Ammonia-contained waste water high-efficiency biochemical processing method

A biochemical treatment and waste water technology, which is applied in the treatment of ammonia-containing waste water and waste water with high ammonia concentration and low COD concentration. It can solve the problems of difficult control of nitrosation stage, unstable system and low treatment load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

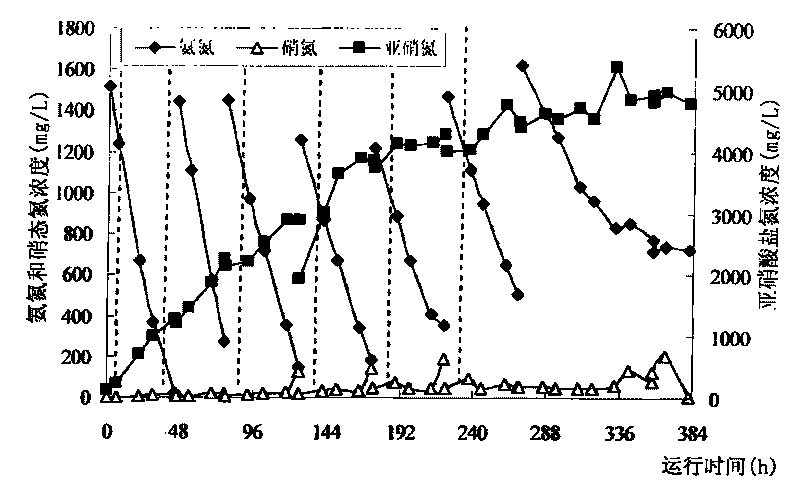

[0031] Embodiment 1 contains the cultivation of nitrous bacteria flora inoculum

[0032] The nitrifying bacteria cultivated in the laboratory are used as the inoculum, and the MLSS after inoculation is 1.0g / L, and the ammonia-containing wastewater with a self-prepared concentration of 300mg / L (COD value 30mg / L) is used as the reactor feed water, and the pH is controlled at 7.9 , Control the temperature at 20°C and the dissolved oxygen concentration is about 2.0-3.0mg / L. Water is fed intermittently first, and ventilation is stopped after 24 hours of reaction. After natural settlement, the supernatant is discharged, leaving bacteria, and then new ammonia-containing wastewater is added to the reactor. When the removal rate of ammonia nitrogen is greater than 90%, increase the concentration of ammonia nitrogen in the influent, and the range of each increase is 100mg / L. After 8 days, the concentration of ammonia nitrogen in the influent reaches 700mg / L. At this time, it is changed...

Embodiment 2

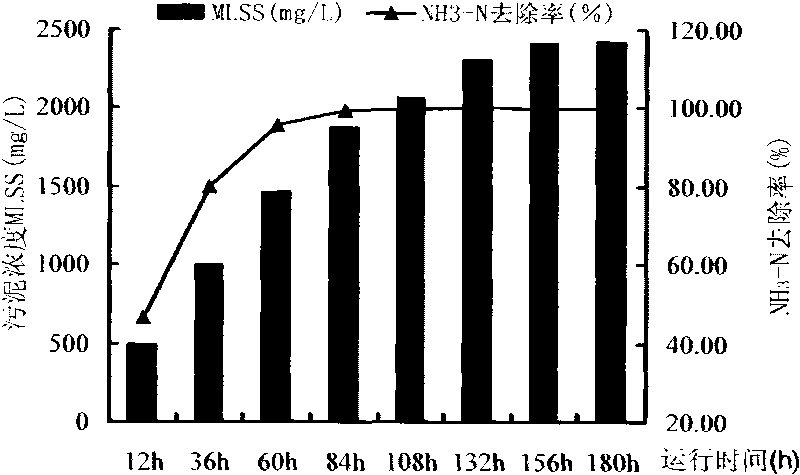

[0033] Embodiment 2 contains the cultivation of nitrous bacteria flora inoculum

[0034] Using nitrosative bacteria enriched in the laboratory and aerobic activated sludge from a sewage plant as the inoculum, the MLSS after inoculation was 0.5g / L, and the high-ammonia wastewater from a catalyst factory was diluted to 200mg / L (COD value 17mg / L L) As the reactor water intake, the pH is controlled at 8.0; the temperature is controlled at 35 ° C, and the dissolved oxygen concentration is 4.5 to 5.5 mg / L; the water is intermittently fed first, and the ventilation is stopped after 24 hours of reaction, and the supernatant is removed after natural settlement. Leave the bacteria, and then add new ammonia-containing wastewater to the reactor. When the ammonia nitrogen removal rate is greater than 90%, reduce the dilution factor of the original wastewater to increase the ammonia nitrogen concentration in the influent, and the increase is 80mg / L each time; After 9 days, the ammonia nitro...

Embodiment 3

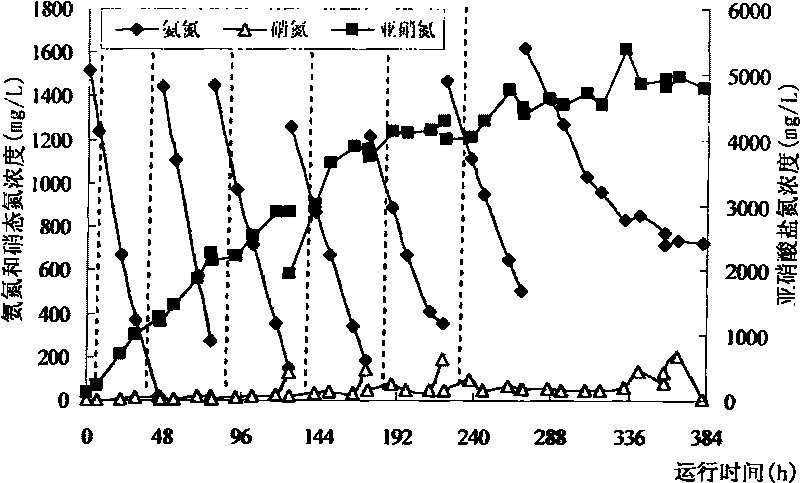

[0035] Embodiment 3 handles the expanded cultivation of the microbial flora of ammonia-containing wastewater

[0036] Carry out the enlarged culture of thalline with the nitrous bacterium flora that embodiment 1 obtains and activated sludge as inoculum, the inoculum size of nitrous bacterium flora is 0.5g / L by MLSS, and the activated sludge dosage is reactor 30% of the volume, the concentration of ammonia nitrogen in the influent is 1500mg / L, and the COD is 46mg / L. The pH is controlled at 7.9, the temperature is controlled at 25°C, and the dissolved oxygen concentration is 2.0-3.0 mg / L. The culture method of supplementing ammonia salt in batches is adopted, adding once every 24 to 48 hours. After supplementing ammonia salt, the concentration of ammonia nitrogen in the culture solution is higher than 1200mg / L. After 10 days of cultivation, the MLSS is 2.8g / L. After that, the ammonia nitrogen is removed After the natural sedimentation, remove the supernatant and leave the bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com