Method for preparing mesoporous carbon material for electrochemical capacitor

A capacitor and electrochemical technology, applied in the field of preparation of mesoporous carbon materials for electrochemical capacitors, can solve the problems of long time consumption and high energy consumption, and achieve the effects of reducing production costs, saving grinding costs, and saving the amount of activators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Mesoporous carbon MC ZnCl2-1-600-20 Concrete preparation process is as follows:

[0025] (1) Pretreatment of peanut shells: After washing the peanut shells cut into small pieces with ordinary water, wash them at 110 o C drying at constant temperature for 12 hours, the air-dried base moisture of the obtained peanut shells is 9.52%, the ash content is 1.30%, the volatile content is 68.34%, and the fixed carbon content is 20.84%. Put 20g of peanut shells into a beaker and add 200mL of 0.5M KOH solution , heating the beaker on a magnetic heating stirrer for 2 hours, washing the peanut shells with distilled water at 70-80°C until the pH value of the filtrate is 7, and drying the washed peanut shells at a constant temperature of 110°C for 12 hours to obtain pretreated peanut shells;

[0026](2) Preparation of mesoporous carbon: Measure 60mL of distilled water into a beaker, weigh 13.5g of zinc chloride solid and dissolve in the distilled water in the beaker, weigh...

Embodiment 2

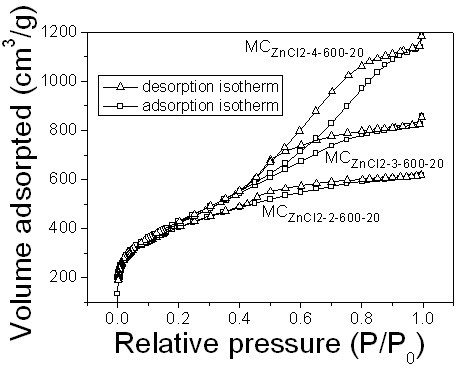

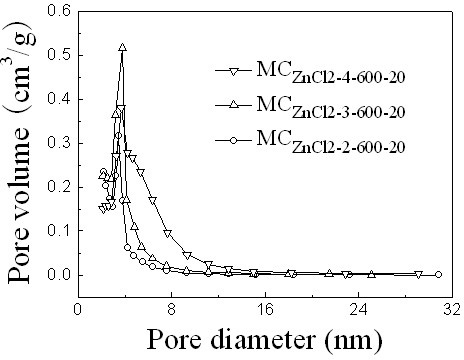

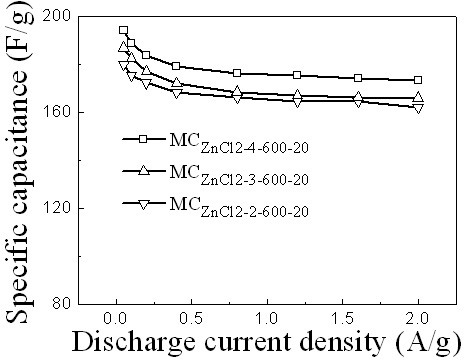

[0028] Example 2: Mesoporous carbon MC ZnCl2-2-600-20 Concrete preparation process is as follows:

[0029] (1) Pretreatment of peanut shells: implemented in the same manner as step (1) in Example 1.

[0030] (2) Implement in the same manner as step (2) in Example 1, except that the zinc chloride solid weighed is 18 g; the peanut shell obtained in step (1) is weighed 9 g.

[0031] (3) According to the same method as step (3) in Example 1, the difference is that the obtained mesoporous carbon is marked as MC ZnCl2-2-600-20 .

Embodiment 3

[0032] Example 3: Mesoporous carbon MC ZnCl2-3-600-20 Concrete preparation process is as follows:

[0033] (1) Pretreatment of peanut shells: implemented in the same manner as step (1) in Example 1.

[0034] (2) Carry out the same method as step (2) in Example 1, except that the zinc chloride solid weighed is 20.25 g; and the peanut shell obtained in step (1) is weighed 6.75 g.

[0035] (3) According to the same method as step (3) in Example 1, the difference is that the obtained mesoporous carbon is marked as MC ZnCl2-3-600-20 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com