Method and device for removing dioxin from high-temperature flue gas

A high-temperature flue gas and dioxin technology, which is applied in combustion methods, combined devices, separation methods, etc., can solve the problems of small processing gas volume, regular replacement, environmental hazards, etc., to improve adsorption and decomposition efficiency, improve service life, The effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

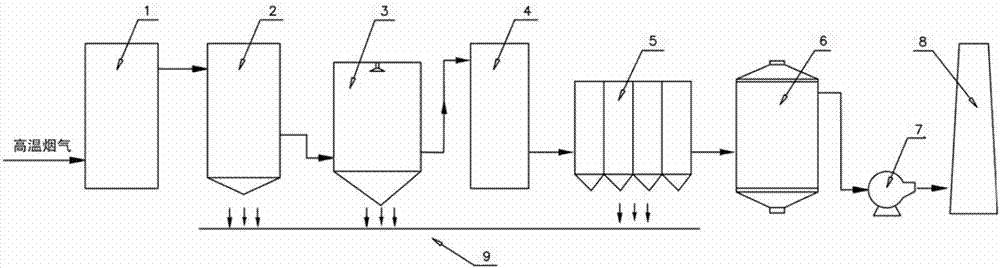

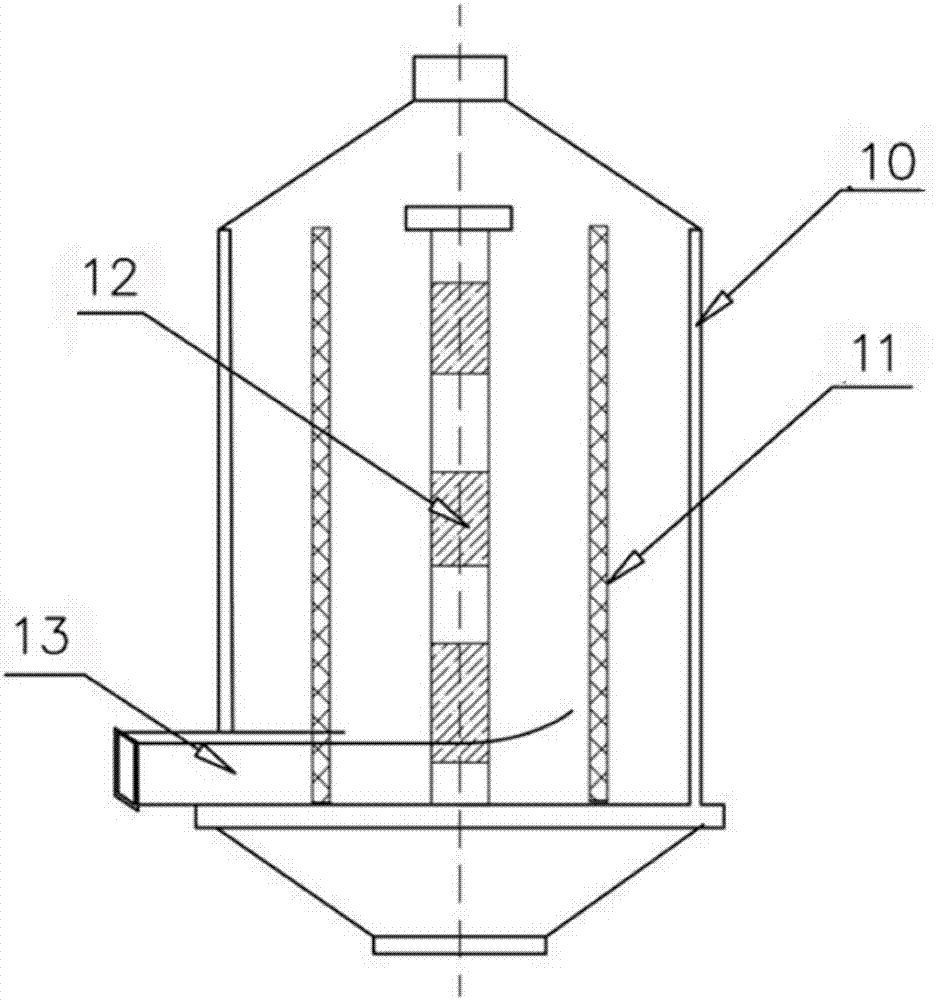

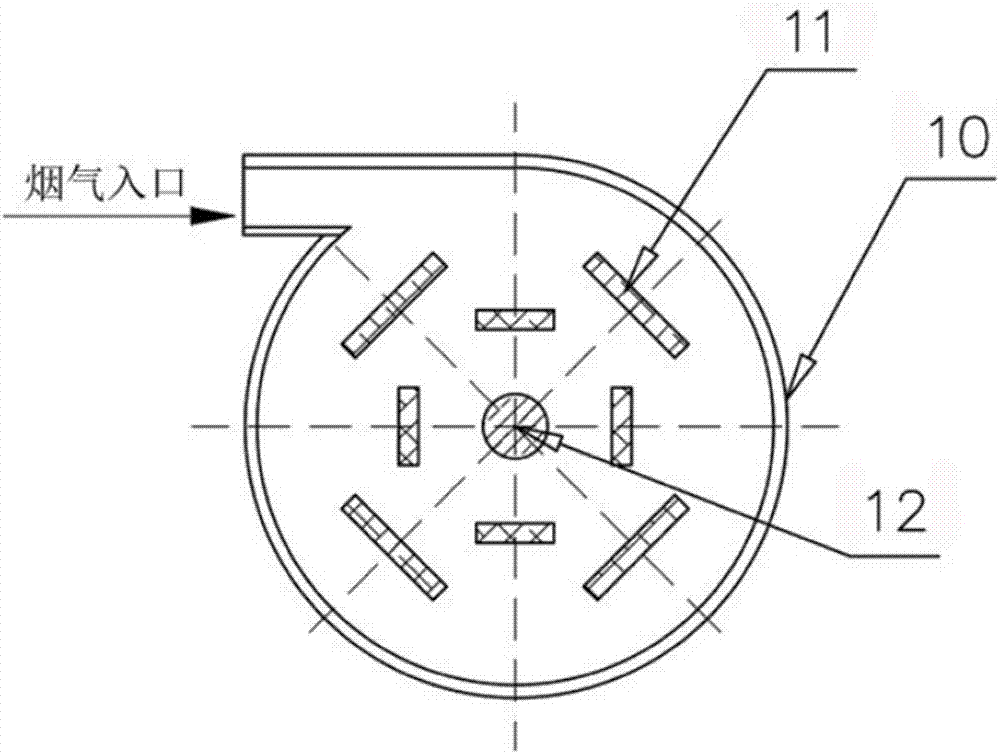

[0048] Firstly, waste heat is recovered from the high-temperature flue gas at 1400°C to reduce the temperature to 850°C; then the flue gas passes through a ceramic filter arranged in the flue to filter out particles above 30 μm, and then passes through a high-frequency filter with a working voltage of 80kV Dust removal by high-voltage electrostatic precipitator, the dust concentration is reduced to 20mg / m 3 Below; the flue gas after electrostatic precipitating is passed into the semi-dry reaction tower, and at a temperature of 750 ° C, 1.2 times the stoichiometric lime emulsion is sprayed to remove the acid gas in the flue gas; the flue gas after deacidification is quickly cooled to 120°C; the cooled flue gas passes through the bag filter for secondary dust removal, and the dust concentration is reduced to 10mg / m 3 Below; finally the flue gas is passed into the photolysis purification tower, and the toxic and harmful gases such as dioxin in the flue gas are adsorbed by the zeo...

Embodiment 2

[0050] First, waste heat is recovered from the high-temperature flue gas at 1350°C to reduce the temperature to 820°C; then the flue gas passes through a ceramic filter arranged in the flue to filter out particles above 30 μm, and then passes through two high-frequency generators with a working voltage of 60kV Dust removal by high-voltage electrostatic precipitator, the dust concentration is reduced to 20mg / m 3 Below; the flue gas after electrostatic precipitator is passed into the semi-dry reaction tower, and at 720 ° C, spray 1.5 times the stoichiometric sodium carbonate solution to remove the acid gas in the flue gas; the flue gas after deacidification is rapidly cooled to 140°C; the cooled flue gas is dusted twice by the bag filter, and the dust concentration is reduced to 10mg / m 3 Below; finally the flue gas is passed into the photolysis purification tower, the toxic and harmful gases such as dioxin in the flue gas are adsorbed by the activated carbon adsorbent, and are c...

Embodiment 3

[0052] First, waste heat is recovered from the high-temperature flue gas at 1300°C to reduce the temperature to 800°C; then the flue gas passes through a ceramic filter arranged in the flue to filter out particles above 30 μm, and then passes through two high-frequency generators with a working voltage of 70kV Dust removal by high-voltage electrostatic precipitator, the dust concentration is reduced to 20mg / m 3 Below; the flue gas after electrostatic precipitating is passed into the semi-dry reaction tower, and at a temperature of 650 ° C, 1.2 times the stoichiometric sodium hydroxide solution is sprayed to remove the acid gas in the flue gas; the flue gas after deacidification is rapidly The temperature is lowered to 160°C; the flue gas after cooling is dedusted by the bag filter for the second time, and the dust concentration is reduced to 10mg / m 3 Below; finally the flue gas passes into the photolysis purification tower, the toxic and harmful gases such as dioxin in the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com