Carrier rocket booster tank structure for biased concentrated force

A launch vehicle and concentrated force technology, which is applied in the field of launch vehicle storage tank structure, can solve the problems such as not yet collected data, unable to meet the requirements of offset concentration force bearing and diffusion, and achieves good concentration force diffusion effect, strong bearing capacity, Structurally efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to fully and clearly disclose the content of the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings.

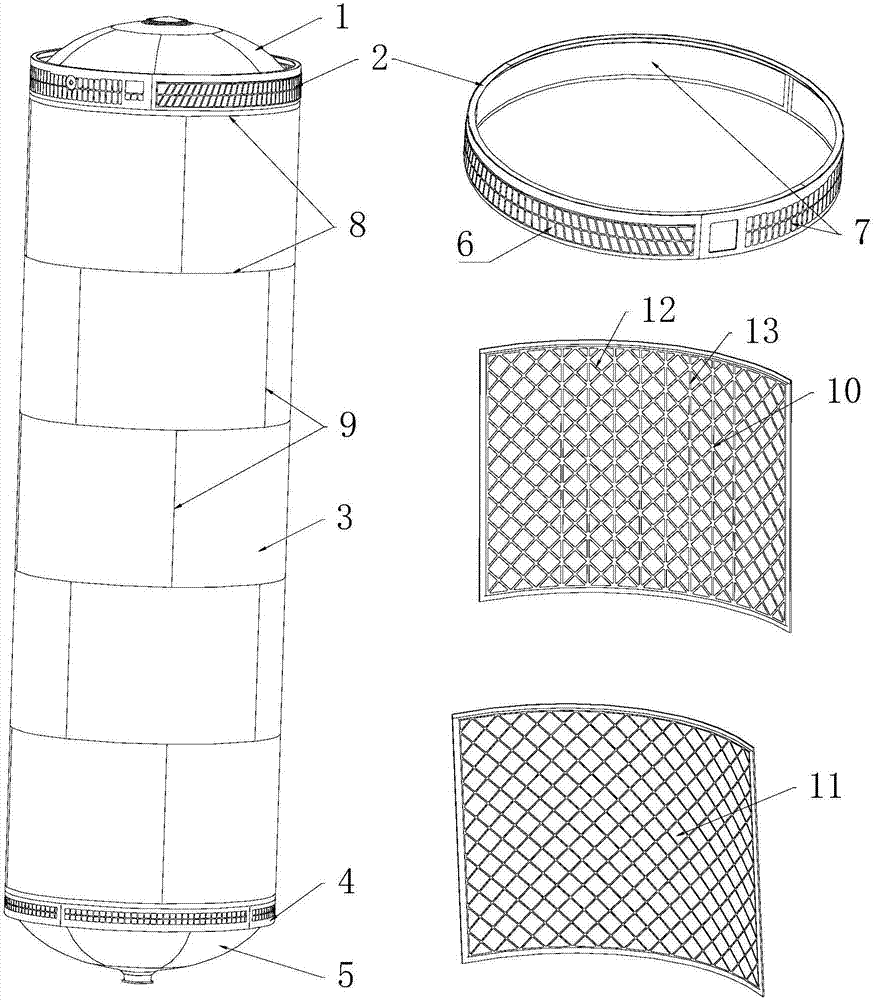

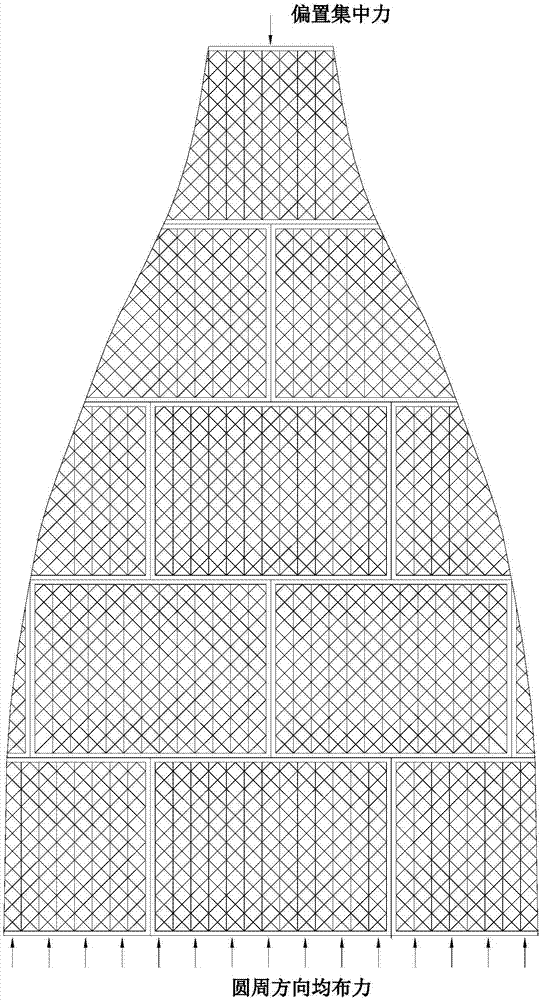

[0015] The present invention provides a carrier rocket booster storage tank structure with biased and concentrated force, which comprises a front short shell 2, a front bottom 1, a tube section 3, a rear bottom 4 and a rear short shell 5, such as figure 1 shown. The five parts constitute the entire storage tank structure through the circumferential weld 8, forming a sealed container that can store propellants and withstand various loads.

[0016] figure 1 The front short shell is welded as a whole by one radial externally reinforced wall plate 6 and two upright externally reinforced wall plates 7, and the radial externally The plate 6 realizes the preliminary diffusion of the biased concentrated force along the circumferential direction, and the two upright externally reinforced wall plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com