C type grounding clamp

A grounding clip and grounding electrode technology, applied in the field of welding, cutting and electroplating, can solve problems such as poor contact, heating of contact parts, fire, etc., and achieve the effect of not easy to pull off and increase the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

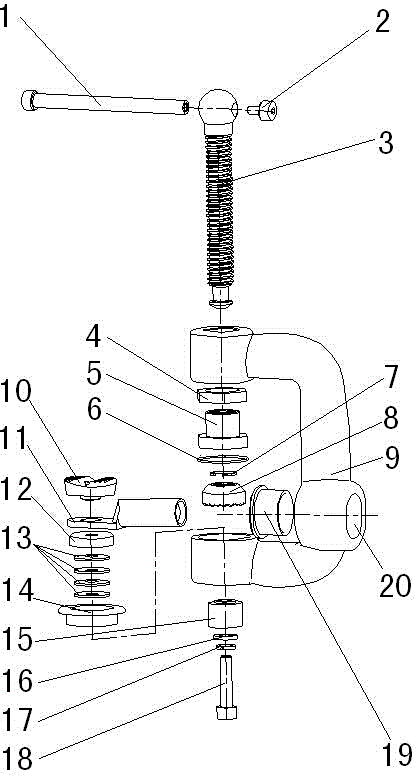

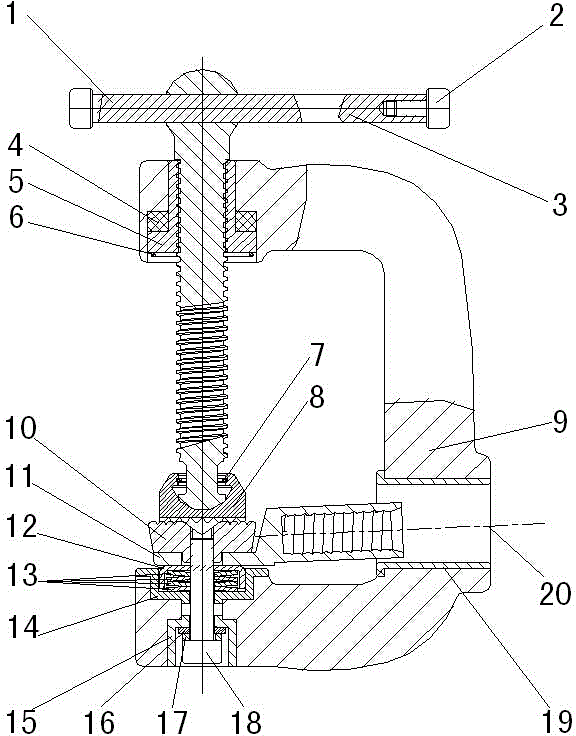

[0018] see figure 1 , figure 2 , this specific embodiment adopts the following technical solutions, a C-shaped grounding clamp, which consists of: a movable handle (1), a limit screw (2), a compression screw (3), an elastic material (4), a screw Sleeve (5), Screw Cover Circlip (6), Screw Circlip (7), Screw Seat (8), C-shaped Structural Part (9), Grounding Electrode (10), Connecting Nose (11), Anti Dust cover (12), elastic material (13), upper insulating seat (14), lower insulating seat (15), flat gasket (16), elastic gasket (17), fastening screw (18), protective cover ( 19), the upper horizontal cable hole (20) of the C-shaped structural member 9, which is characterized in that: the above-mentioned upper left side of the C-shaped structural member (9) is placed in the inner hole of the lower plane, which is covered with elastic material (4). Screw the screw sleeve (5), and clamp the screw sleeve clamp spring (6); put the fastening screw (18) on the elastic washer (17), flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com