Locking device for multistage actuating cylinder

A technology of locking device and actuating cylinder, which is applied to the chassis and other directions, can solve the problems that the retractable mechanism of the landing outriggers cannot be reused, cannot meet the high load capacity of the outriggers, and does not have a multi-stage deployment stroke, etc., to achieve processing Simple, long service life, long deployment stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

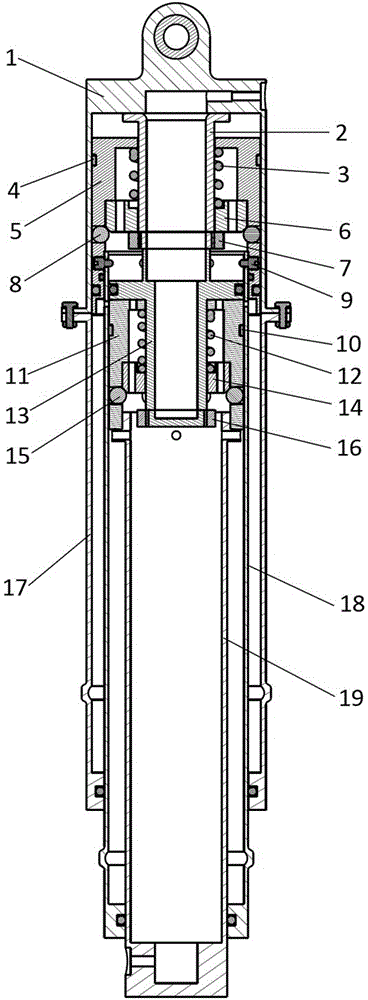

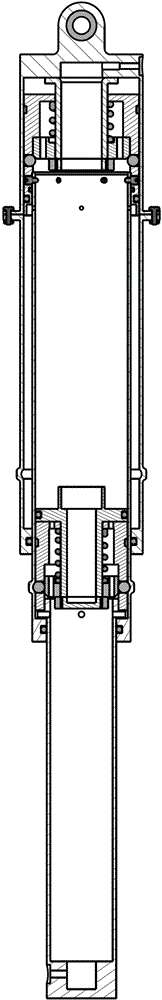

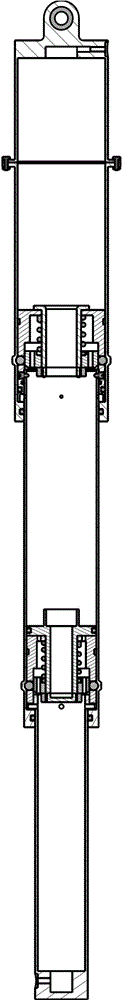

[0023] The invention provides a multi-stage actuator locking device, the overall structure of the device is as follows: figure 1 As shown, the expanded structure of the inner cylinder is shown as figure 2 As shown, the fully expanded structure is shown as image 3 As shown, it includes an end cap 1, an outer cylinder 17, an intermediate cylinder 18, an inner cylinder 19, an upper sliding sleeve 5, a lower sliding sleeve 11, an upper unlocking sleeve 2, a lower unlocking sleeve 13, an upper locking snap ring 6, Lower locking snap ring 14, upper limit snap ring 7, lower limit snap ring 16, connecting screw 9, upper elastic element 3, lower elastic element 12, upper steel ball 8, lower steel ball 15.

[0024] upper sliding sleeve 5 as Figure 4 As shown, it is installed in the cylinder wall composed of the end cover 1 and the outer cylinder 17. A guide belt 4 and a dynamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com