Water pump shaft grinding device and process

A water pump shaft and grinding technology, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, grinding machines, etc., can solve the problems that the grinding accuracy is difficult to guarantee, it is difficult to use electromagnetic centerless fixtures, and vibration lines are easy to occur, and achieve The effect of reducing grinding cost, widening the range of processing and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

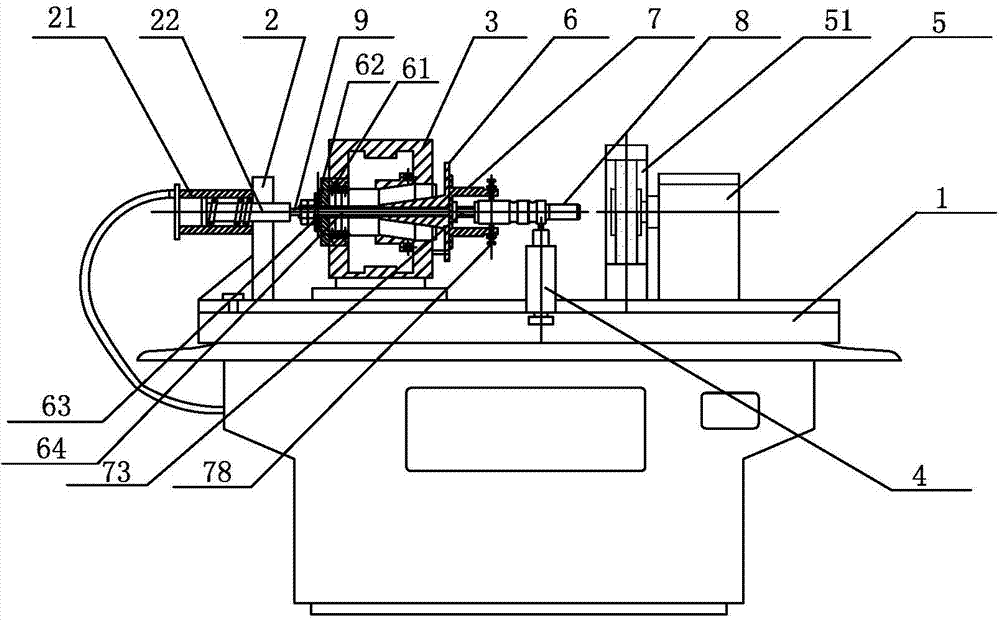

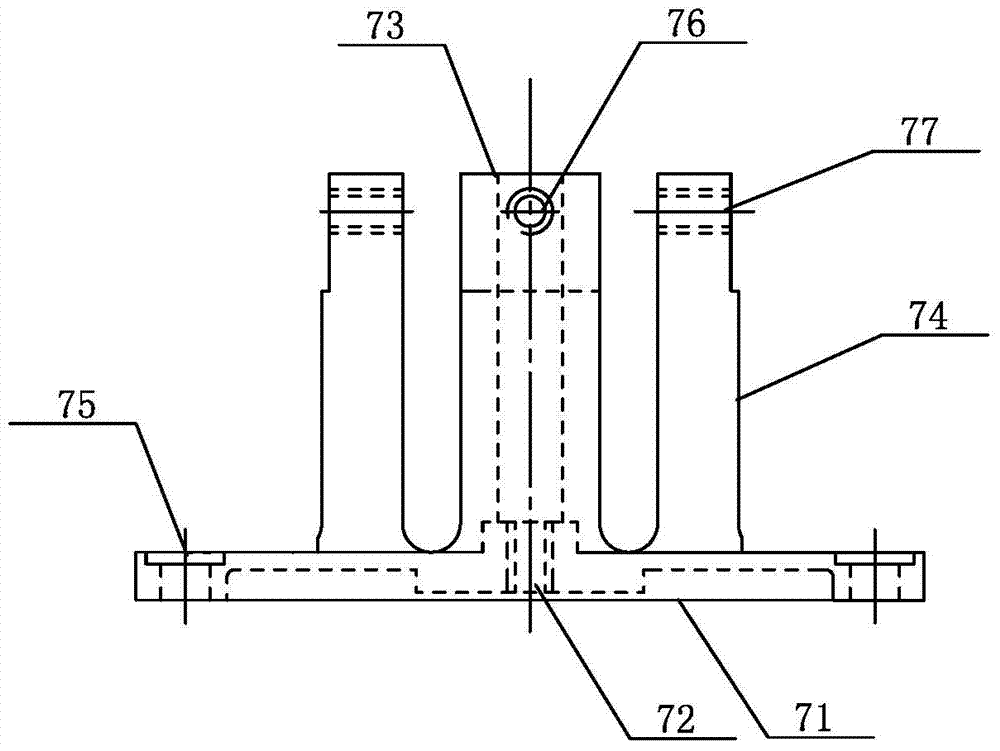

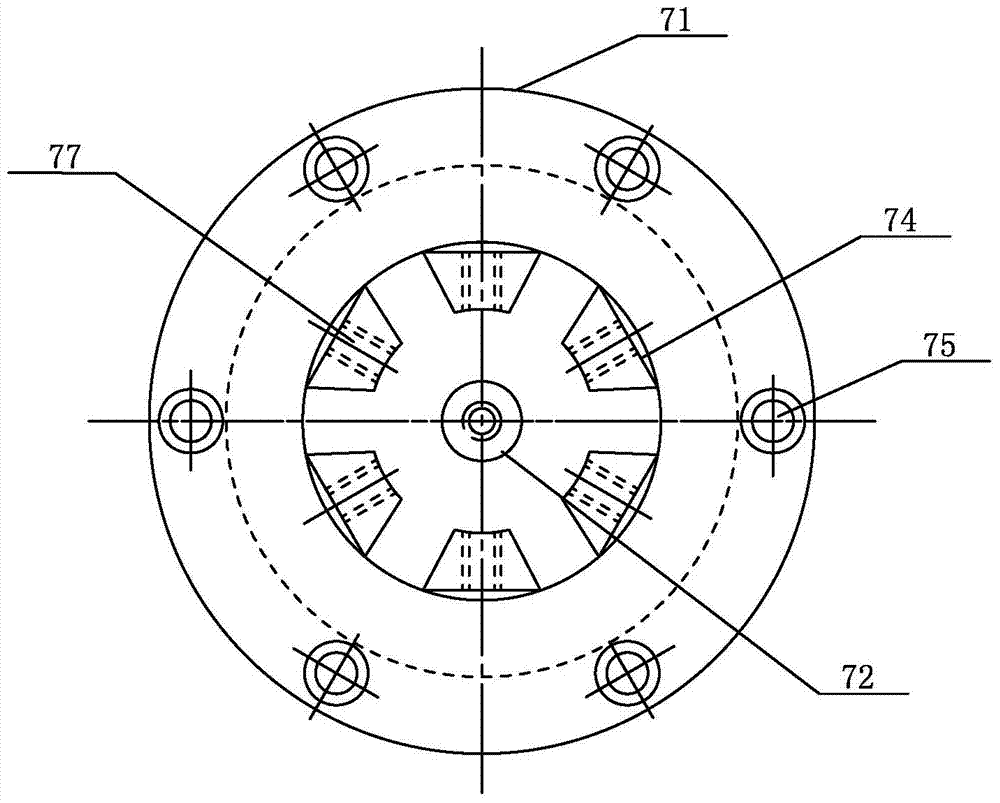

[0026] Such as figure 1 As shown, a water pump shaft grinding device includes a base 1, and an oil cylinder base 2, a head frame 3, a center support 4, and a grinding wheel frame 5 arranged on the upper surface of the base 1 in sequence, and an oil cylinder 21 is installed on one side of the oil cylinder base 2 , the flange 6 is installed on the main shaft 31 of the head frame 3 through the cooperation of the end cover 61 , the thrust bearing 62 and the lock nut 63 in sequence. The film chuck 7 is installed on the main shaft 31 of the head frame 3 through the flange 6, the grinding wheel 51 is installed on the side of the grinding wheel frame 5 close to the film chuck 7, and is used for grinding the water pump shaft 8, and the piston rod 22 of the oil cylinder 21 passes through the push rod 9 is in contact with the center of the film chuck 7, the push rod 9 is slidably installed in the center hole 64 of the flange 6, the above-mentioned piston rod 22, push rod 9, headstock mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com