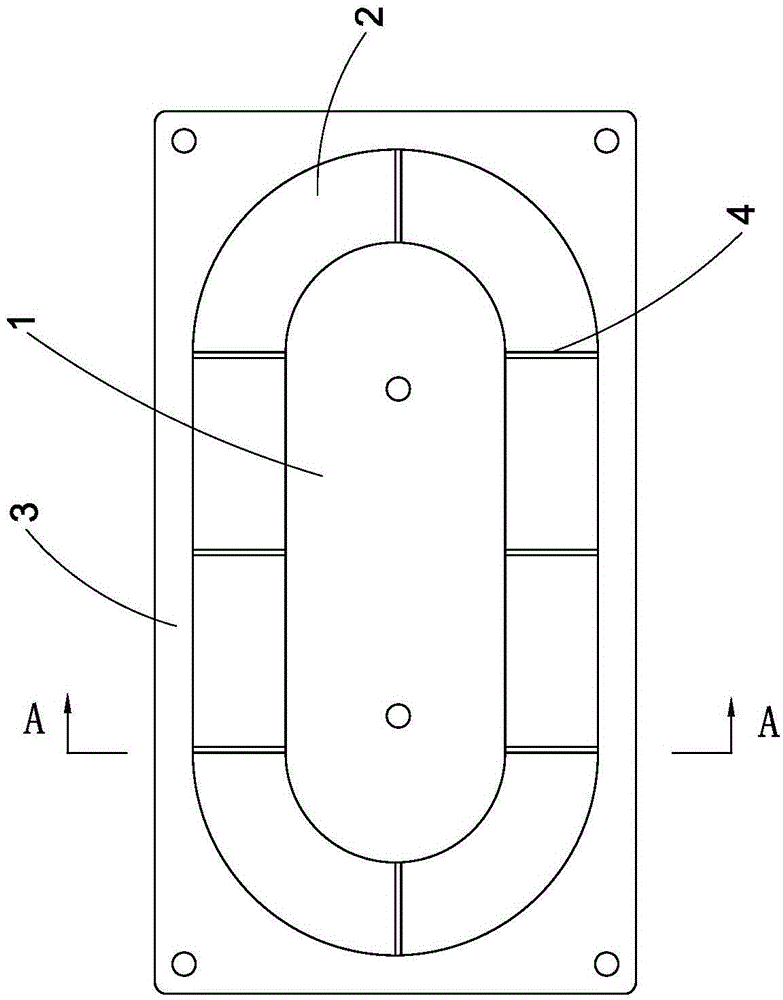

Splice sleeve with elliptical or compound curve cross section

InactiveUS20130028658A1Increases splicing capacity of overlappingMaximum bondingMetal rolling stand detailsRod connectionsEllipseEngineering

A splice sleeve having an elliptical or compound curve cross section for connecting overlapping end portions of reinforcing bars utilized in various types of structures in which steel reinforcing bars are utilized and it is desired to connect the overlapping end portions of the reinforcing bars. The elliptical or compound curve cross section splice sleeve is configured to receive the overlapped end portions of the reinforcing bars and then be filled with hardenable material to resist axial tension and compression exerted on the reinforcing bars. In one embodiment, both ends of the sleeve are provided with an inwardly directed lip to increase the splicing capacity of the elliptical or compound curve cross section sleeve by increasing the resistance against radial outward forces imparted to the hardenable material when axial tension is exerted on the reinforcing bars, and also to serve as a guide to position the rebars to a minimum of about 3 mm from the inside wall surface of the sleeve.

Owner:AE CONNECTOR SOLUTIONS

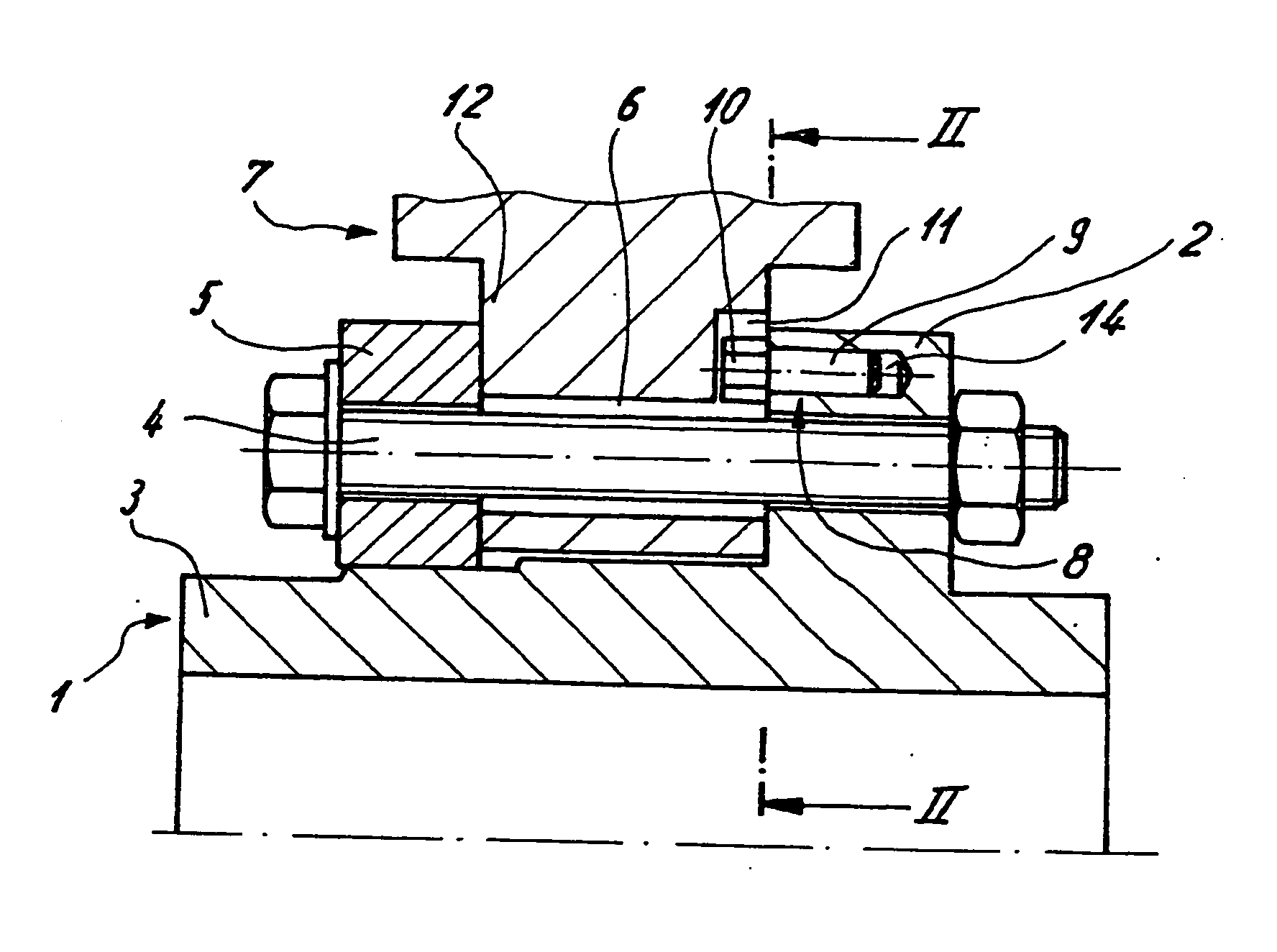

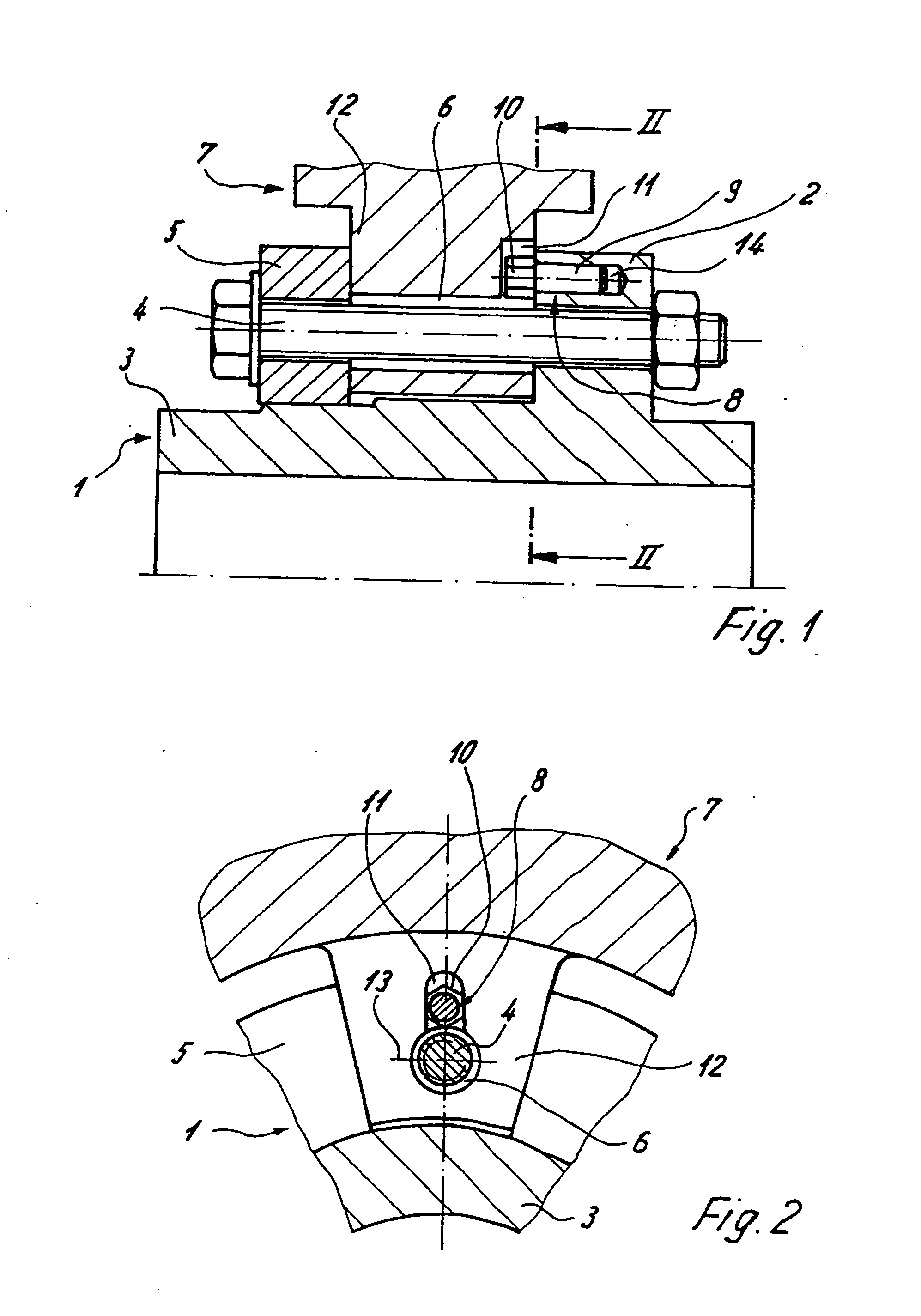

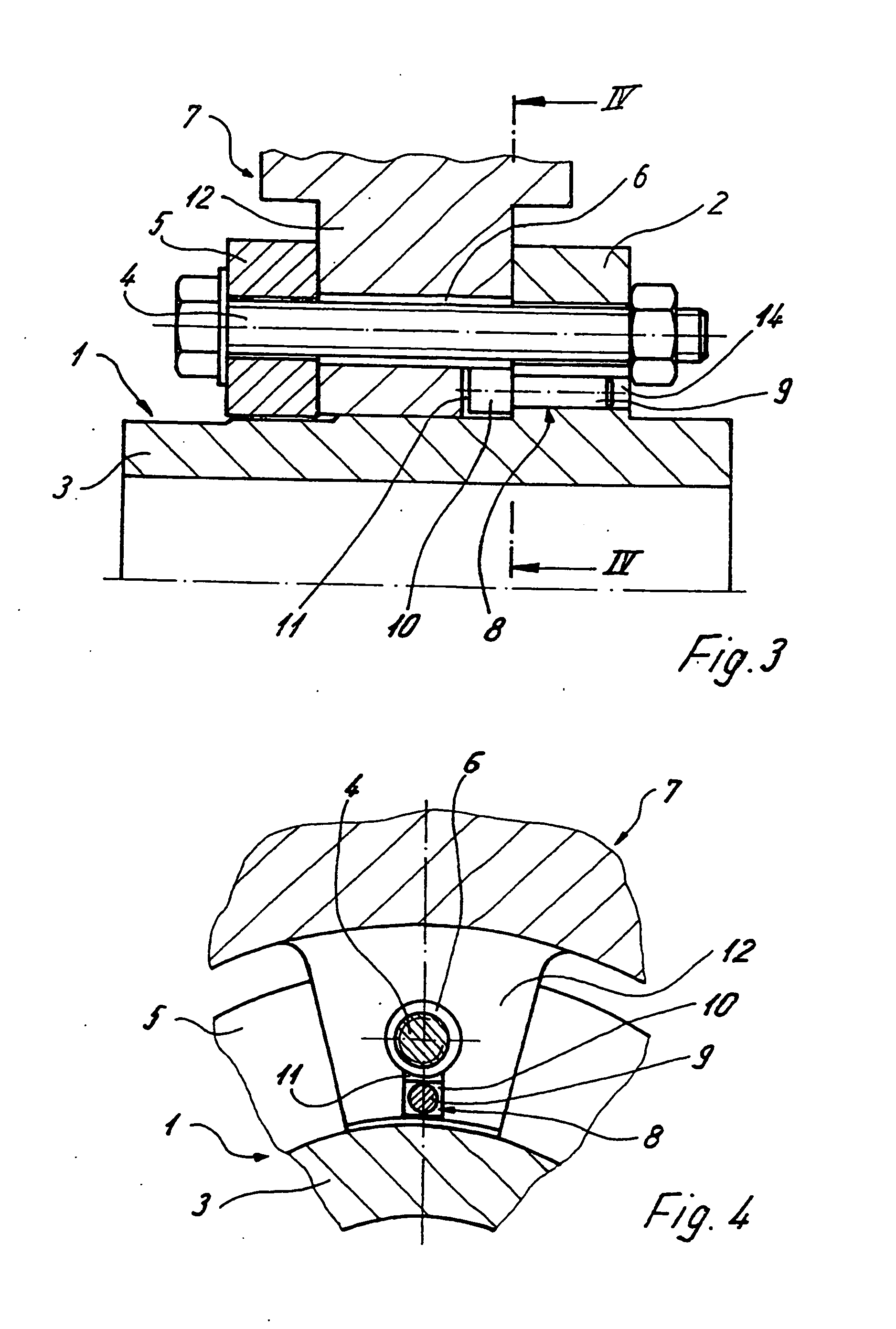

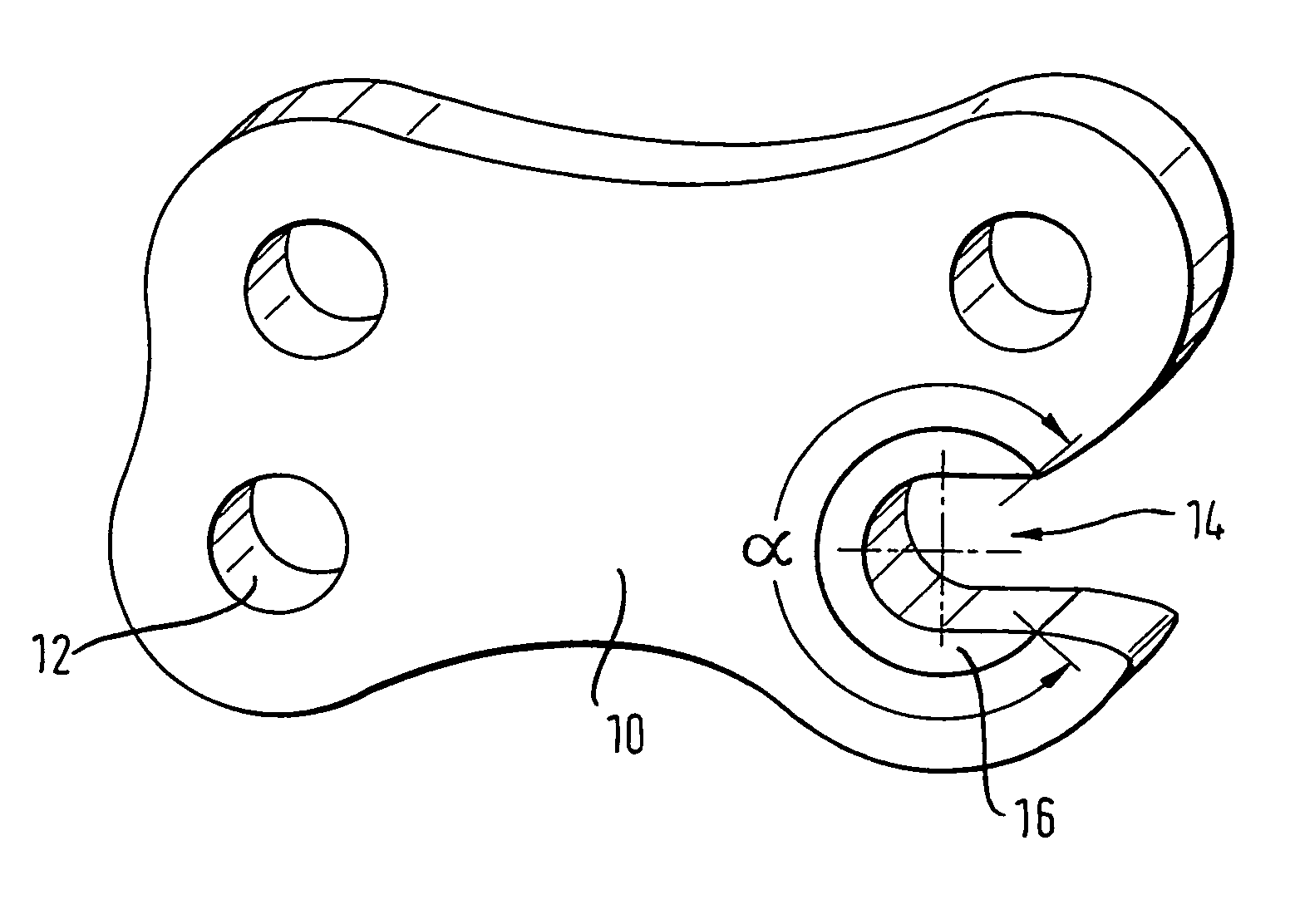

Brake Disk, Especially for a Rail Vehicle

A brake disk for a rail vehicle includes a hub and at least one friction ring having radial grooves. The friction disk is fastened by a clamping bolt to the hub. Also included are sliding elements having a shank and the sliding elements are connected to the hub. The sliding elements engage in the radial grooves for anti-rotation locking and centering of the at least one friction ring. The sliding elements extend parallel to an axis of the clamping bolt.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

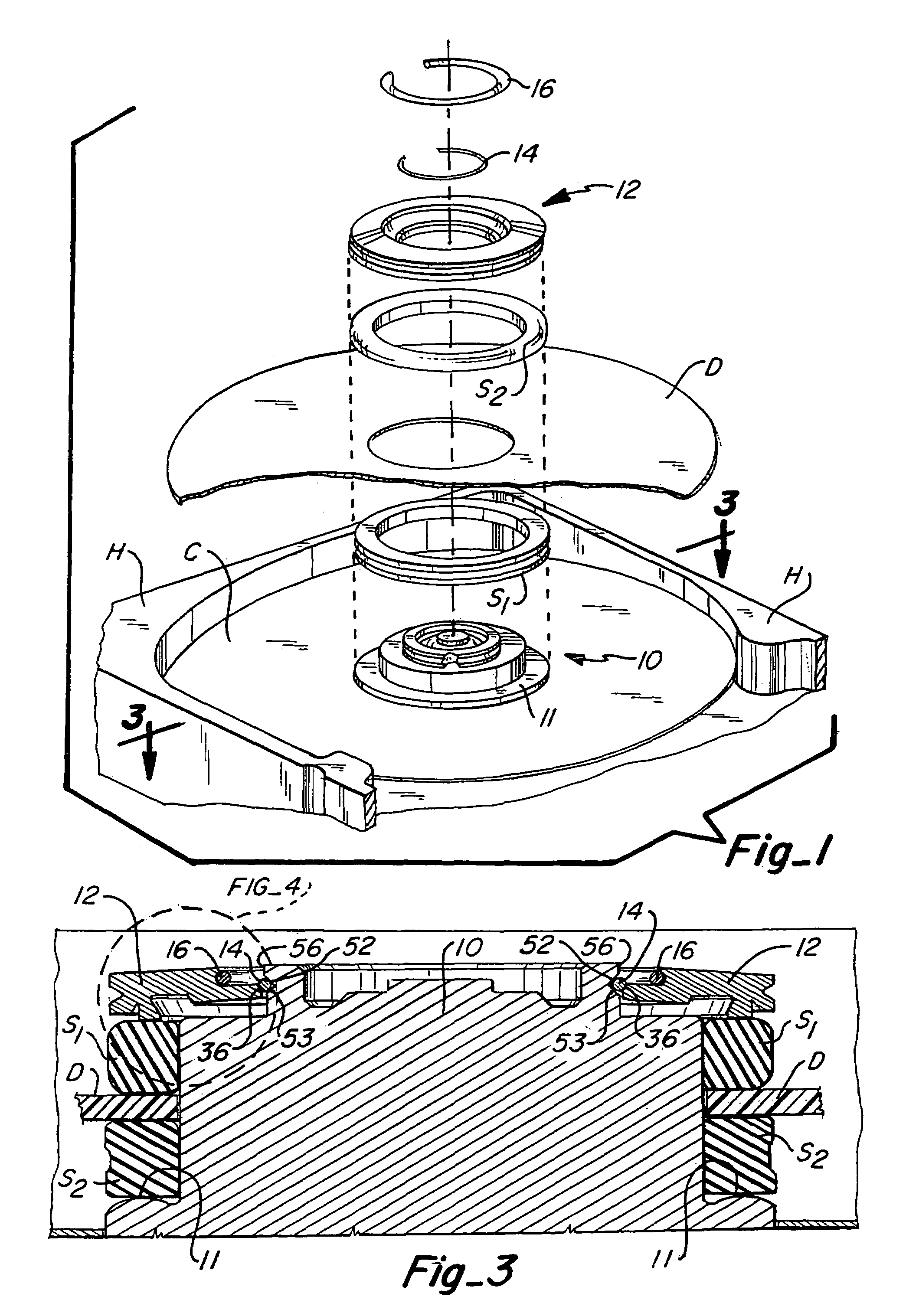

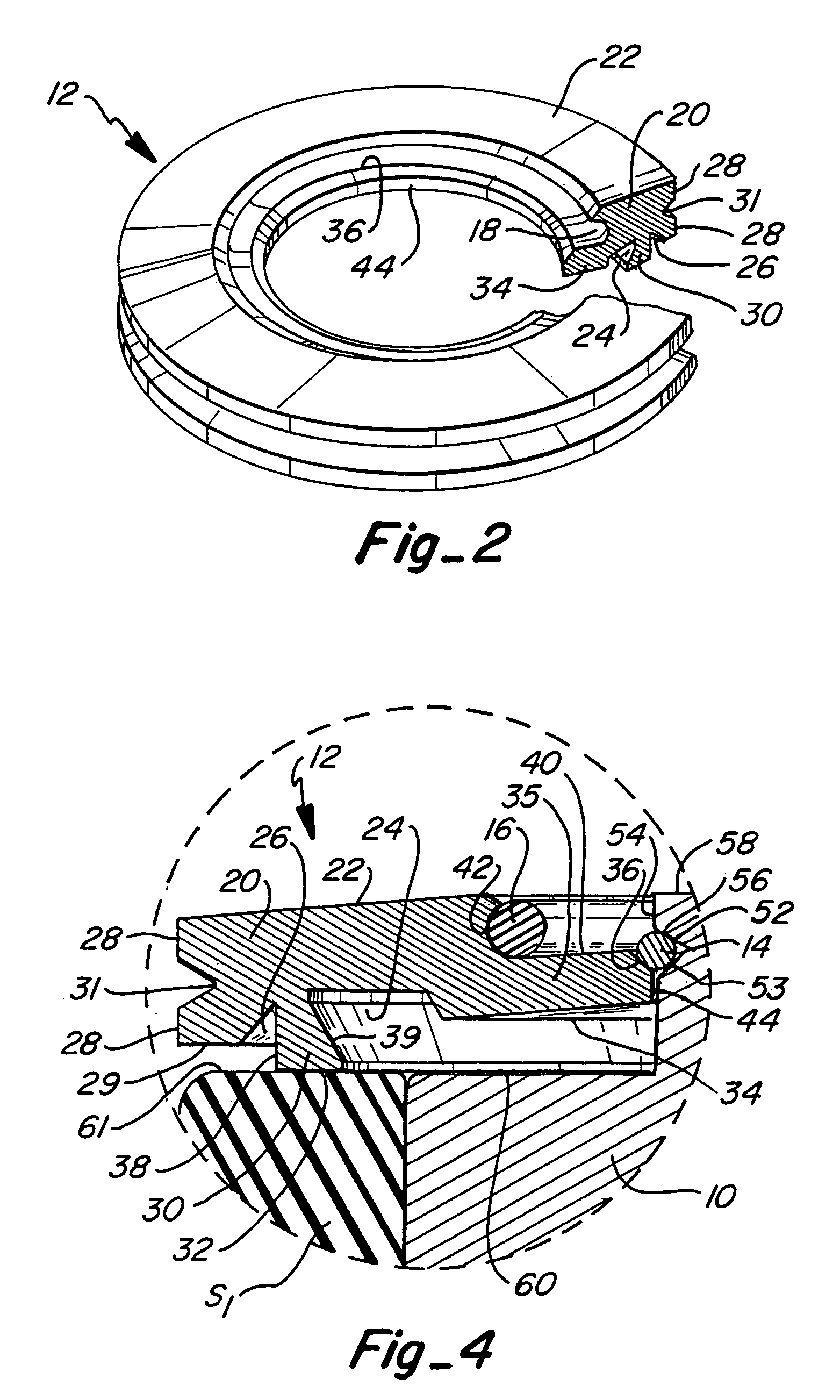

Method of installing a disk clamp over a hub of a disk drive

InactiveUS7181824B1Minimize deflectionUndesirable radial loadingElectrical transducersRecord information storageEngineeringRetaining ring

A disk clamp is provided for securing one or more data storage disks to a disk drive without the need for screws. A preloading device is also provided for installing the disk clamp and removing the disk clamp after installation. The preloading device applies a load to the clamp to deflect the clamp, and allows a retaining ring to be positioned between the disk clamp and the hub of the disk drive. Preloading the disk clamp helps to reduce disk drive contamination, potential damage to the motor hub, and improves reworkability of the disk drive. The preloading device can be incorporated within a manually manipulated preloading device, or within an automated assembly process in which the preloading device is incorporated. Methods are also provided for clamp preloading and clamp installation.

Owner:SEAGATE TECH HDD HLDG +3

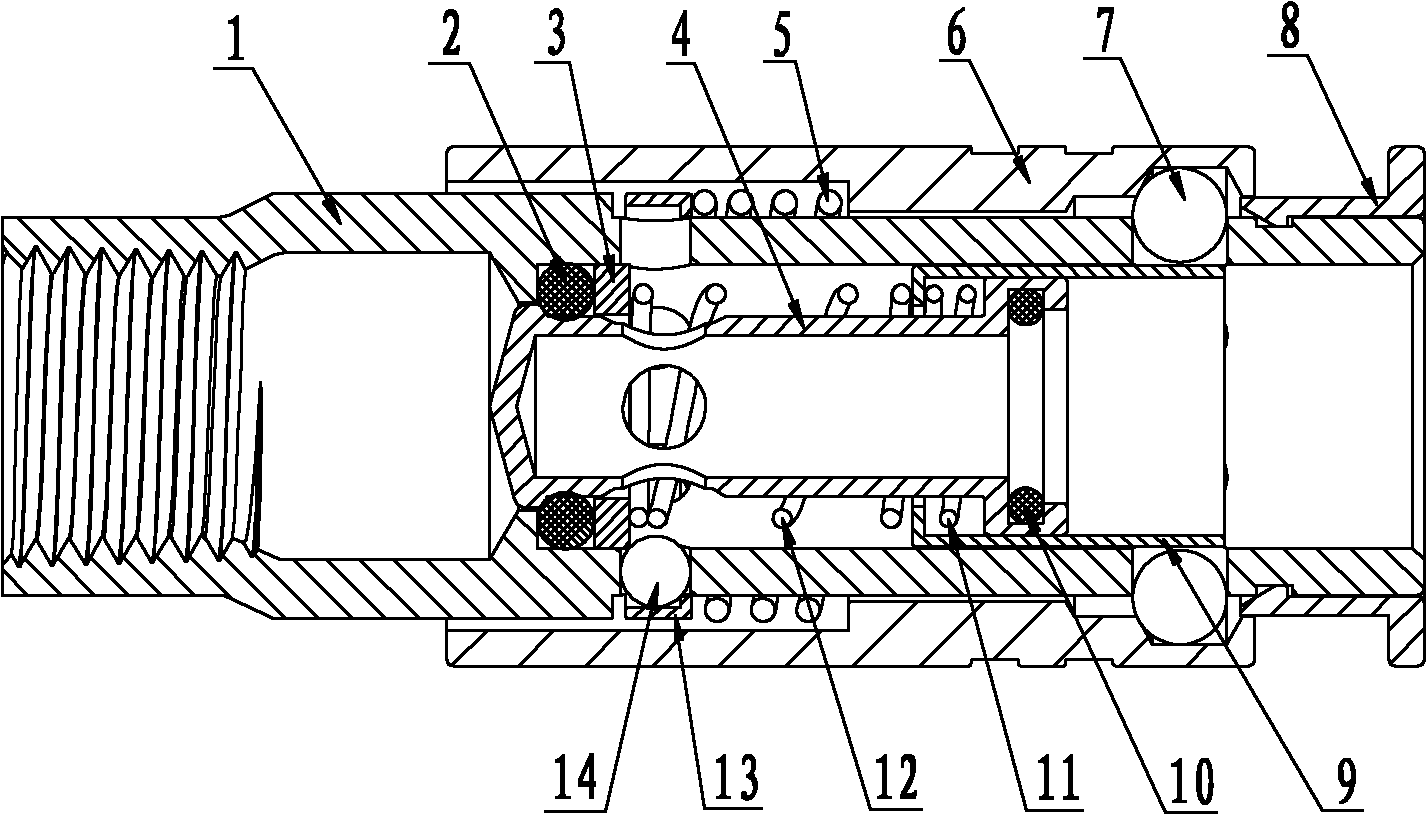

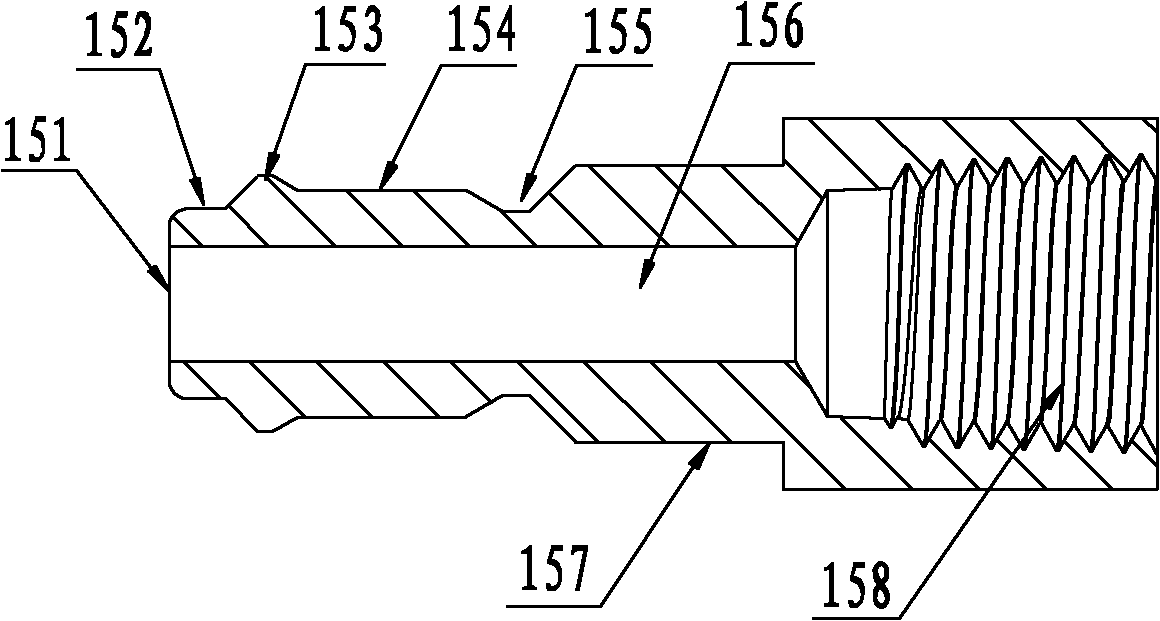

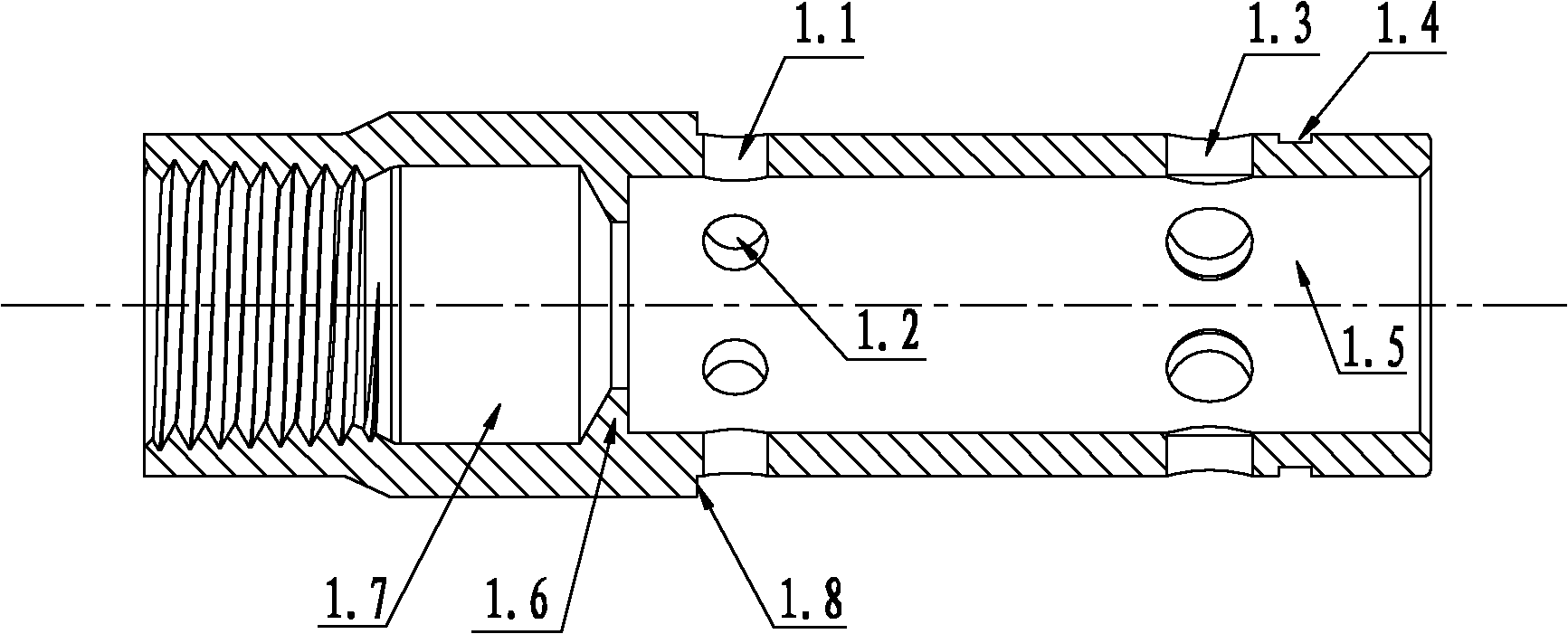

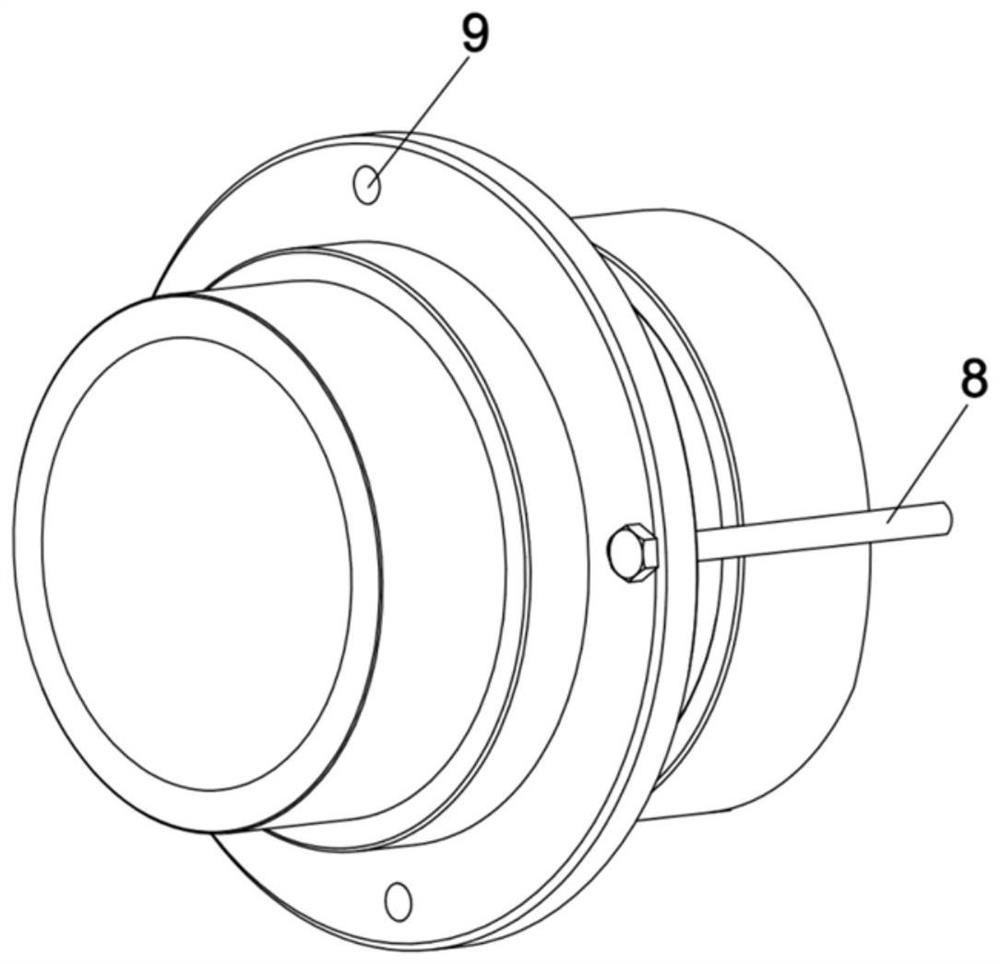

Flush-resistant pneumatic quick-change connector

The invention discloses a flush-resistant pneumatic quick-change connector and an air entraining plug in matched use thereof, wherein the flush-resistant pneumatic quick-change connector comprises an air inlet connecting sleeve, an air inlet seal ring, a seal check ring, a valve core, a slide sleeve spring, a disassembly slide sleeve, a locking steel ball, a protective shaft sleeve, an inner slide sleeve with a shoulder, an air outlet seal ring, an inner sleeve spring, a valve core spring, a radial sleeve and a positioning ball. The three main parts, namely the air inlet connecting sleeve, the valve core and a mobile slide sleeve, have the advantages of simple structure and good machining process; the machining can be finished by adopting a conventional low-cost mechanical machining method; the structure of the air entraining plug is extremely simple, and the machining cost is low; the flush-resistant pneumatic quick-change connector and the air entraining plug are in matched use, have the quick-change function and can prevent the flush phenomenon from occurring when the air entraining plug is detached; and all the functions of the safety pneumatic quick-change connector in the Chinese patent CN201152427Y can be realized, and the cost is 30-50% lower than that of the safety pneumatic quick-change connector.

Owner:庄志军 +1

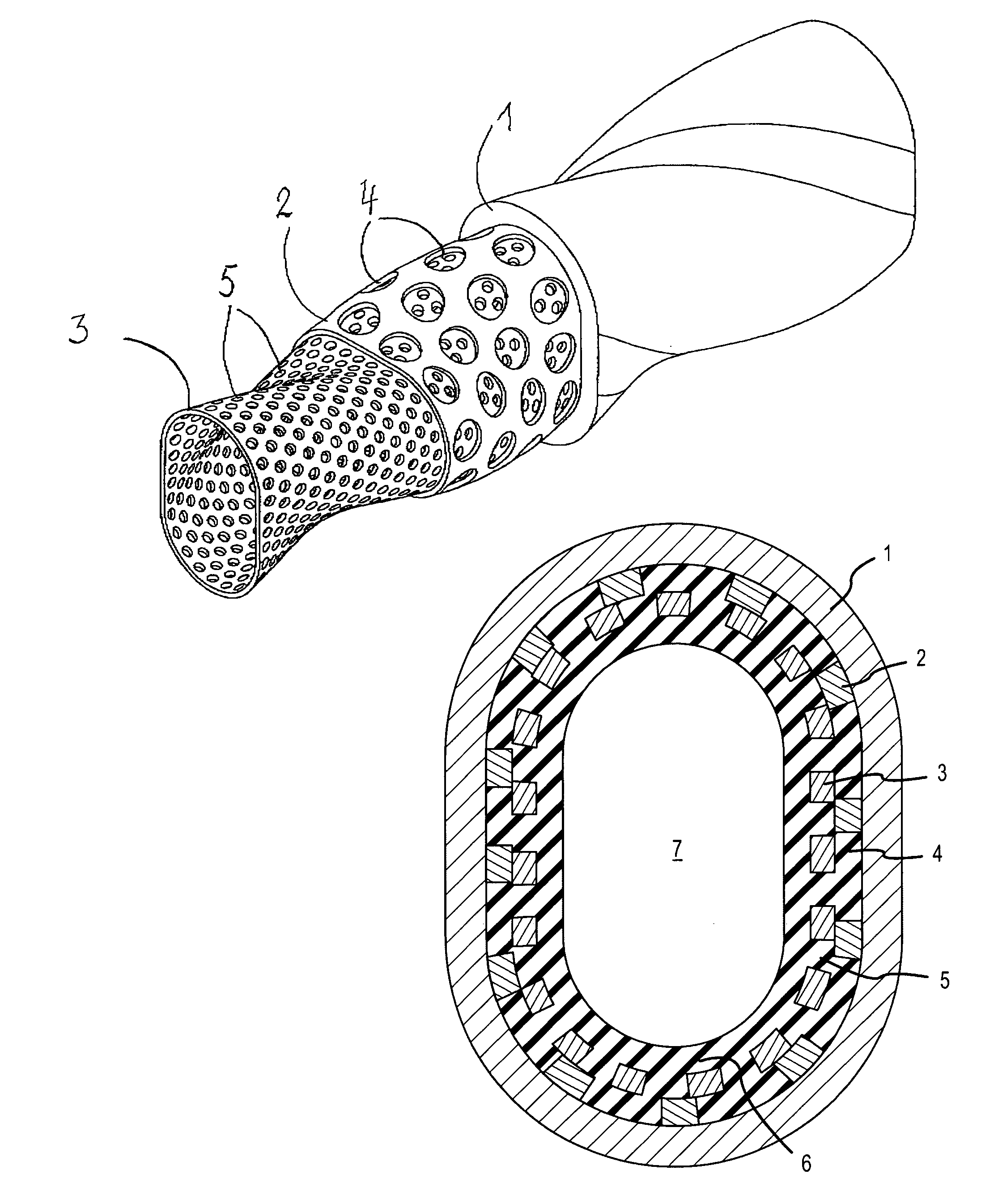

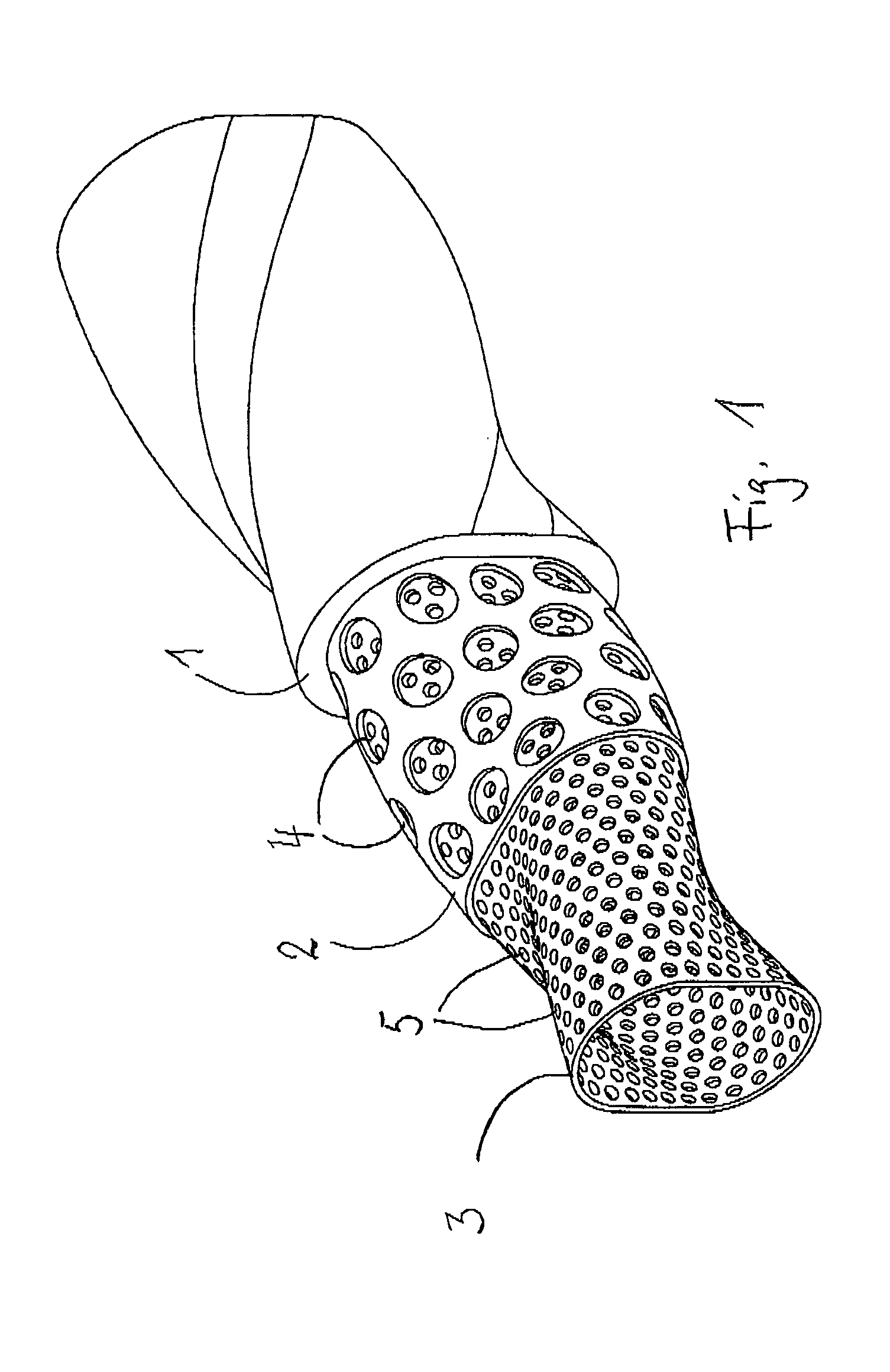

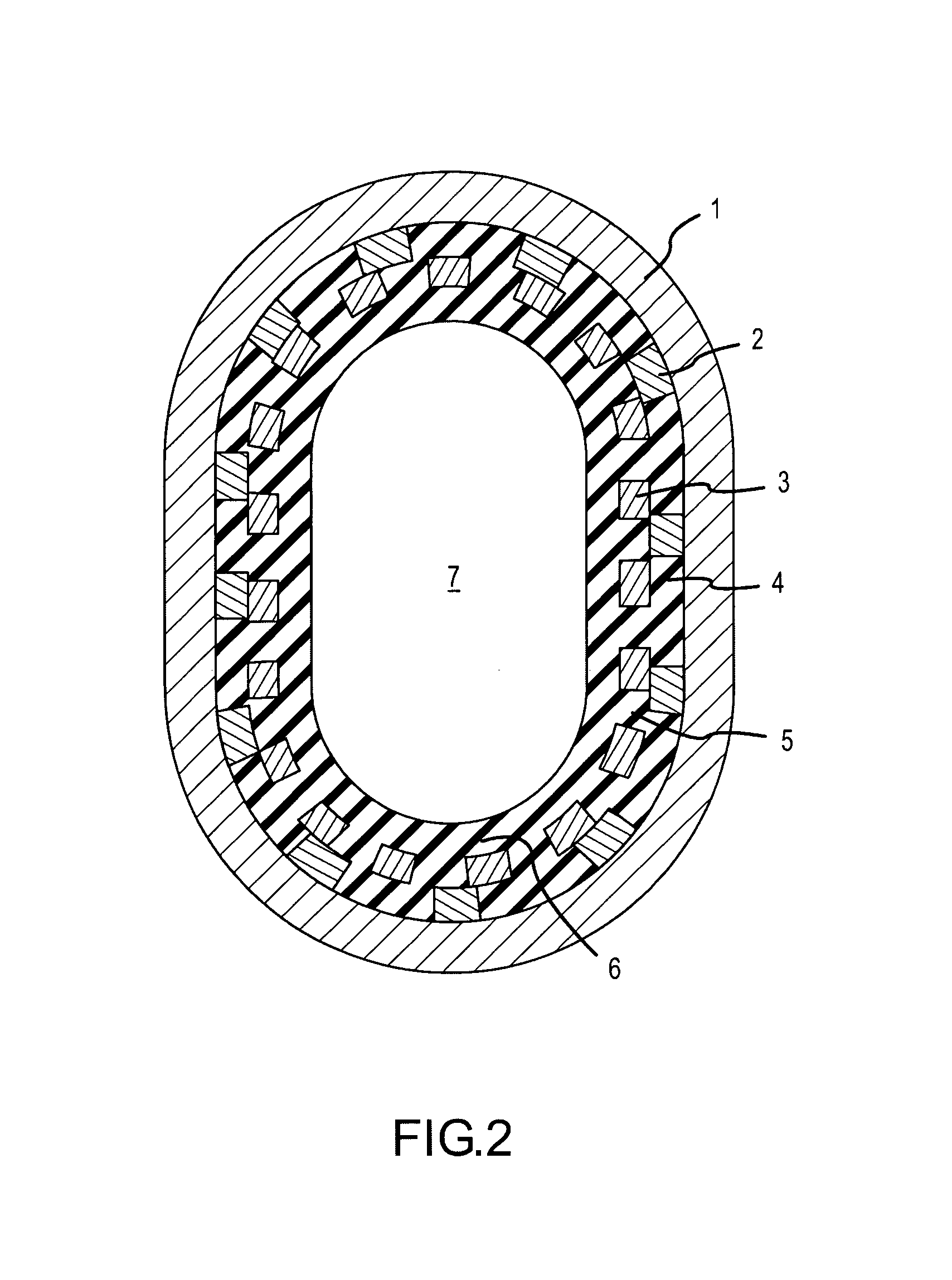

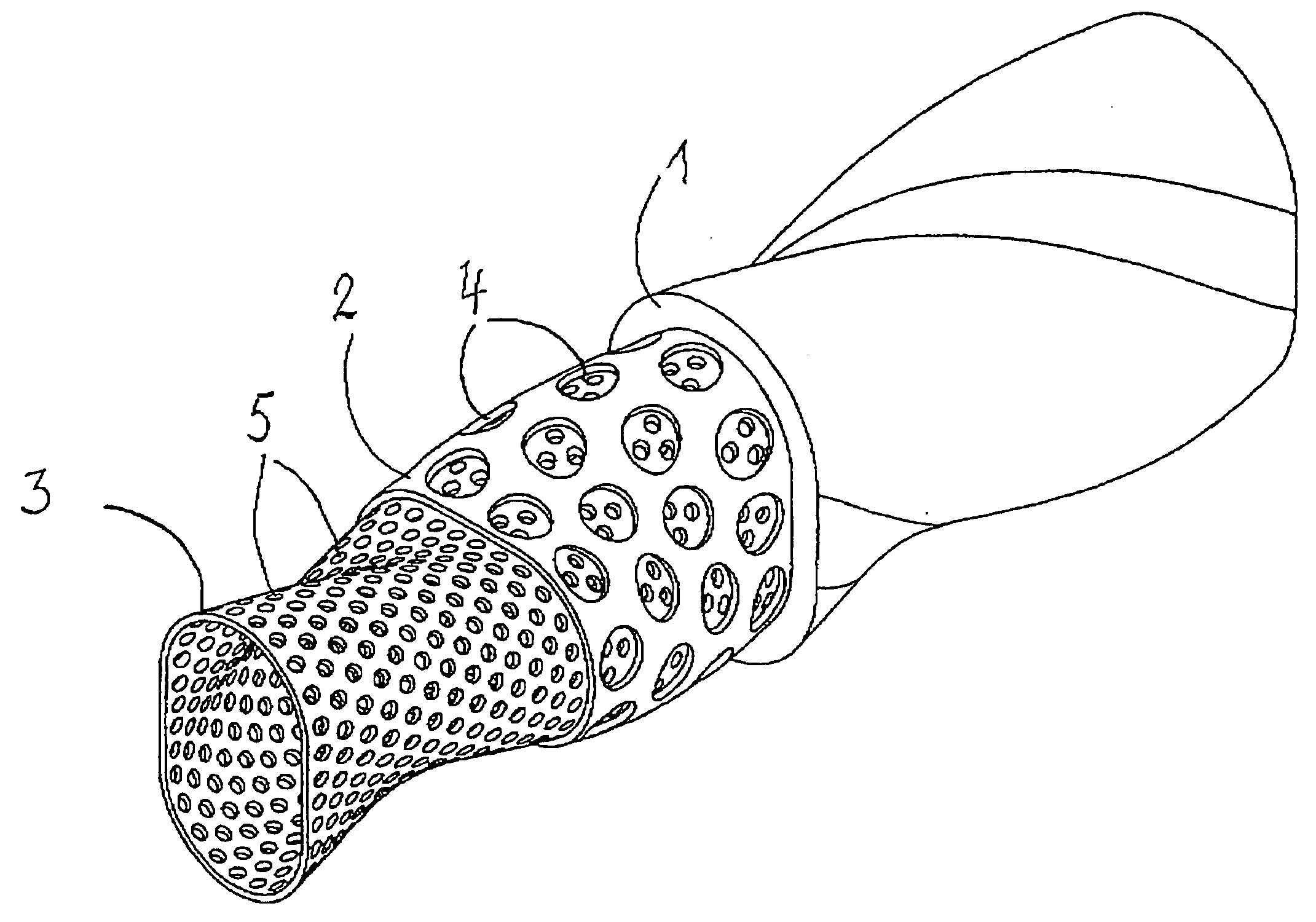

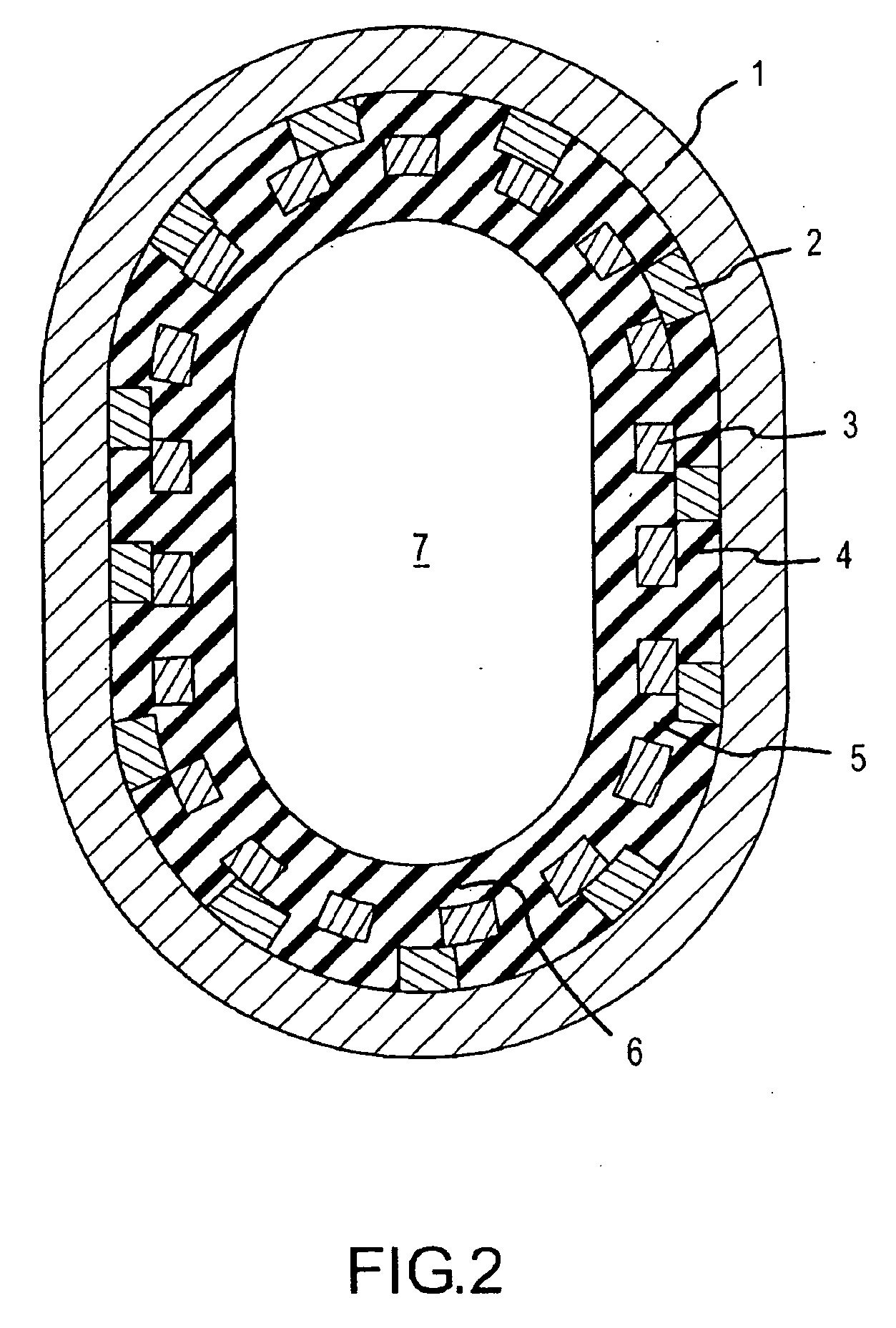

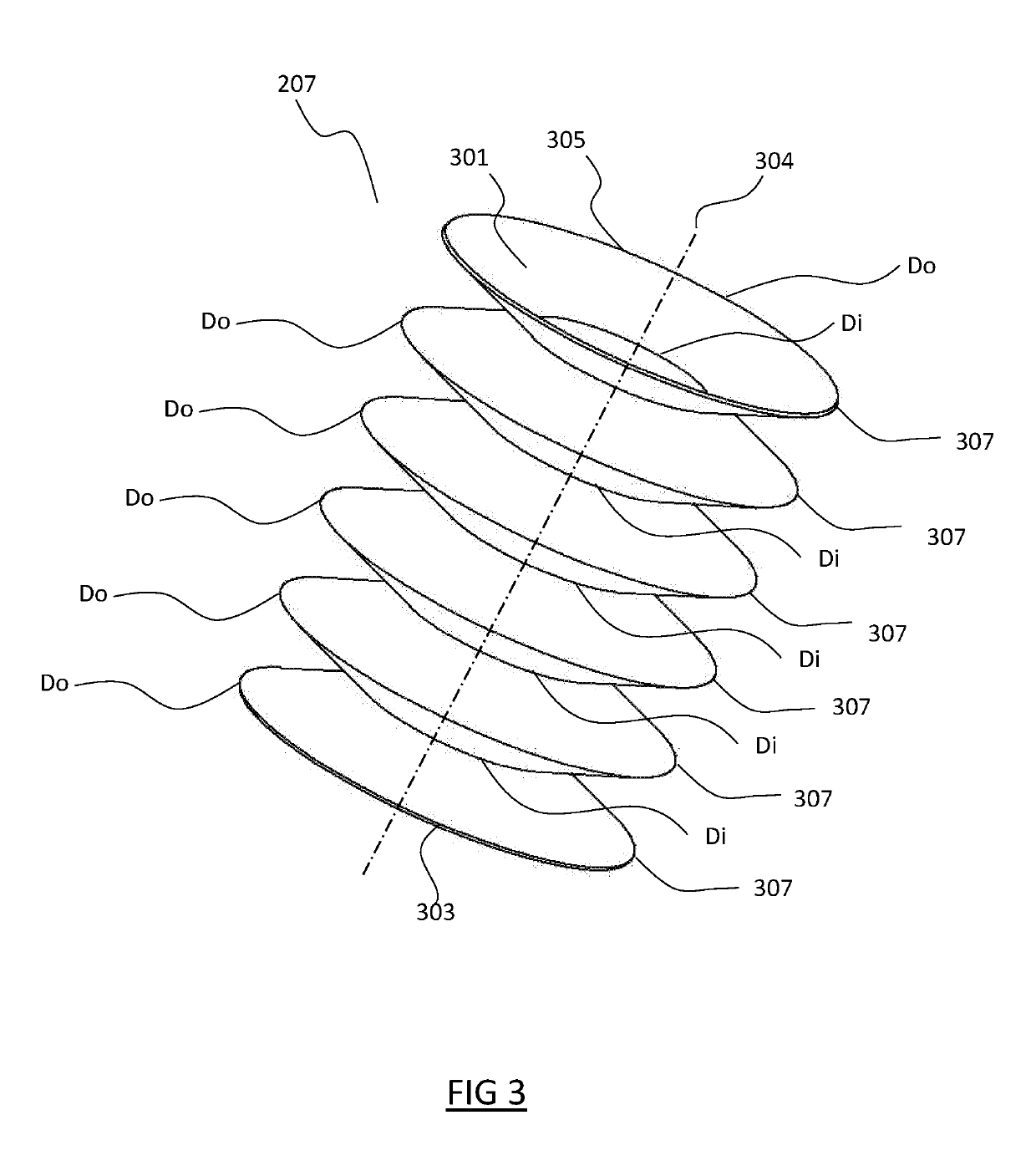

Stator for an eccentric screw pump or an eccentric worm motor operating on the moineau principle

ActiveUS7131827B2Different aperture diameterPrevent radial displacementEngine of intermeshing engagement typeRotary piston pumpsRigid rotorEngineering

The invention relates to a stator for an eccentric screw pump or an eccentric worm motor, including an outer tube that is provided with a lining of rubber or a rubber-like material and has a hollow space or cavity, in the shape of a double or multiple spiral, for accommodating a rigid rotor that is also in the form of a spiral, whereby the stator has one spiral more than does the motor. So that the stator also remains functional under conditions where the fixed connection between the lining and the outer tube could be destroyed, e.g. due to chemical influences or high temperatures, the invention proposes disposing two inner tubes that have apertures in the lining.

Owner:ARTEMIS KAUTSCHUK UND KUNST & CIE

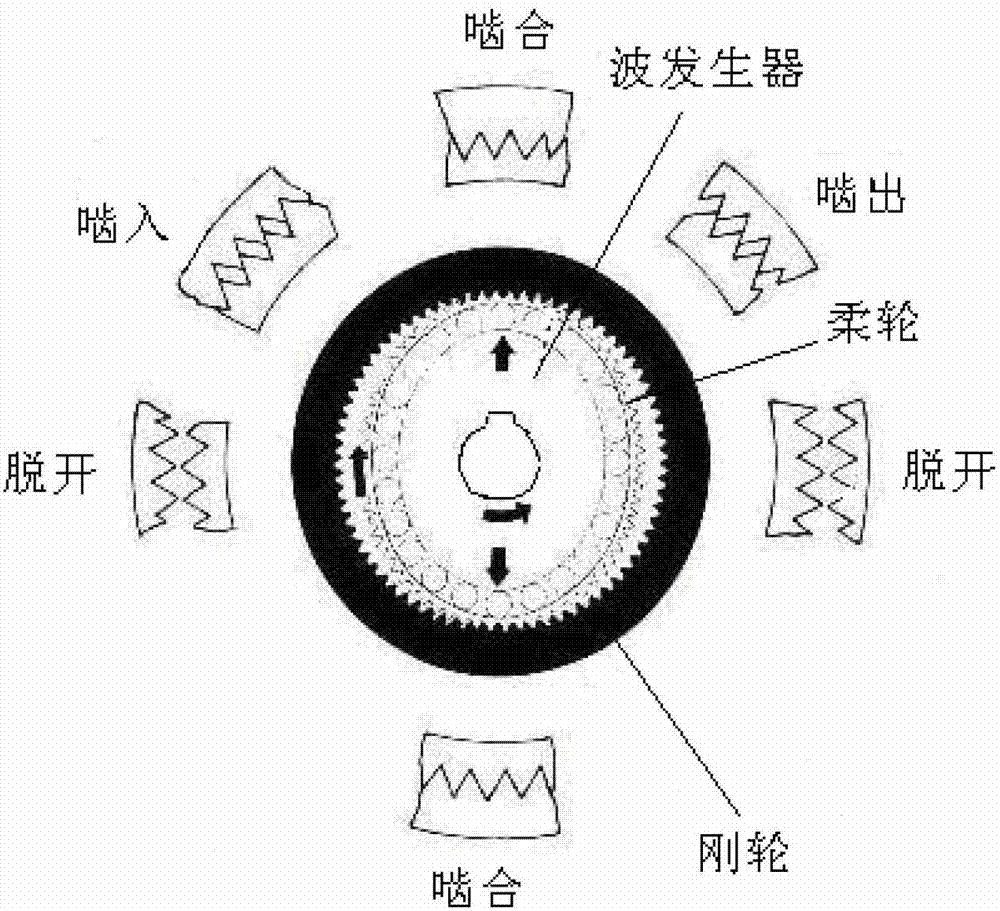

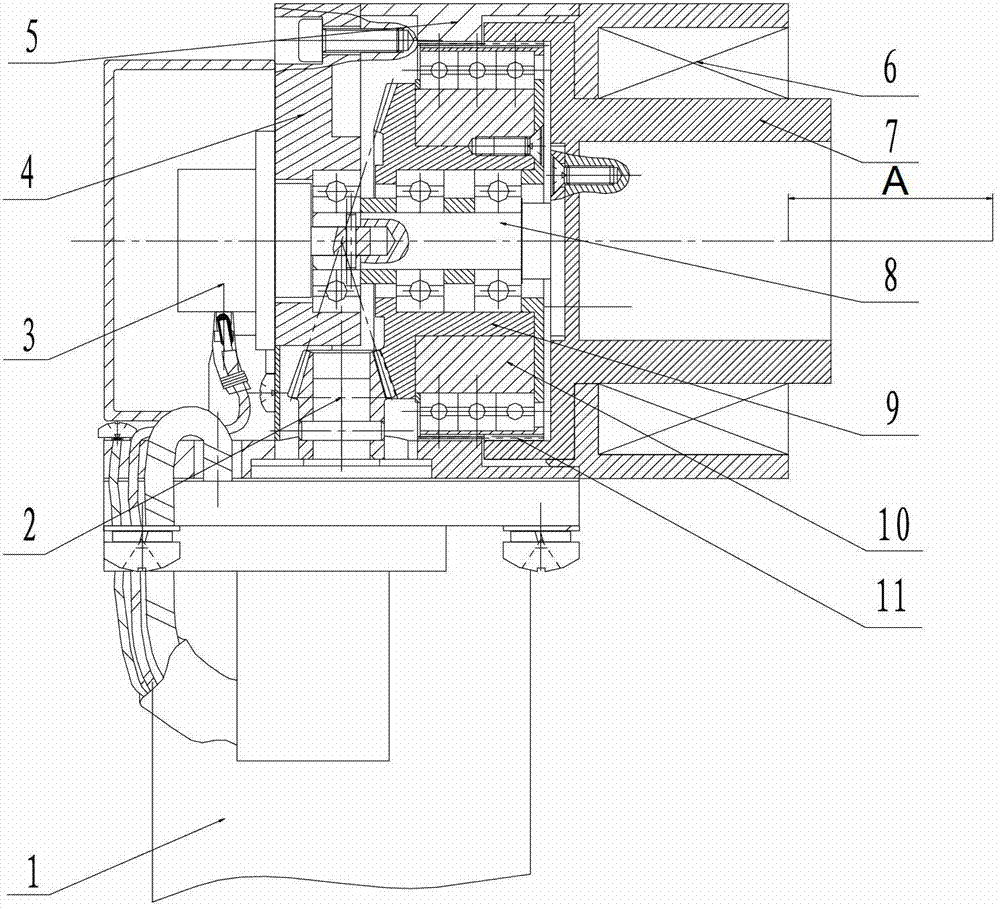

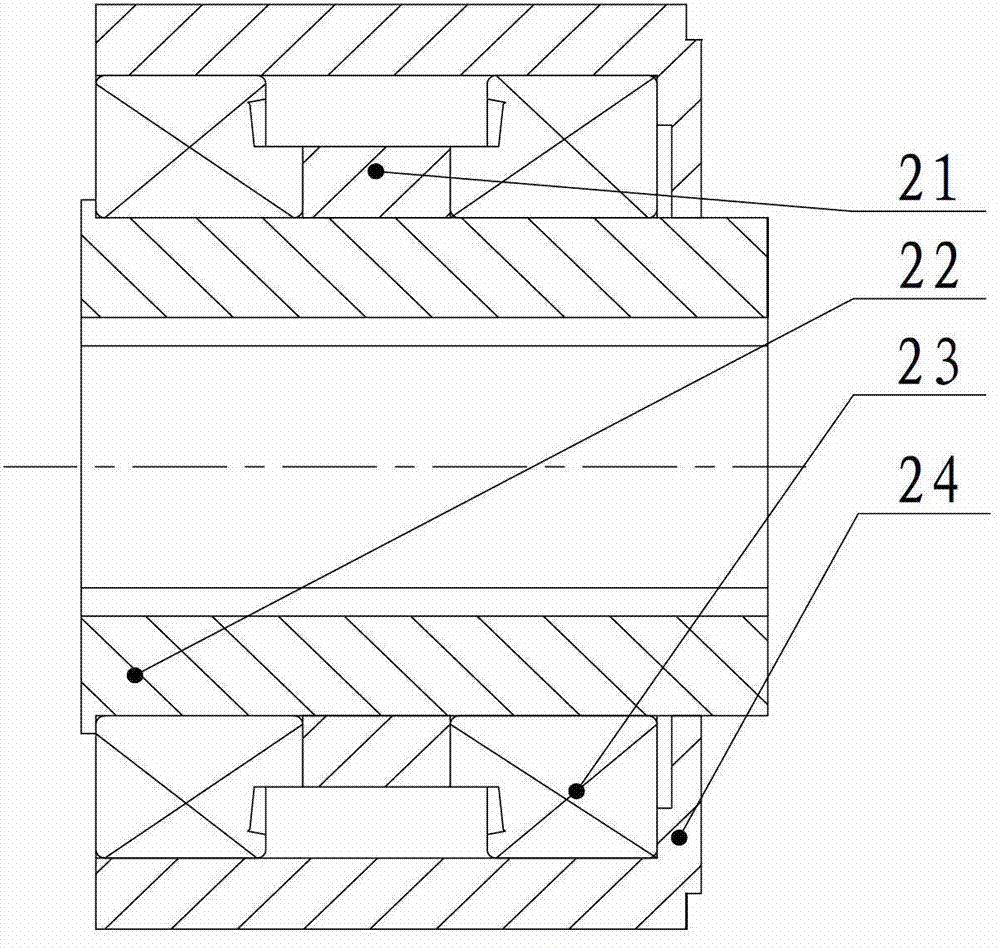

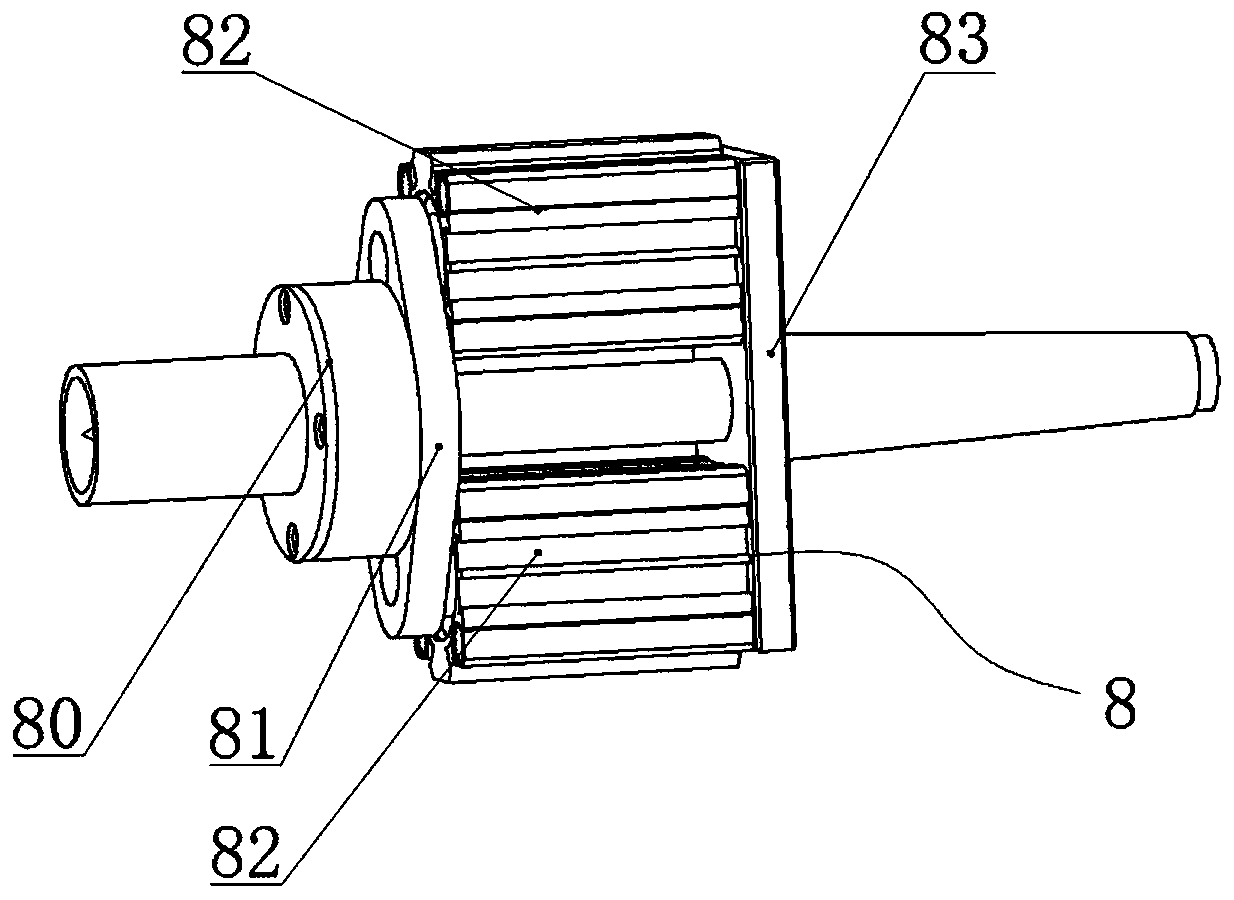

Air vehicle and electric steering engine capable of resisting large bending torque thereof

ActiveCN102765475AStrong carrying capacityPrevent radial displacementWith power amplificationFlight vehicleBending moment

The invention discloses an electric steering engine capable of resisting large bending torque. The electric steering engine capable of resisting the large bending torque comprises a harmonic speed reducer, an output shaft and a connection assembly, wherein the output shaft is fixedly connected with an output steel wheel of the harmonic speed reducer, and the connection assembly is arranged between the output shaft and a load, used for transmitting torque and fixedly connected onto an elastic body. According to the electric steering engine, the connection assembly additionally arranged between the output shaft and the load is used for transmitting the torque and fixedly connected onto the elastic body, so that the connection assembly bears the bending torque from the output shaft. By utilizing the elastic body to unload the bending torque, separation of a carrying object of the bending torque of the electric steering engine is achieved, and the output shaft is only responsible for transmitting the torque. Therefore, the electric steering engine has the advantages of being resistant to the large bending torque, high in reliability and strong in bearing capability, avoids radial displacement of the output shaft under the effect of the being torque, and meets the requirement for long service life of middle-long distance high-altitude air vehicles. The invention further discloses an air vehicle applying the electric steering engine capable of resisting the large bending torque. The air vehicle is high in reliability, long in service life and especially suitable for middle-long distance flight.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

Stator for an eccentric screw pump or an eccentric worm motor operating on the moineau principle

InactiveUS20070053783A1Different aperture diameterPrevent radial displacementEngine sealsOscillating piston enginesRigid rotorEngineering

The invention relates to a stator for an eccentric screw pump or an eccentric worm motor, including an outer tube that is provided with a lining of rubber or a rubber-like material and has a hollow space or cavity, in the shape of a double or multiple spiral, for accommodating a rigid rotor that is also in the form of a spiral, whereby the stator has one spiral more than does the motor. So that the stator also remains functional under conditions where the fixed connection between the lining and the outer tube could be destroyed, e.g. due to chemical influences or high temperatures, the invention proposes disposing two inner tubes that have apertures in the lining.

Owner:ARTEMIS KAUTSCHUK UND KUNST & CIE

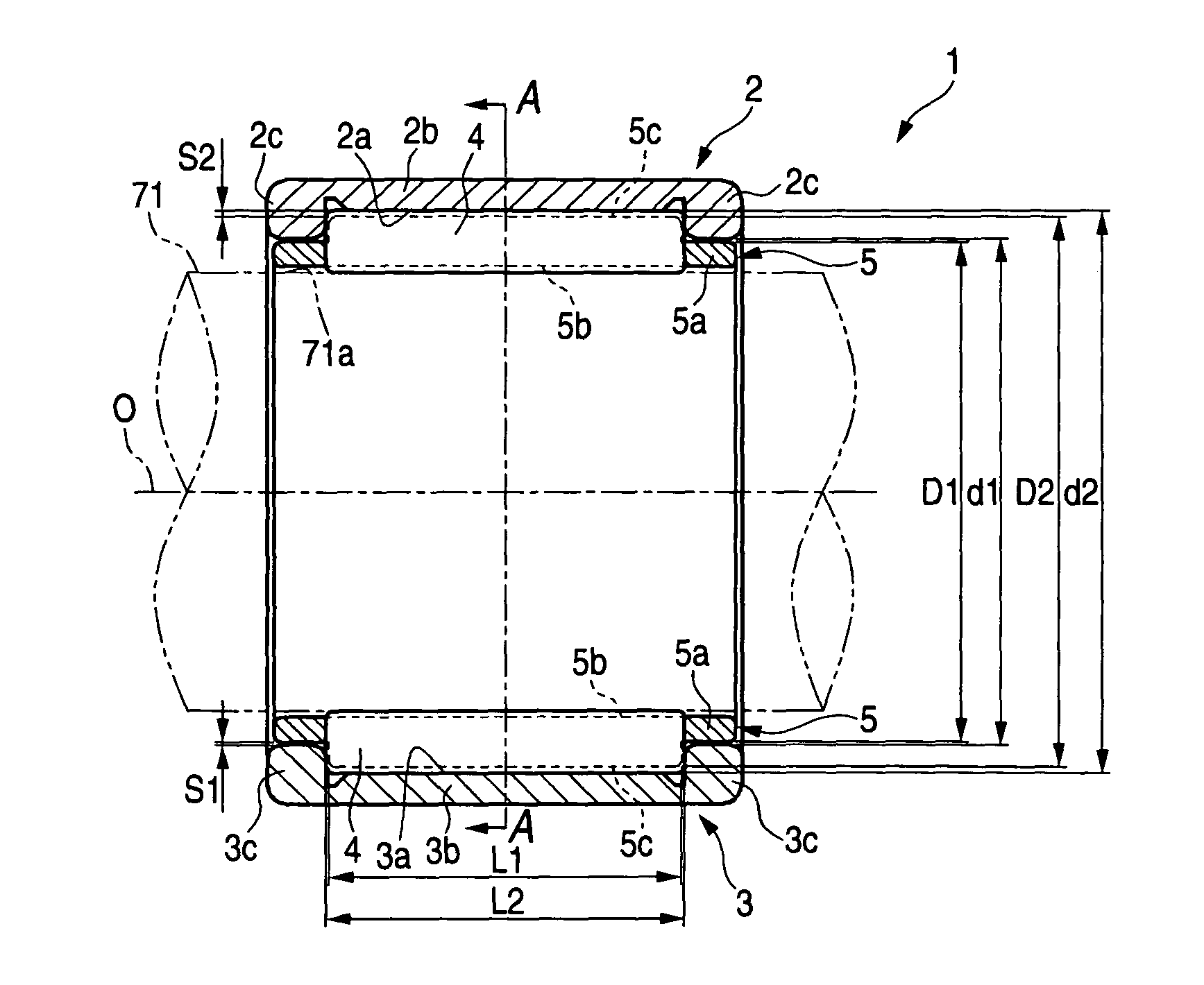

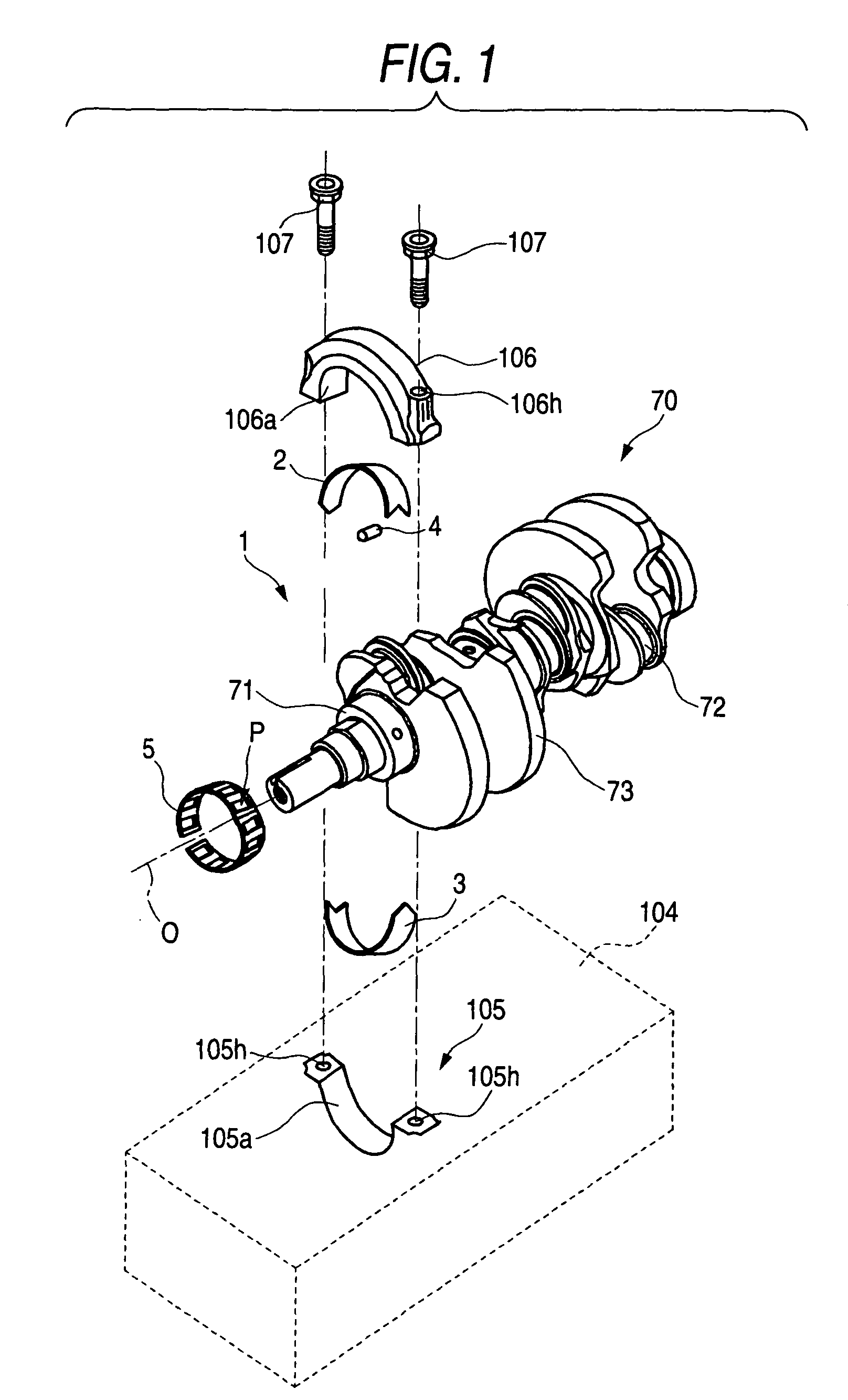

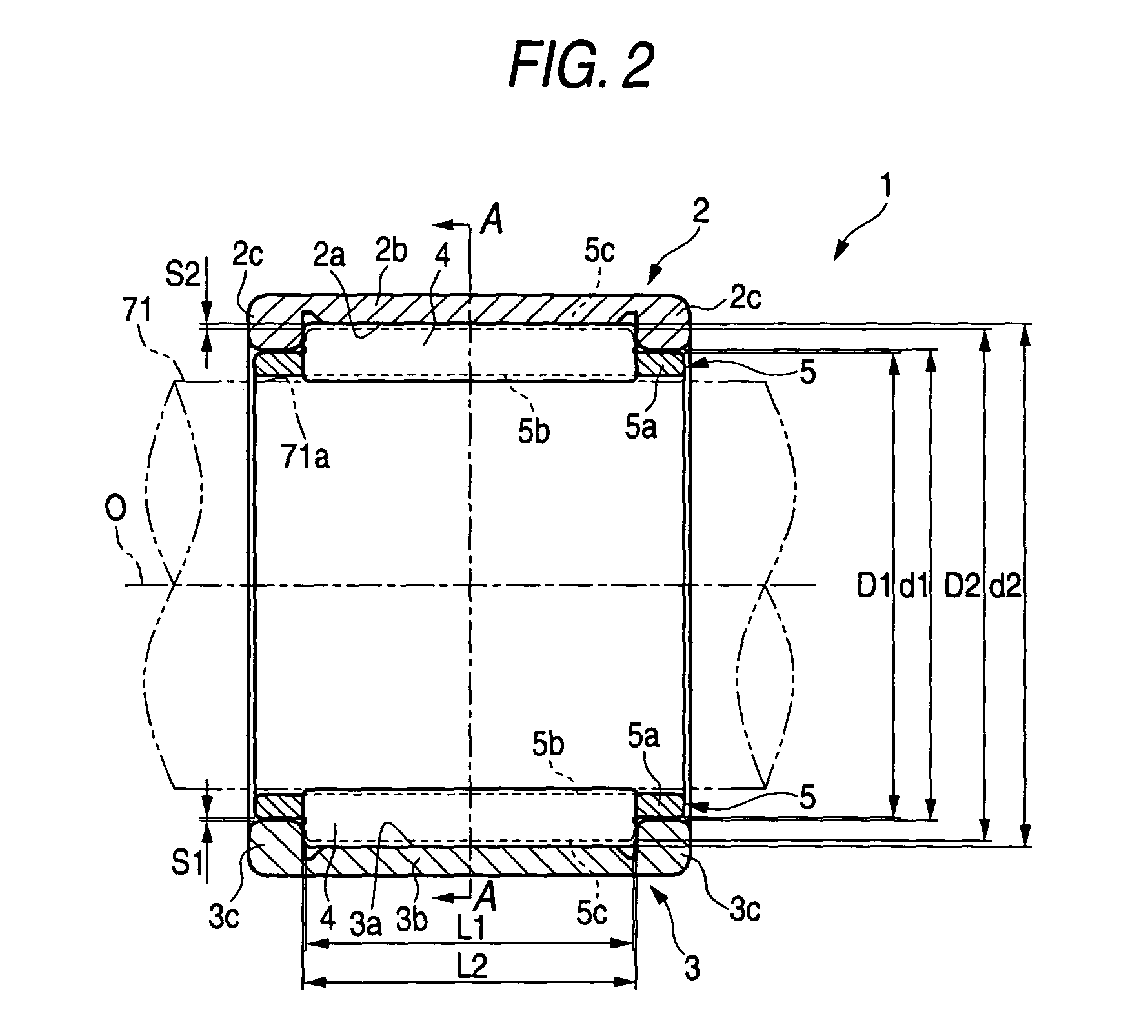

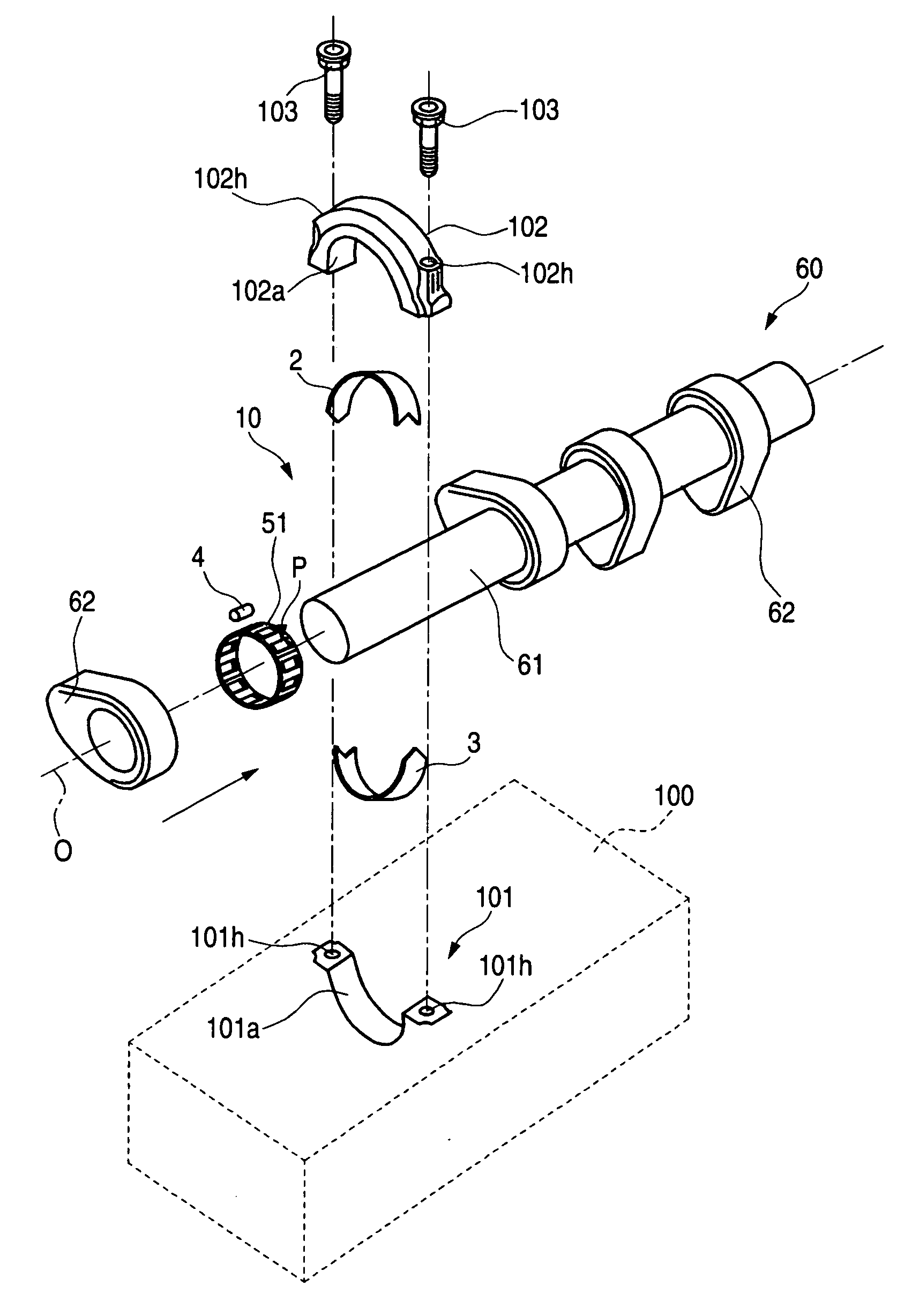

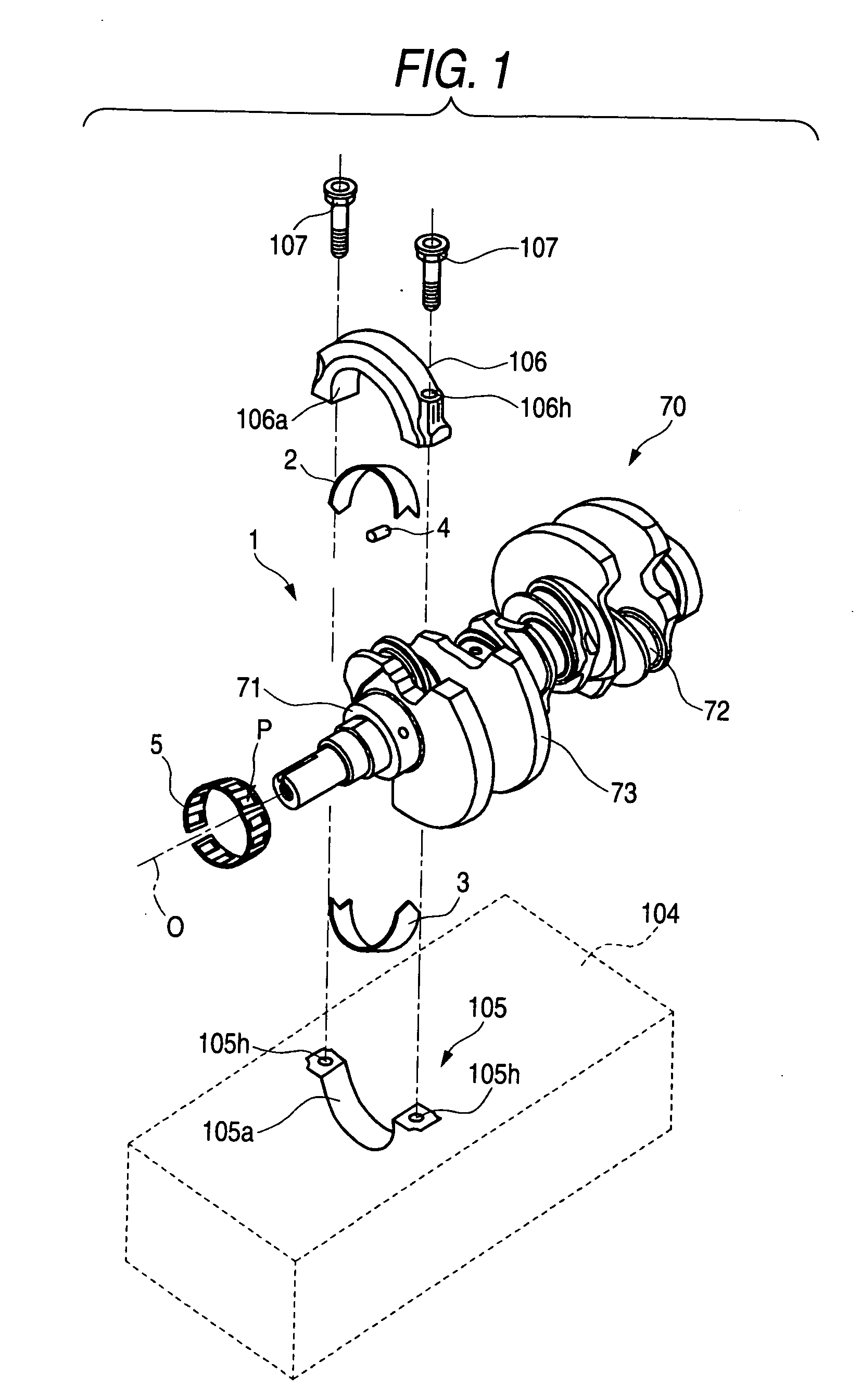

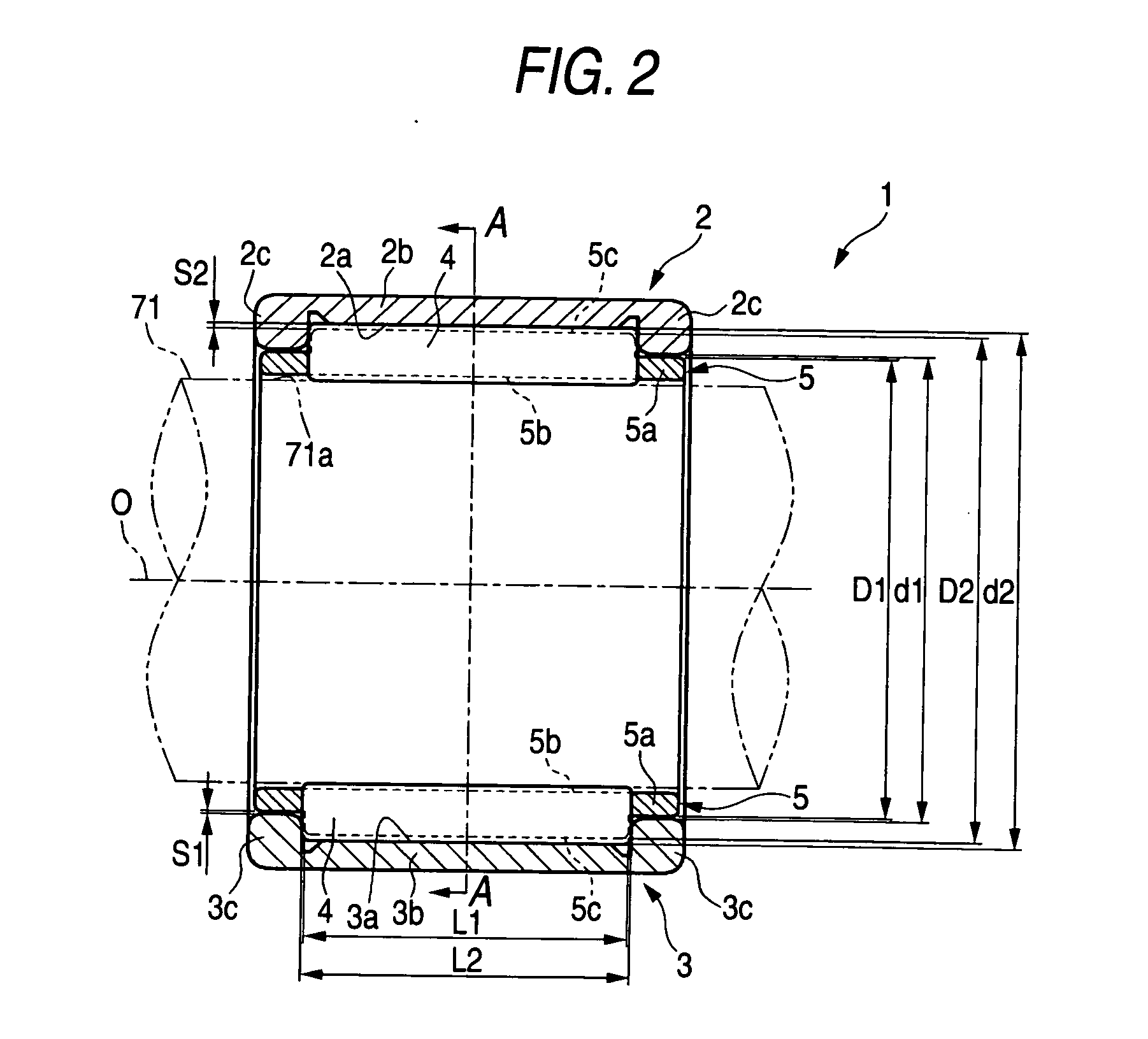

Roller bearing

InactiveUS7828485B2Prevent radial displacementTorque loss can be preventedValve arrangementsRoller bearingsEngineeringCentrifugal force

The clearance between the outer peripheral surface of an annular portion of a cage and the inner peripheral surface of each of rib portions of outer-ring split pieces is set to be smaller than the clearance between the radial end surface of a projection portion of the cage and the inner peripheral surface of each of body portions of the outer-ring split pieces. When a centrifugal force due to engine rotation acts upon the cage, the inner peripheral surface of each of the rib portions of the outer-ring split pieces touches the outer peripheral surface of the annular portion of the cage before the inner peripheral surface of each of the body portions of the outer-ring split pieces touches the radial end surface of the projection portion of the cage. Thus, the radial displacement of the cage can be prevented in good time.

Owner:JTEKT CORP

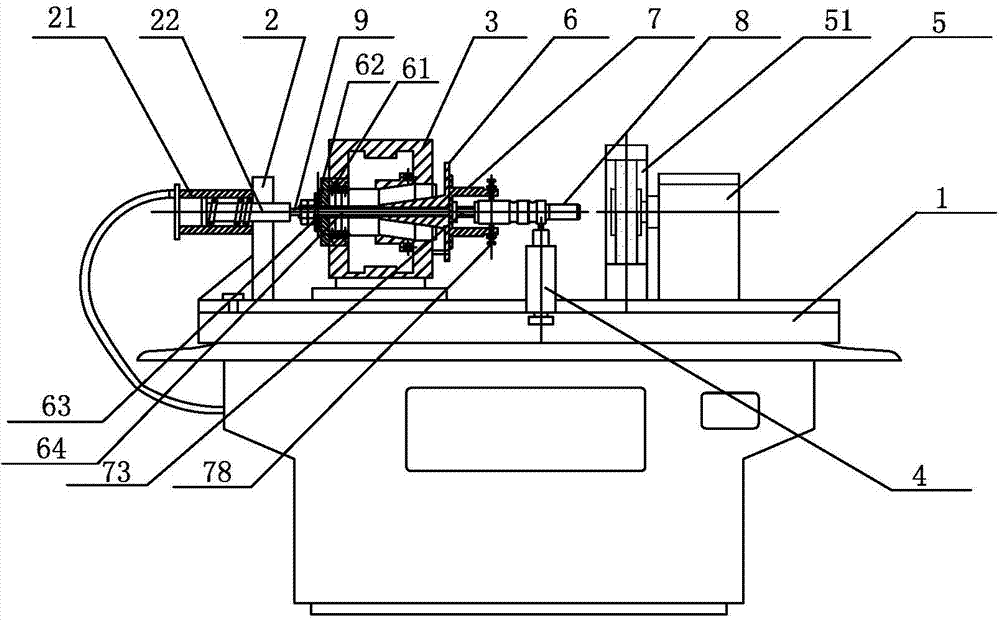

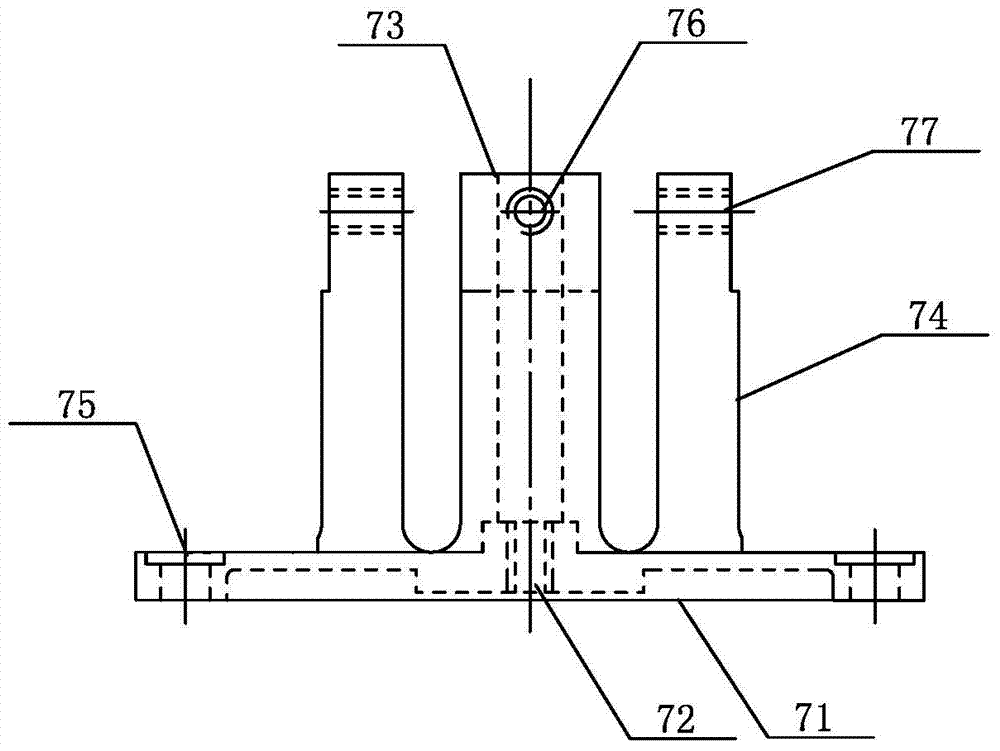

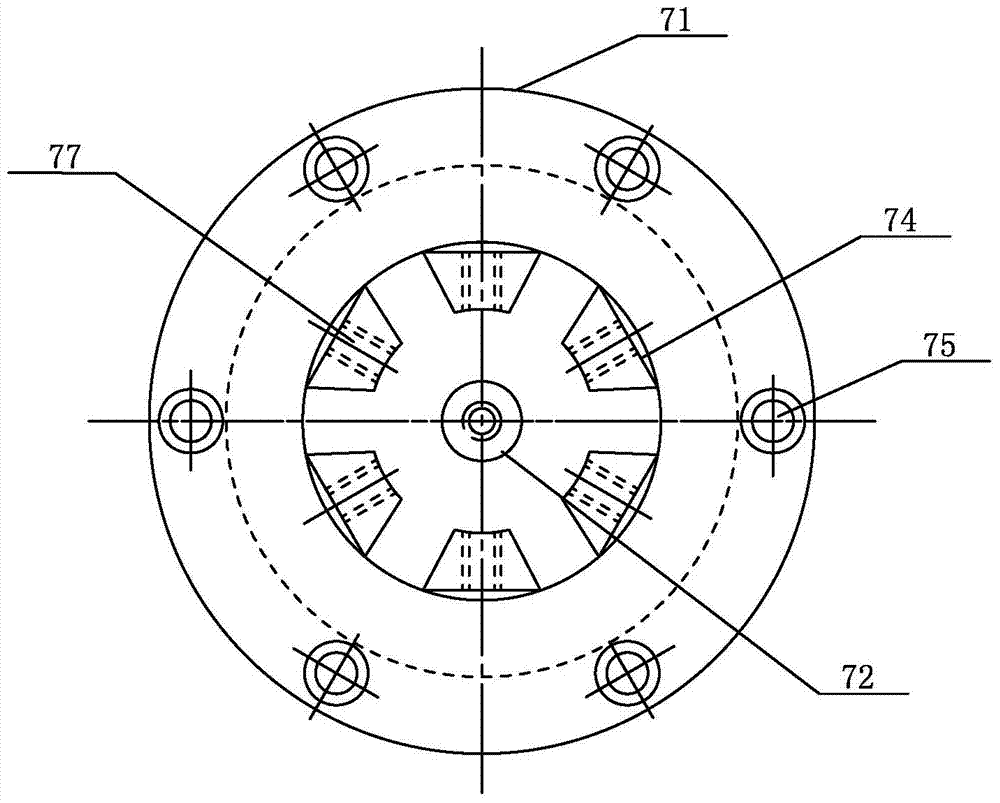

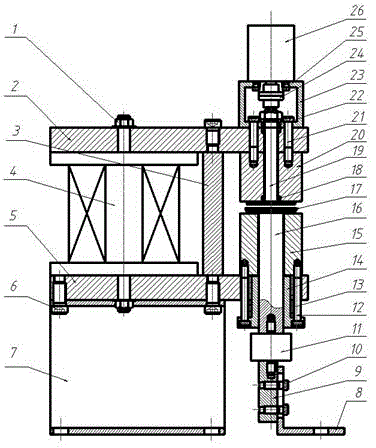

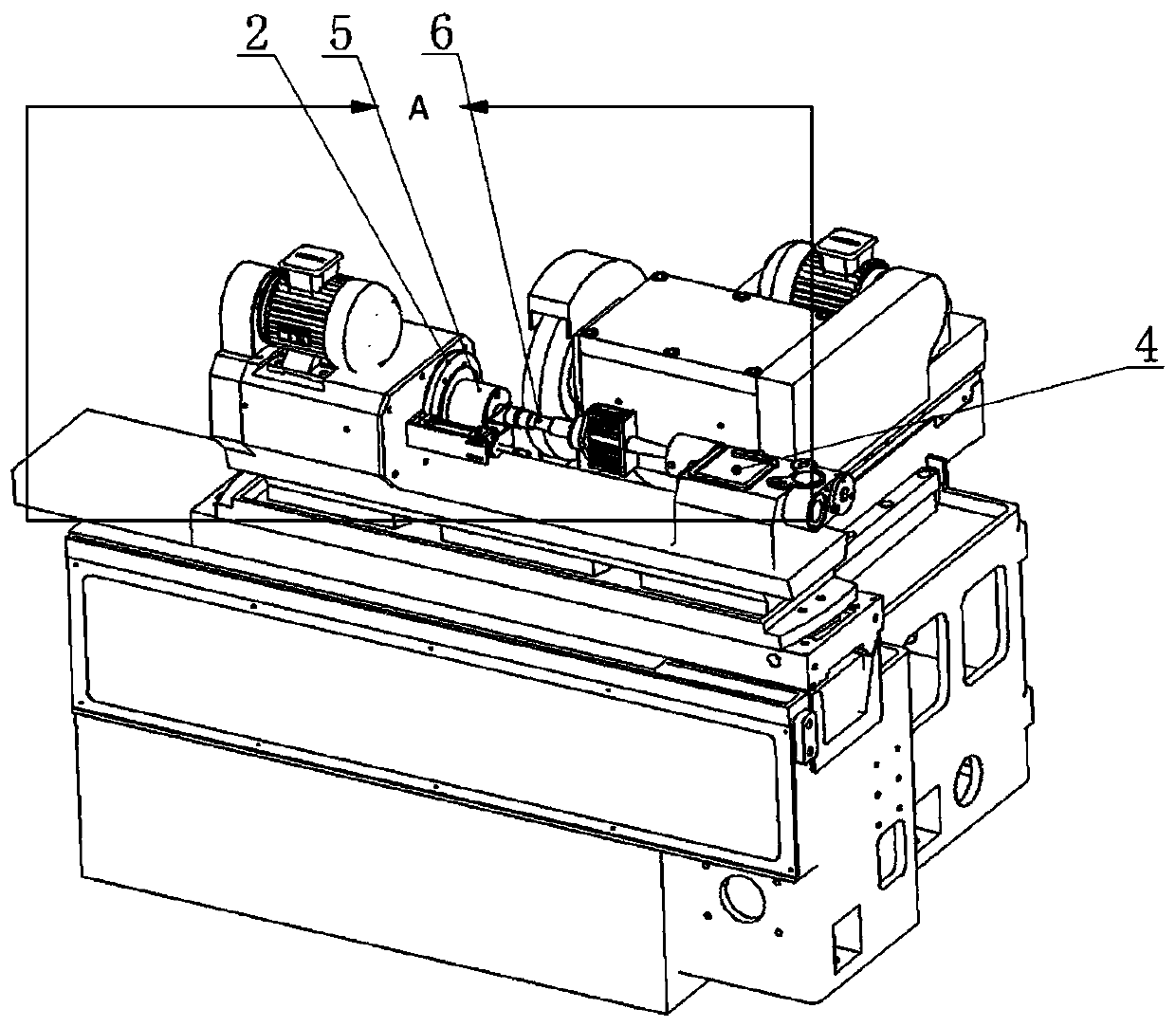

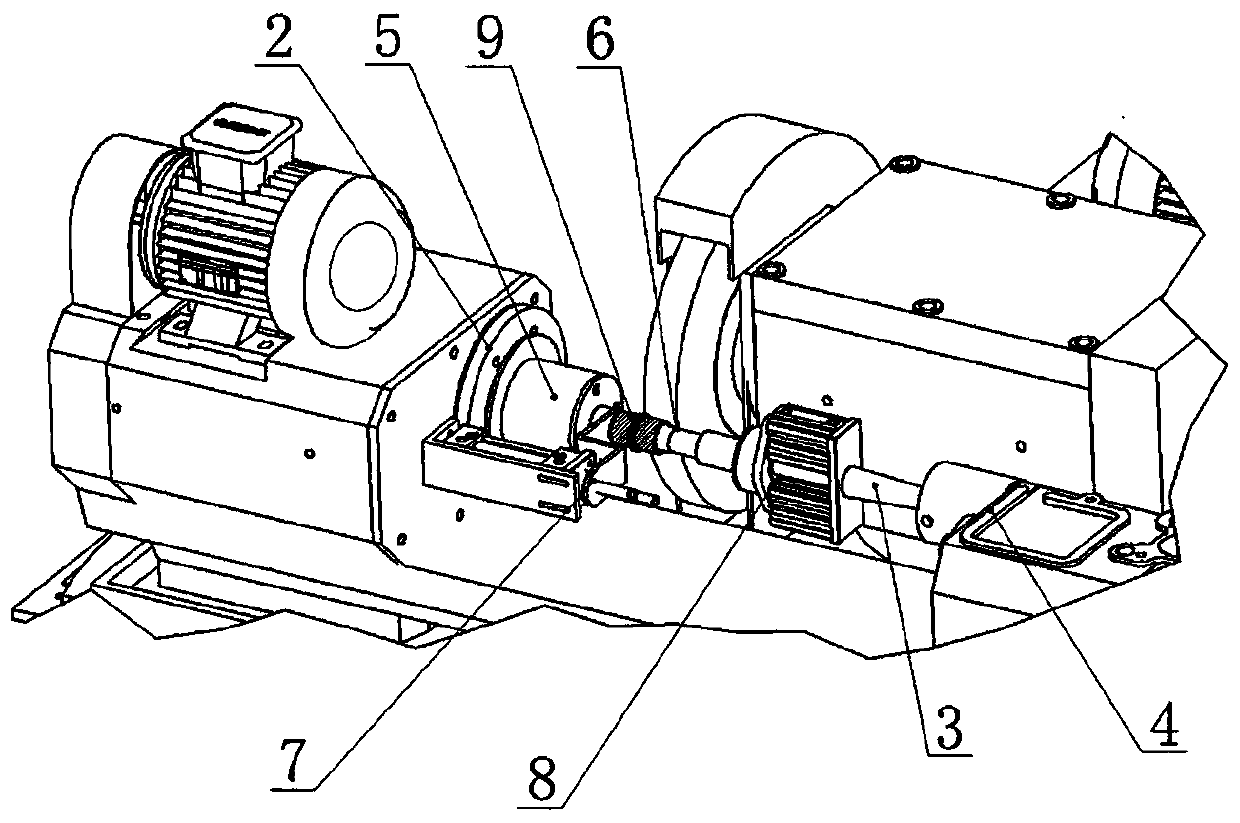

Water pump shaft grinding device and process

ActiveCN103537969AReduce grinding costsSmall footprintGrinding machinesGrinding work supportsBearing surfaceGrinding wheel

The invention discloses a water pump shaft grinding device and process and belongs to the field of machinery. The water pump shaft grinding device comprises a base, an oil cylinder base, a head rack, a central bearing and a grinding wheel bracket, wherein the oil cylinder base, the head rack, the central bearing and the grinding wheel bracket are sequentially arranged on the upper surface of the base. A film chuck is mounted on a spindle of the head rack through a flange and provided with a plurality of claws, and the central bearing is perpendicularly mounted between the film chuck and the grinding wheel. By the water pump shaft grinding device and process, a water pump shaft is clamped or unclamped by means of elastic deformation generated by the film chuck, occupation space of the clamping position is few, a bearing surface of a lower bearing is an inclined surface, radial displacement is prevented during grinding, the water pump shaft can be supported by only one central bearing without using a pressing wheel, and accordingly, grinding of steps and grooves of the multi-step water pump shaft with small double-groove center distance is realized.

Owner:浙江省新昌新轴实业有限公司

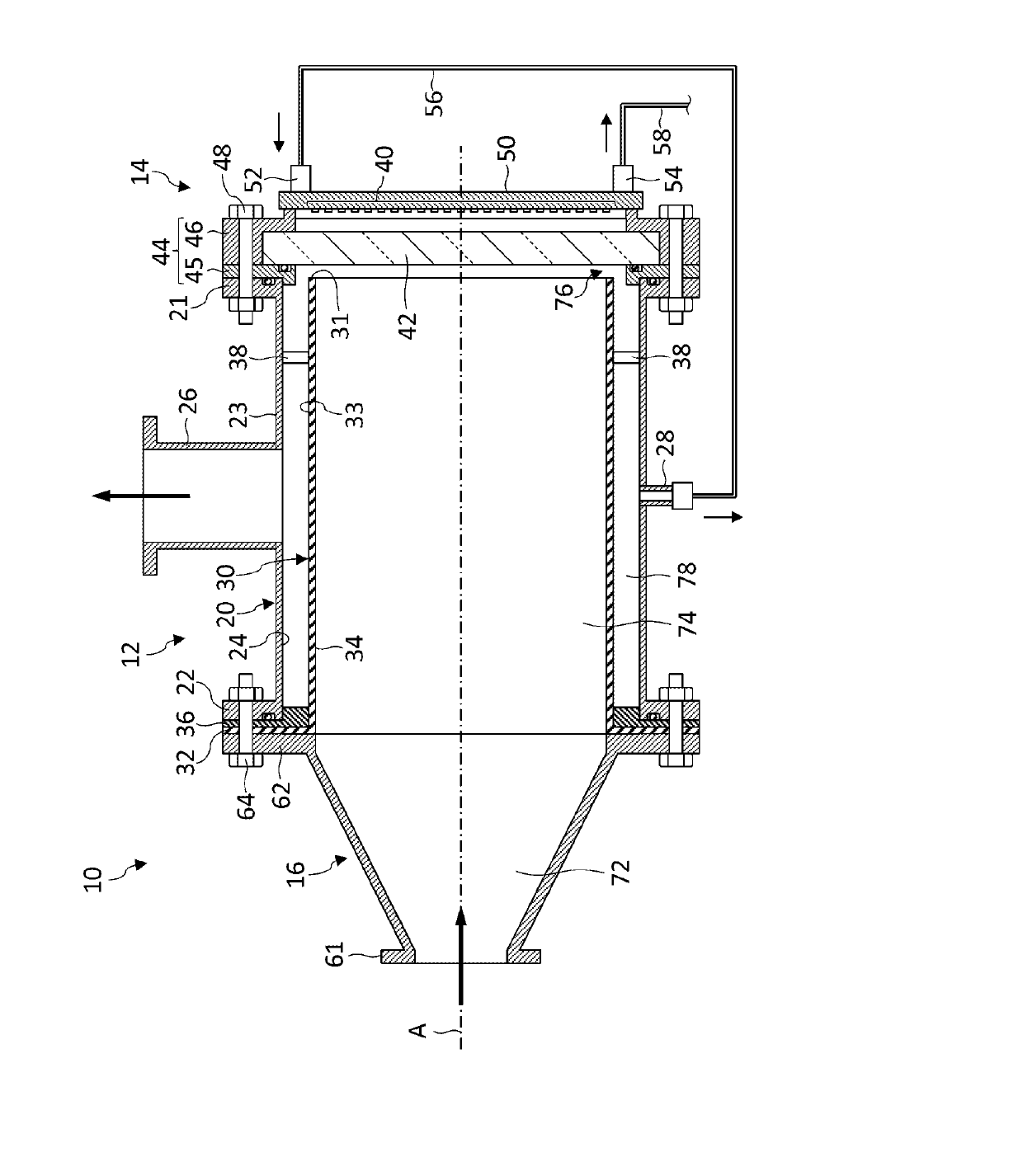

Water treatment device and water treatment method

ActiveUS20190256380A1Improve water treatment effectStraighten flowWater/sewage treatment by irradiationSpecific water treatment objectivesUltraviolet lightsMechanical engineering

A water treatment device includes: a dual-pipe structure unit including an outer pipe, an inner pipe provided in the outer pipe, and a prevention member provided between the outer pipe and the inner pipe; and a light source unit radiating ultraviolet light in the axial direction to irradiate water subject to treatment flowing in the inner pipe. The inner pipe includes an opposing end facing the light source unit across a gap and an inflow end positioned opposite to the opposing end. The outer pipe includes an outflow port provided on an outer circumferential surface of the outer pipe. The water subject to treatment flowing out of the inner pipe via the gap flows out from the outflow port.

Owner:NIKKISO COMPANY +2

Splice sleeve with elliptical or compound curve cross section

InactiveUS20140020328A1Great dimensionIncreases bonding and strengthBuilding repairsRod connectionsEngineeringRebar

A splice sleeve having an elliptical or compound curve cross section for connecting overlapping end portions of reinforcing bars utilized in various types of structures in which steel reinforcing bars are utilized and it is desired to connect the overlapping end portions of the reinforcing bars. The splice sleeve is configured to receive the overlapped end portions of the reinforcing bars and then be filled with hardenable material to resist axial tension and compression exerted on the reinforcing bars. In one embodiment, both ends of the sleeve are provided with an inwardly directed lip to increase the splicing capacity of the sleeve and also to serve as a guide to position the rebars to a minimum of about 3 mm from the inside wall surface of the sleeve.

Owner:AE CONNECTOR SOLUTIONS

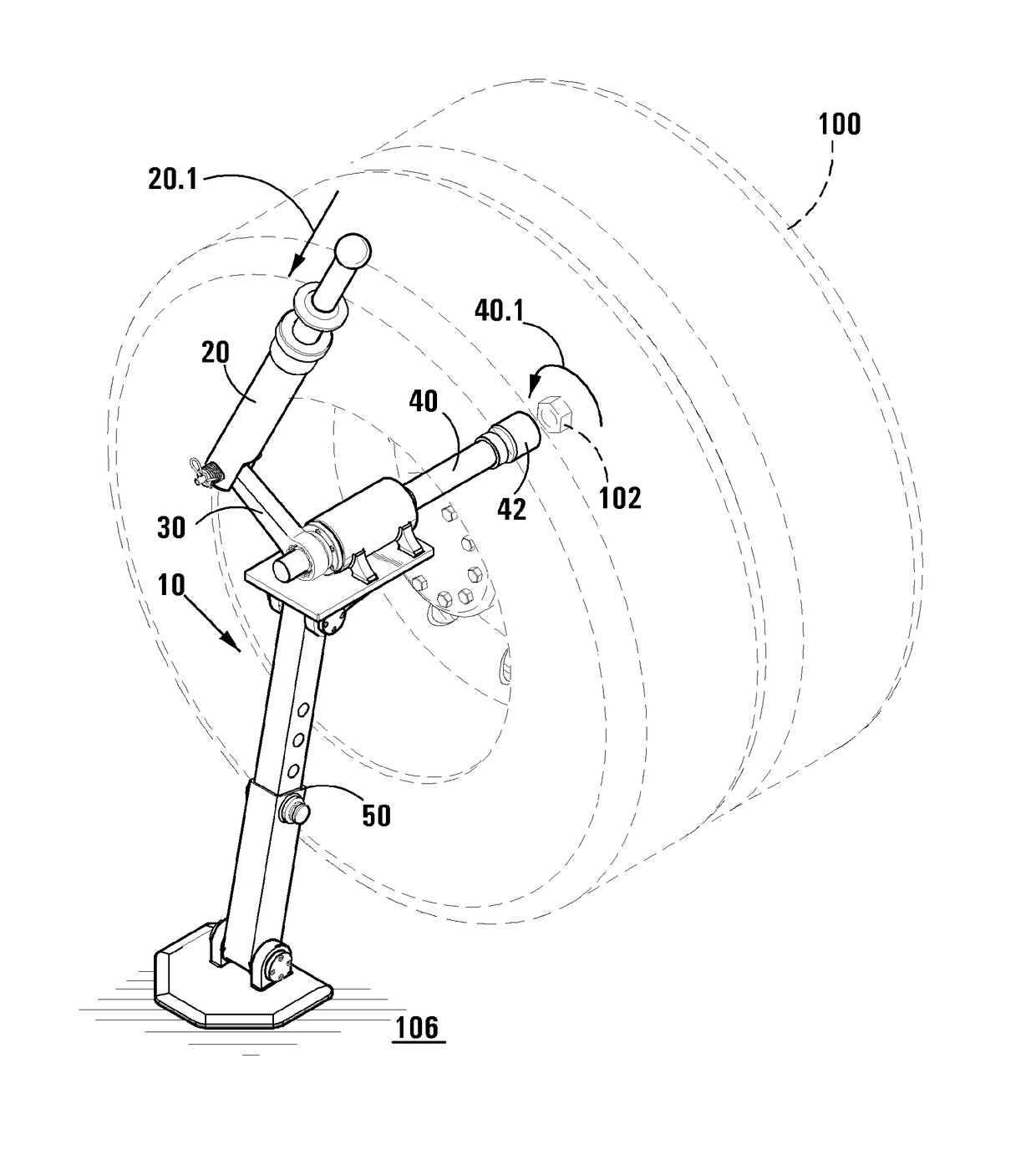

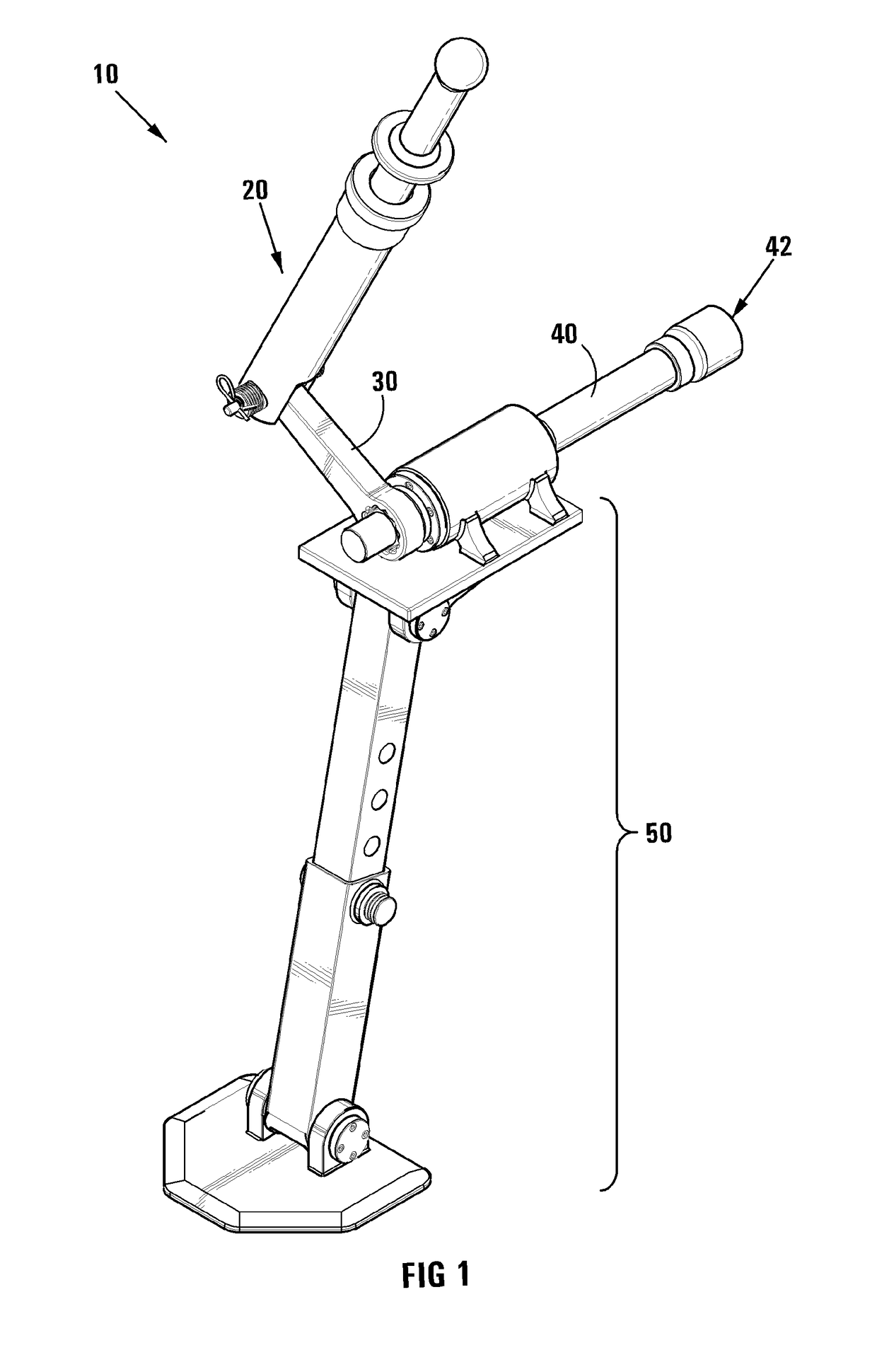

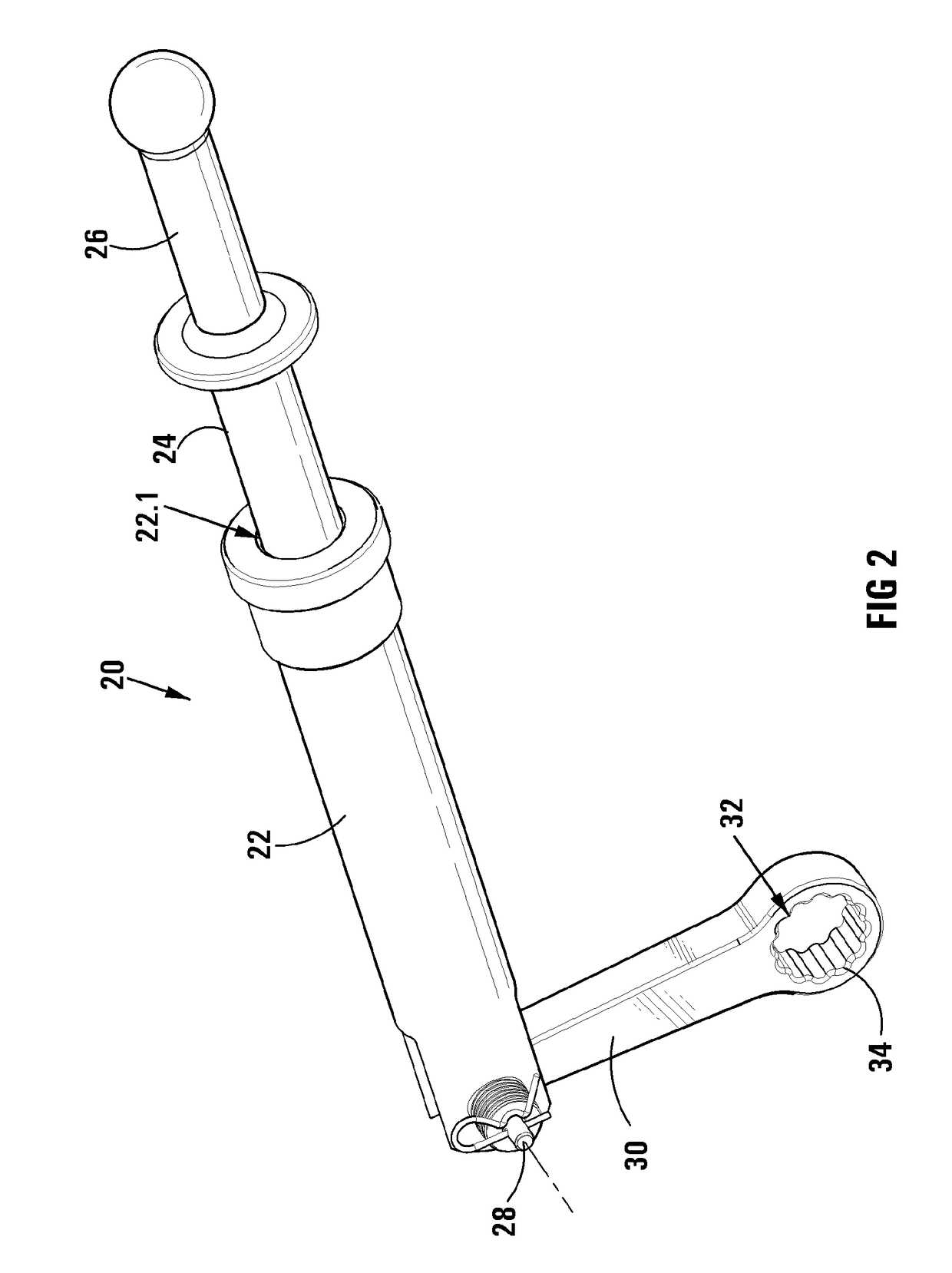

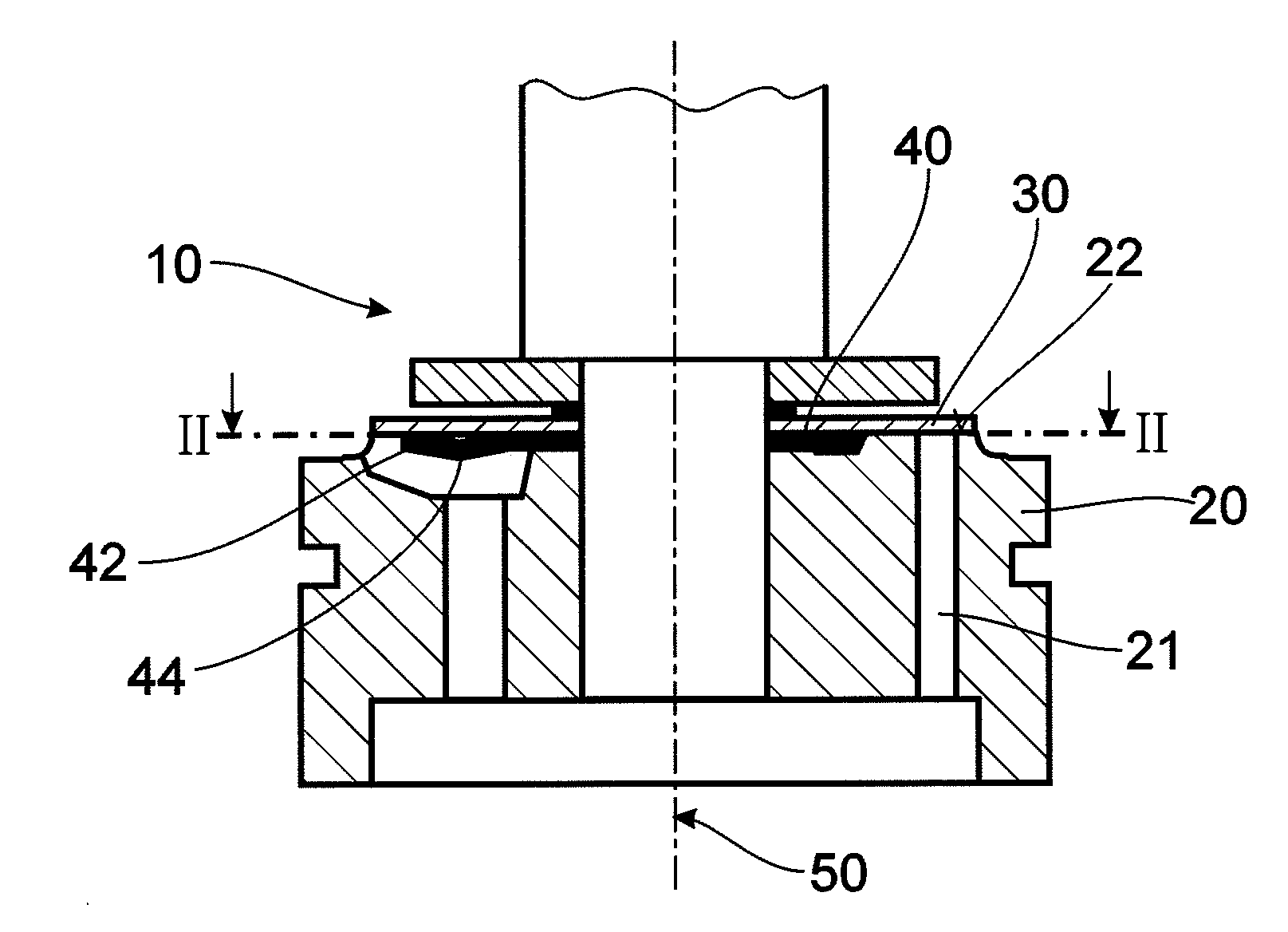

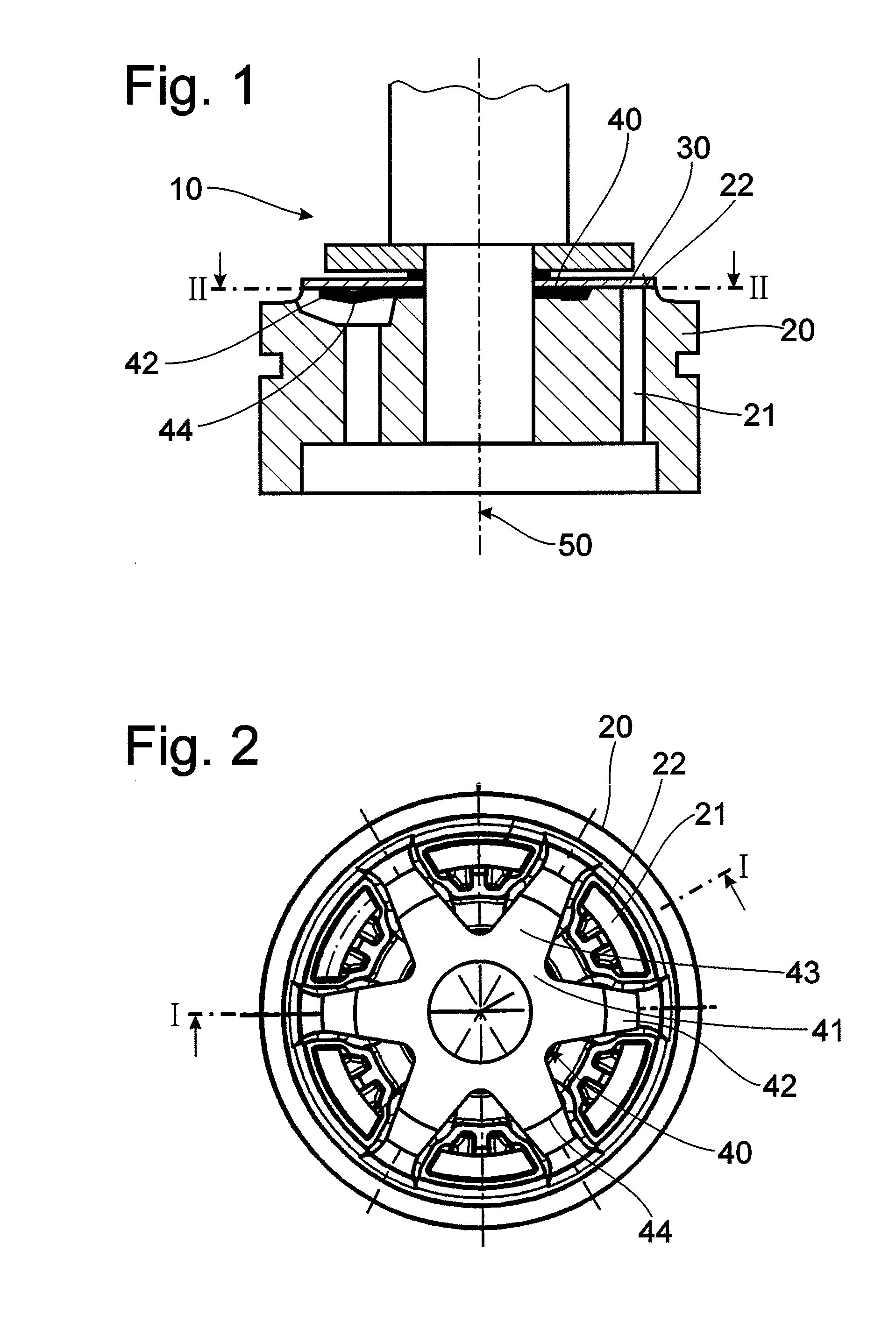

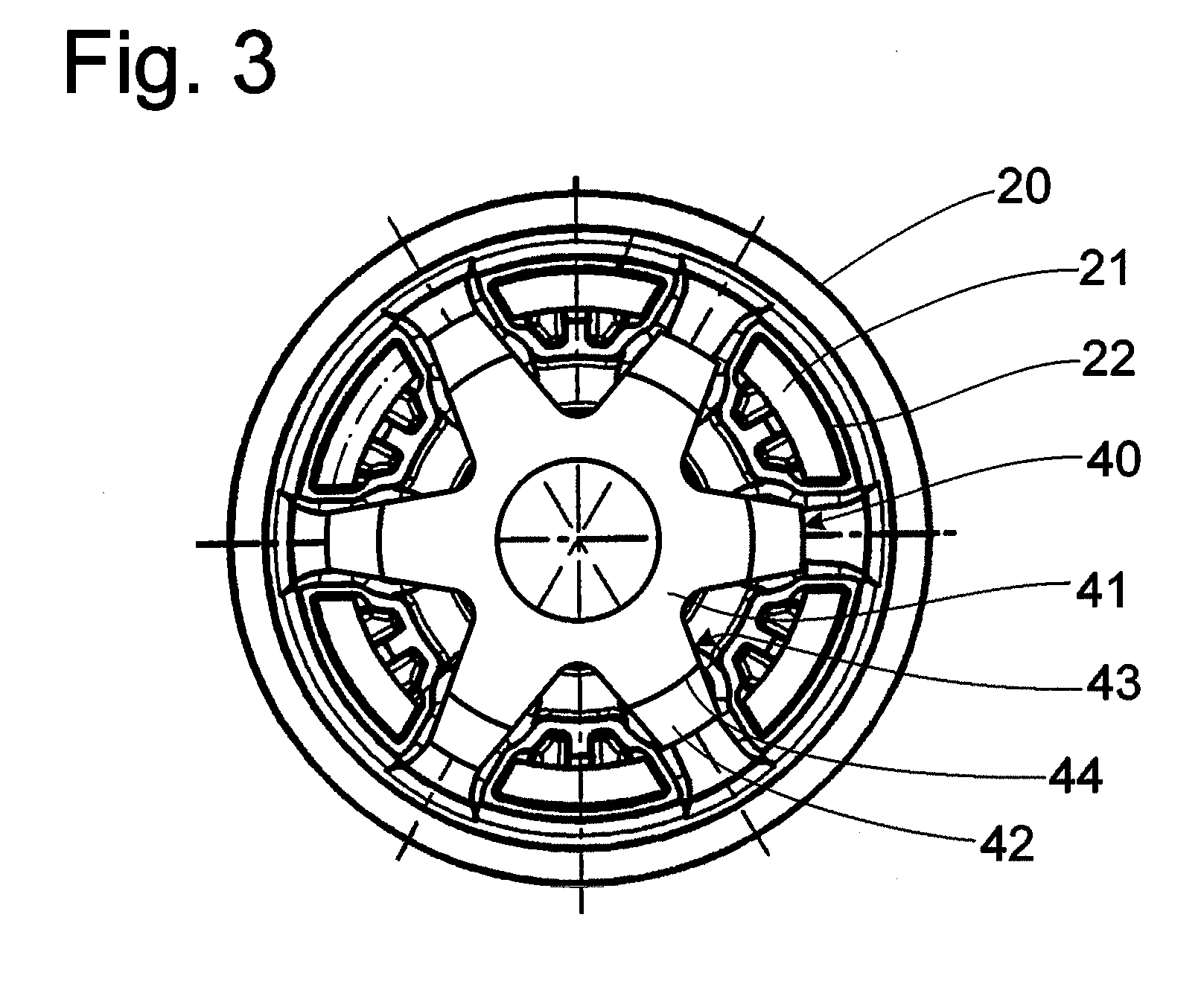

Assembly for loosening or tightening mechanical nuts (esp. wheel nuts)

InactiveUS10065454B2Prevent radial displacementBig impactWheel mounting apparatusWrenchesSupport surface

An assembly (200) for loosening or tightening mechanical nuts includes a socket arm (40) defining a socket (42) at its distal end for engaging a mechanical nut (102); a crank (30) connected or connectable at its first end transversely to a proximate end of the socket arm (40); a sliding hammer (20) connected or connectable to a second end of the crank (30), thereby being operable to impart a rotational impact on the socket arm (40) via the crank (30); and a support structure (250) connected or connectable at its proximate end to one of the socket arm (40), crank (30), or sliding hammer (20) and defining at its remote end a support surface (260) operable to bear against an external structure (100) thereby to support the assembly (200) in use.

Owner:THE TRUSTEES FOR THE TIME BEING OF LE MOULIN TRUST

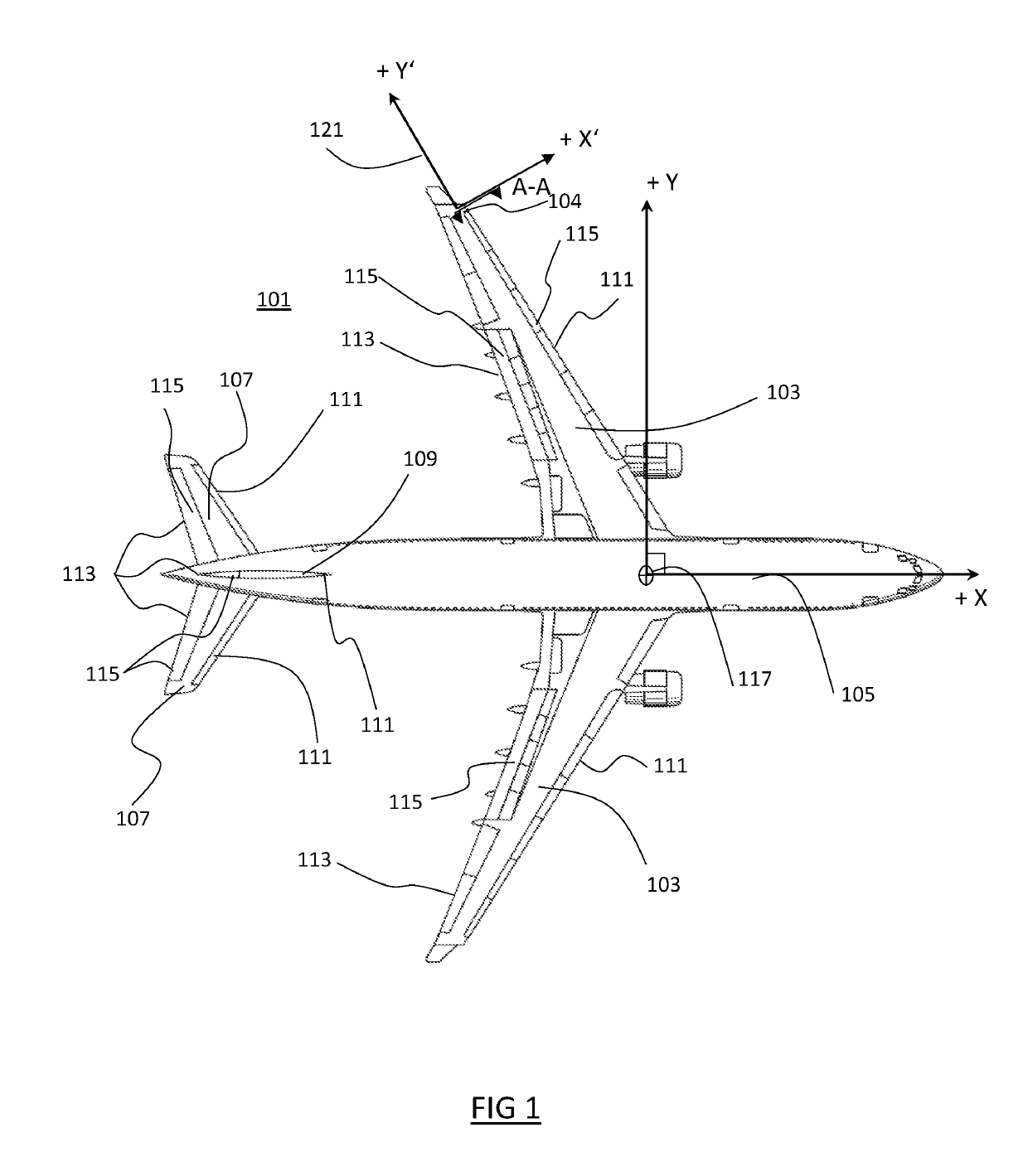

Aircraft joint with a curable composite bushing

ActiveUS20190162233A1Quick installationEasy to storeShaftsBearing componentsBiomedical engineeringRadial displacement

An aircraft structural joint comprising a first structural component provided with an attachment hole that is configured to receive an corresponding attachment fastener provided by a second structural component; a curable composite bush compressed and cured between an outer diameter of the attachment fastener and the attachment hole when the first component is mounted to the second component, wherein the curable composite bush, when cured, prevents radial displacement of the attachment fastener within the attachment hole.

Owner:AIRBUS OPERATIONS GMBH

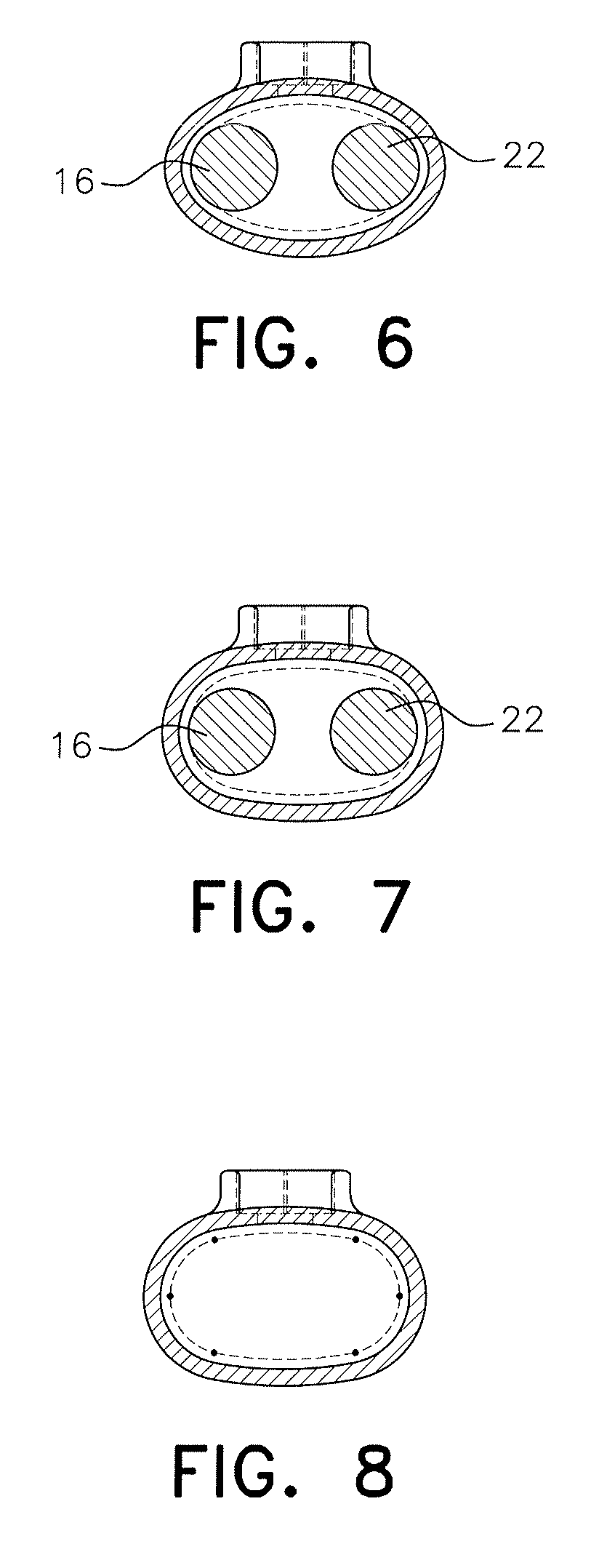

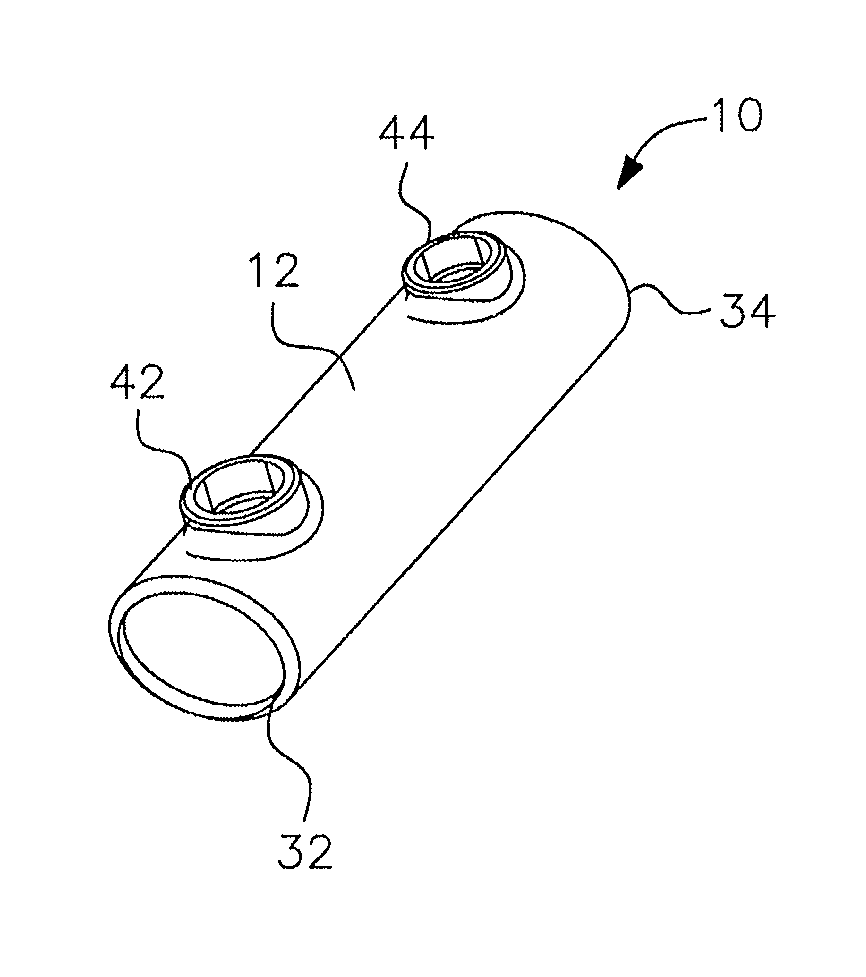

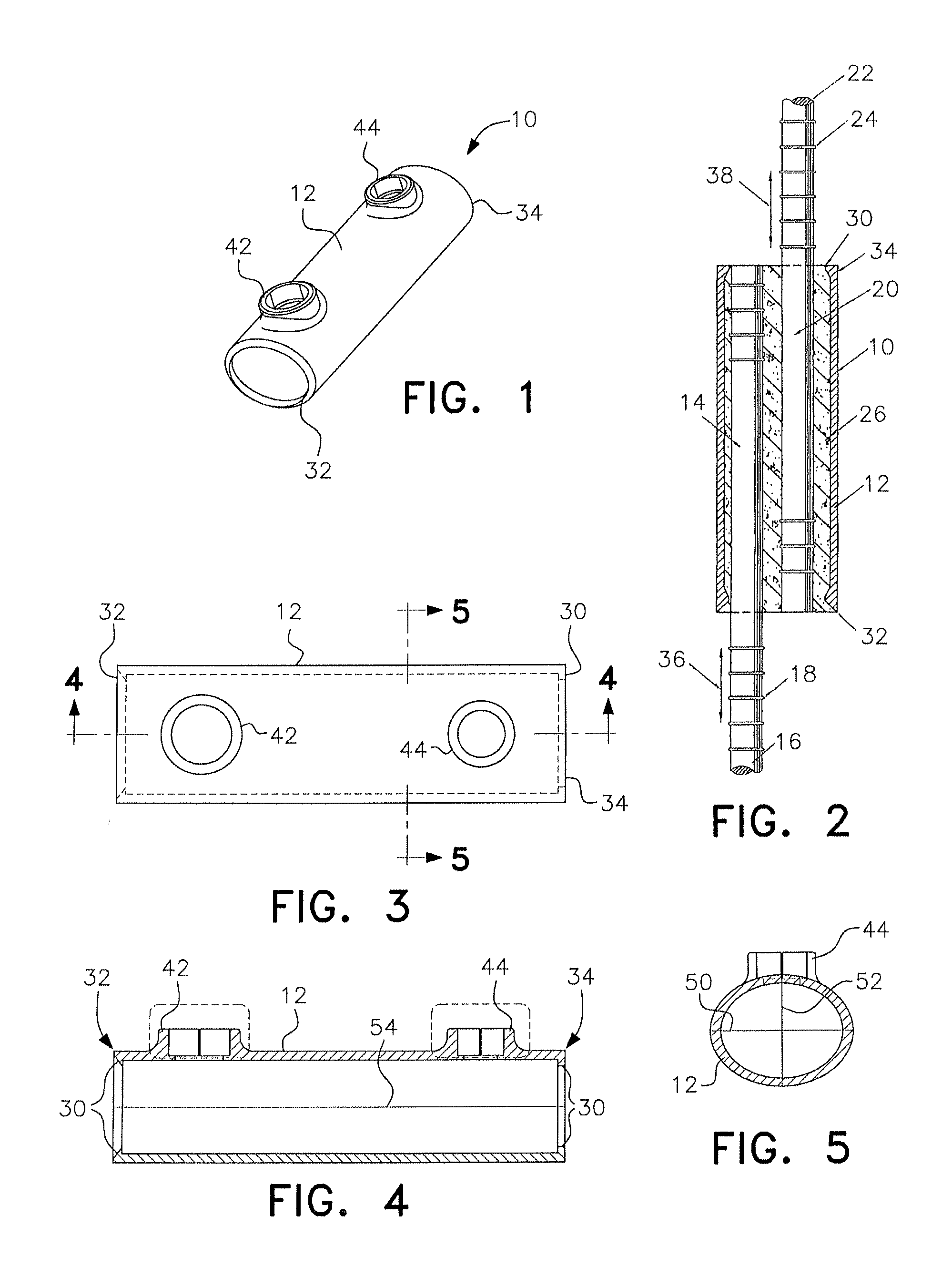

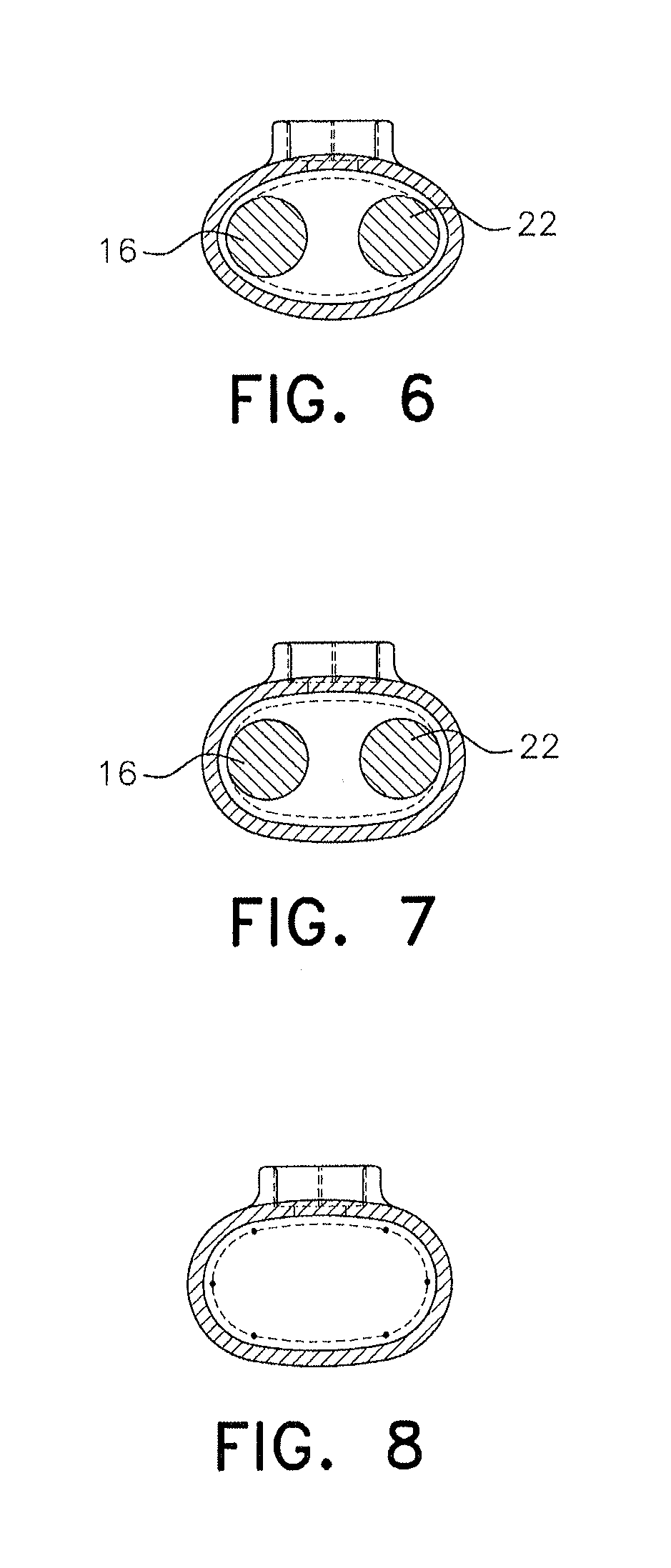

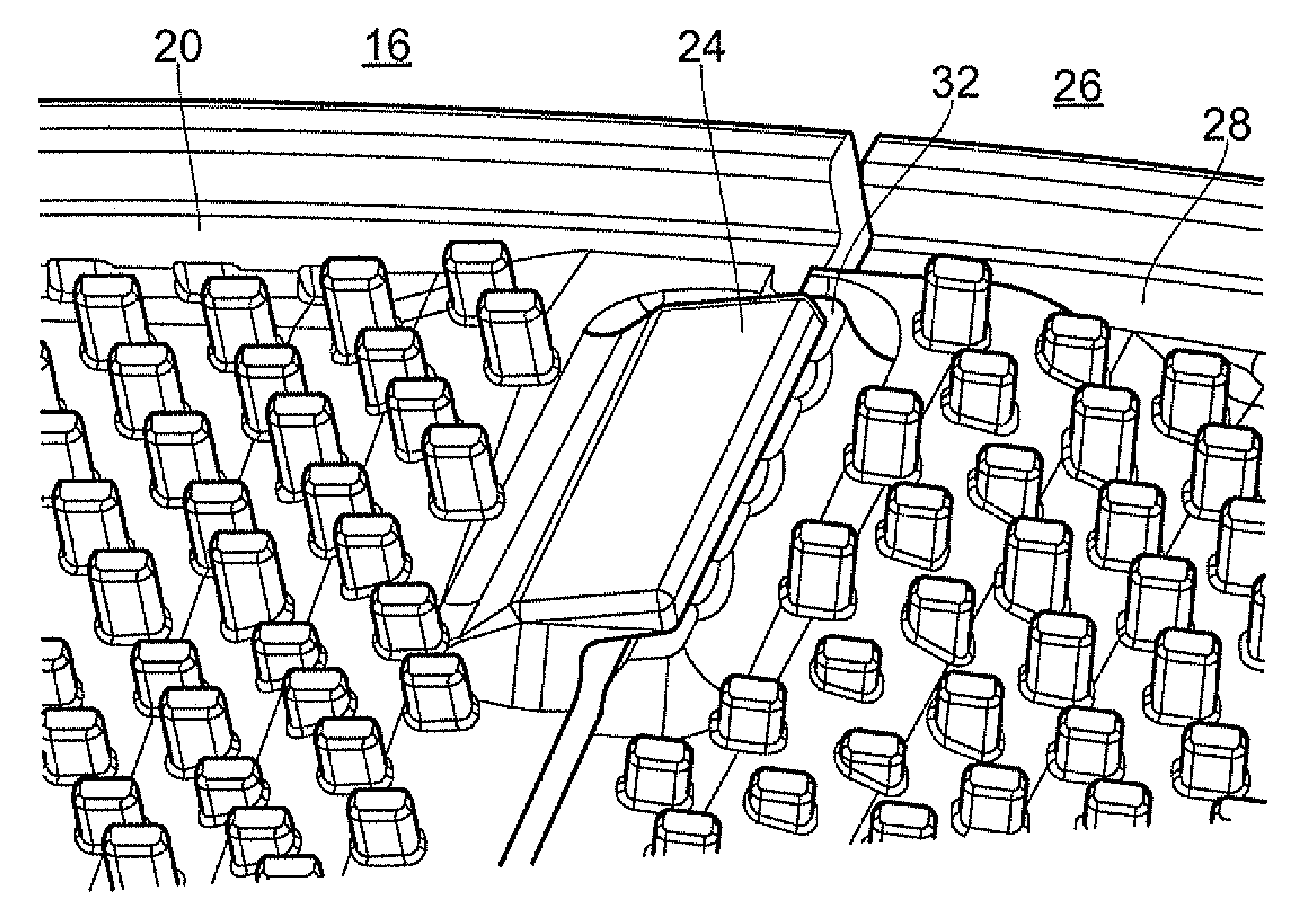

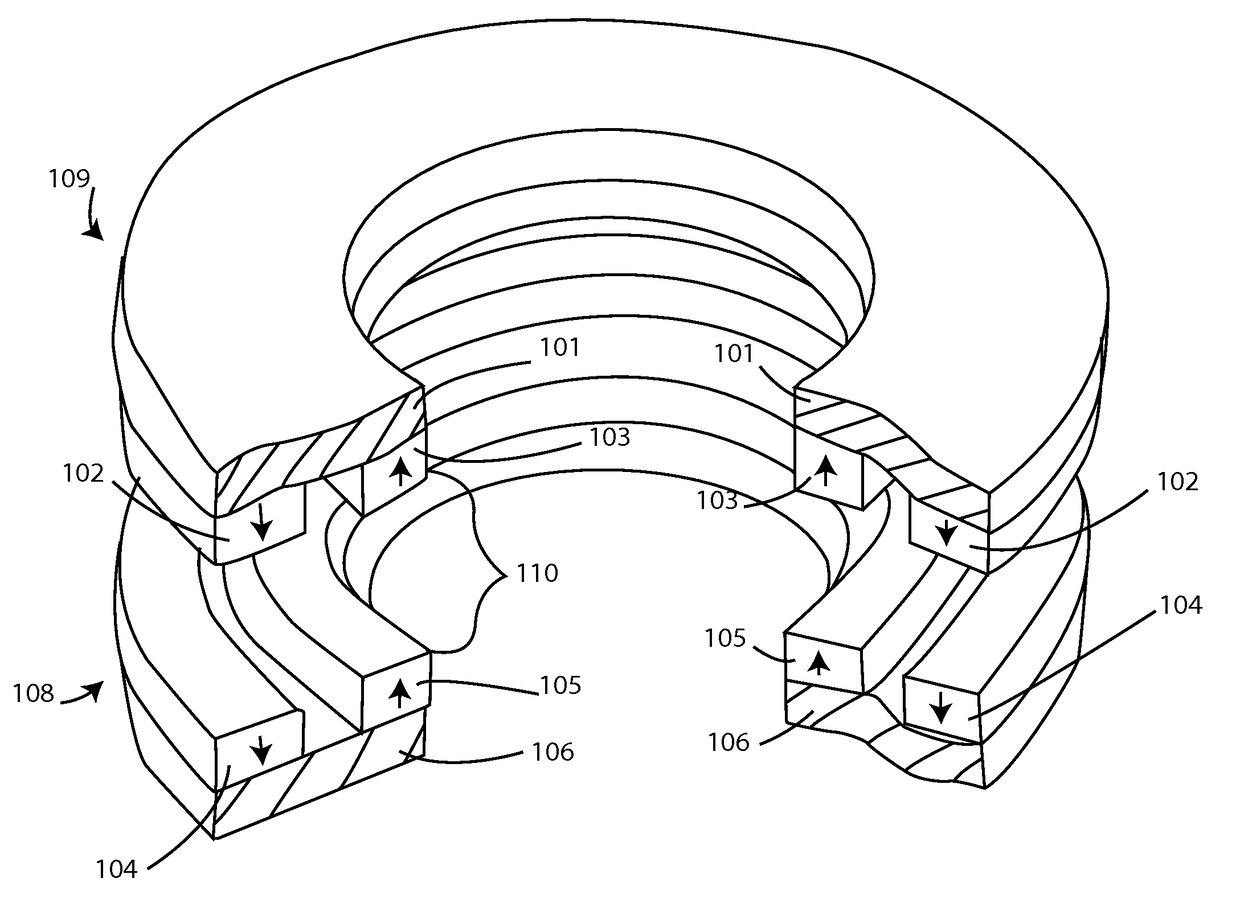

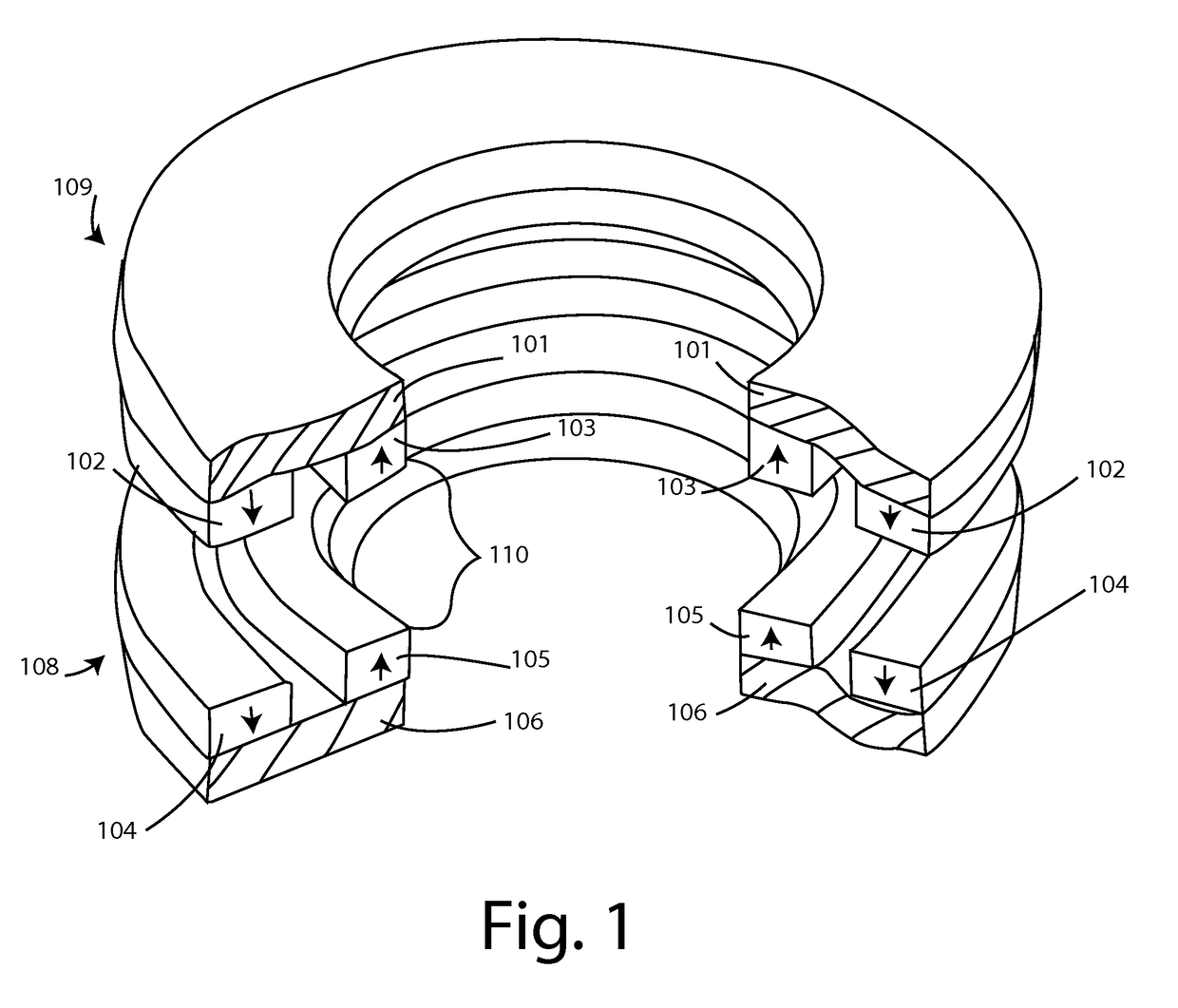

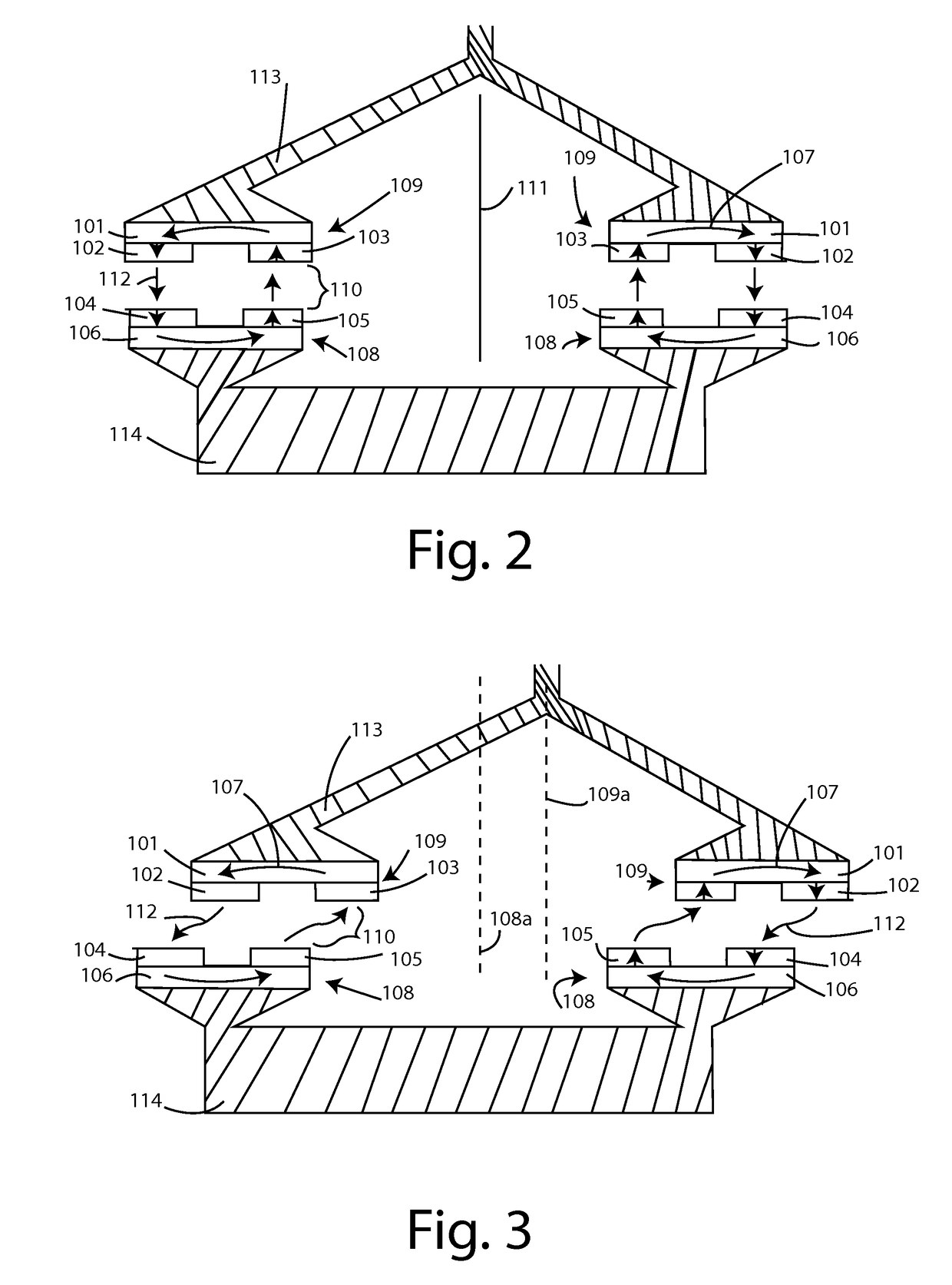

Assembly for a turbomachine

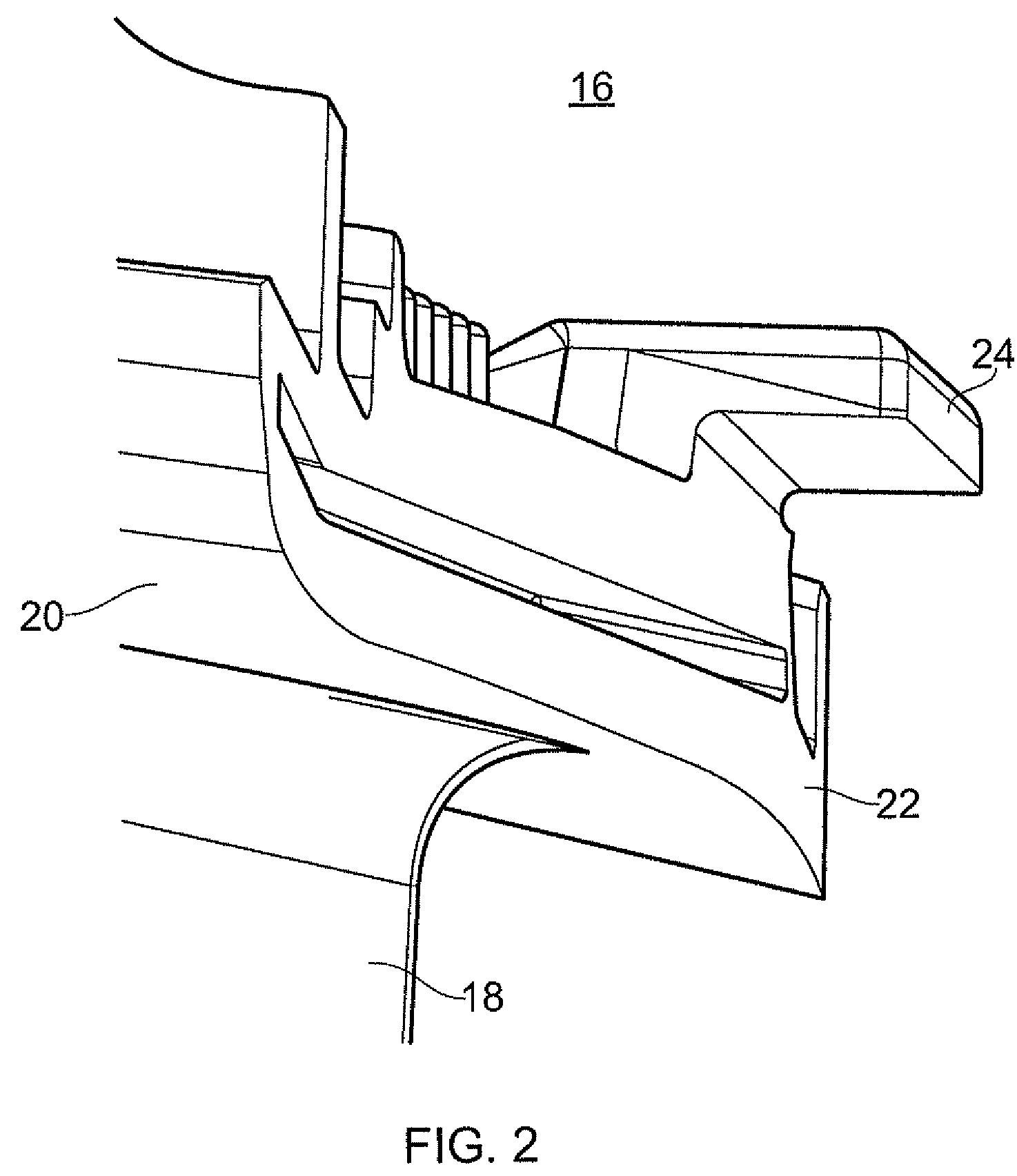

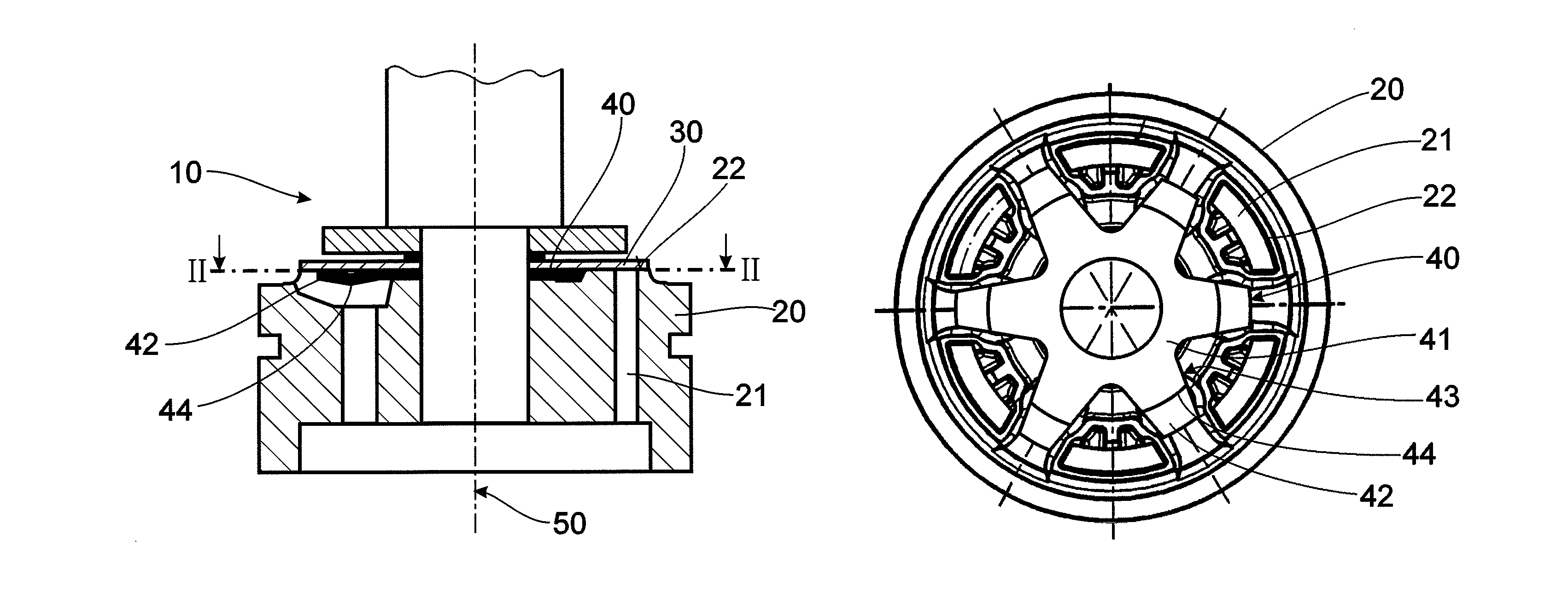

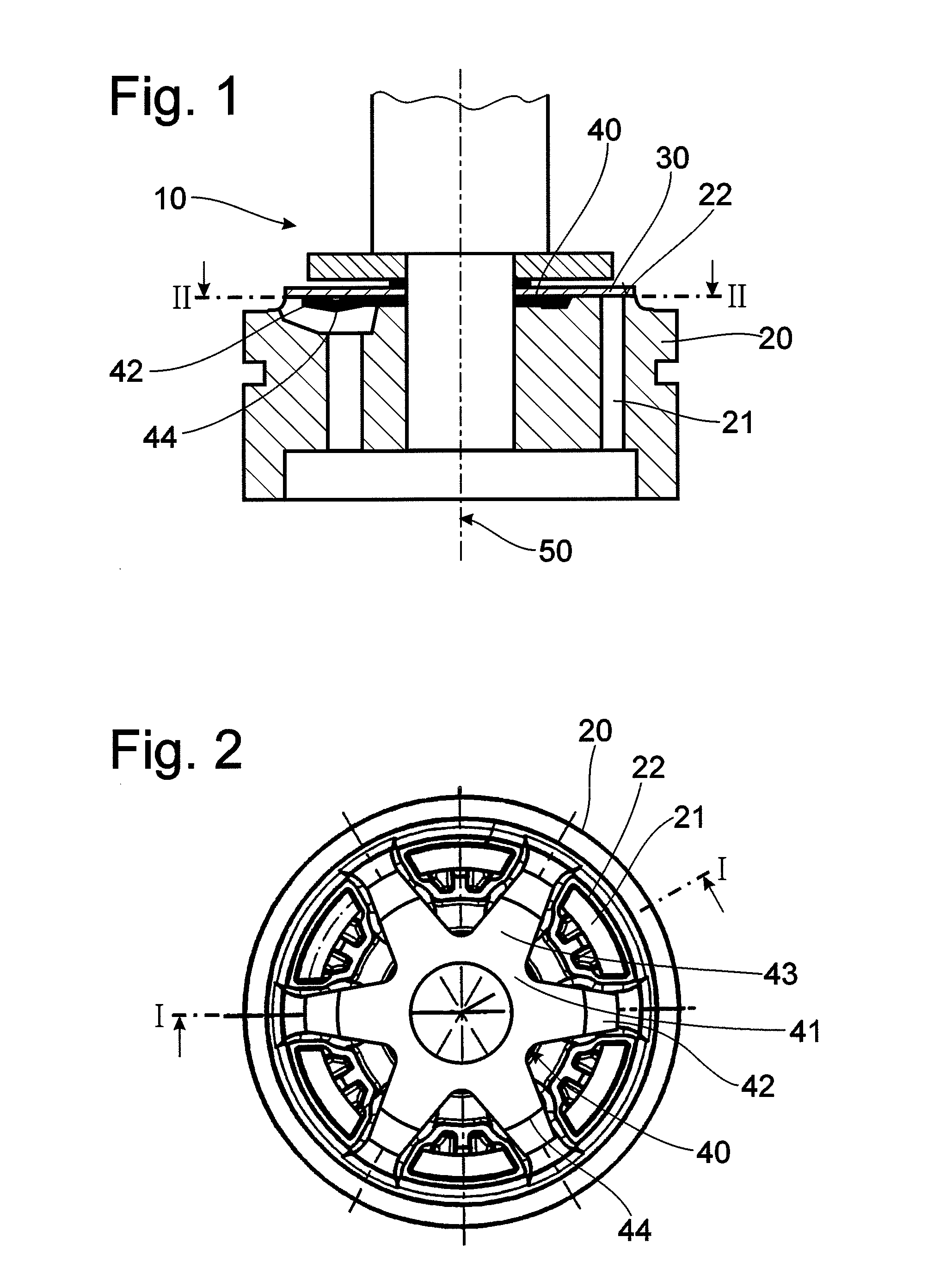

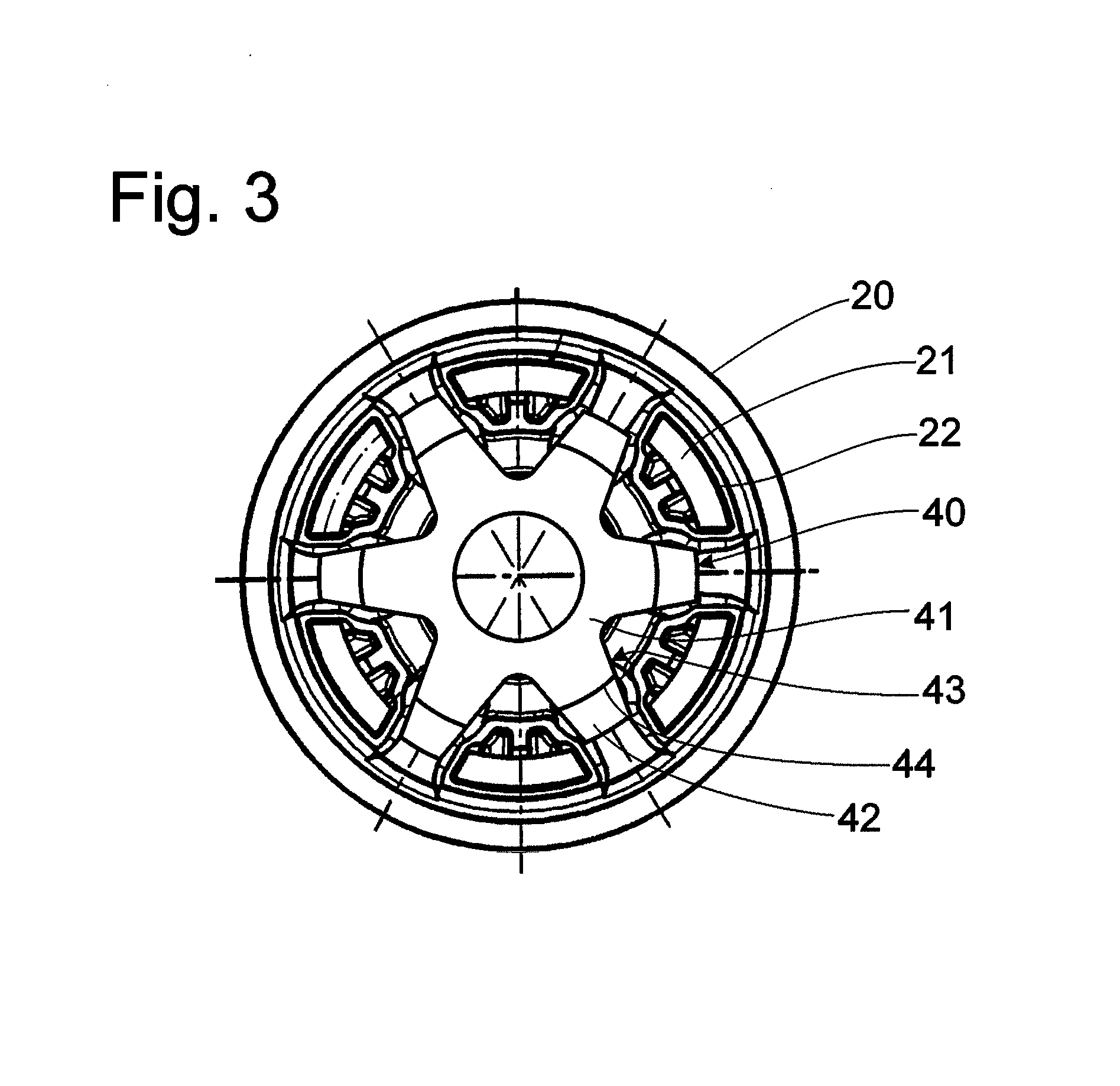

InactiveUS8596970B2Prevent radial displacementIncrease displacementPump componentsEngine fuctionsAnnular arrayRadial displacement

An assembly for a turbomachine comprising: a plurality of components (16, 26) which, in use, are assembled into a circumferentially extending annular array; each component having a radially outer platform (20, 28), the outer platforms (20, 28) of the components (16, 26) forming a ring in the assembled array; wherein adjacent components (16, 26) interface at adjacent surfaces (22, 30) of their outer platforms (20, 28); wherein the outer platforms (20, 28) each comprise at least one lug (24) which extends from the outer platform (20) over a portion of the outer platform (28) of an adjacent component (26), and in use prevents relative radial displacement of the outer platform (20, 28) of the adjacent component (16, 26).

Owner:ROLLS ROYCE PLC

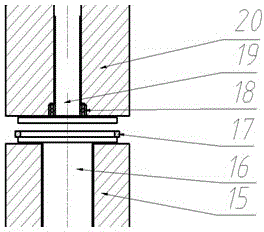

Damping valve arrangement for a vibration damper

InactiveUS8794265B2Reduce tapping noiseReduce developmentSpringsCheck valvesSpring forceVibration damper

Owner:ZF FRIEDRICHSHAFEN AG

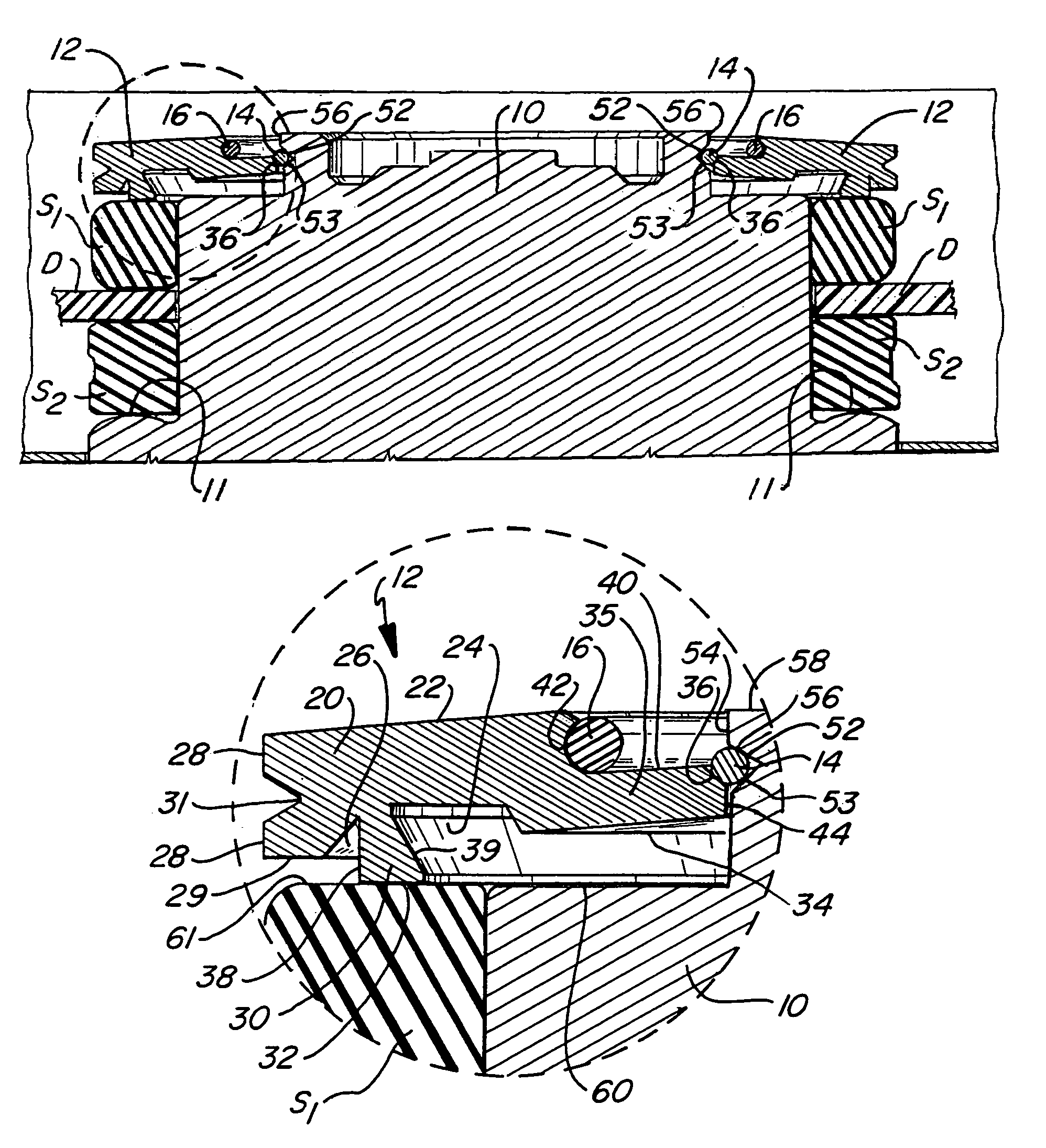

Damping Valve Arrangement For A Vibration Damper

InactiveUS20120138837A1Reduce tapping noiseReduce developmentSpringsMachines/enginesSpring forceEngineering

A damping valve arrangement for a vibration damper includes a damping valve body, which has at least one through-flow opening for the damping medium, and at least one valve disk which at least partly covers the through-flow openings under the influence of a closing force. The damping valve arrangement includes at least one spring element which has at least one supporting portion axially supported at another structural component part of the damping valve arrangement, and at least one spring portion disposed at a distance from the supporting portion and which introduces a spring force into the valve disk at least indirectly, wherein the spring force of the spring element is directed counter to the closing force acting on the valve disk, and wherein the spring force of the spring element is less than the closing force of the valve disk.

Owner:ZF FRIEDRICHSHAFEN AG

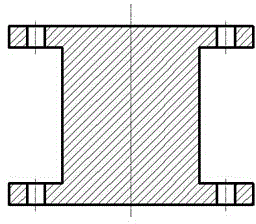

Single-coil magnetorheological fluid normal stress testing device

InactiveCN104913871ASimple structureEasy to assembleMeasurement of force componentsBall bearingCoupling

The invention relates to a single-coil magnetorheological fluid normal stress testing device. The single-coil magnetorheological fluid normal stress testing device includes an upper magnetic conduction plate, a steel I beam, an iron core, a lower magnetic conduction plate, a lower magnetic conduction shaft sleeve, a lower shearing shaft disc, an upper shearing shaft disc, an upper magnetic conduction shaft sleeve, a bearing sleeve, a motor support, a coupling and a motor; the upper magnetic conduction plate and the lower magnetic conduction plate are fixedly connected with each other through the steel I beam; one side of a space between the upper magnetic conduction plate and the lower magnetic conduction plate is connected with the iron core, and the other side of the space is provided with the upper shearing shaft disc and the lower shearing shaft disc; the upper shearing shaft disc is installed on the upper magnetic conduction plate through a ball bearing and the bearing sleeve; the motor is installed above the upper magnetic conduction plate through the motor support; the motor is connected with the upper shearing shaft disc through the coupling; and the lower shearing shaft disc is installed on the lower magnetic conduction plate through a linear bearing. According to the single-coil magnetorheological fluid normal stress testing device of the invention, a single-coil device is adopted, so that the whole structure of the single-coil magnetorheological fluid normal stress testing device is simple and compact, and easy to be assembled; and a non-magnetic O-shaped check ring is arranged at the outer edge of the lower shearing shaft disc, so that the climb of magnetorheological fluid can be prevented; and the steel I beam fixing structure is adopted, so that a gap of the upper shearing shaft disc and the lower shearing shaft disc can be ensured.

Owner:SHANGHAI INST OF TECH

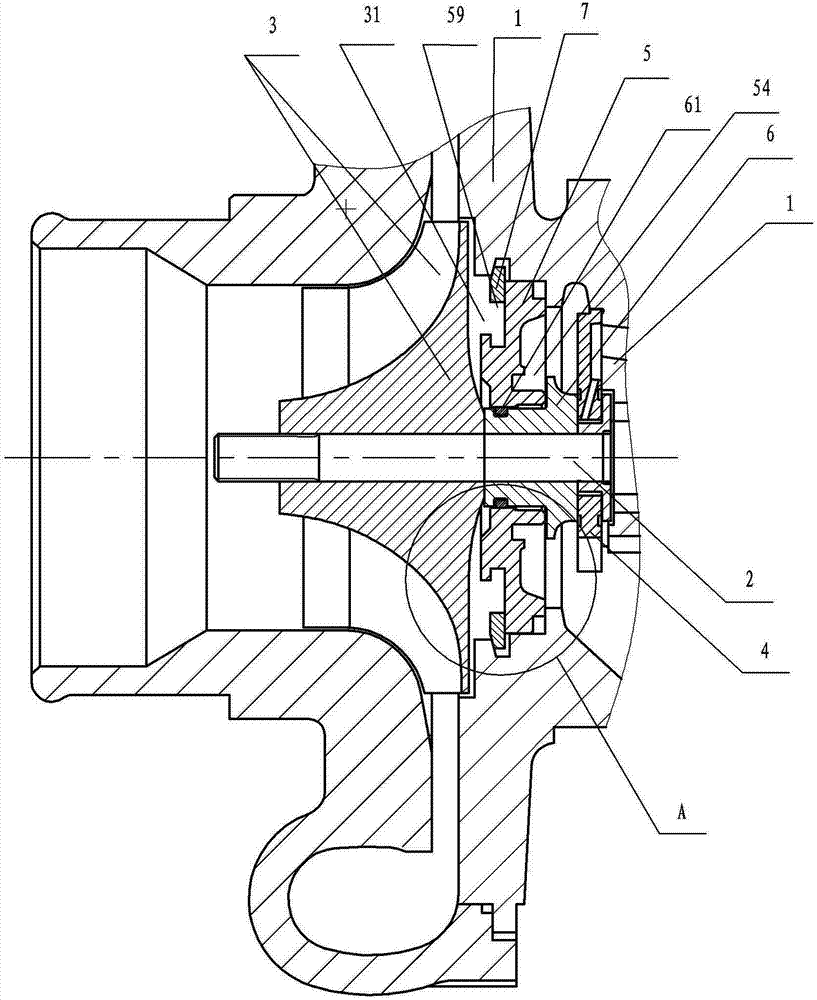

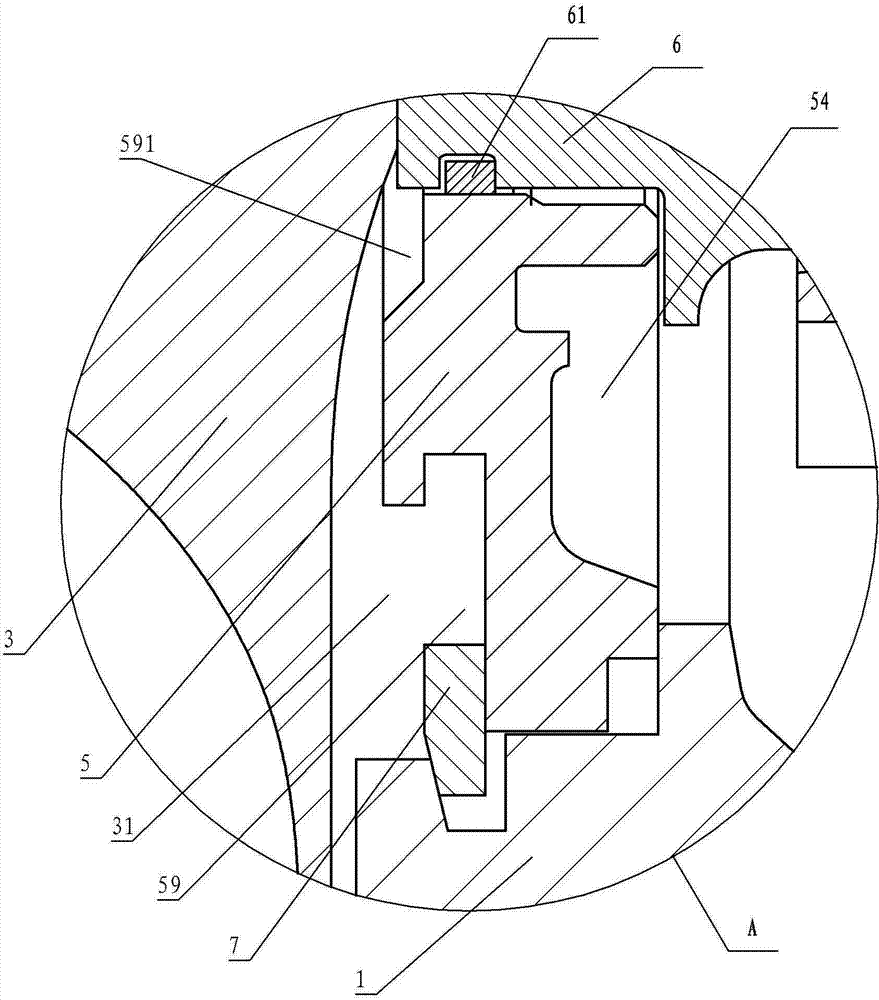

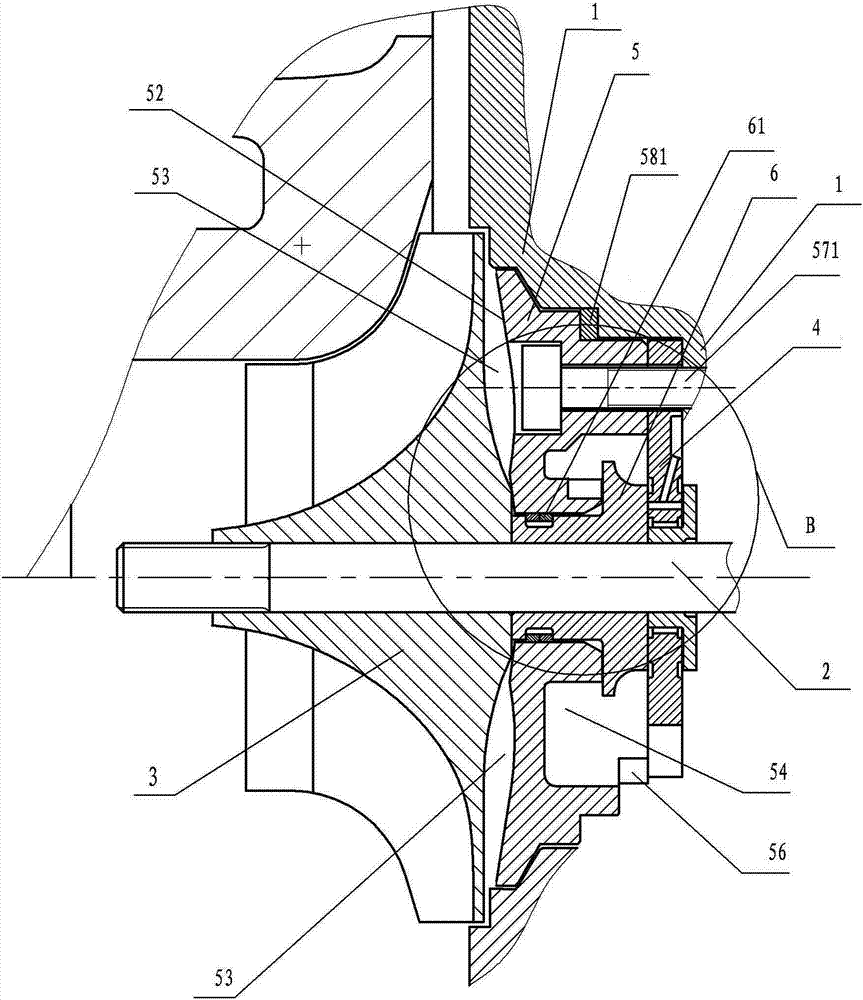

Gas compressor end sealing structure of turbocharger

ActiveCN102926824AImprove sealingPrevent axial movementMachines/enginesEngine componentsImpellerTurbocharger

The invention discloses a gas compressor end sealing structure of a turbocharger. The gas compressor end sealing structure comprises a bearing body (1), a rotator (2), a gas compressor impeller (3), a thrust bearing (4), a sealing oil cover (5) and a sealing sleeve (6), wherein a screw hole (57) is arranged on the sealing oil cover (5); the sealing oil cover (5) is fixedly arranged on the bearing body (1) through a bolt (571); the outside surface (52) of the sealing oil cover (5) is a concave surface; the outside surface (52) of the sealing oil cover (5) is adjacent to the back surface of the gas compressor impeller (3) at a position close to an installation hole (51) of the sealing oil cover (5); and an oil storage cavity (55) for storing lubricating oil can be arranged at the upper part on the inner side wall of the annular guide cavity (54) of the sealing oil cover (5). The gas compressor end sealing structure is stable in internal structure and small in cavity of the outer side surface of the sealing oil cover, can supercharge and choke flow secondarily to form an oil film in advance. Moreover, the gas compressor end sealing structure is good in oil leakage resistance effect, can buffer axial force and can reduce starting friction and damages.

Owner:HUNAN TYEN MACHINERY

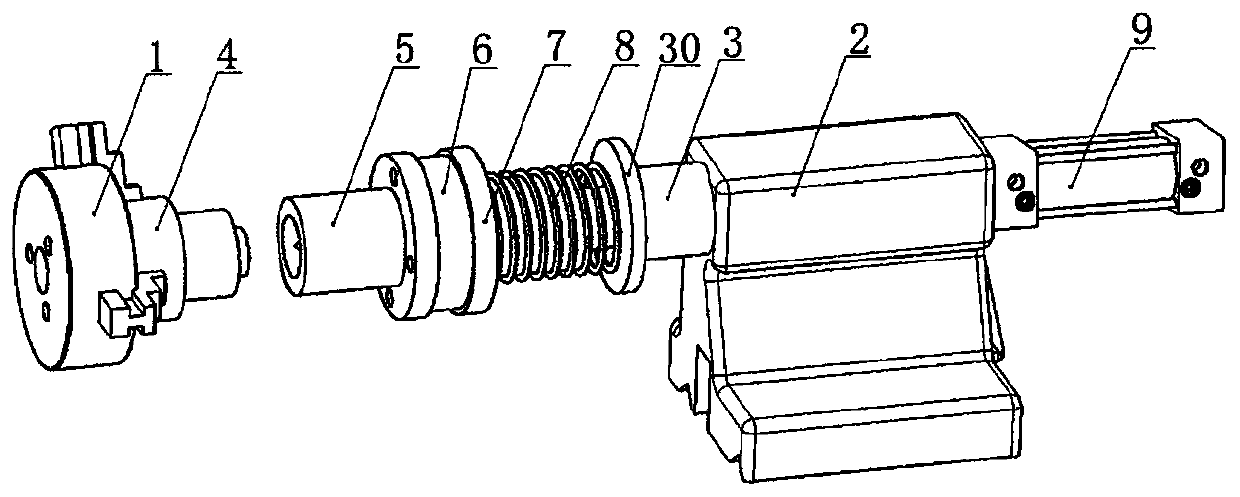

Automatic fixture device for clamping shaft sleeve parts on cylindrical grinding machine

PendingCN111408985AGuaranteed coaxialityGuaranteed machining accuracyRevolution surface grinding machinesGrinding work supportsPhysicsCylindrical grinding

The invention relates to the field of grinding machine processing, in particular to an automatic fixture device for clamping shaft sleeve parts on a cylindrical grinding machine. The cylindrical grinding machine comprises a chuck, a center seat and a tail center, the automatic fixture device comprises a mandrel, a first rotary sliding shaft sleeve, a plane bearing, a second rotary sliding shaft sleeve, a spring and an air cylinder, the mandrel is fixed on the chuck, the tail end of the tail center is installed on the center seat in a sliding mode, the cylinder is fixed at the tail end of the center seat, a cylinder shaft penetrates through the center seat and is connected at the tail end of the tail center, the first rotary sliding shaft sleeve, the plane bearing and the second rotary sliding shaft sleeve are sequentially arranged on the tail center from head to tail in a sleeving mode, a limiting step is further arranged on the tail center, the spring is installed between the second rotary sliding shaft sleeve and the limiting step, and shaft sleeve parts are clamped and fixed between the mandrel and the first rotary sliding shaft sleeve. According to the automatic fixture device,the automatic pressing of the parts is realized, the coaxiality of the parts during machining is guaranteed, the eccentric condition of the machined shaft sleeve parts is prevented, and the machiningprecision of the parts is improved.

Owner:重庆机电职业技术大学

Radial-loading Magnetic Reluctance Device

InactiveUS20170343043A1Function increaseEffectively focus magnetic fluxEngine componentsBearingsRotational axisMagnetic bearing

A magnetic bearing retains a rotatable shaft in a selected position by magnetic coupling between two circularmagnetic assemblies, one of which is connected to the shaft. Each magnetic coupling completes a magnetic circuit. Shaft rotation does not affect the magnetic circuit, but radial displacement of the shaft disrupts the magnetic circuit and increases magnetic reluctance. Increasing magnetic reluctance inhibits radial displacement. The shaft thereby supports a load while rotating freely, constrained to a selected position by forces of magnetic reluctance. A bearing may be employed to maintain gap distance between the magnetic assemblies.

Owner:WALSH RAYMOND JAMES

Roller bearing

InactiveUS20080240641A1Prevent radial displacementTorque loss can be preventedValve arrangementsRotary combination bearingsEngineeringCentrifugal force

The clearance between the outer peripheral surface of an annular portion of a cage and the inner peripheral surface of each of rib portions of outer-ring split pieces is set to be smaller than the clearance between the radial end surface of a projection portion of the cage and the inner peripheral surface of each of body portions of the outer-ring split pieces. When a centrifugal force due to engine rotation acts upon the cage, the inner peripheral surface of each of the rib portions of the outer-ring split pieces touches the outer peripheral surface of the annular portion of the cage before the inner peripheral surface of each of the body portions of the outer-ring split pieces touches the radial end surface of the projection portion of the cage. Thus, the radial displacement of the cage can be prevented in good time.

Owner:JTEKT CORP

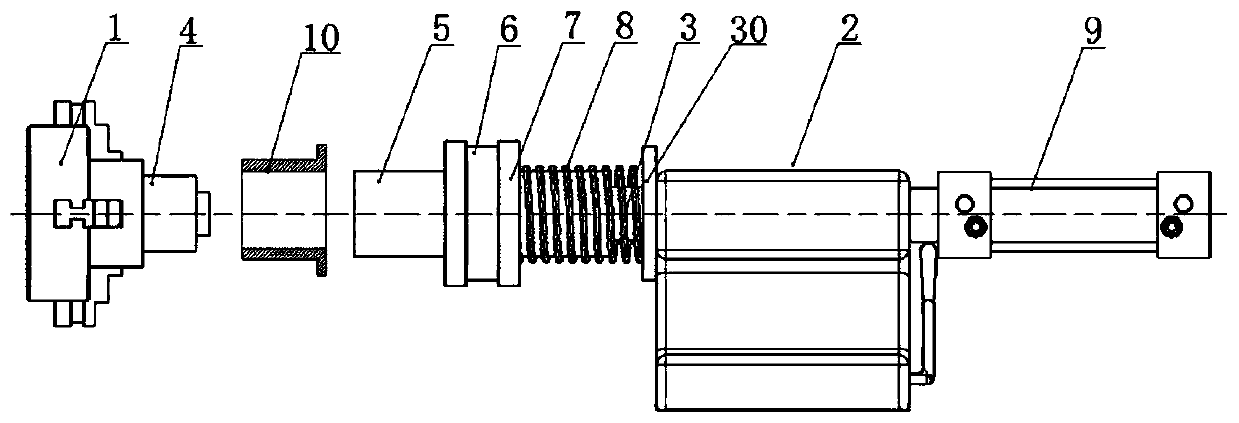

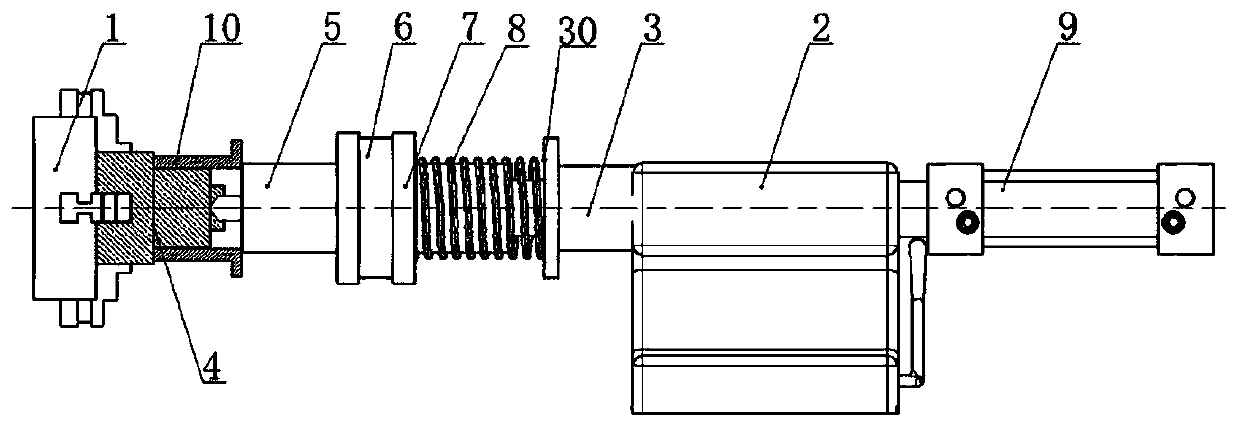

Special fixture for cylindrical grinding machine

PendingCN111515774AClearance adjustment is simpleRelaxation is easy to controlRevolution surface grinding machinesGrinding work supportsPhysicsProcessing accuracy

The invention relates to the field of machining by a grinding machine, in particular to a special fixture for a cylindrical grinding machine. The special fixture is used for abrasive machining of shaft sleeve type parts, the cylindrical grinding machine comprises a head thimble, a tail thimble, a turntable rack for fixing the head thimble and a tailstock rack for fixing the tail thimble, the special fixture for the cylindrical grinding machine comprises a chuck sleeve, a suspension shaft for the shaft sleeve parts, an ejecting mechanism and a pressing mechanism, the chuck sleeve covers the head thimble and is fixed to the turntable rack, one end of the suspension shaft extends into the chuck sleeve, the head thimble is propped against the head end of the suspension shaft, the ejecting mechanism is parallel to the chuck sleeve and the suspension shaft and fixedly connected on the cylindrical grinding machine, and the pressing mechanism is arranged on the tailstock rack in a sleeving manner and used for pressing the shaft sleeve type parts arranged on the suspension shaft in a sleeving manner. According to the special fixture, automatic pressing and automatic dismounting of the partsare realized, coaxiality of the parts during machining is guaranteed, the eccentric condition of the shaft sleeve parts is prevented, and the machining precision of the parts is improved.

Owner:重庆机电职业技术大学

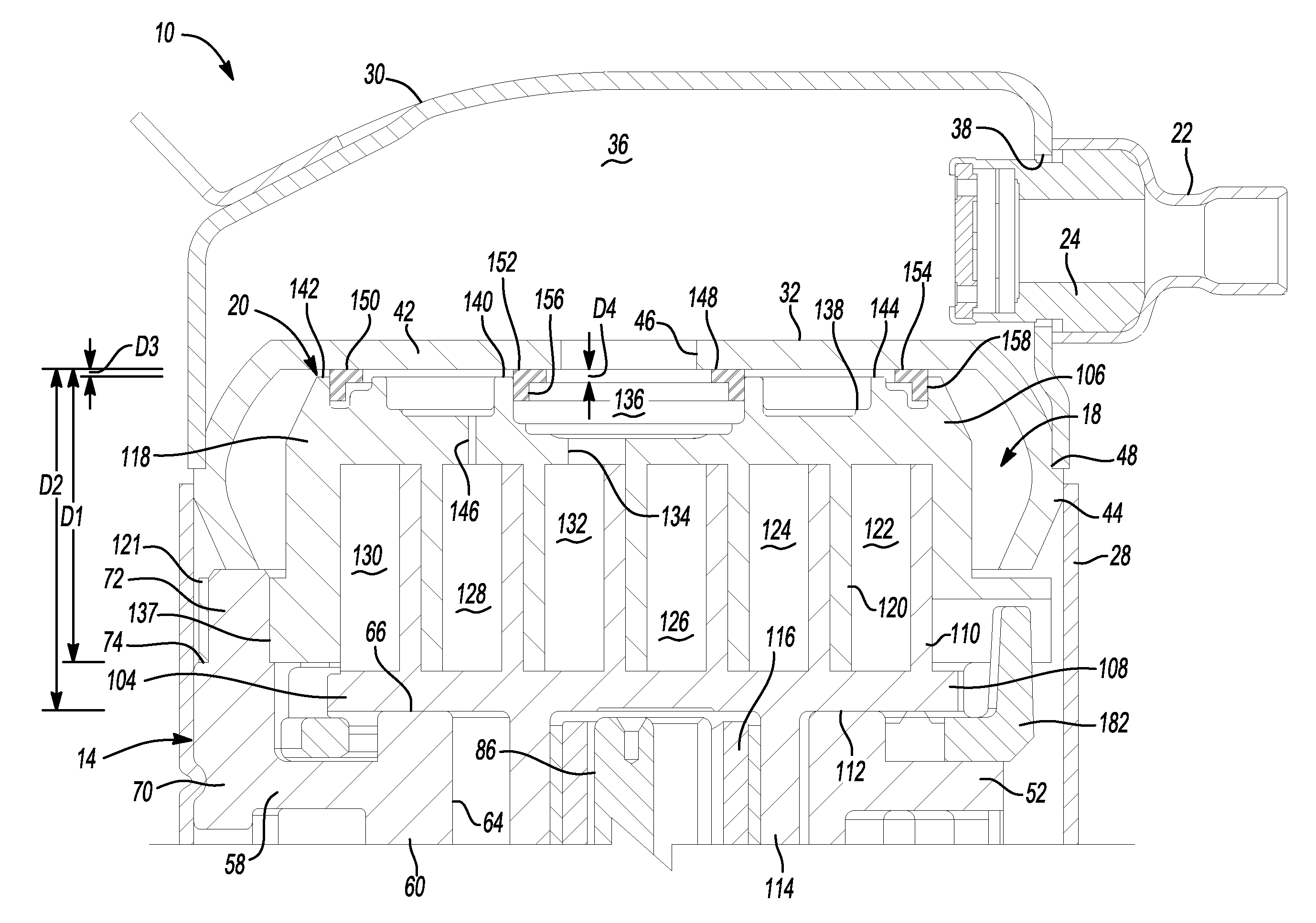

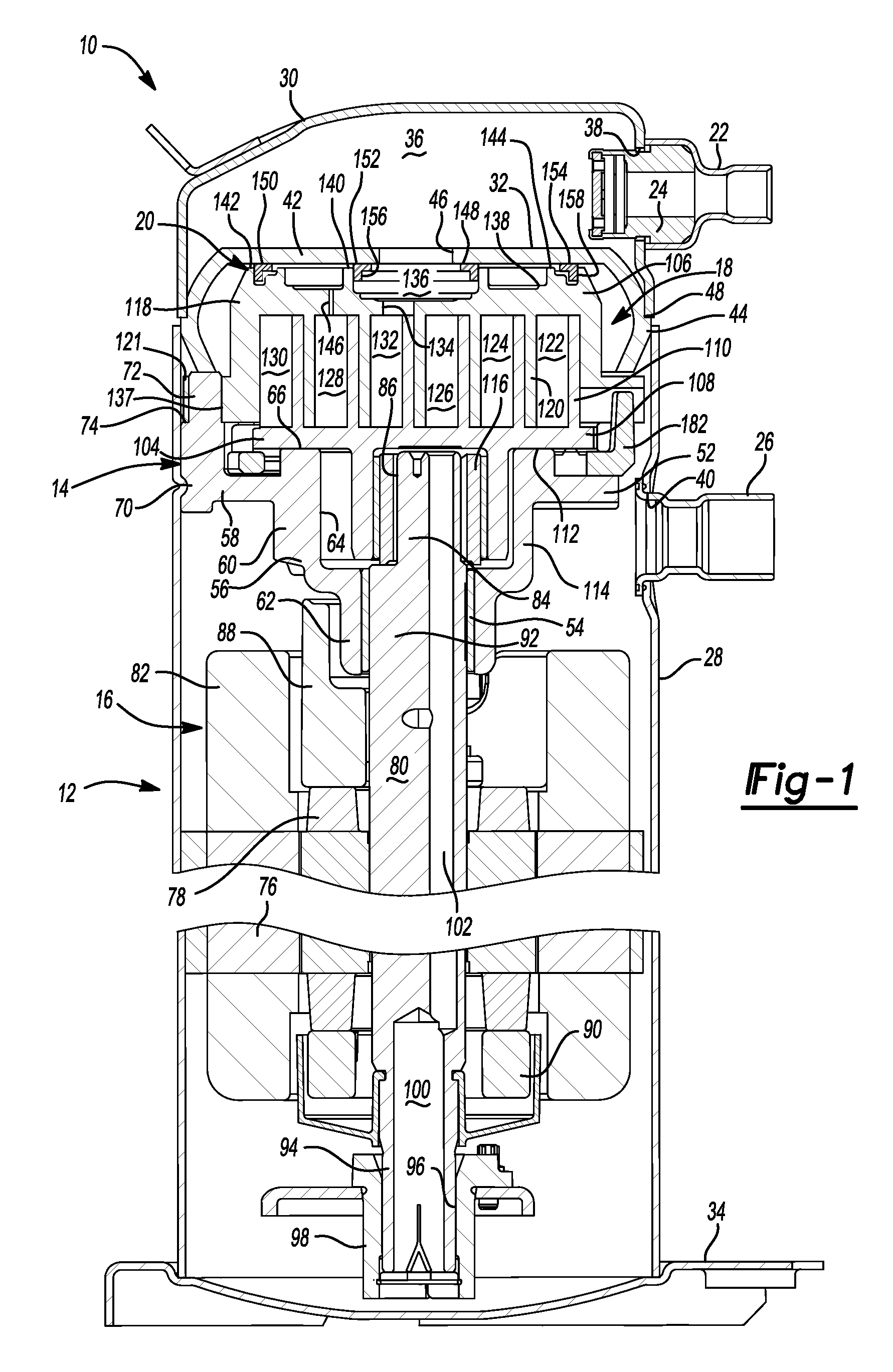

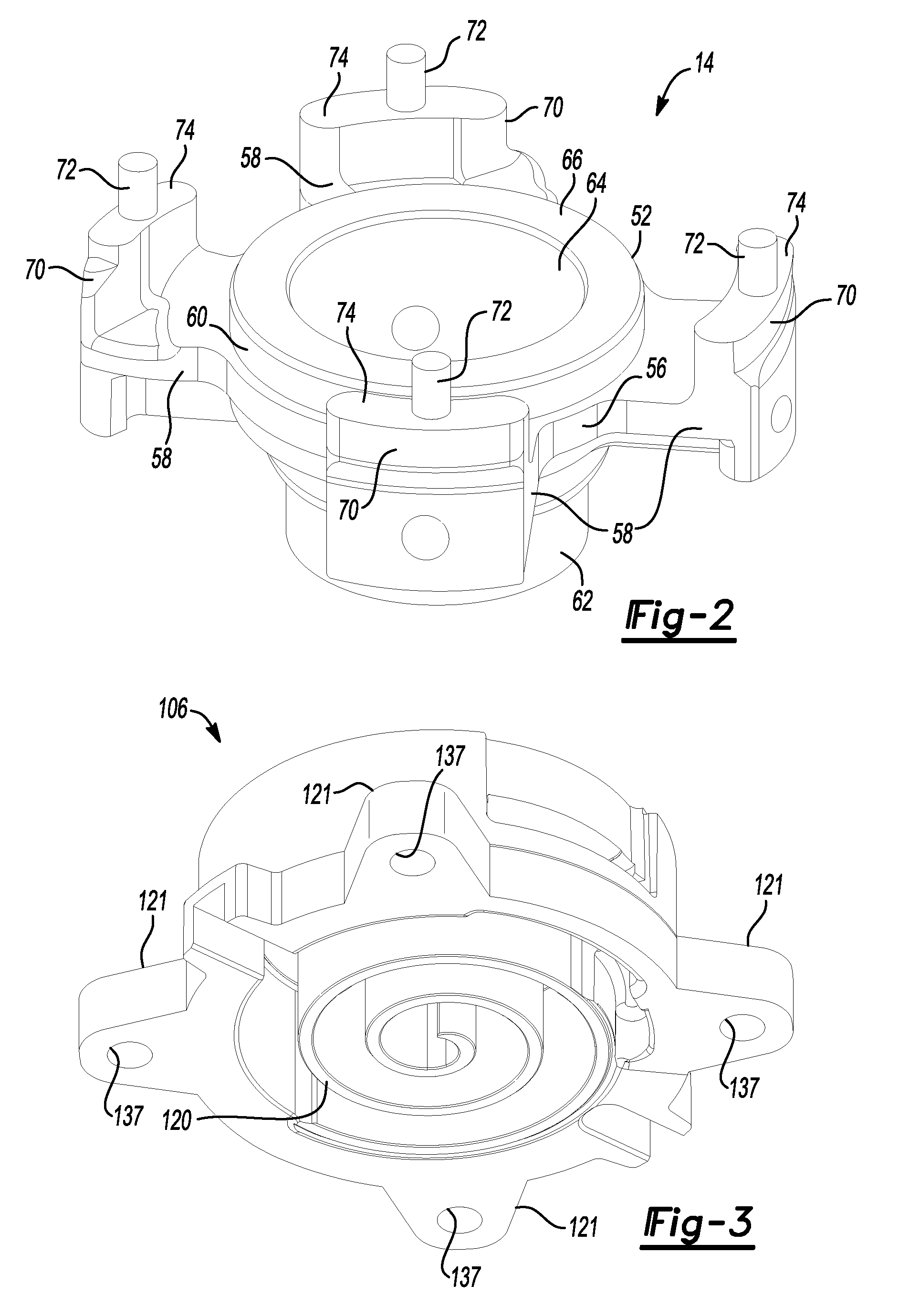

Compressor having improved sealing assembly

InactiveUS8033803B2Prevent radial displacementAvoid displacementRotary/oscillating piston combinations for elastic fluidsPiston ringsEngineeringMechanical engineering

A compressor may include a shell, a bearing housing assembly located within and secured to the shell, a compression mechanism supported on the bearing housing assembly, a partition extending over the compression mechanism, and an annular seal assembly. The partition may be fixed to the shell and may abut an axial end surface of the bearing housing assembly to control a maximum axial distance between the partition and the compression mechanism. The annular seal may be sealingly engaged with the compression mechanism and the bearing housing assembly and may have a generally L-shaped cross-section including a first leg extending generally laterally between the compression mechanism and the partition. The first leg may have an axial thickness that is greater than the maximum axial distance.

Owner:EMERSON CLIMATE TECH INC

C type grounding clamp

ActiveCN105226402APrevent radial displacementAchieving a constant clamping forceConnections effected by permanent deformationClamped/spring connectionsEngineeringThermal expansion

The invention discloses a C type grounding clamp and relates to the field of welding and cutting electroplating and the like. Different from the grounding clamp in the prior art, the grounding clamp is not used as a conductive carrier between a grounding cable and a workpiece, and pressure change caused by vibration and expansion caused by heat and contraction caused by cold between the grounding cable and the workpiece can be automatically compensated. Connection performance between the grounding cable and the workpiece can be effectively improved, so that the performance and profile can be perfect. Production cost is low, virtual connection is prevented, and each part can be individually replaced and maintained after being damaged. The C type grounding clamp makes the best use of everything, and generates great value for clients. Practicality is strong and popularization usage is favorable.

Owner:马春辉

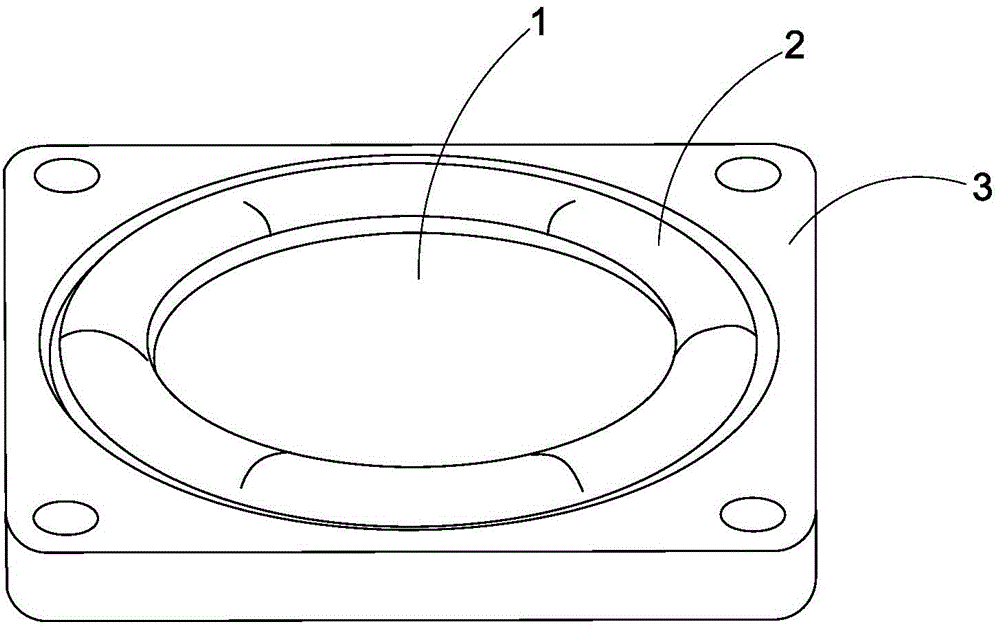

Dangling edge structure of vibration unit of loudspeaker

The invention discloses a dangling edge structure of a vibration unit of a loudspeaker. The dangling edge structure is arranged between a vibration element and a frame of the vibration unit of the loudspeaker, and comprises an elastic dangling edge and a plurality of spacing ribs, wherein the elastic dangling edge is arranged at the periphery of the vibration element and extends between the vibration element and the frame; each spacing rib raises outwardly and extends from the elastic dangling edge and extends between the vibration element and the frame; and each spacing rib and the internal circumferential surface of the frame form point connection on the section along the length direction of each spacing rib. The vibration unit with the dangling edge structure is applicable to manufacture of the loudspeaker or a passive vibration plate.

Owner:NINGBO SHENGYA ELECTRONICS

Quick-change attachment

ActiveUS7086804B2Improve tool lifeSimple and cost-effectiveMechanical machines/dredgersShaftsEngineeringCantilever

The invention relates to a quick-change attachment to connect a tool, preferably, to the boom of a hydraulic excavator, comprising a boom-connecting quick-change attachment component to accommodate a tool, one end of which has a pin, and the other end of which is retained within a bearing of the quick-change attachment by positive-fit or friction engagement. According to the invention, a bushing in the form of a half-liner having a large support angle is inserted in the bearing.

Owner:LEIBHERR HYDRAULIKBAGGER GMBH

Engine bearing bush mounting and dismounting tool

ActiveCN112975338APrevent radial deformationPrevent radial displacementMetal working apparatusEngineeringMechanical engineering

The invention discloses an engine bearing bush mounting and dismounting tool, and belongs to the field of engine assembly. The engine bearing bush mounting and dismounting tool comprises a tool body. The two ends of the tool body are a dismounting end and a mounting end respectively, and the mounting end sequentially comprises a guide journal and a bearing bush matching journal in the direction away from the dismounting end. The diameter of the guide journal is larger than that of the bearing bush matching journal, the bearing bush matching journal is used for sleeving two half bushes of a bearing bush, and a step surface between the guide journal and the bearing bush matching journal is a bearing bush thrust surface. A guide ring can be hooped on the peripheries of the two half bushes and can provide radial limiting for the bearing bush in the mounting process, so that the two half bushes are prevented from radial deformation or radial displacement. In addition, the guide ring can axially move along the guide journal in the press-fitting process so as to play an axial limiting role in mounting of the bearing bush and determine the press-in amount of the bearing bush pressed into a bearing seat. The engine bearing bush mounting and dismounting tool is simple in structure and low in manufacturing cost, and the assembly precision is easy to guarantee.

Owner:FAW JIEFANG AUTOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com