Splice sleeve with elliptical or compound curve cross section

a sleeve and cross section technology, applied in the direction of rod connection, furniture joining, structural elements, etc., can solve the problems of limited expansion of the grout mass, increase the bonding and strength of the connection, etc., to achieve maximum bonding and shear resistance, increase the splicing capacity of the overlapping, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In describing preferred embodiments of the invention illustrated in the drawings, specific terminology will be resorted to for the sake of clarity. However, the invention is not intended to be limited to the specific terms so selected, and it is to be understood that each specific term includes all technical equivalents which operate in a similar manner to accomplish a similar purpose.

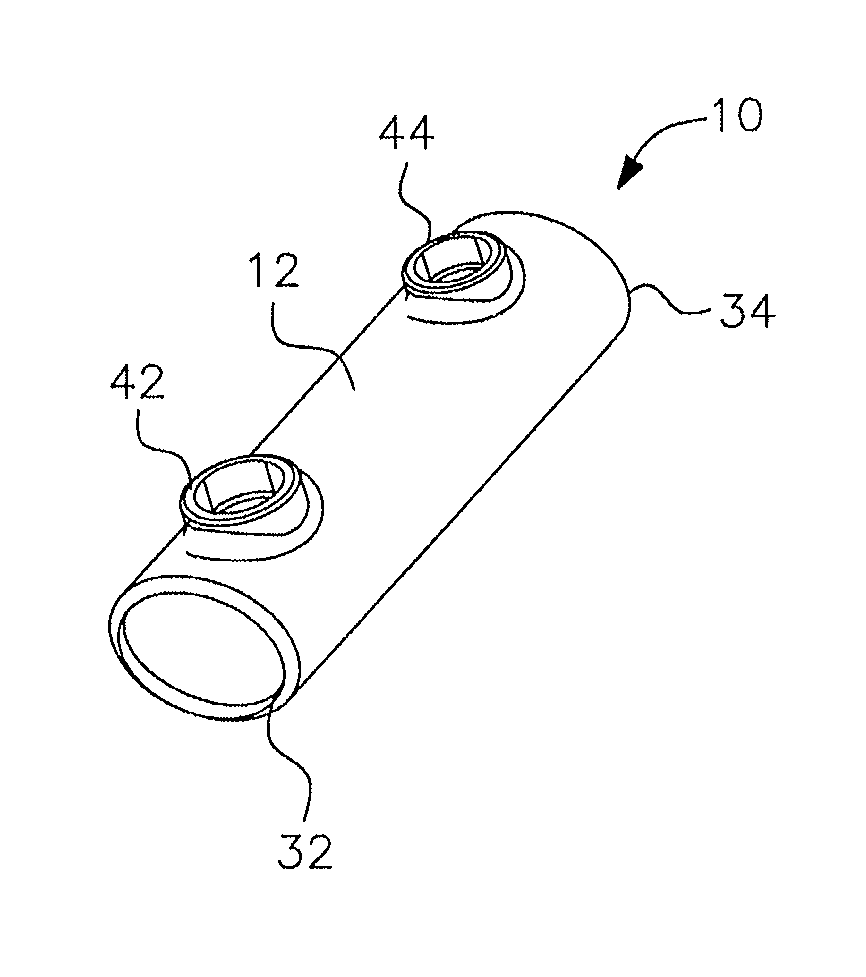

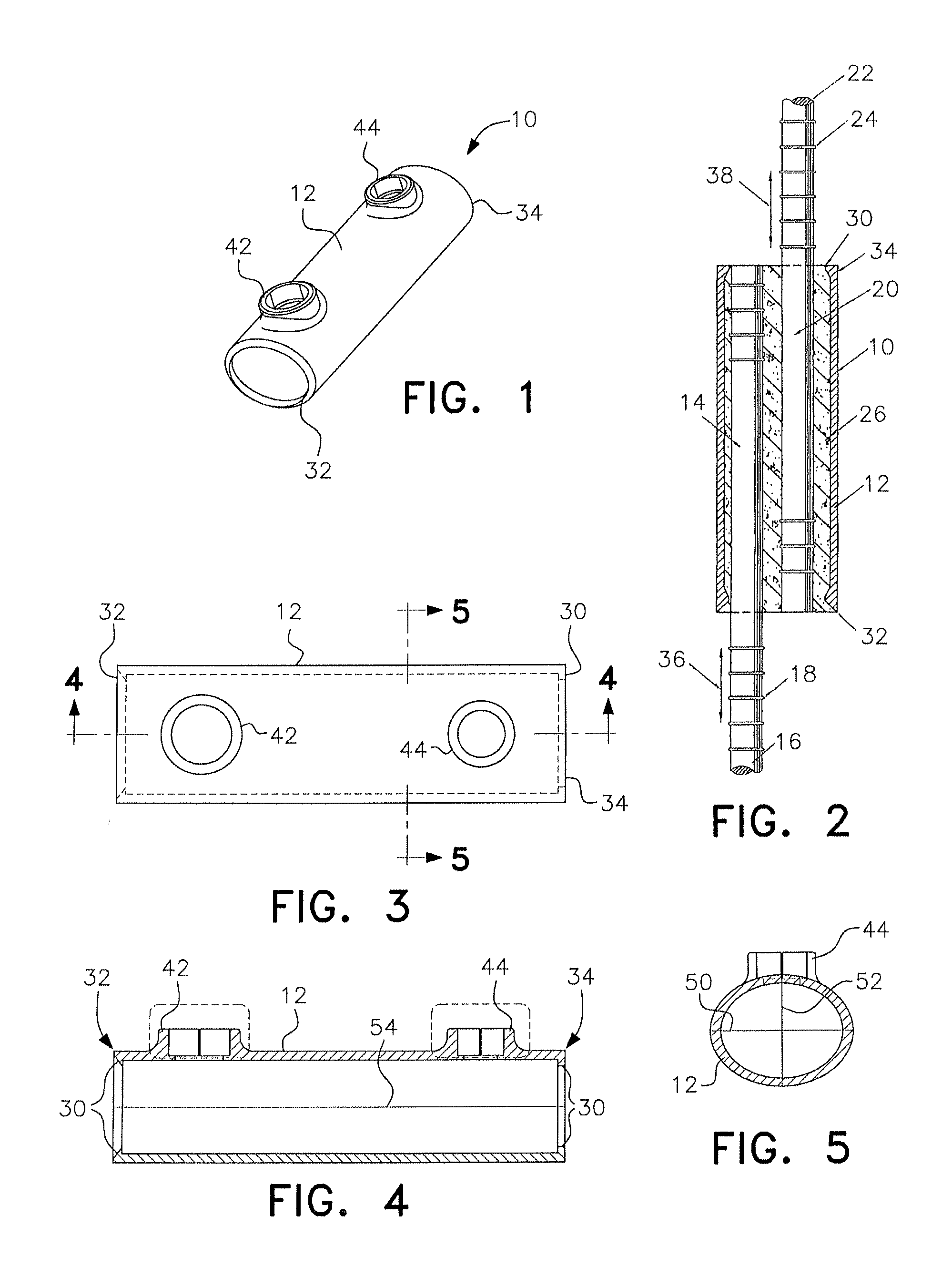

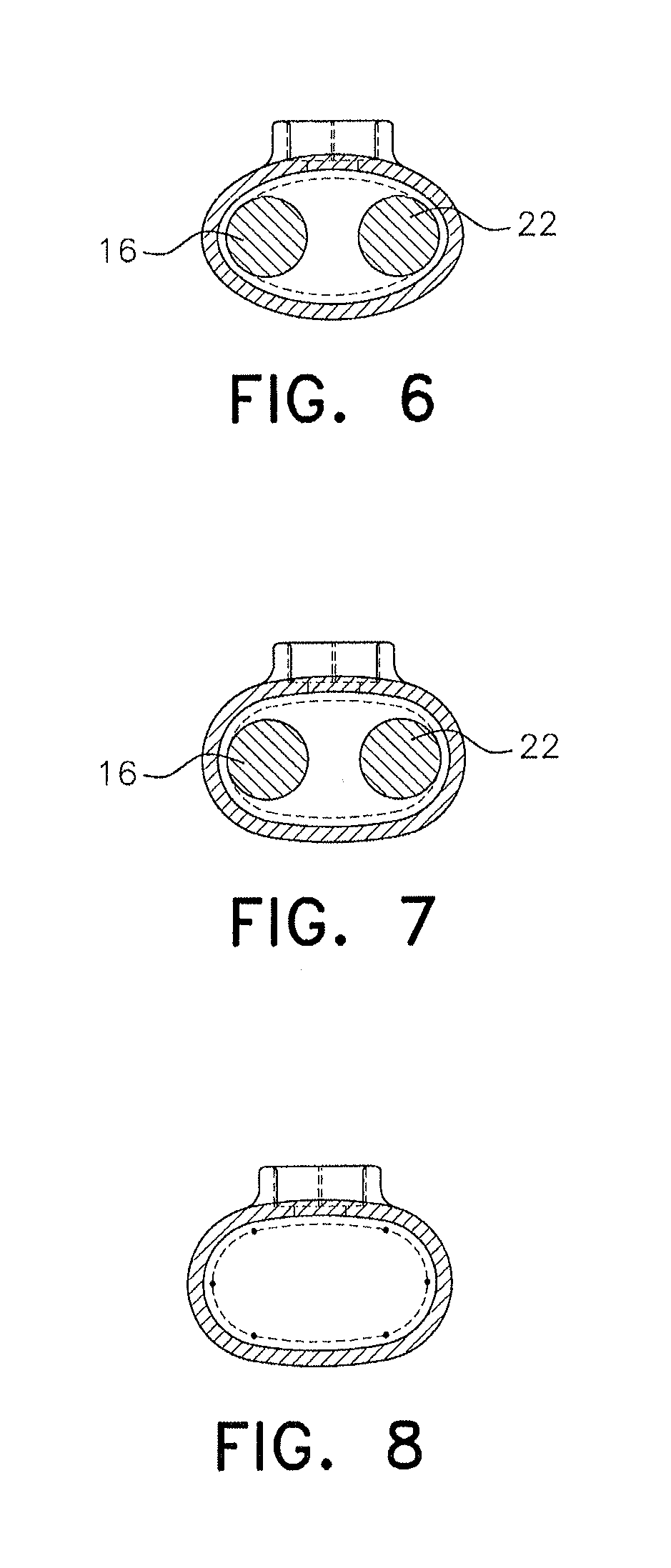

[0027]Referring now specifically to the drawings and FIG. 1 in particular, the splice sleeve of the present invention is generally designated by numeral 10 and includes a short section of rigid steel tubing or pipe forming a sleeve 12 of elliptical cross section configuration. When the sleeve is vertically oriented in use, as shown in FIG. 2, the sleeve 12 receives the upper end portion 14 of a lower reinforcing bar 16 having longitudinally spaced peripheral ribs or projections 18 thereon. The sleeve 12 also receives the lower end portion 20 of an upper reinforcing bar 22 which also has longitudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com