Flush-resistant pneumatic quick-change connector

A head and valve core technology, applied in the direction of mechanical equipment, couplings, etc., can solve problems such as complex structure, unsatisfactory processing technology, and difficult processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

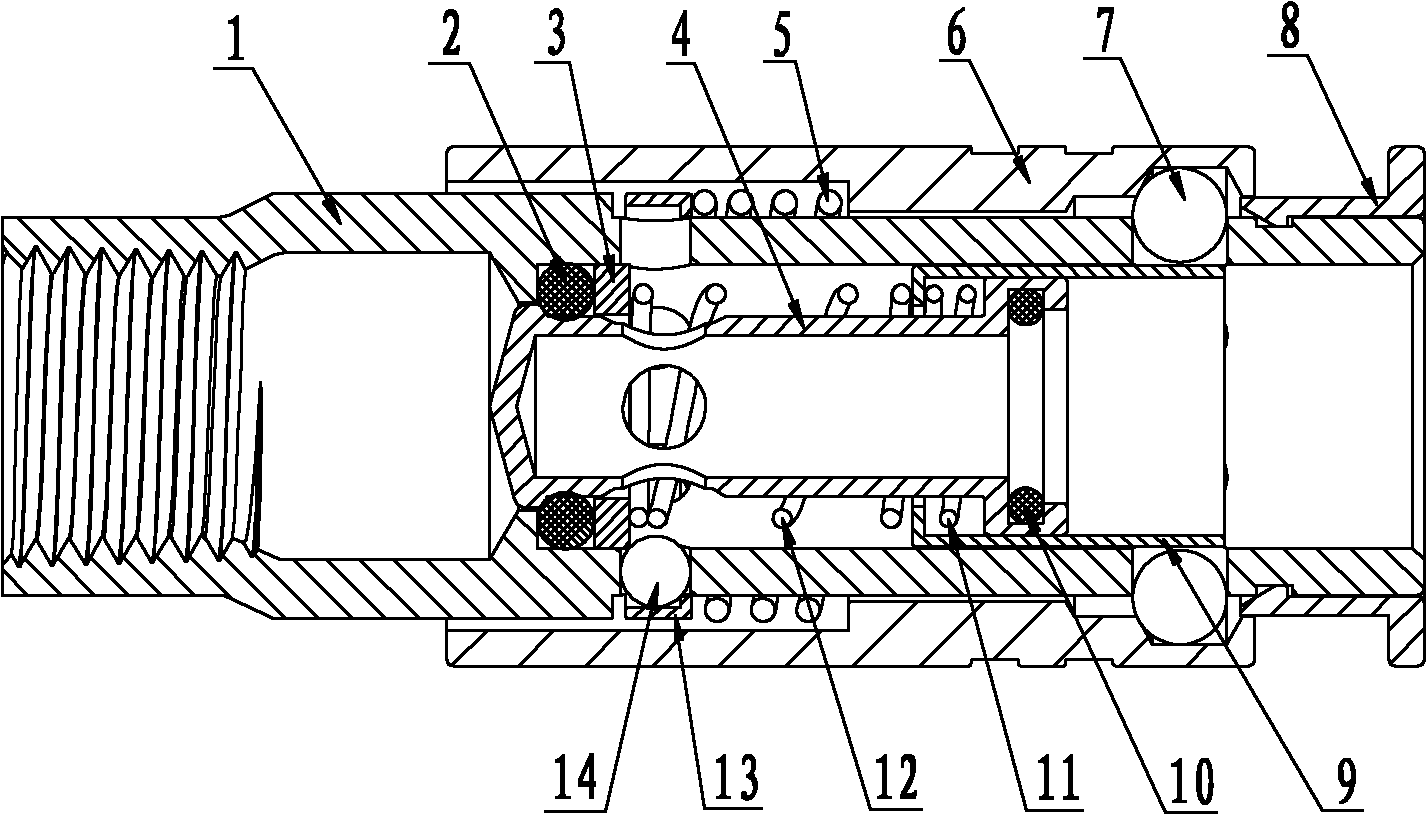

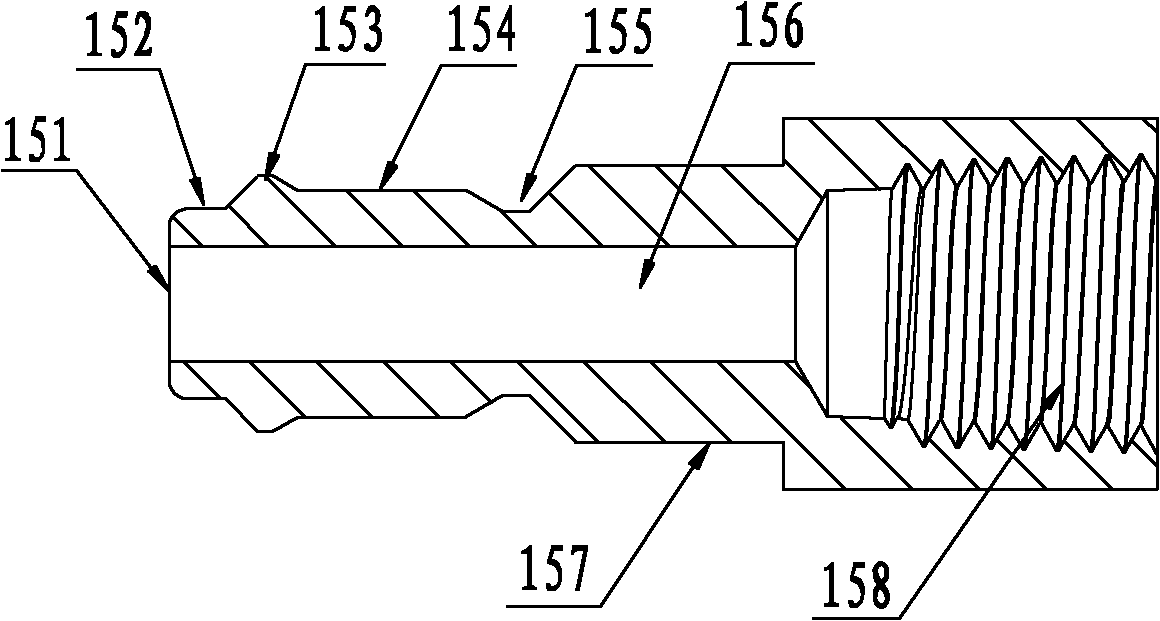

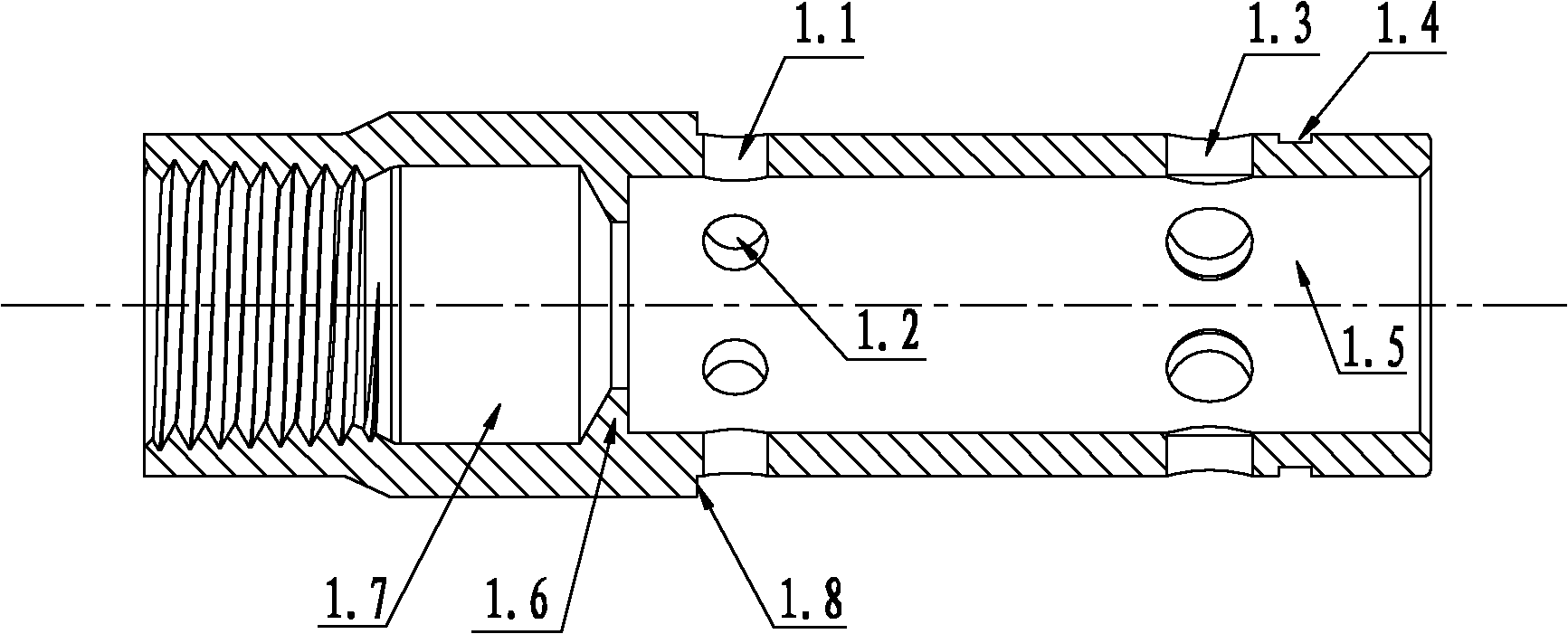

[0020]Embodiment 1: An anti-flush type pneumatic quick-change joint, including an air intake adapter 1, an air intake sealing ring 2, a sealing retaining ring 3, a valve core 4, a sliding sleeve spring 5, a dismounting sliding sleeve 6, and a locking steel ball 7. Protective shaft sleeve 8, inner sliding sleeve 9, air outlet sealing ring 10, inner sleeve spring 11, valve core spring 12, radial sleeve 13 and positioning beads 14, the left section of the air inlet sleeve 1 is the connecting section, The right section of the air intake joint 1 is a matching section, and the outer circle of the left end of the matching section of the air intake joint 1 is provided with a positioning bead hole 1.1 and a pressure relief hole 1.2, and the positioning bead hole 1.1 and the pressure relief hole 1.2 are spaced along the circumferential direction distribution, a positioning bead 14 is placed in the positioning bead hole 1.1, and the left side of the positioning bead 14 is used to limit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com