Thermal hydrolysis pretreatment device and process for sludge with high solid content based on anaerobic digestion

A pretreatment device, anaerobic digestion technology, applied in the direction of sludge treatment, biological sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of long sludge residence time, low treatment efficiency, long residence time, etc., to achieve Good heating effect, high solid content rate of incoming mud and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

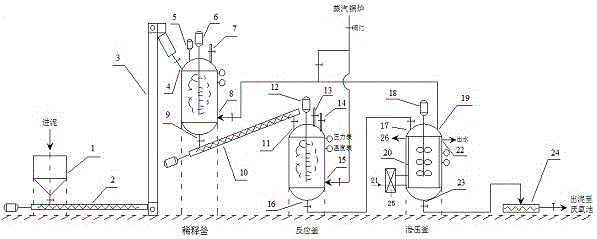

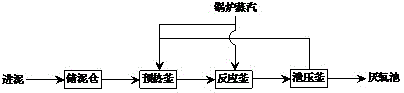

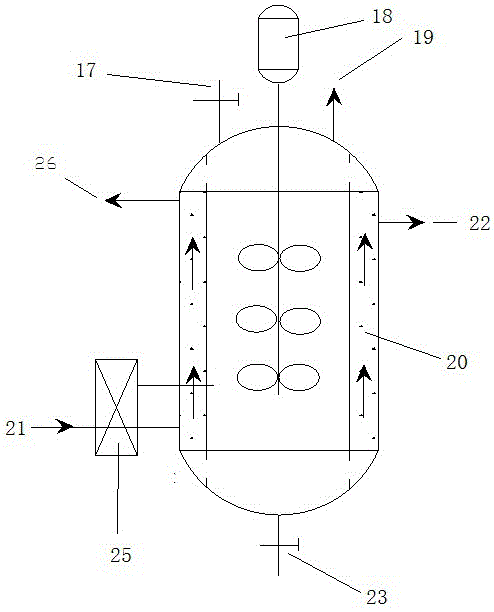

Method used

Image

Examples

application example 1

[0063] A city sewage treatment plant has a treatment scale of 100,000 t / d, a sludge (solid content of 20%) yield of 50 t / d, and an organic matter content of about 40% on a dry basis. If anaerobic digestion is carried out directly, according to the relevant domestic engineering examples, the gas production is almost 0; if the high-efficiency thermal hydrolysis pretreatment process of the present invention is used for anaerobic digestion pretreatment, the entire hydrolysis process and subsequent anaerobic heat preservation consume a total of 170°C steam About 10000t / d, equivalent to biogas (CH 4 Content 60~65%) The demand is about 1300m 3 / d, and the anaerobic digestion gas production after hydrolysis is expected to be 1700m 3 / d, the biogas supply-demand ratio is 1.31, and the residual biogas product volume is 400m 3 / d.

application example 2

[0065] A city sewage treatment plant has a treatment scale of 200,000 t / d, a sludge (solid content of 20%) yield of 100 t / d, and an organic matter content of about 50% on a dry basis. If anaerobic digestion is carried out directly, according to domestic related engineering examples, the gas production is about 1000m 3 / d; if the high-efficiency thermal hydrolysis pretreatment process of the present invention is used for anaerobic digestion pretreatment, the entire hydrolysis process and subsequent anaerobic heat preservation consume a total of about 18000 t / d of steam at 170 ° C, equivalent to biogas (CH 4 Content 60~65%) The demand is about 2000m 3 / d, and the anaerobic digestion gas production after hydrolysis is expected to be 5000m 3 / d, the supply-demand ratio of biogas is 2.5, and the residual product of biogas is 3000m 3 / d.

application example 3

[0067] The treatment scale of a city sewage treatment plant is 400,000 t / d, the yield of sludge (20% solid content) is 200 t / d, and the dry organic matter content of sludge is about 60%. If anaerobic digestion is carried out directly, according to domestic related engineering examples, the gas production is about 5500m 3 / d; if the high-efficiency thermal hydrolysis pretreatment process of the present invention is used for anaerobic digestion pretreatment, the entire hydrolysis process and subsequent anaerobic heat preservation consume a total of about 32000 t / d of steam at 170 ° C, equivalent to biogas (CH 4 Content 60~65%) The demand is about 3200m 3 / d, and the anaerobic digestion gas production after hydrolysis is expected to be 12000m 3 / d, the biogas supply-demand ratio is 3.75, and the remaining biogas product volume is 8800m 3 / d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com