Around synchronization hydraumatic jacking process of upper module of ultra-large marine oil platform

An offshore oil and cycle synchronization technology, applied in the field of offshore oil engineering, can solve the problem of increasing the number of cranes used on the construction site and the difficulty of crane operations, increasing the overall size of the upper block and the difficulty of precision control, increasing the number of times large cranes are used, etc. problems, achieve the effect of shortening the construction period, high practicability, and reducing the cost of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

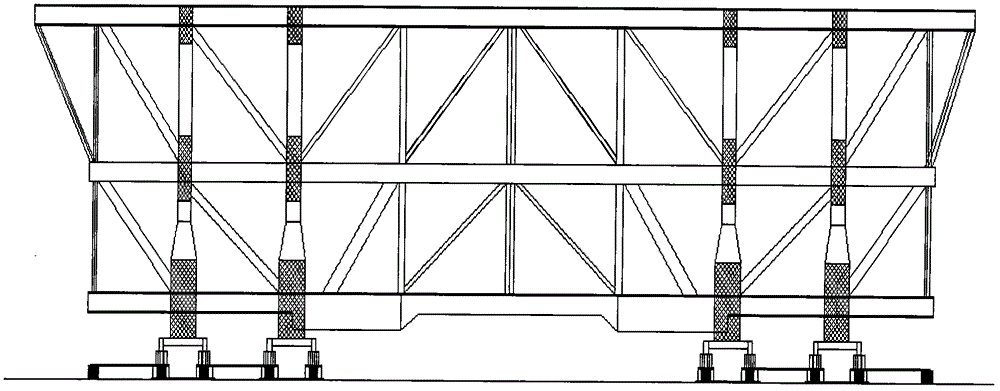

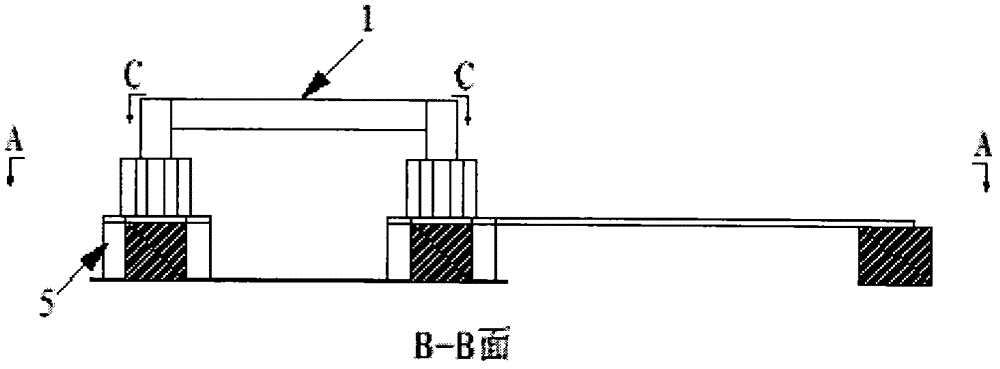

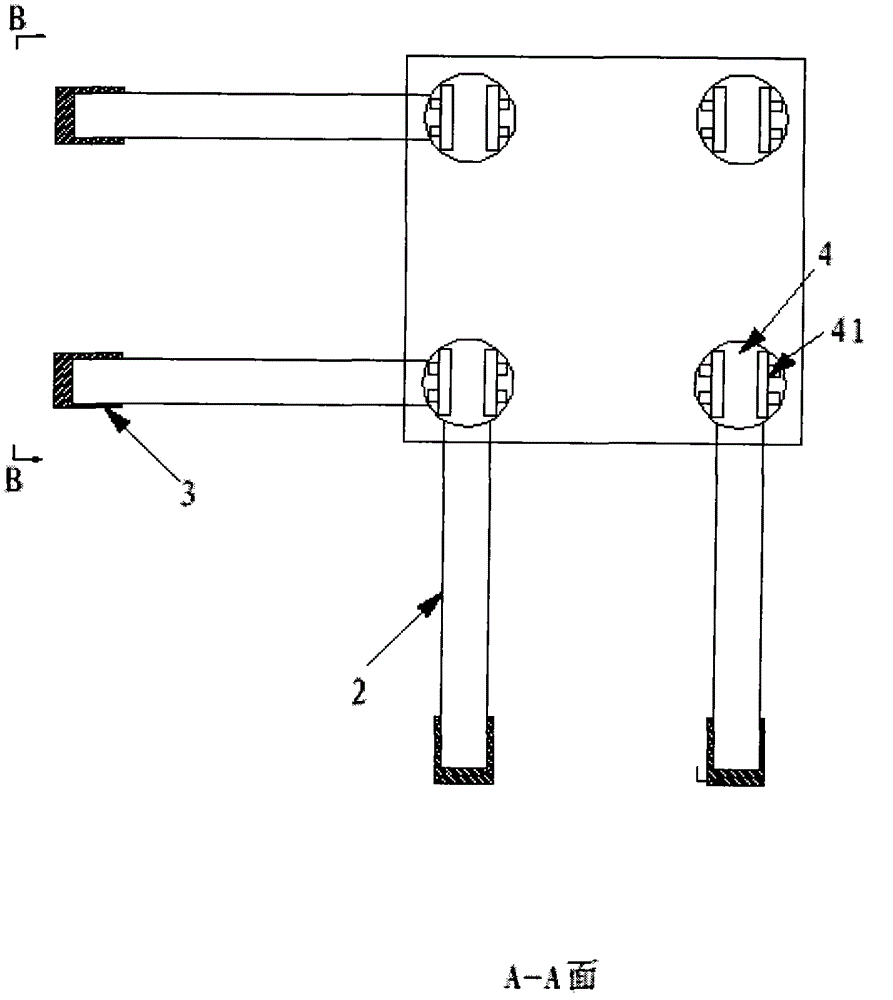

[0057] As shown in the figure - the following steps are adopted when the upper block 10 and the lower support structure 11 of the present invention are built until they need to be lifted:

[0058] The first step: if Figure 1-Figure 4As shown, ① remove the support pier at the bottom of each leg of the upper block 10, and arrange the hydraulic jack 7, the upper support frame 1, the lower base 5 of several rotating support mechanisms 4, and the lower base 5 of the upper block 10 legs. At the bottom, the upper support frame 1 is installed on the upper part of the hydraulic jack 7, and the lower bases 5 of several rotating support mechanisms 4 are arranged around the hydraulic jack 7; and are arranged between the hydraulic jack 7 and the upper support frame 1 The supporting structure 4 and the supporting beam 6 are rotated, and the slide rail pier 3 is arranged under the sliding rail 2 of the rotating supporting structure 4 . ②The hydraulic jack 7 is connected with the pump stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com