Patents

Literature

172results about How to "Reduce civil cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

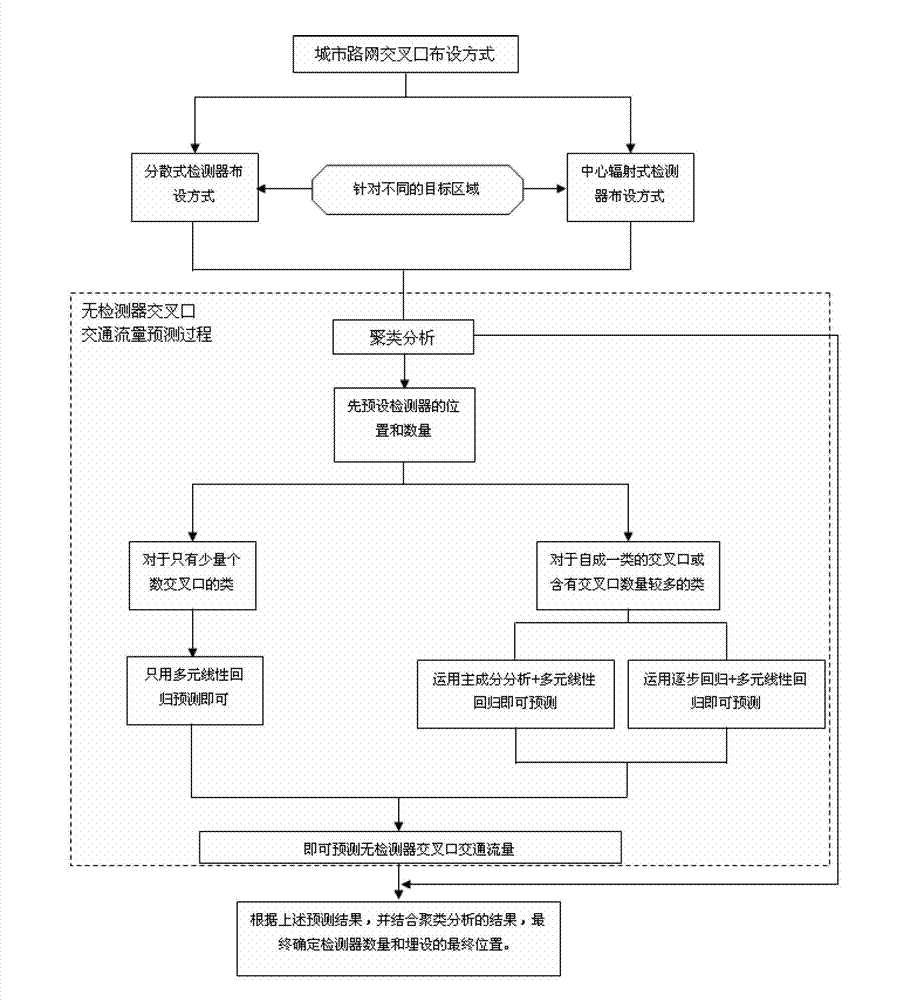

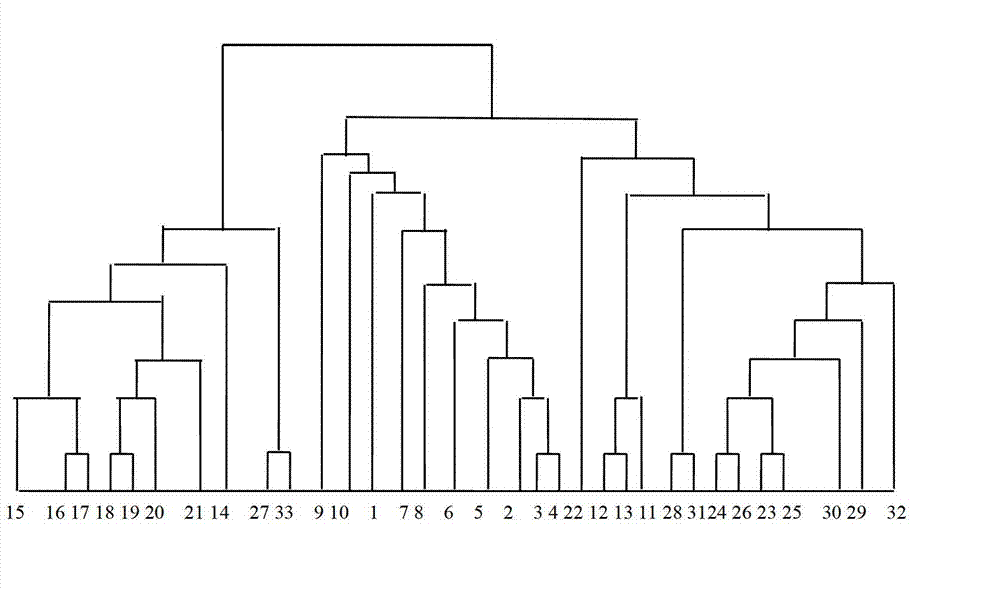

Method for laying urban road network traffic flow detectors

InactiveCN103198672AWide coverageReduce civil costRoad vehicles traffic controlPredictive methodsBusiness forecasting

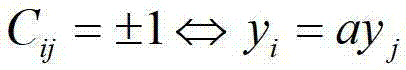

The invention discloses a method for laying urban road network traffic flow detectors. The method includes the following steps: selecting a laying mode for the detectors; carrying out clustering analysis; presetting the positions and the number of the detectors; selecting a forecasting method; forecasting traffic flows of intersections without detectors with the selected forecasting method; and according to forecast results, combined with a clustering pedigree chart, finally confirming the positions and the number of the detectors. Correlation among the traffic flows and then a statistic method are used for determining the laying positions of the urban road network traffic flow detectors, and the method for laying the urban road network traffic flow detectors has the advantage of being wide in coverage. The traffic flow detectors are just laid on a small number of intersections in an urban road network, so that civil engineering cost is low, workload is small, and economical efficiency is good. Only limit detector laying on the intersections and limit infrastructure investments need to be carried out to obtain traffic flow information of the whole urban road network, so that macro-management of the whole urban road network is achieved.

Owner:DALIAN MARITIME UNIVERSITY

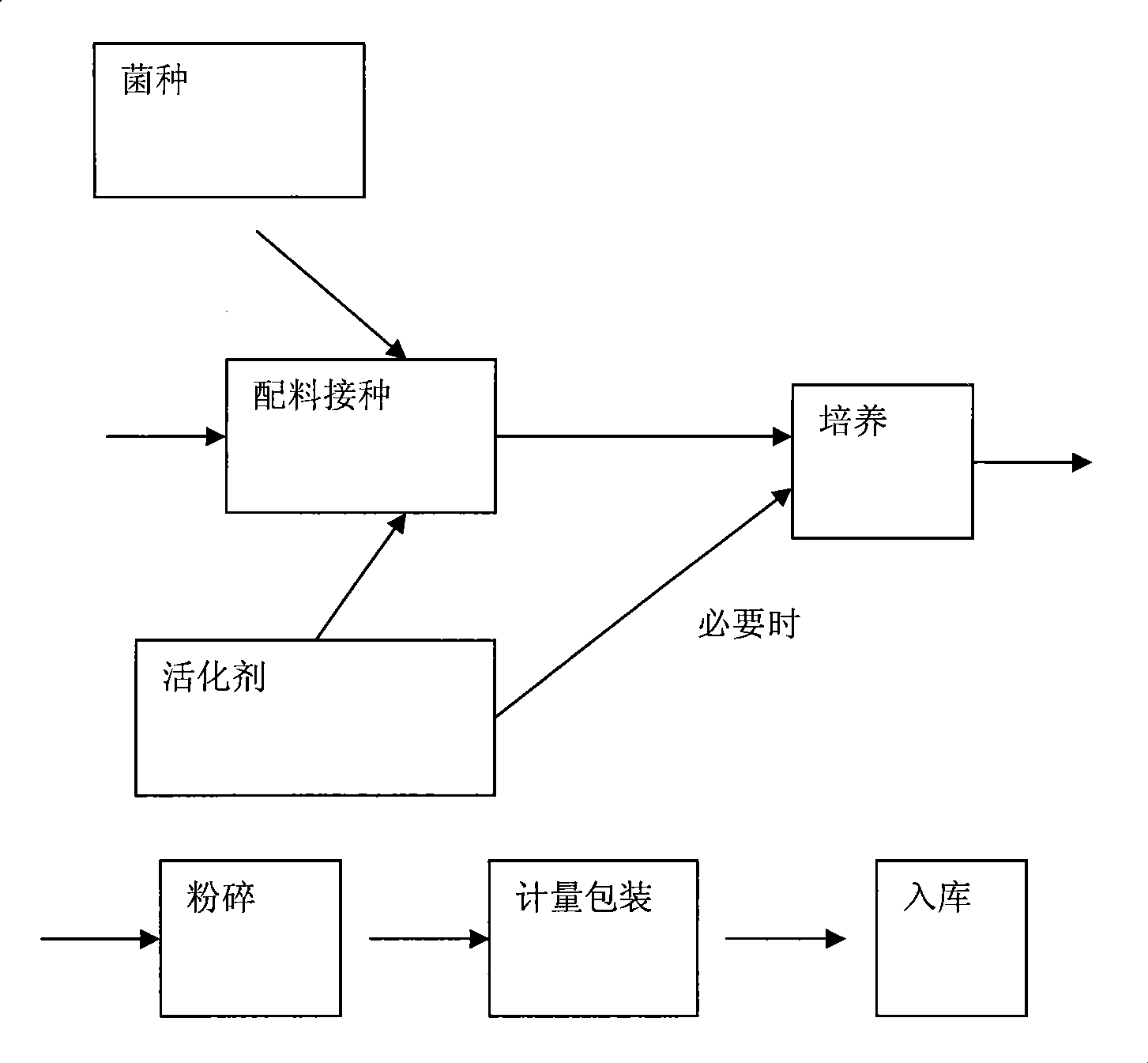

Manufacturing method of king baby dry-sprinkling ecological fermentation bed

A manufacturing method of a king baby dry-sprinkling ecological fermentation bed is characterized in that a microbial strain part of the fermentation bed mainly consists of a saw powder part and a zymocyte agent which are laid on the fermentation bed according to the sequence of one layer of the saw powder part and one layer of the diluted microbial strain part, each layer is 5-10cm thick, the process is repeated for a plurality of times, and the ecological fermentation bed is made by treading and leveling to 50cm. The manufacturing method can help reduce the thickness of a traditional fermentation bed and lower the cost of fermentation bed padding; and the fermentation bed has the advantages of no prior fermentation requirement, laying for immediate use, dry fermentation, no water control requirement, asynchronous fermentation, nonredundant fermentation, less raw material waste, longer service life than conventional fermentation beds, no auxiliary material addition and simplest operation.

Owner:北京华夏康源科技有限公司

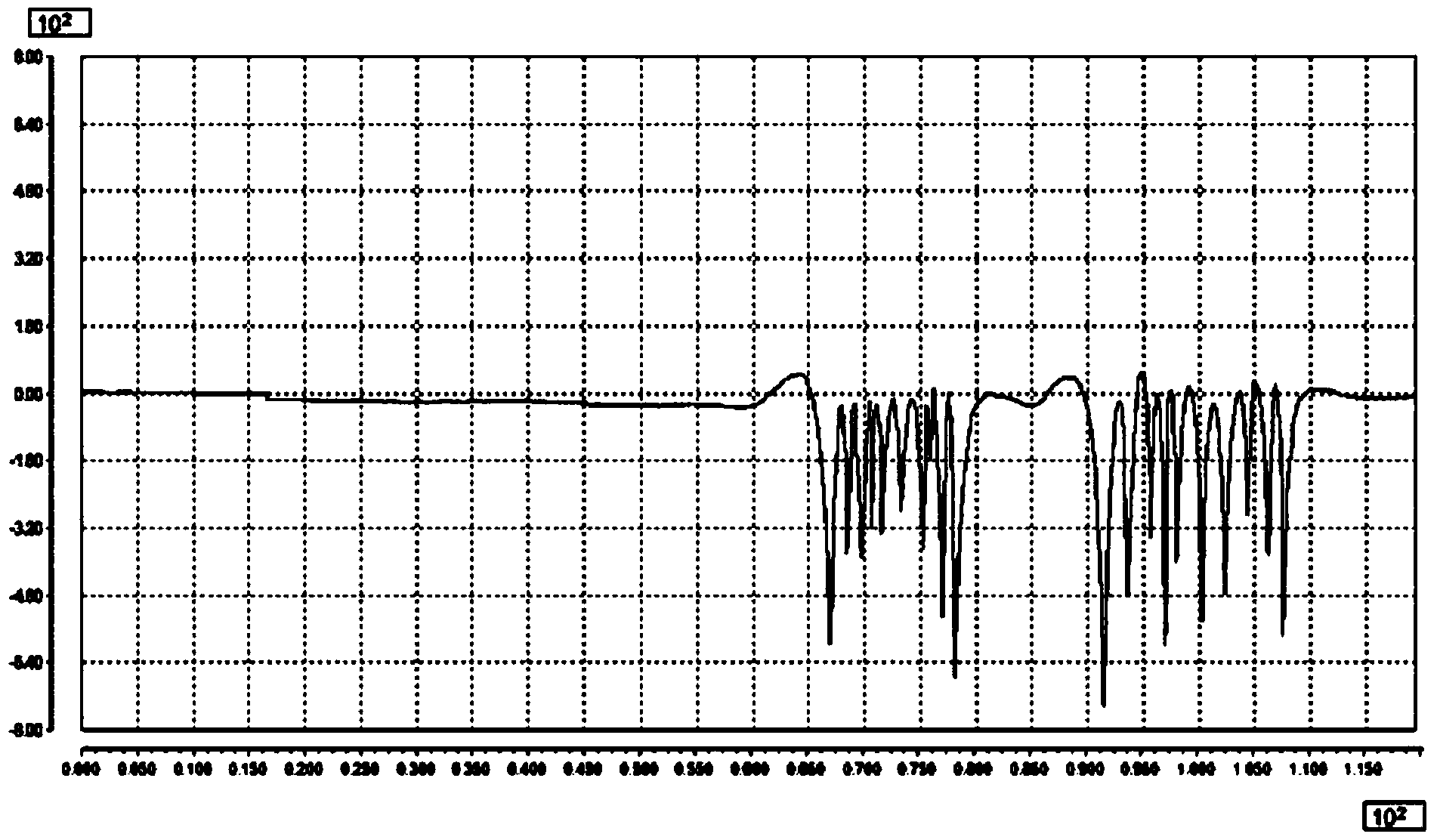

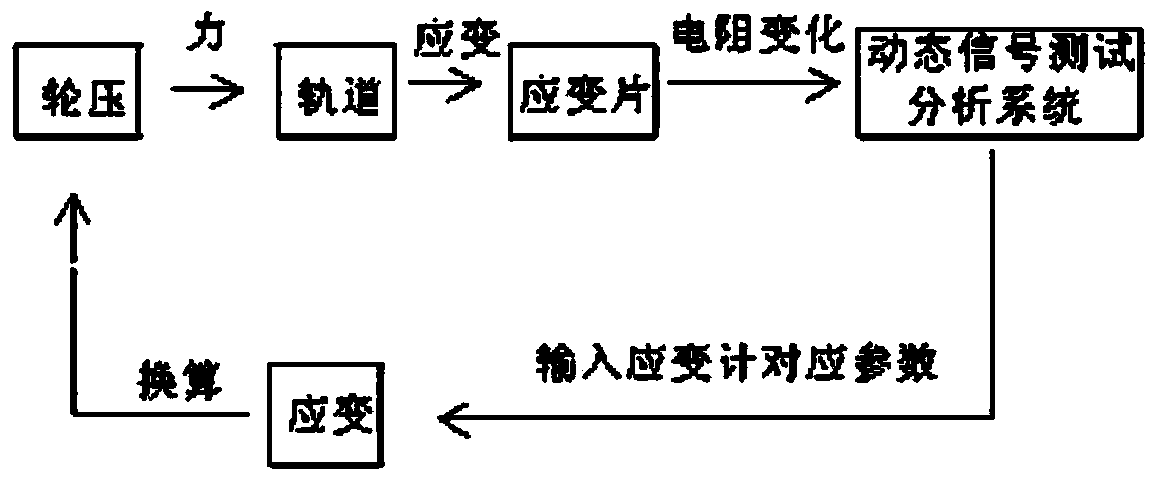

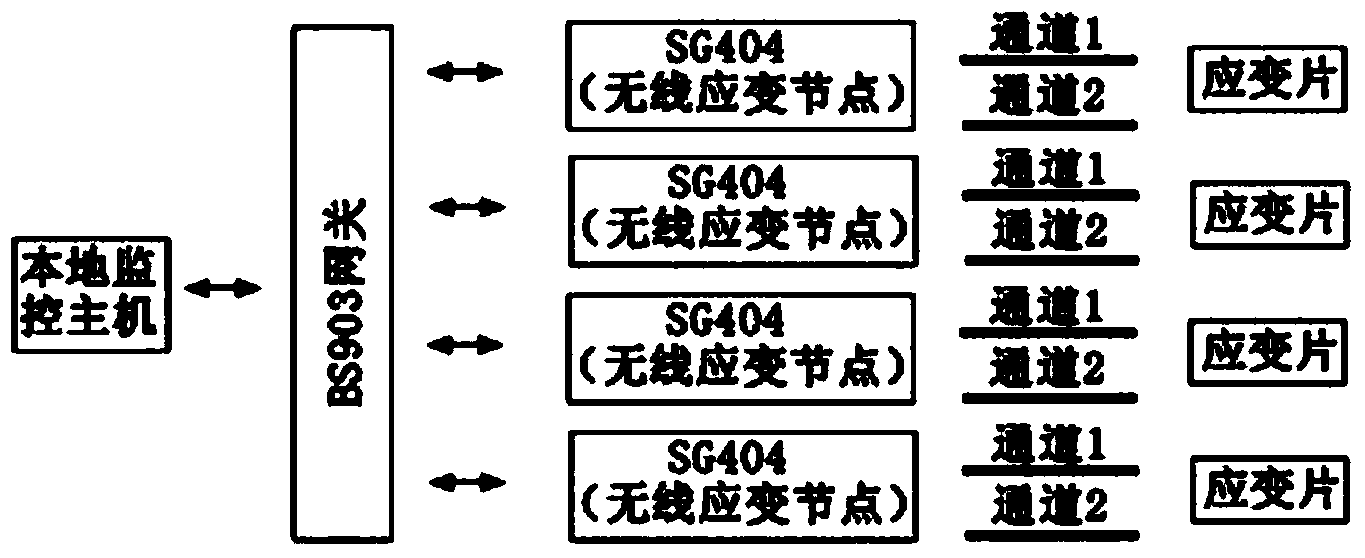

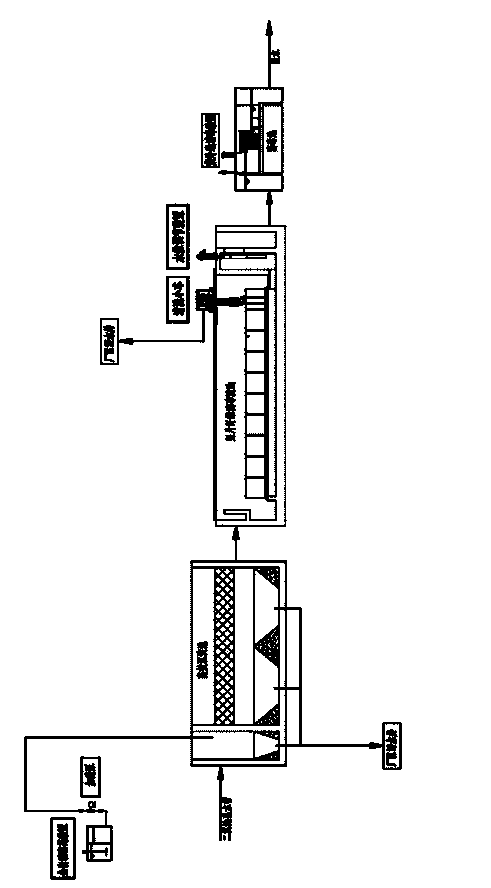

Measuring method for crane cart wheel pressure

ActiveCN104034469ALoose arrangementOptimize layoutApparatus for force/torque/work measurementLifting capacityEngineering

The invention discloses a measuring method for a crane cart wheel pressure. The measuring method for the crane cart wheel pressure includes steps that (1) distributing foils, to be specific, pasting strain foils at the lateral surface of a cart track; (2) building a wheel pressure monitoring system, to be specific, connecting the strain foils and wireless strain nodes with a monitoring host; (3) calibrating, to be specific, enabling a crane to locate in a no-load state, enabling a crane dolly to locate at a proper position, enabling the cart to pass the cart track in a constant speed, and using the wheel pressure monitoring system to record a strain-time curve so as to obtain a wheel pressure and strain calibrating coefficient (shown in the description); (4) measuring the cart wheel pressure on site, to be specific, when the dolly is located at a set position according to a set lifting capacity, gathering the corresponding strain value, and converting the strain value into the corresponding wheel pressure (shown in the description). The measuring method for the crane cart wheel pressure is easy and practical, is capable of precisely measuring the actual value of each wheel pressure, is more direct and reliable than a calculation method, is capable of directly reflecting the wheel pressure non-uniformity of the crane under different working conditions and provides essential data for optimizing, using and maintaining the crane wheels and saving civil engineering cost.

Owner:NANTONG BRANCH OF SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

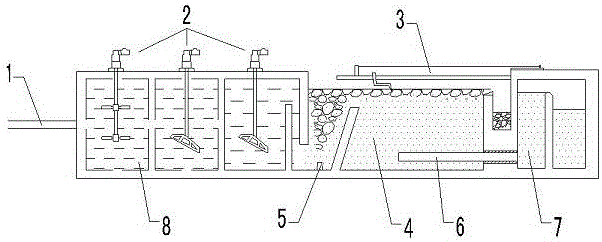

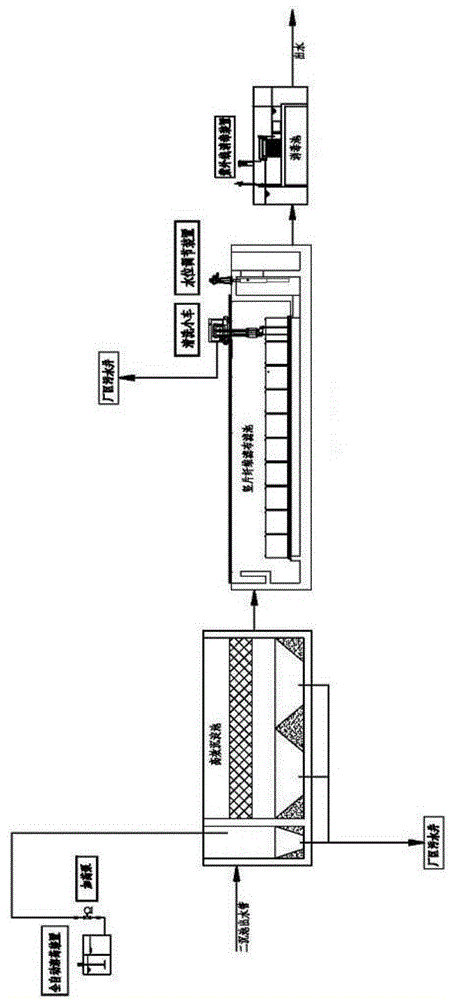

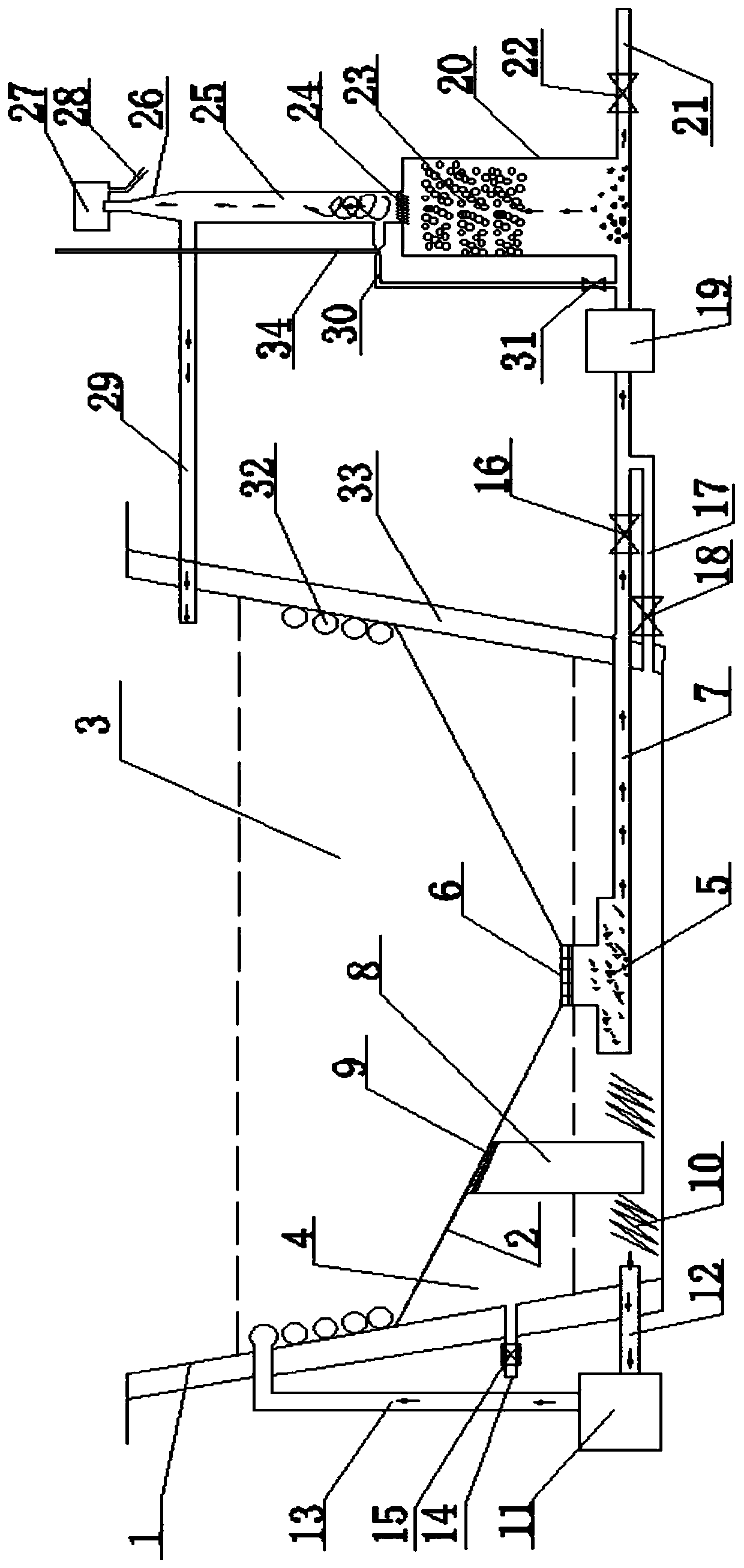

Advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction

ActiveCN103848542ASolve the problem that phosphorus cannot be removed by using aloneReduce pool capacityMultistage water/sewage treatmentPolyacrylamideSewage

The invention discloses an advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction. The advanced wastewater treatment technology is a combined technology of an efficient settling basin and a riser fiber filter cloth filter tank added between a secondary sedimentation tank and a disinfecting tank of the original process of a sewage treatment plant; an efficient sedimentation tank is composed of two modules of a quick mixing region and an efficient sedimentation region; a FeCl3 chemical is fed to the quick mixing region so as to be agitated to react with sewage; the adding amount of the FeCl3 chemical is 5-8mg / L; the standing time of the quick mixing region is 1.5-2 minutes; the standing time of the efficient sedimentation region is 15-20 minutes; the standing time of the riser fiber filter cloth filter tank is 8-12 minutes; effluent of the secondary sedimentation tank is firstly processed by the efficient sedimentation tank, and then processed by the riser fiber filter cloth filter tank, finally achieves the first level A of discharge standard for sewage treatment after passing through the disinfecting tank. By adopting the advanced wastewater treatment technology, the problems that the efficient sedimentation tank process is independently used, so that effluent SS is unstable, and the filter cloth filter tank is independently used and thus phosphorus cannot be removed are effectively solved, a flocculating agent does not need to be excessively fed again, the dosing cost is greatly reduced, and fouling on an online monitoring instrument probe caused by feeding polyacrylamide (PAM) is avoided.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

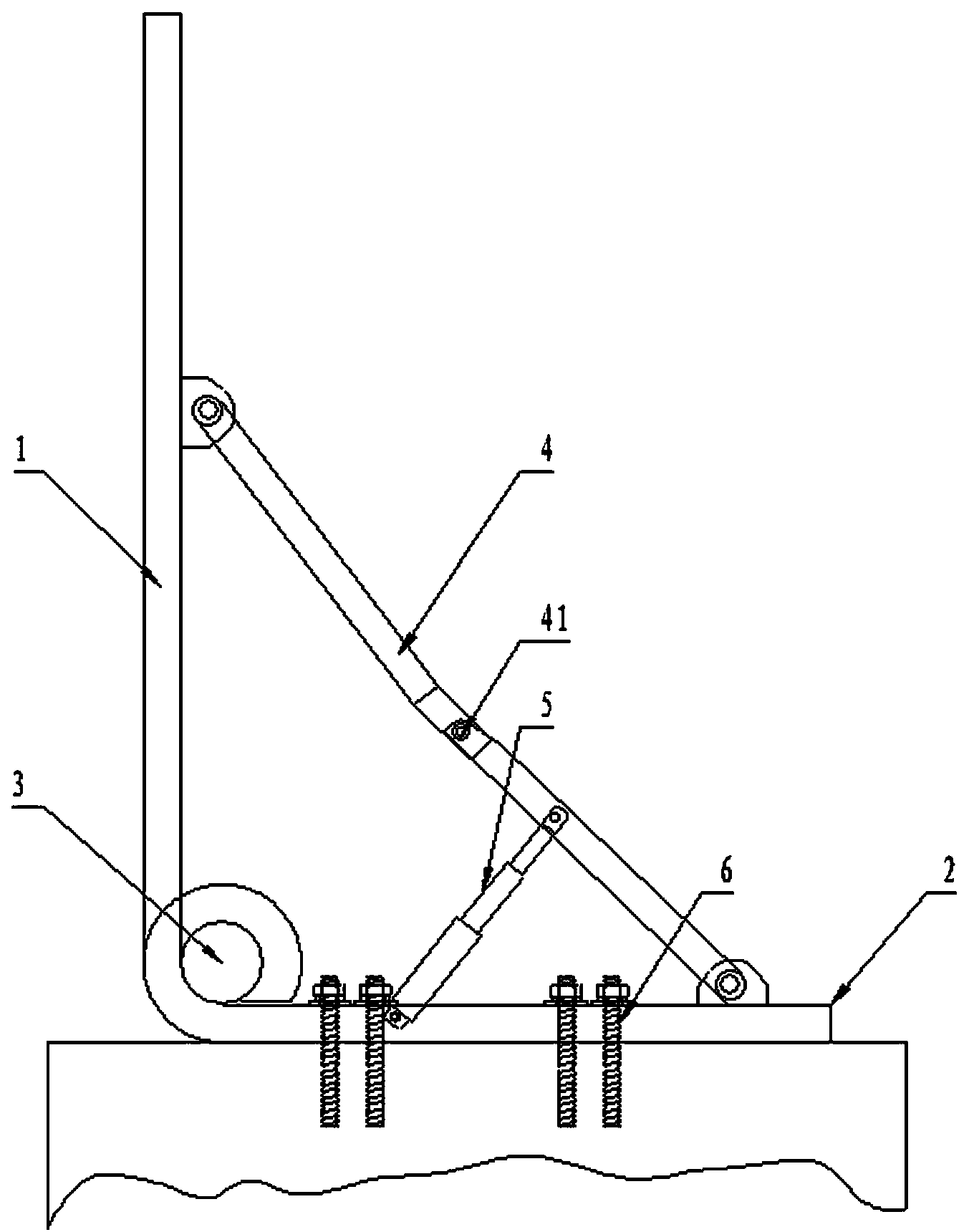

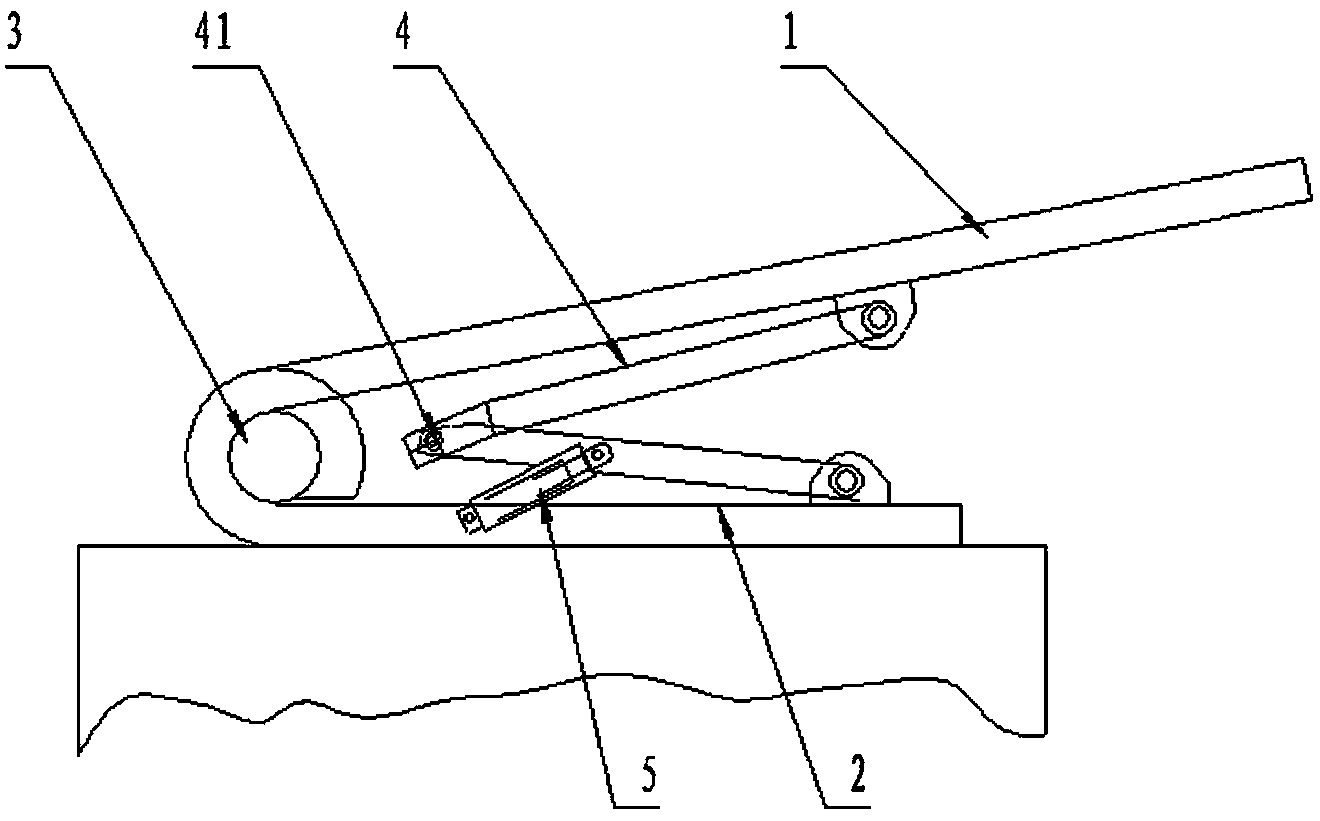

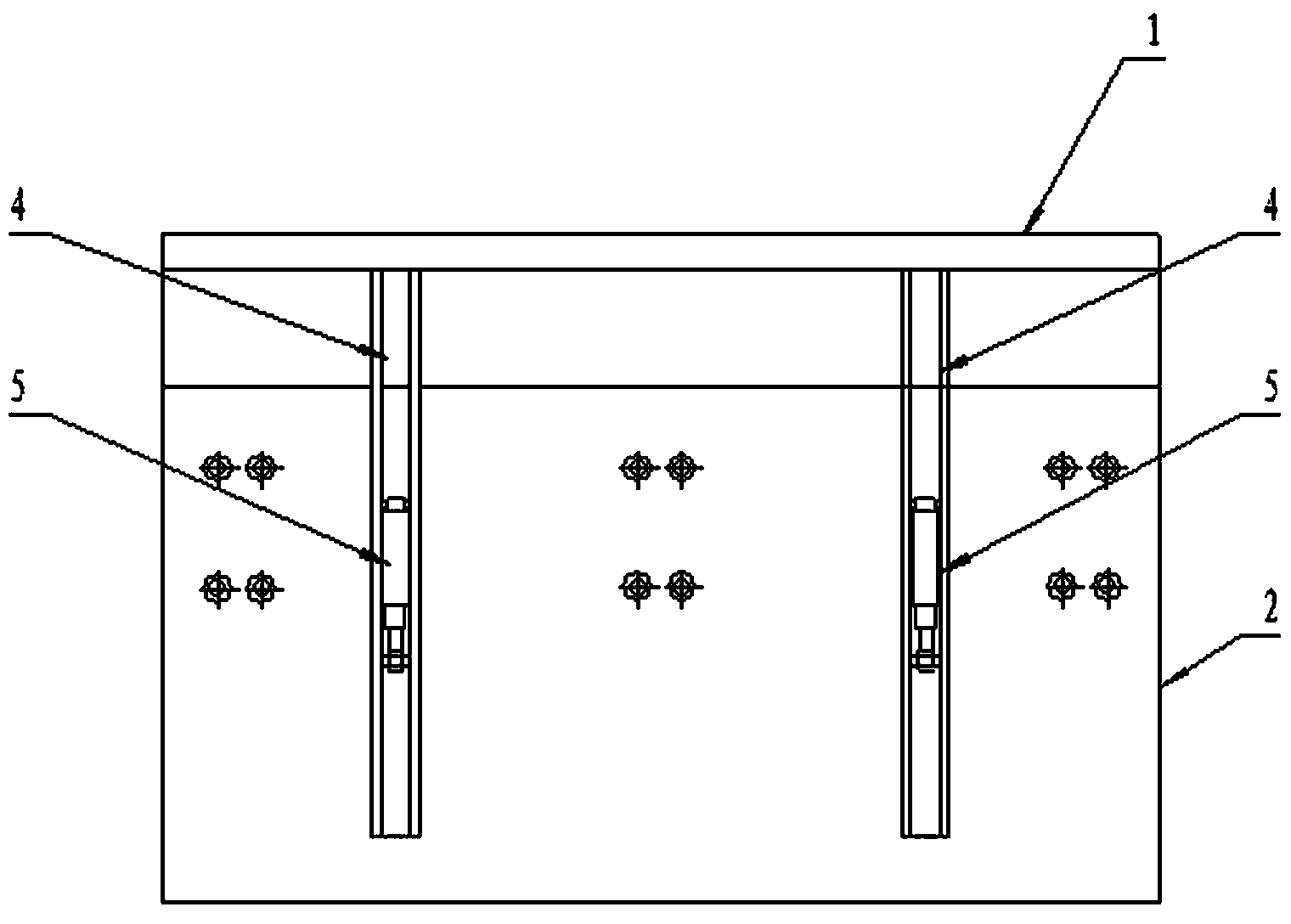

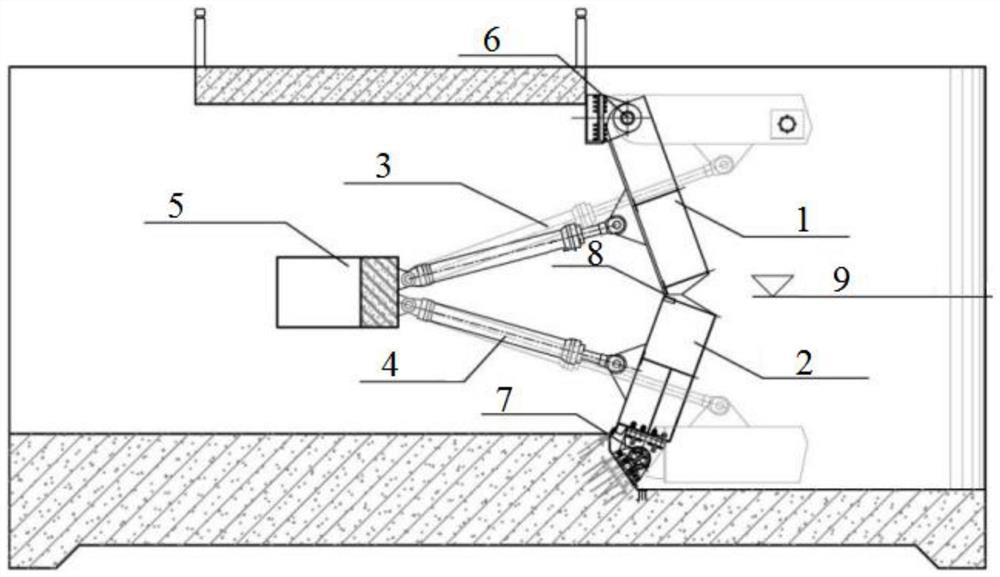

Movable and foldable water stopping device

The invention discloses a movable and foldable water stopping device which comprises a dam body and a base. The dam body is connected with the base through a clamping type connecting shaft. One end of a crank arm supporting rod is connected with the dam body, the other end of the crank arm supporting rod is connected with the base, the crank arm supporting rod is divided into an upper part and a lower part, and the upper part and the lower part are buckled together through a lock catch. One end of a piston rod is connected with the crank arm supporting rod, and the other end of the piston rod is connected with the base. The base is provided with a plurality of embedded bolts. The movable and foldable water stopping device has the advantages of being easy to mount and dismount, long in service life, scientific and reasonable in mechanics structure, not prone to corrosion, good in stability of products, and capable of achieving a good water stopping and flood discharge function in a water conservancy project.

Owner:程斌

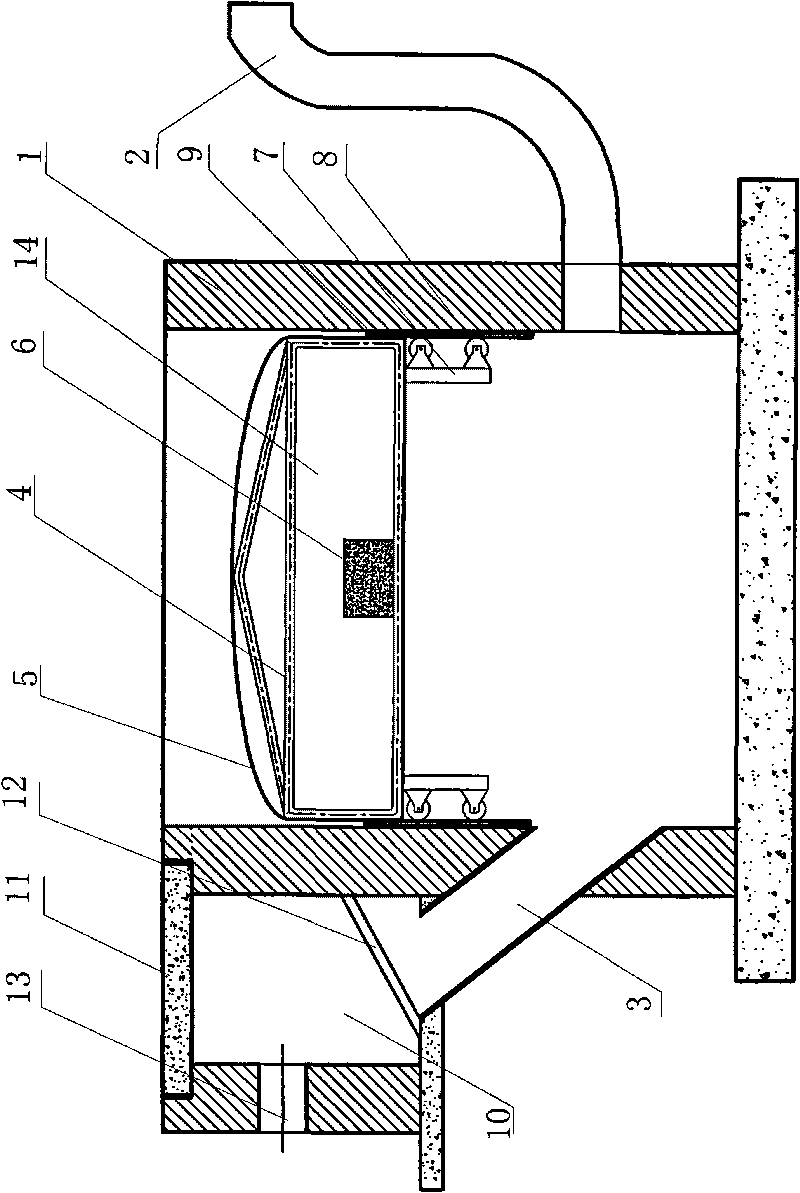

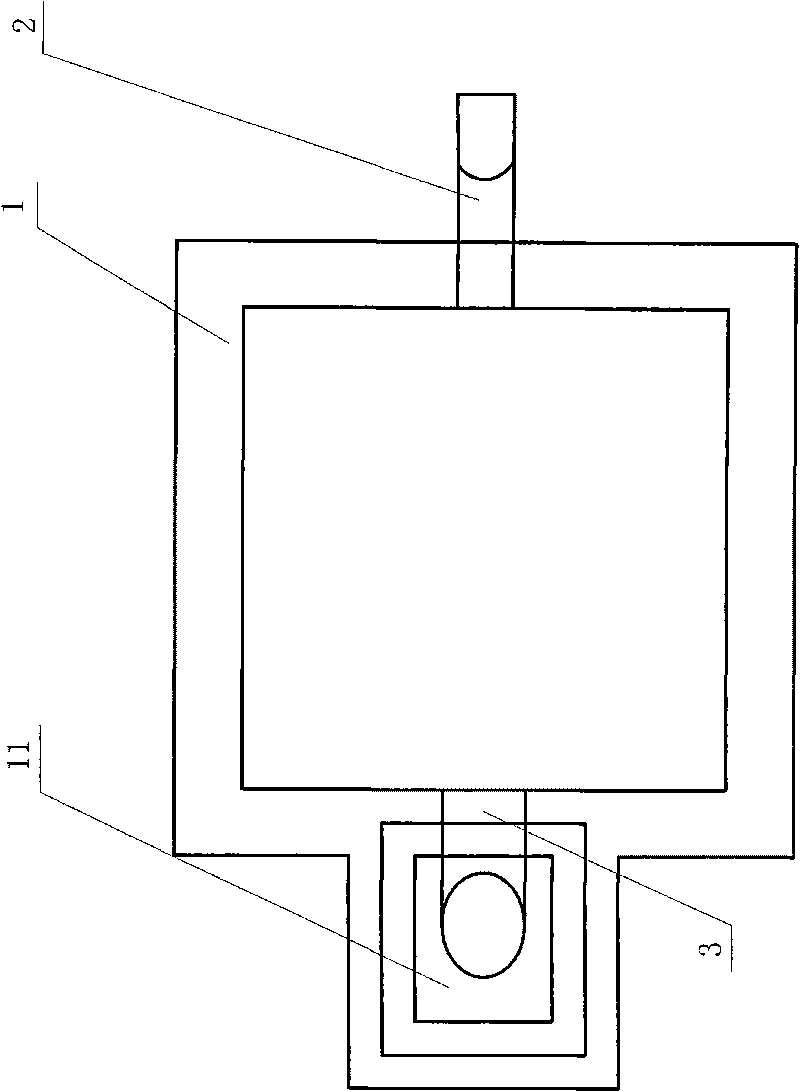

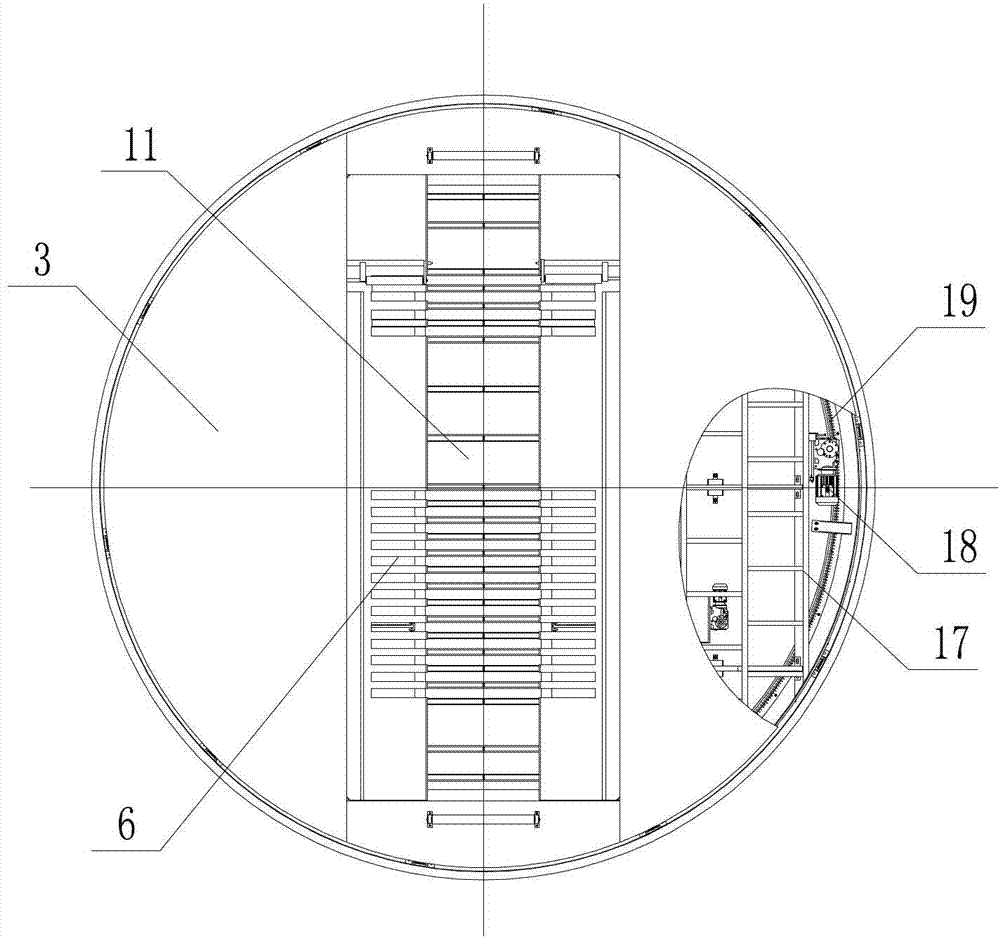

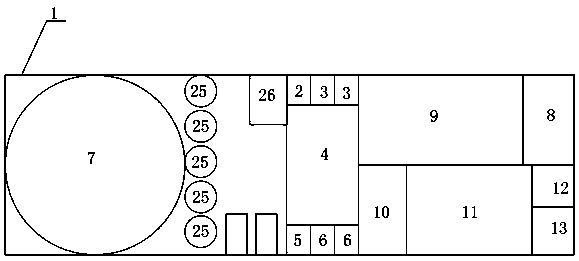

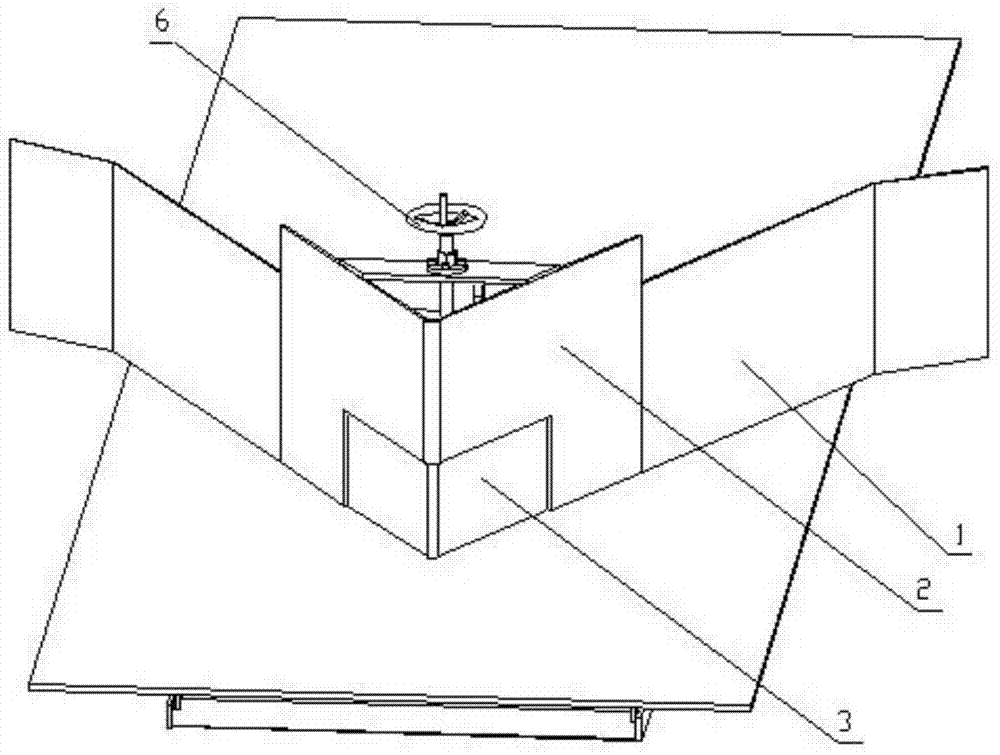

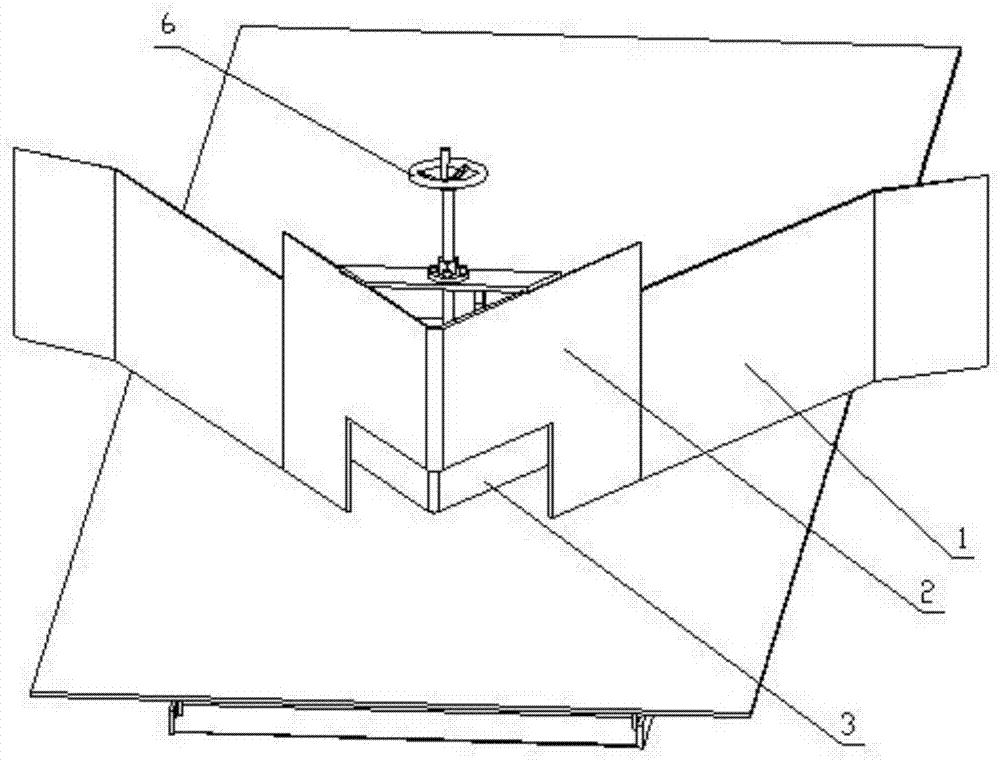

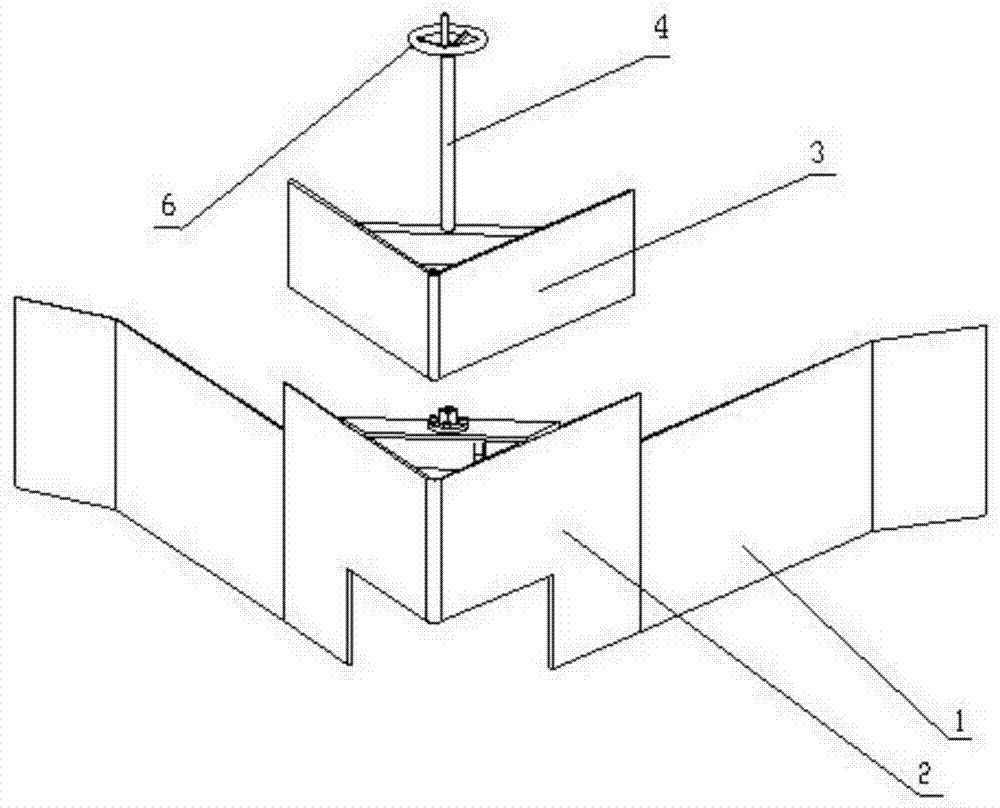

Gas generation and storage integrated biomass pool

InactiveCN101735943AIncreased gas storage spaceEasy to adjustGas production bioreactorsWaste based fuelEngineeringAtmospheric pressure

The invention discloses a gas generation and storage integrated biomass pool, comprising a biomass pool body (1), a discharge water sealing pipe (2), an inclined charging pipe (3) and a top cover. The gas generation and storage integrated biomass pool is characterized in that: the top cover is a floating top cover (1) installed in the biomass pool body, the bottom surface of the floating top cover is provided with a pulley frame (7) and a pulley (8), and the pulley is inserted into a slide rail (9) at the inner wall of the biomass pool body. A counter weight (6) is installed on a base beam a framework (4) of the floating top cover. A grate (12) is installed at the inlet of the inclined charging pipe. In the invention, the integration of gas generation and gas storage of the biomass pool is achieved by the arrangement of the floating top cover and the counter weight, the ratios of gas generation and gas storage are high, and the air pressure in the biomass pool is constant and adjustable, thereby the normal and stable work of marsh gas appliances is guaranteed; simultaneously, the floating top cover is detachable, people can pull out and clean residues outside the biomass pool, which is safe and convenient; in addition, the arranged grate prevents larger objects, such as plastic bags, tree branches and the like from entering the biomass pool.

Owner:CHONGQING LIHUA ENVIRONMENTAL ENG

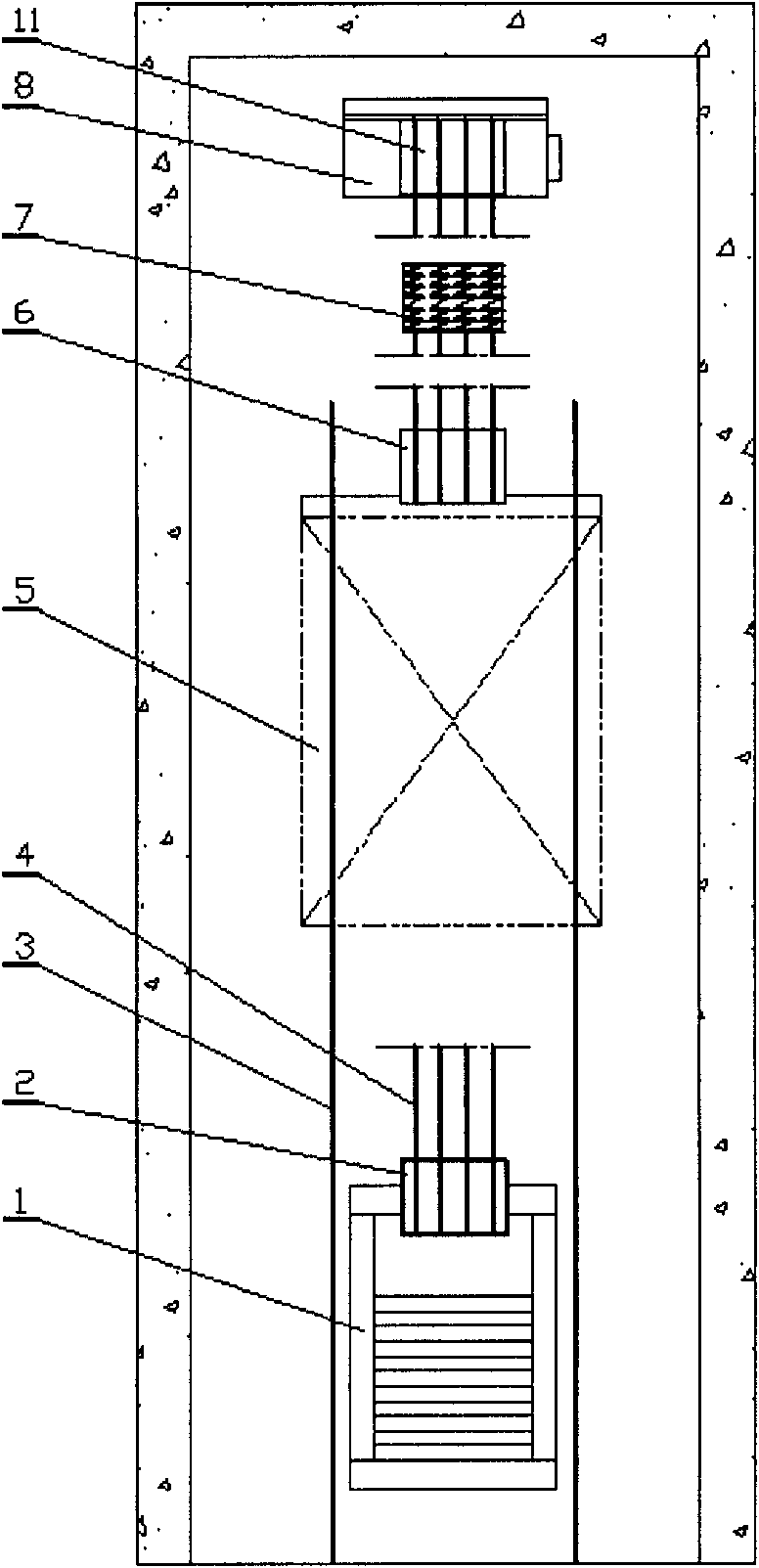

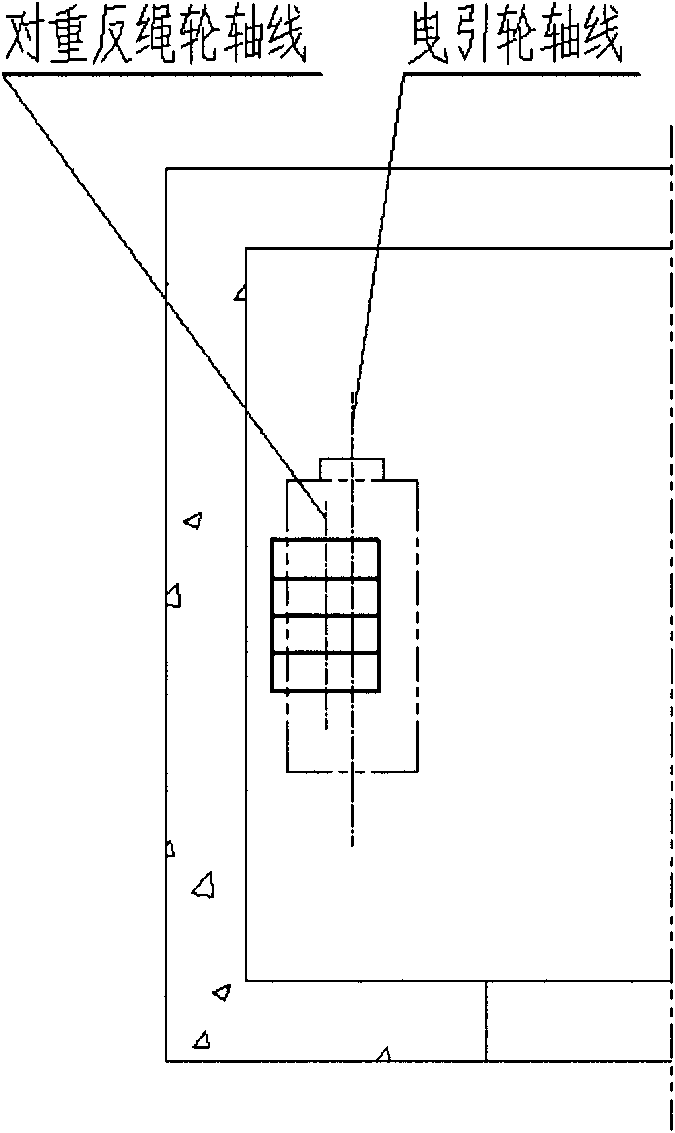

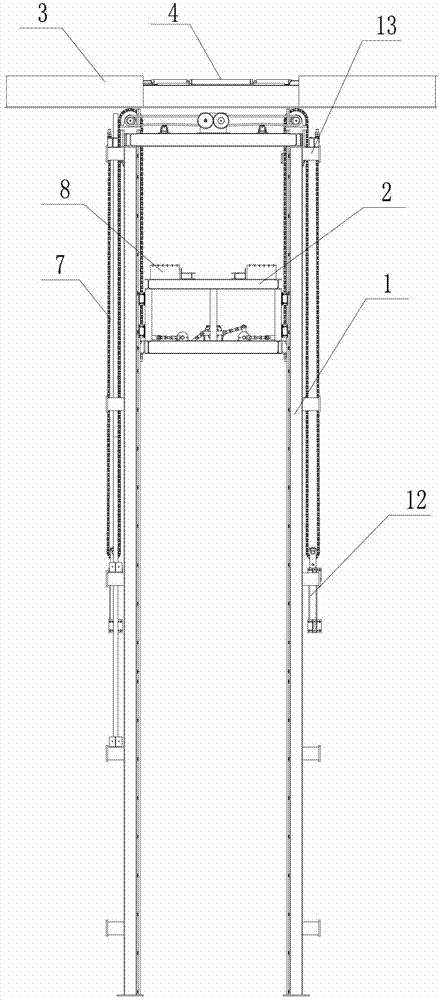

Winding mode of elevator steel wire rope and elevator

InactiveCN102180393AAddresses significant performance degradationGuaranteed uptimeElevatorsVertical projectionEngineering

The invention relates to a winding mode of an elevator steel wire rope and an elevator. The elevator comprises elevator parts, wherein a counterweight wheel (2) is arranged at the upper part of a counterweight device (1); a traction machine (8) is arranged above the counterweight device (1); the axis of a traction wheel (11) and the axis of the counterweight wheel (2) are arranged in parallel or at an included angle of 0 to 90 degrees in the positive and negative directions. After winding around two crosshead sheaves (6), the steel wire rope or a steel strip (4) is lifted to the traction machine (8) to bypass the traction wheel (11) in the anticlockwise direction, then is descended to the counterweight device (1) to bypass the counterweight wheel (2) in the anticlockwise direction, is lifted and finally is fixed on a counterweight side thimble rod rope socket (7). The counterweight side thimble rod rope socket (7) are arranged in three modes: 1, the counterweight side thimble rod rope socket (7) is arranged right below a vertical projection plane of the traction machine (8); 2, the counterweight side thimble rod rope socket (7) is arranged right below in a region that the vertical projection plane extends backwards along the depth direction of a shaft; and 3, the counterweight side thimble rod rope socket (7) is arranged right below in a region that the vertical projection plane extends forwards along the depth direction of the shaft. Due to the simple winding mode, the stripe traction machine can be widely applied to the elevator without a machine room, the elevator with the machine room or other types of elevators.

Owner:HANGZHOU OPTIMAX TECH

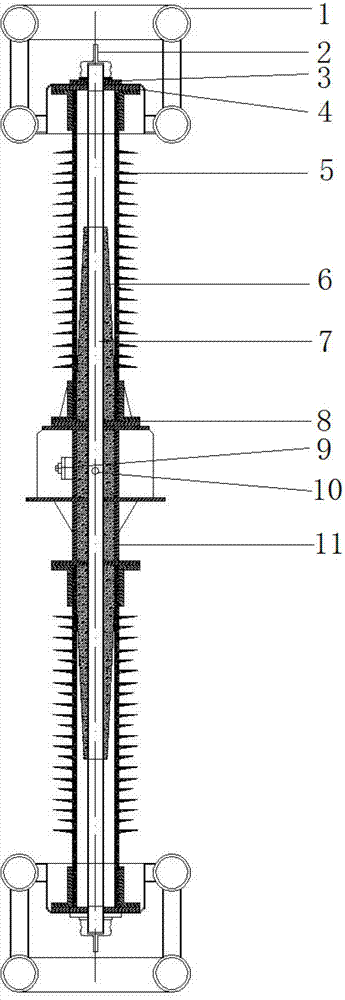

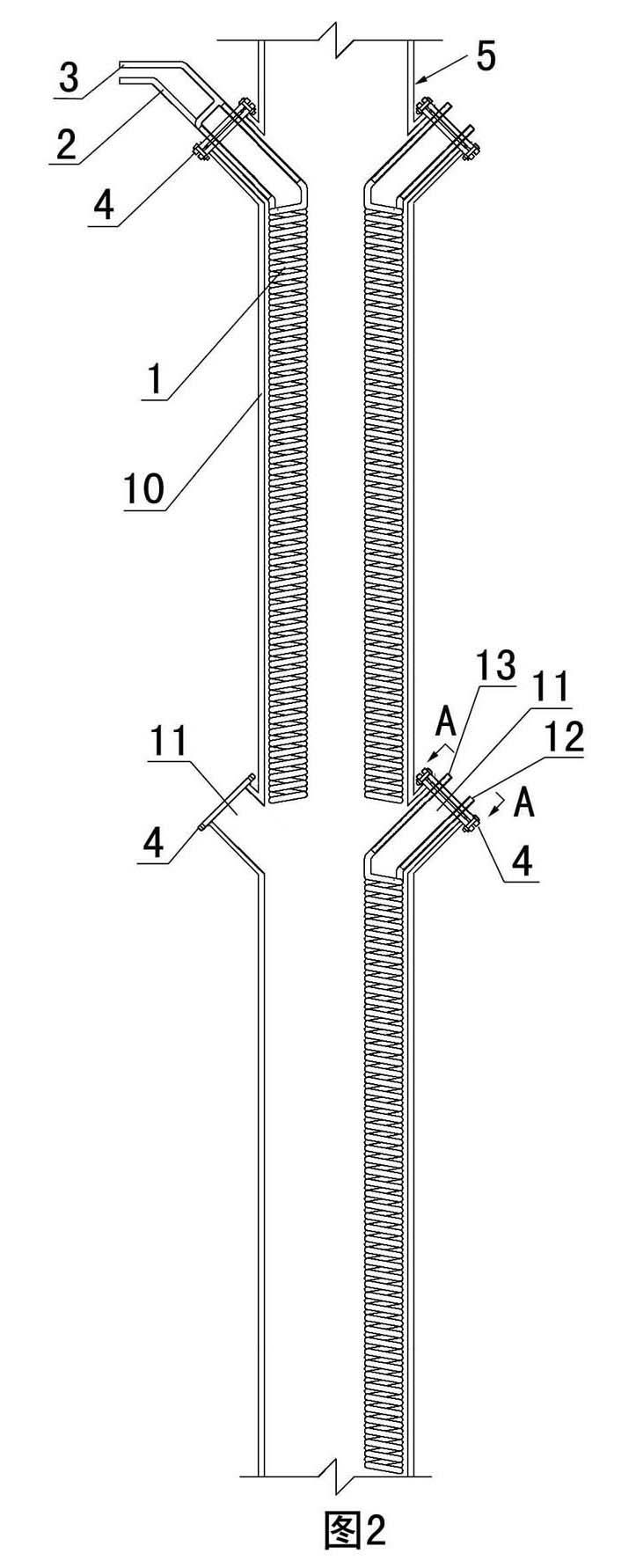

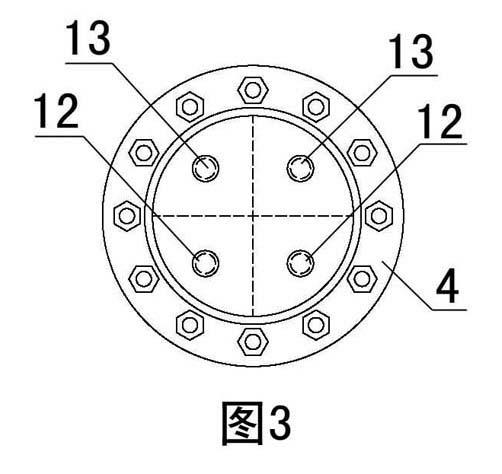

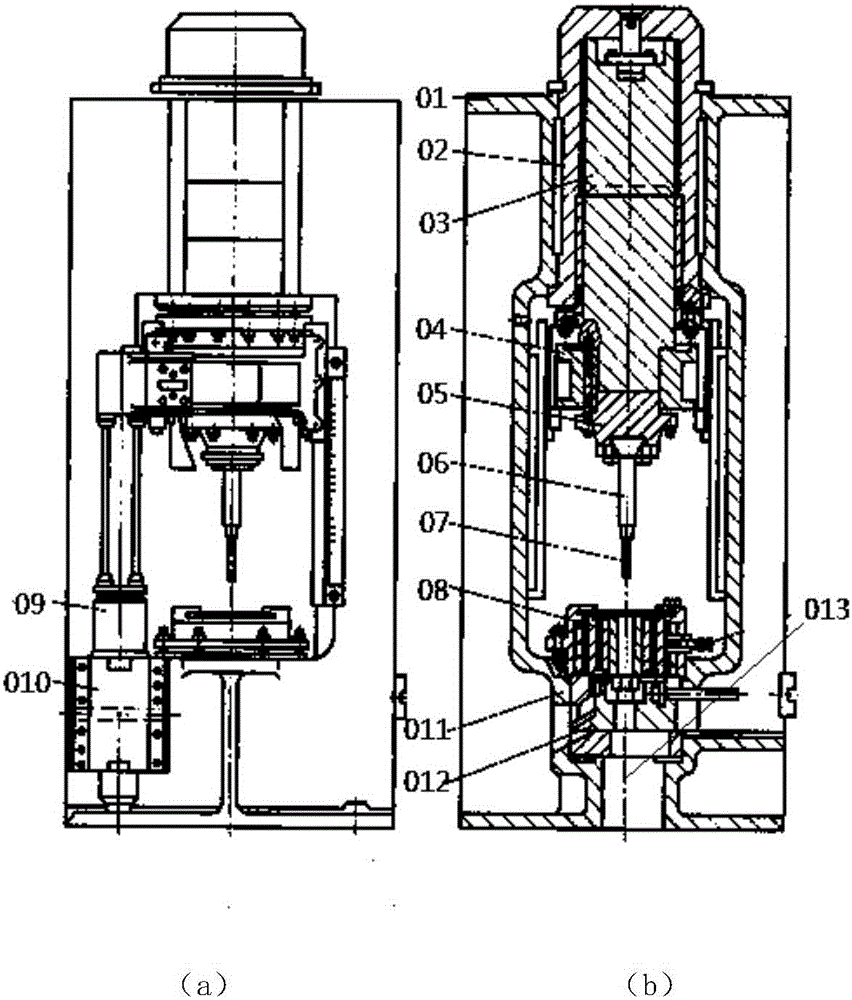

Resin impregnated paper capacitance type extra-high-voltage alternating current-direct current wall bushing

InactiveCN103500967AStrong anti-pollution flashover abilityReduce weightPartially enclosed bus-bar installationsInsulating bodiesCapacitanceEngineering

The invention introduces a resin impregnated paper capacitance type extra-high-voltage alternating current-direct current wall bushing which is provided with a conducting rod (7), wherein the conducting rod (7) is provided with a terminal board (2), a capacitance core (6) in a resin impregnated paper structure is sheathed in a middle section of the conducting rod (7), a sleeve (11) is sheathed on the capacitance core (6), insulating coatings (5), cross sections of which are in multilayer umbrella skirt shapes, are sheathed on both sides of the sleeve (11), and a test tap (9) and an SF6 gas pressure gage (10) are radially connected to the capacitance core (6). The bushing has the advantages that (1) the anti-pollution flashover capability is strong; (2) the civil engineering cost is reduced, and cool leakage of a phytotron is reduced; (3) the influence of heating of a conducting tube of the bushing is favorably reduced; (4) installation and overhaul are convenient; (5) an operating state of the bushing can be monitored in real time; (6) gas leakage is not likely to appear; (7) the grade of design voltage is high, and the application prospect is wide.

Owner:STATE GRID CORP OF CHINA +2

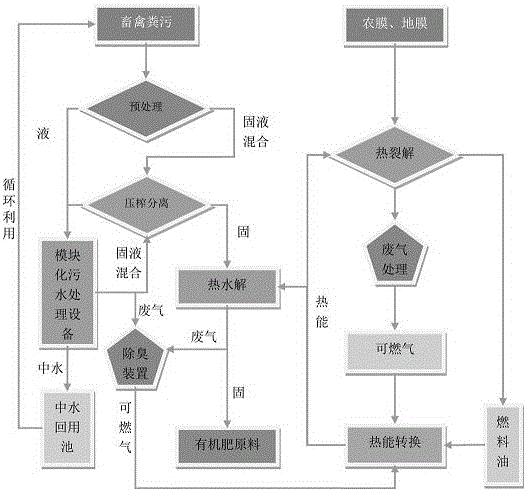

Comprehensive treatment technology of farming excrement and mulching film non-point source pollution

InactiveCN106145608AAchieve deacidification and deodorizationAchieve inactivation and sterilizationByproduct vaporizationWaste water treatment from animal husbandryEnvironmental resistanceFlocculation

The invention discloses a comprehensive treatment technology of farming excrement and mulching film non-point source pollution. The technology comprises the following steps: (1) with a livestock excrement flocculation concentration squeezed separation treatment technology, adding a flocculating agent into the livestock excrement, separating the livestock excrement added with the flocculating agent by a mechanical roller screen, and dehydrating with a screw extrusion dehydrator; (2) performing sewage treatment by a modular sewage treatment equipment, wherein a modular A / O device, a flocculating agent adding device, a flocculation separation and disinfection integrated device and a solid-liquid separation squeezing device are adopted; (3) with a solid excrement acid removal thermal hydrolysis technology, performing solid excrement treatment in an acid removal thermal hydrolysis way; and (4) with a mulching film cracking technology, selecting the heating rate, pyrolysis temperature and catalyst and determining the heating rate and pyrolysis temperature of the technology and corresponding product recycling and environment-friendly treatment technology to realize an environmental protection effect of 'treating waste with waste' and avoiding secondary pollution.

Owner:陈永进

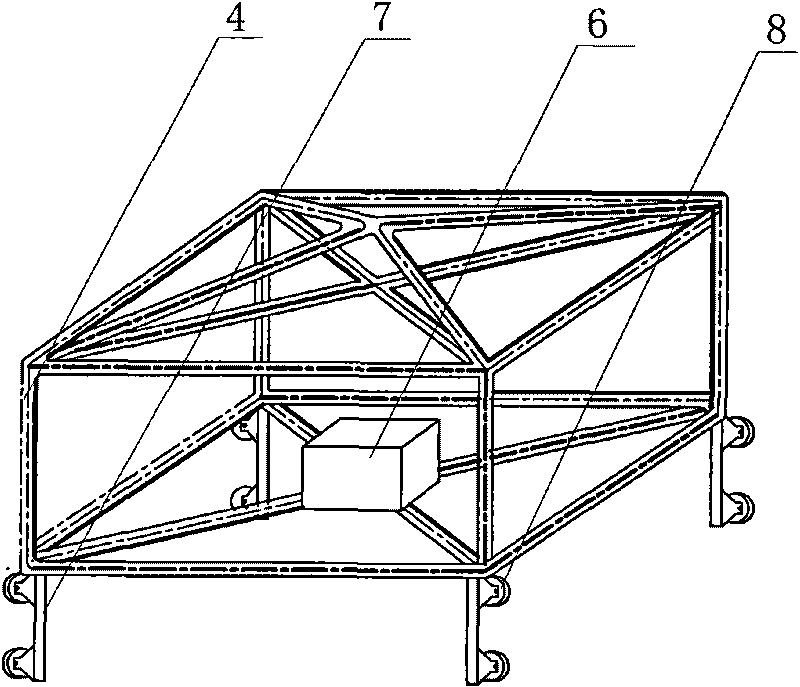

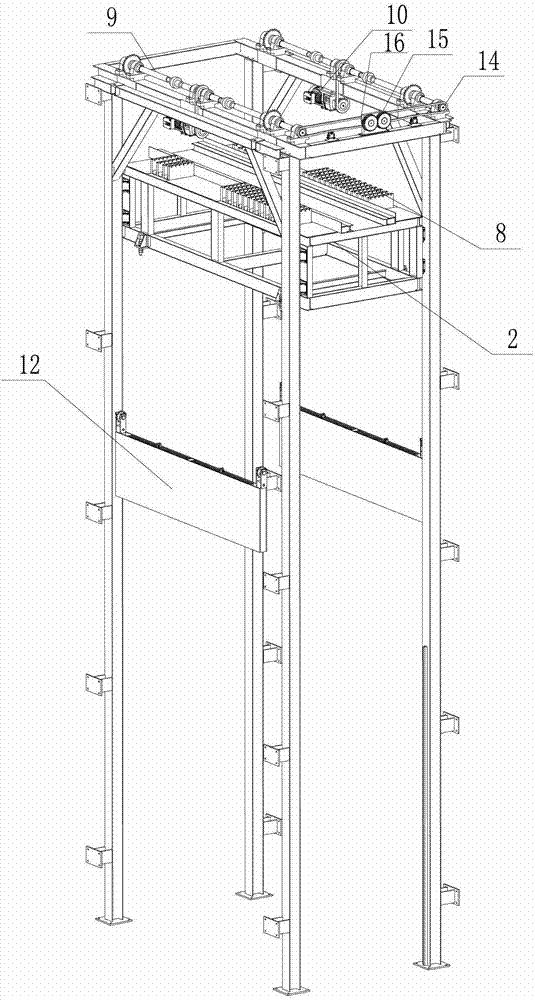

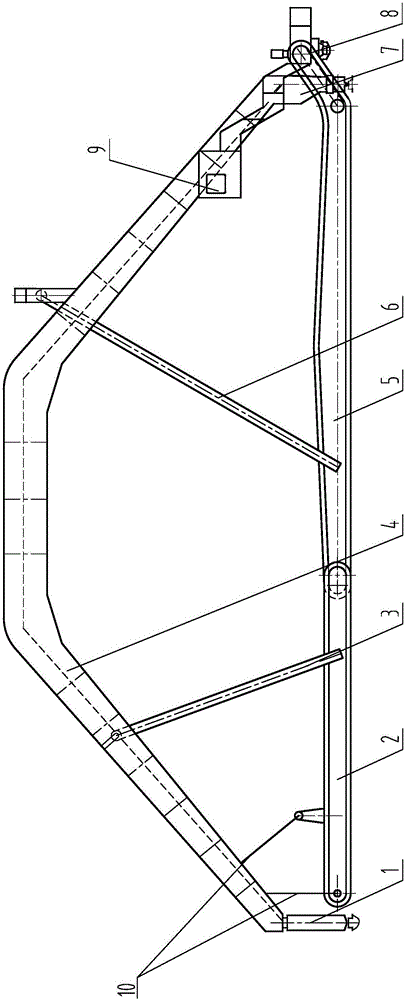

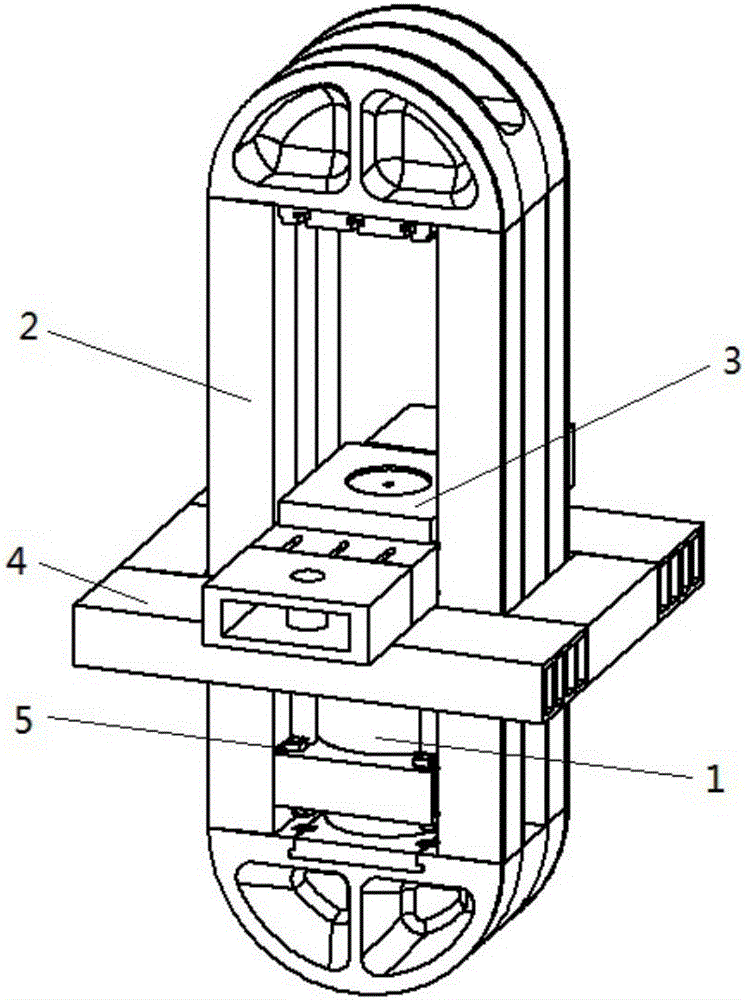

Three-dimensional garage elevator with opening and closing rotary disc at top part

ActiveCN102889015AImprove efficiencyReduce civil costParkingsAutomotive engineeringElectrical and Electronics engineering

The invention relates to a three-dimensional garage elevator with an opening and closing rotary disc at the top part. A rotary disc is arranged at the top parts of vertical elevator columns; a parking lane is arranged at the middle of the rotary disc; the parking lane is composed of two main comb tooth parking boards; the main comb tooth parking boards are driven by gears at two sides of the rotary disc so as to form an opening and closing type structure; an elevation platform board is arranged below the parking lane; four angles of the elevation platform board are connected with an elevation mechanism (of the elevator) arranged at the top parts of the vertical elevator columns; secondary comb tooth parking boards which are arranged staggering with the main comb tooth parking boards are arranged on the elevation platform board; and the heights of the comb teeth of the secondary comb tooth parking boards are higher than the heights of the comb teeth of the main comb tooth parking boards. By adoption of the three-dimensional garage elevator, the efficiency in parking and starting a car is improved; the opening and closing rotary disc and the elevator are combined integrally, so that the time for parking and starting the car is reduced, the area for installing the rotary disc is saved; and more cars can be stored, so that the use efficiency of a garage is improved.

Owner:JIANGSU ZHONGTAI PARKING IND CO LTD +1

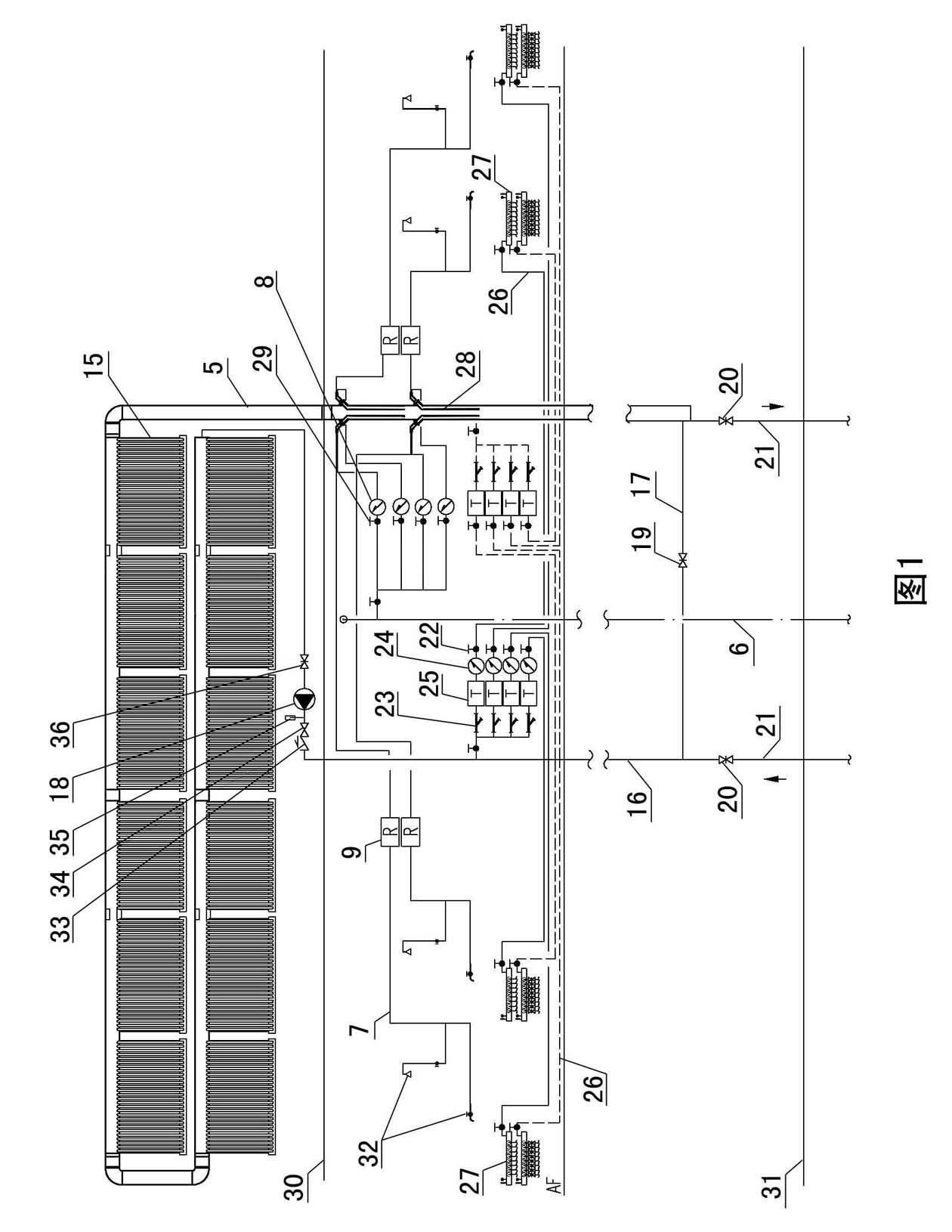

Solar comprehensive heating system capable of supplying heat and hot water integrally for house

ActiveCN102661615AAvoid pipe burstAvoid technical problems such as air blockageSolar heating energySolar heat devicesWater useCollector device

A solar comprehensive heating system capable of supplying heat and hot water integrally for a house comprises a vacuum tube solar collector, a collector water inlet pipe, a collector water outlet pipe, a heat storage pipeline, a heat exchanger, a domestic hot water pipe and a hot water use terminal. The collector water inlet pipe and the collector water outlet pipe are communicated with the solar collector. The collector water outlet pipe is communicated with the heat storage pipeline and is part of the heat storage pipeline. The heat storage pipeline is communicated with the collector water inlet pipe through connecting water pipes provides with switch valves. The collector water inlet pipe and the heat storage pipeline are connected with a low temperature radiation heating manifold through heating pipes so as to form water circulation. Water circulation between the vacuum tube solar collector and municipal heating hot water pipes are formed by the aid of the collector water inlet pipe and the heat storage pipeline. The solar comprehensive heating system is simple in structure, low in manufacture and maintenance cost, and low in maintenance difficulty.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

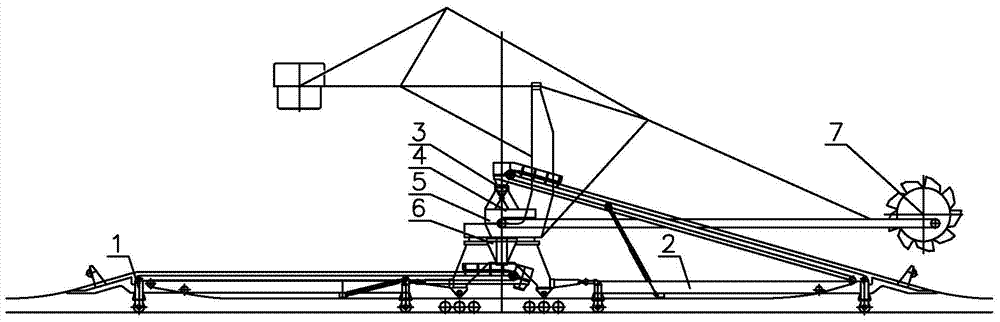

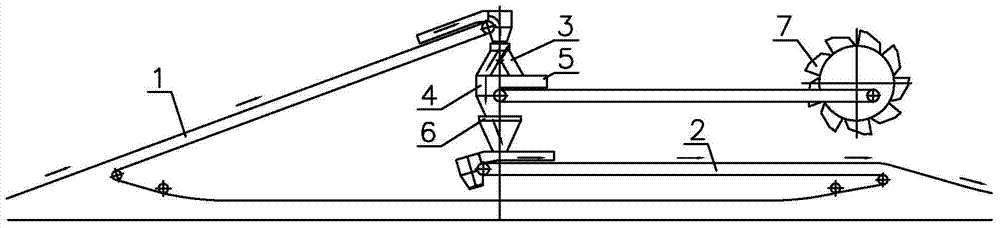

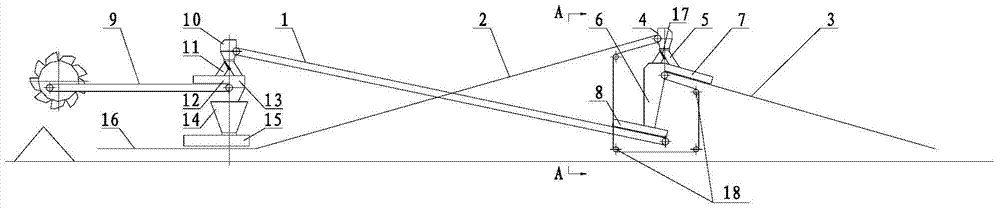

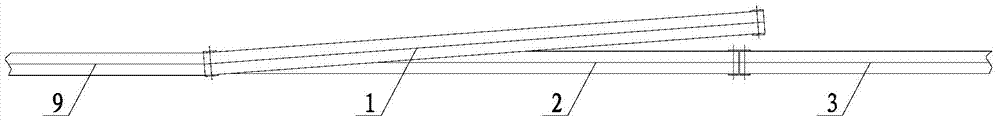

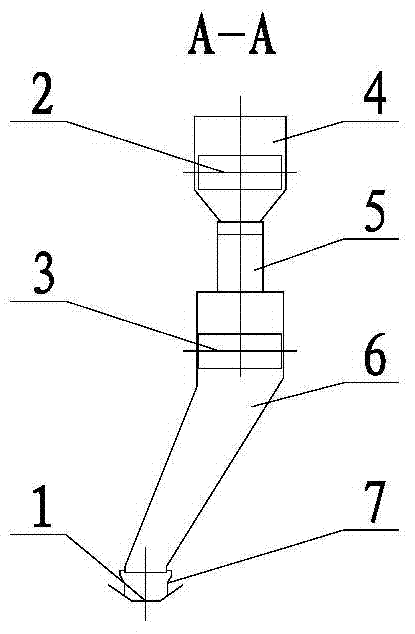

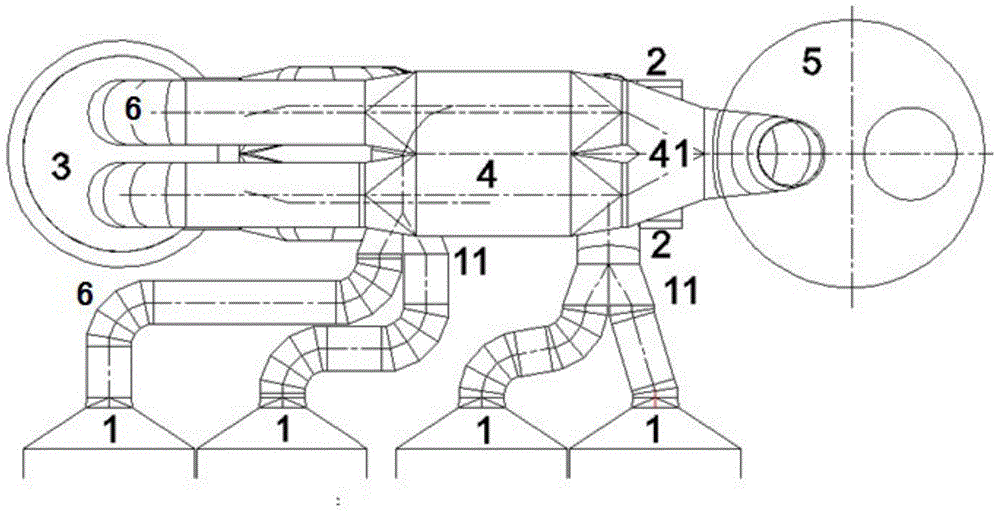

Full-function bucket-wheel stacker-reclaimer and material reclaiming method thereof

The invention discloses a full-function bucket-wheel stacker-reclaimer and a material reclaiming method thereof. The full-function bucket-wheel stacker-reclaimer is characterized in that the full-function bucket-wheel stacker-reclaimer comprises a host machine, a movable tail vehicle device I, a movable tail vehicle device II, a furcation hopper device, a suspended arm material guide groove device, an inclined hopper device and a center lower portion hopper device; through two-position combination of the movable tail vehicle device I and the movable tail vehicle device II, together with position changes of a movable plate inside the furcation hopper device, and through a ground conveyor belt, the single full-function bucket-wheel stacker-reclaimer can realize the functions that two-way incoming materials are stacked to a stock ground, the two-way incoming materials are directly connected, reclaimed materials are conveyed in two directions and the two-way incoming materials are separated. The full-function bucket-wheel stacker-reclaimer and the material reclaiming method thereof have the advantages that the single stacker-reclaimer is complete in function, the equipment investment cost and the civil engineering cost are lowered, the utilization rate of the stock ground is improved, the operation cost is lowered, the structure is simple, use and maintenance are convenient, and the production efficiency is greatly improved.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

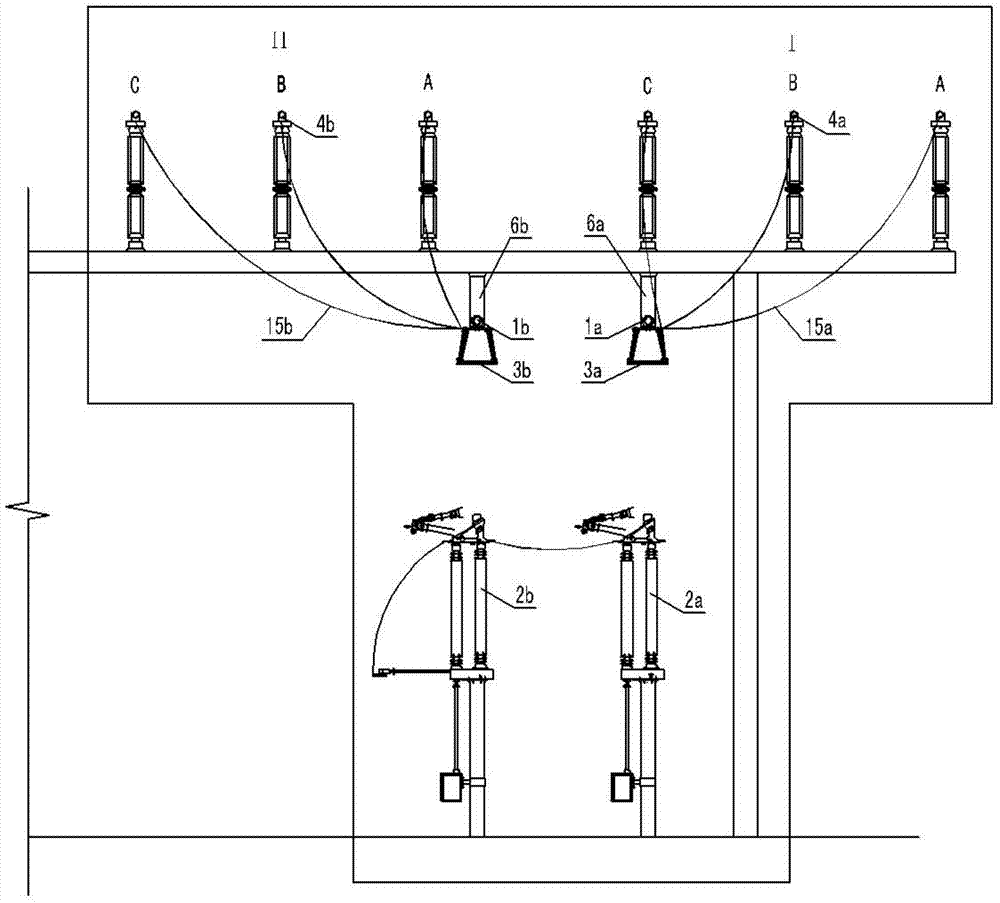

Disconnecting switch arrangement structure for transformer substation power distribution unit

The invention discloses a disconnecting switch arrangement structure for a transformer substation power distribution unit. The disconnecting switch arrangement structure is characterized in that a vertical telescopic 0-degree disconnecting switch is adopted, and each movable contact in the 0-degree disconnecting switch is arranged along a direction parallel to a tubular bus bar; an insulating bar is arranged above the movable contacts of the 0-degree disconnecting switch along the direction parallel to the tubular bus bar according to a set height; each static contact in the 0-degree disconnecting switch is distributed on the insulating bar at set intervals; each tubular bus bar fixedly arranged on a tubular bus bar framework is connected with each corresponding static contact in the 0-degree disconnecting switch through leads. By adopting the disconnecting switch arrangement structure, the longitudinal size of a power distribution unit area can be reduced effectively, the floor area of a transformer substation is reduced, and the application range of an AIS (Automatic Identification System) power distribution unit is enlarged.

Owner:ANHUI ELECTRIC POWER DESIGN INST CEEC

Double-leaf flap gate

PendingCN112323737AHeight halvedHalf the weightBarrages/weirsArtificial water canalsRiver routingStructural engineering

The invention provides a double-leaf flap gate. The double-leaf flap gate comprises an upper leaf gate leaf and a lower leaf gate leaf, the upper leaf gate leaf and the lower leaf gate leaf are both horizontal gates and are both arranged at a river channel gate opening, the upper leaf gate leaf is rotated upwards to be opened, and the lower leaf gate leaf is rotated downwards to be opened. The double-leaf flap gate further comprises an upper hoist driving the upper leaf gate leaf to rotate upwards to be opened or rotate downwards to be closed and a lower hoist driving the lower leaf gate leafto rotate downwards to be opened or rotate upwards to be closed, one end of the upper hoist is hinged to the upper leaf gate leaf, one end of the lower hoist is hinged to the lower leaf gate leaf, theother end of the upper hoist and the other end of the lower hoist are both hinged to a hoist base, and the joint of the upper leaf gate leaf and the lower leaf gate leaf is flush with the landscape water level of the inland river.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

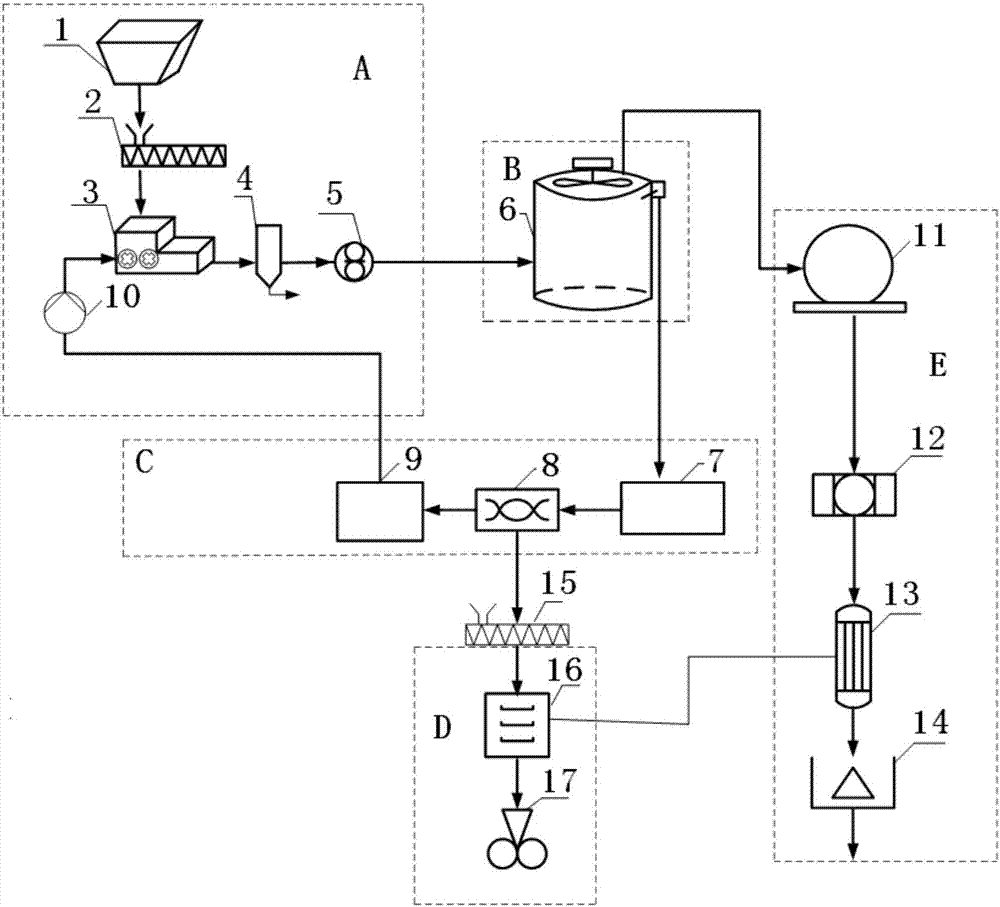

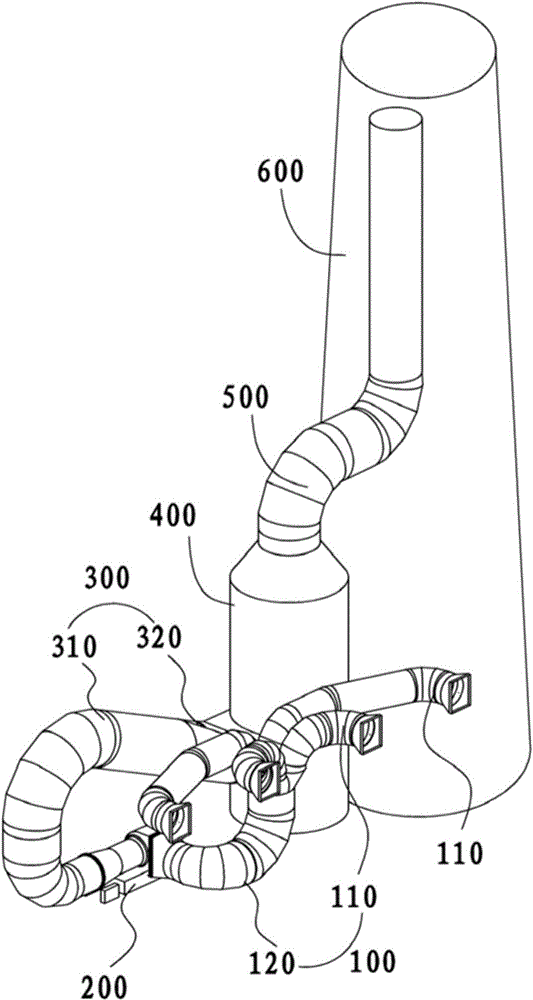

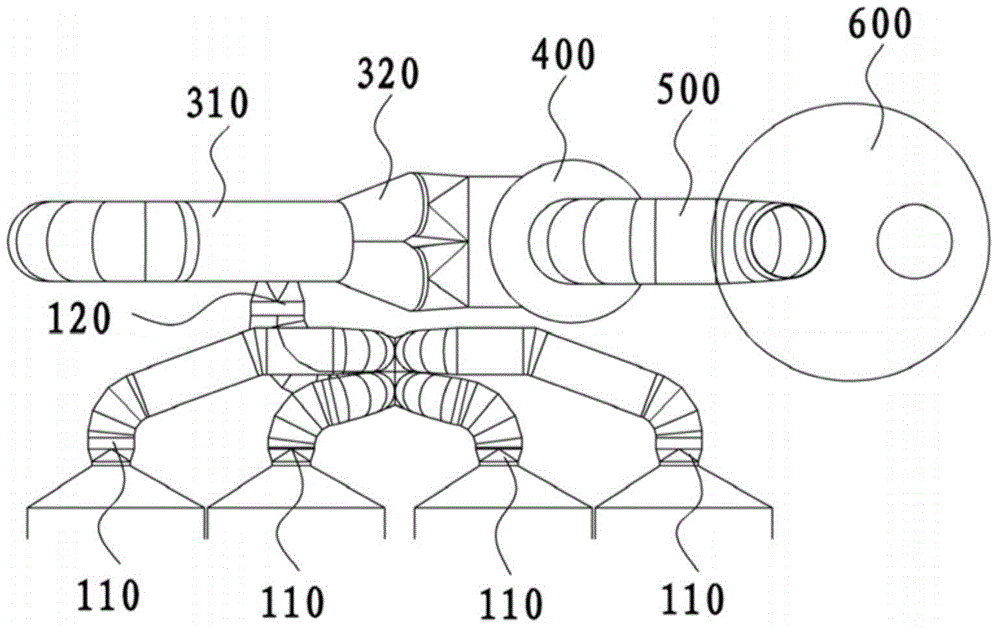

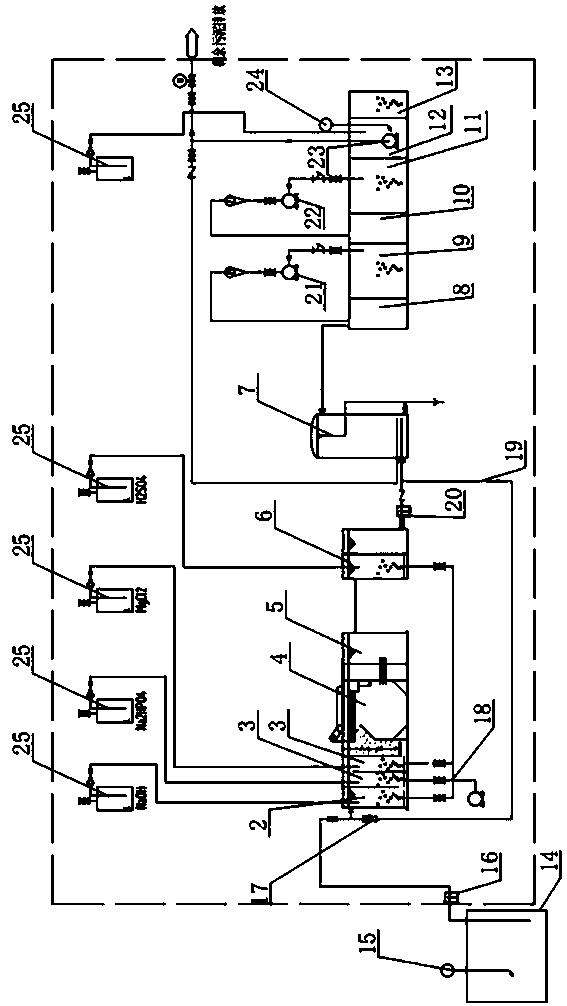

System and method for anaerobic digestion and biogas purification of waste fruits and vegetables

PendingCN106906126AReduce civil costSimple feeding methodBiological substance pretreatmentsGas production bioreactorsFiberHollow fibre membrane

The invention provides a system and method for anaerobic digestion and biogas purification of waste fruits and vegetables. The system comprises five component parts including a charging unit, an anaerobic digestion unit, a biogas slurry filtering unit, a biogas residue drying unit and a biogas purifying unit. The system generates biogas through an anaerobic digestion process, and the generated biogas is used for drying biogas residue to prepare pellet fuel. The system further uses a technical system and method for preparing biogas through a hollow fiber membrane system. The system and method allow efficient conversion of waste and covert waste fruits and vegetables to biogas and pellet fuel through anaerobic digestion and a hollow fiber membrane separation system.

Owner:扬州首创投资有限公司

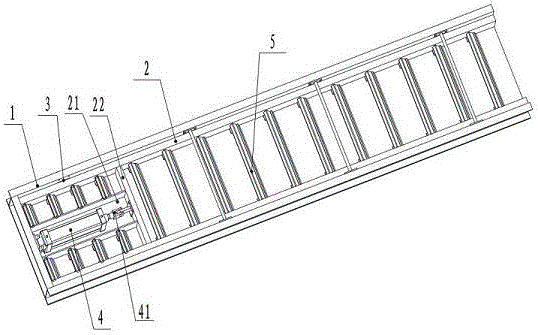

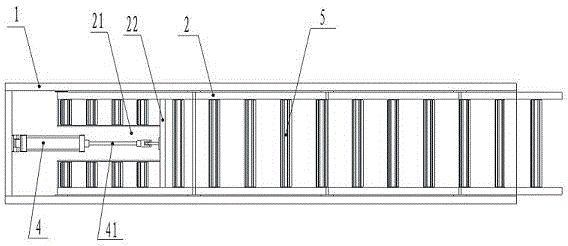

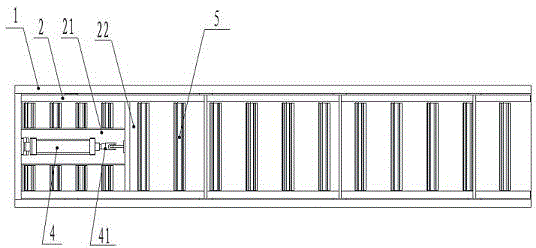

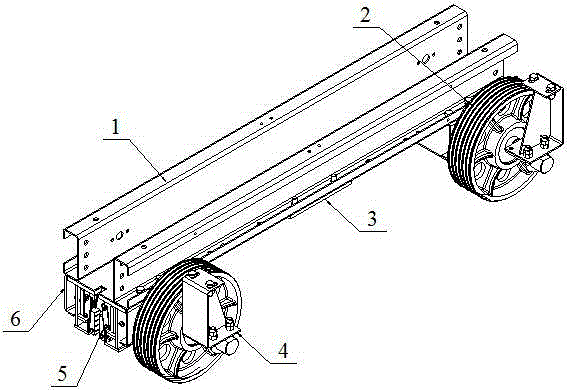

Abrasive material scraping plate automatic recovery equipment for sandblasting room

InactiveCN104552031AGuaranteed uptimeReduce energy consumptionAbrasive machine appurtenancesAbrasive blastingReciprocating motion

The invention discloses abrasive material scraping plate automatic recovery equipment for a sandblasting room. The abrasive material scraping plate automatic recovery equipment comprises a fixed rack, sliding racks, roller groups, a cylinder pushing device and reversible sand scraping plates, wherein the sliding racks are installed on the upper part of the fixed rack, the roller groups are respectively installed at the inner side edges of the fixed rack and are in sliding connection with the sliding racks, a plurality of reversible sand scraping plates which are uniformly arranged in parallel are transversely installed between the sliding racks, the cylinder pushing device is installed at the middle part of the upper end of the fixed rack and extends to the sliding racks, and the sliding racks are pushed by the cylinder pushing device to conduct reciprocating motion. Through the way, the abrasive material scraping plate automatic recovery equipment for the sandblasting room provided by the invention is of a mechanical type, so that long-term reliable operation can be ensured, and the sliding racks are pushed by the cylinder pushing device to conduct reciprocating motion, so that energy consumption of the equipment is low, the maintenance cost is low and trenches of the scraping plates are shallow, thereby reducing the civil construction cost.

Owner:太仓联洲机械设备有限公司

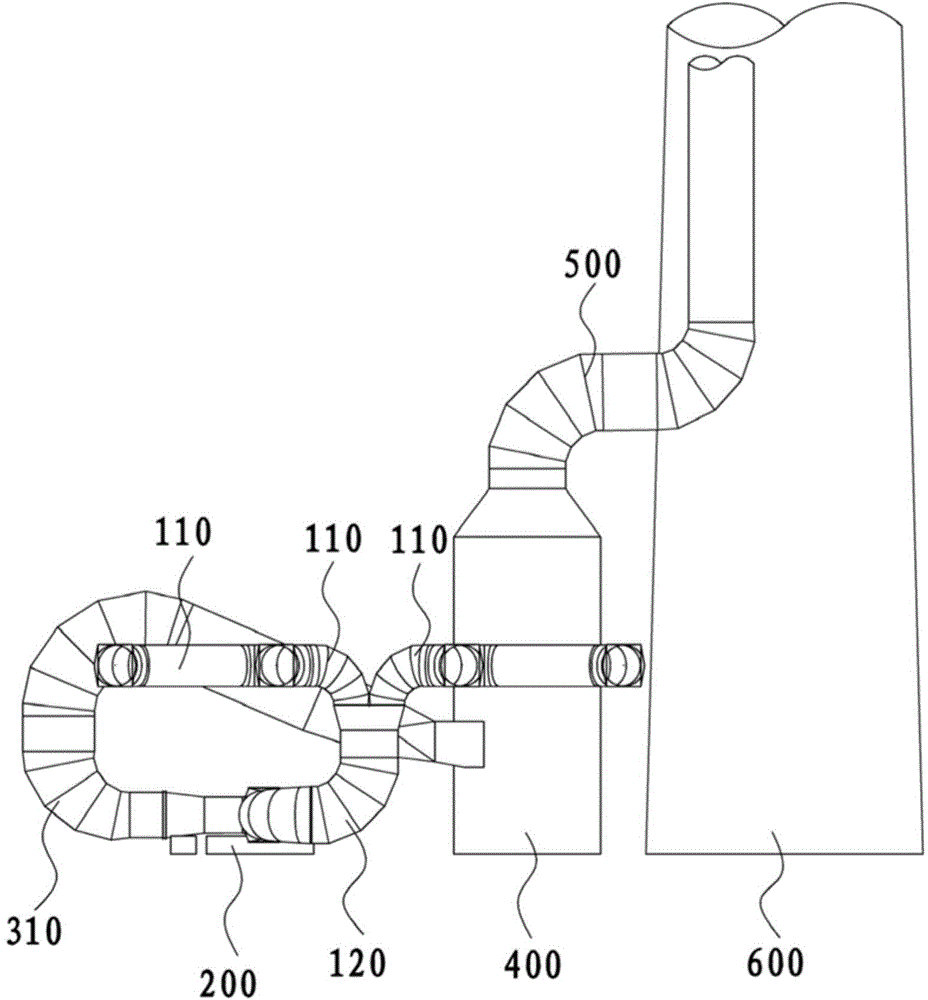

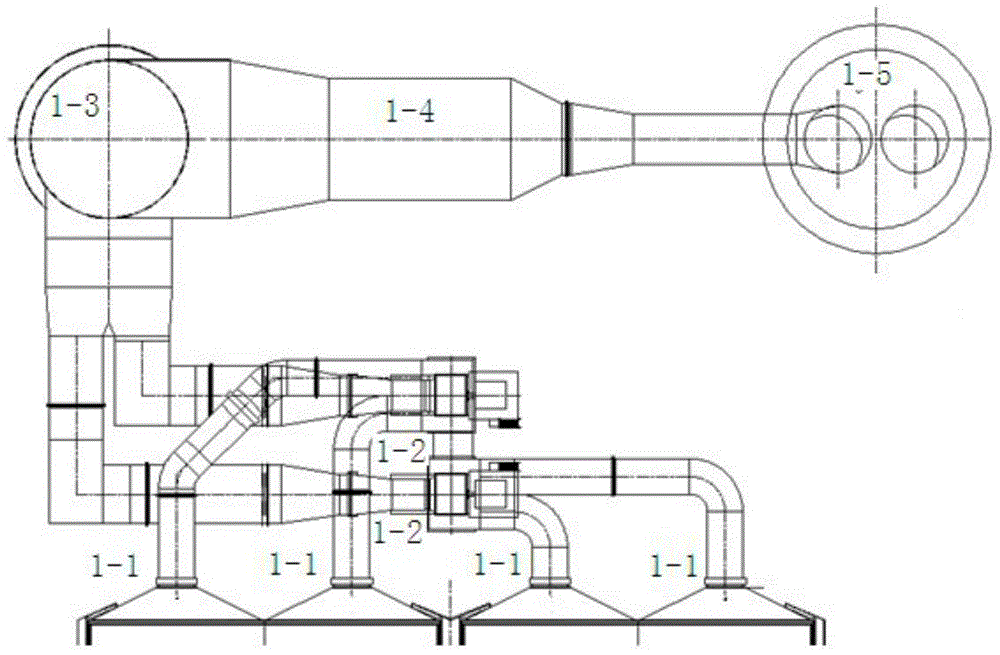

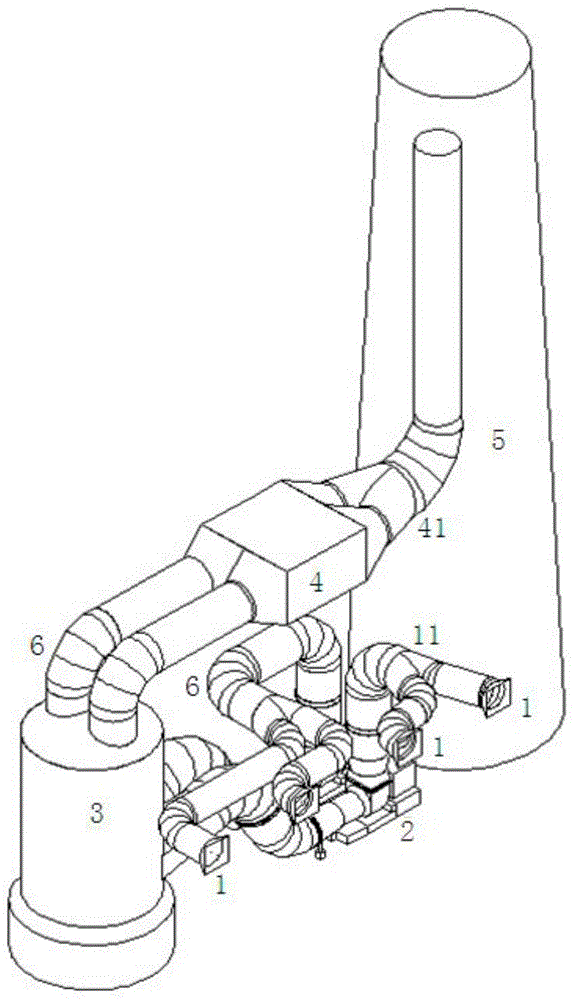

Equipment arrangement structure provided with single-row induced draft fan behind dust catcher and flue gas system

The invention discloses an equipment arrangement structure provided with a single-row induced draft fan behind a dust catcher and a flue gas system. The equipment arrangement structure provided with a single-row induced draft fan behind the dust catcher comprises the single-row induced draft fan, a desulfurization absorption tower and a chimney, wherein the single-row induced draft fan, the desulfurization absorption tower and the chimney are successively connected by flues; the center lines of the single-row induced draft fan, the desulfurization absorption tower and the chimney are positioned on the same plane; the desulfurization absorption tower and the chimney are both vertically arranged; the single-row induced draft fan is laterally arranged on the outer side of the desulfurization absorption tower; the outlet of the single-row induced draft fan is back onto the desulfurization absorption tower; an outlet flue is connected by directly facing the inlet of the desulfurization absorption tower after slowly rotating. All pieces of equipment behind the dust catcher are subjected to spatial combined arrangement of a horizontal straight line shape, so that the arrangement among all pieces of equipment is more compact, occupied lands are reduced, the length of connection flues is reduced so as to save the materials of the flues, all pieces of equipment behind the dust catcher are reasonably arranged, and a stereo space behind the dust catcher is effectively utilized.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

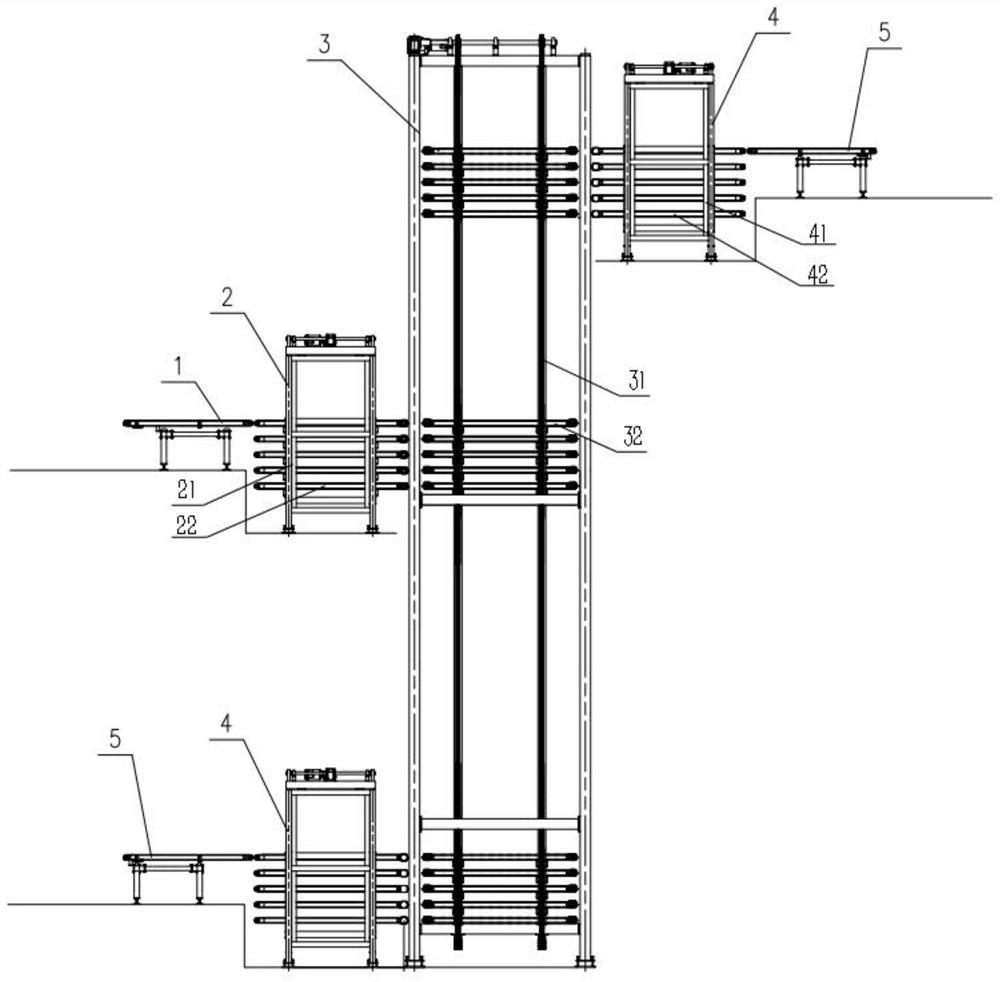

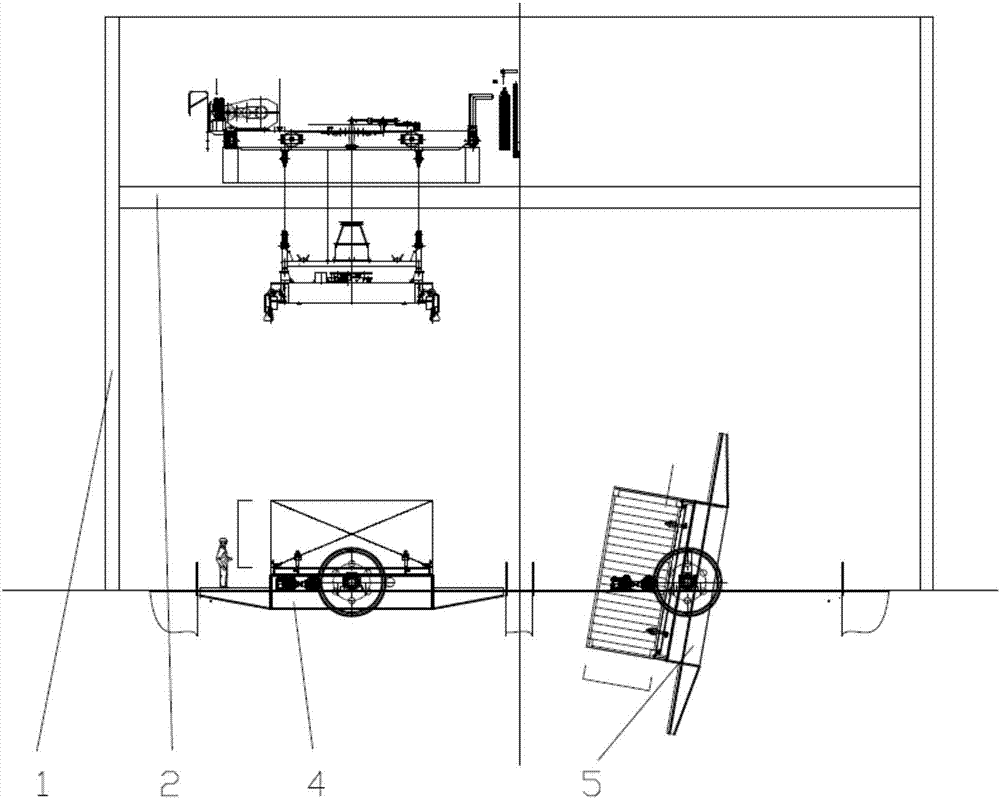

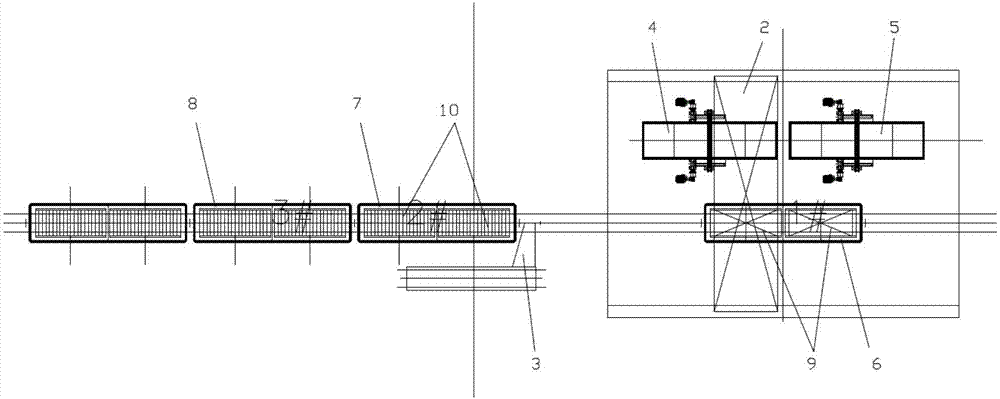

Plate glass production line three-dimensional conveying device and method

ActiveCN112340450AReduce civil costIncrease productivityConveyorsCharge manipulationFlat glassEngineering

The invention discloses a plate glass production line three-dimensional conveying device and method, and belongs to the technical field of glass production. The plate glass production line three-dimensional conveying device comprises a sheet collecting device which is arranged at the tail end of an original sheet production line, each lifting roller way can ascend and descend in the height direction of a sheet collecting lifting rail, and plate glass can move in the driving direction of a driving part in the sheet collecting roller way; each vertical roller way can ascend and descend in the height direction of a vertical lifting rail, the vertical roller ways can be opposite to the sheet collecting roller ways, and the plate glass can move in the horizontal direction of the vertical rollerways; and a sheet sending device arranged at the head end of a deep processing line or a stacking machine roller way, each sheet sending roller way can ascend and descend in the height direction of asheet sending lifting rail, and the plate glass can move in the driving direction of a driving component in the sheet sending roller way. According to the plate glass production line three-dimensional conveying device and the method provided by the invention, the utilization efficiency of workshop space is improved, and the overall manufacturing efficiency is improved.

Owner:CHINA TRIUMPH INT ENG

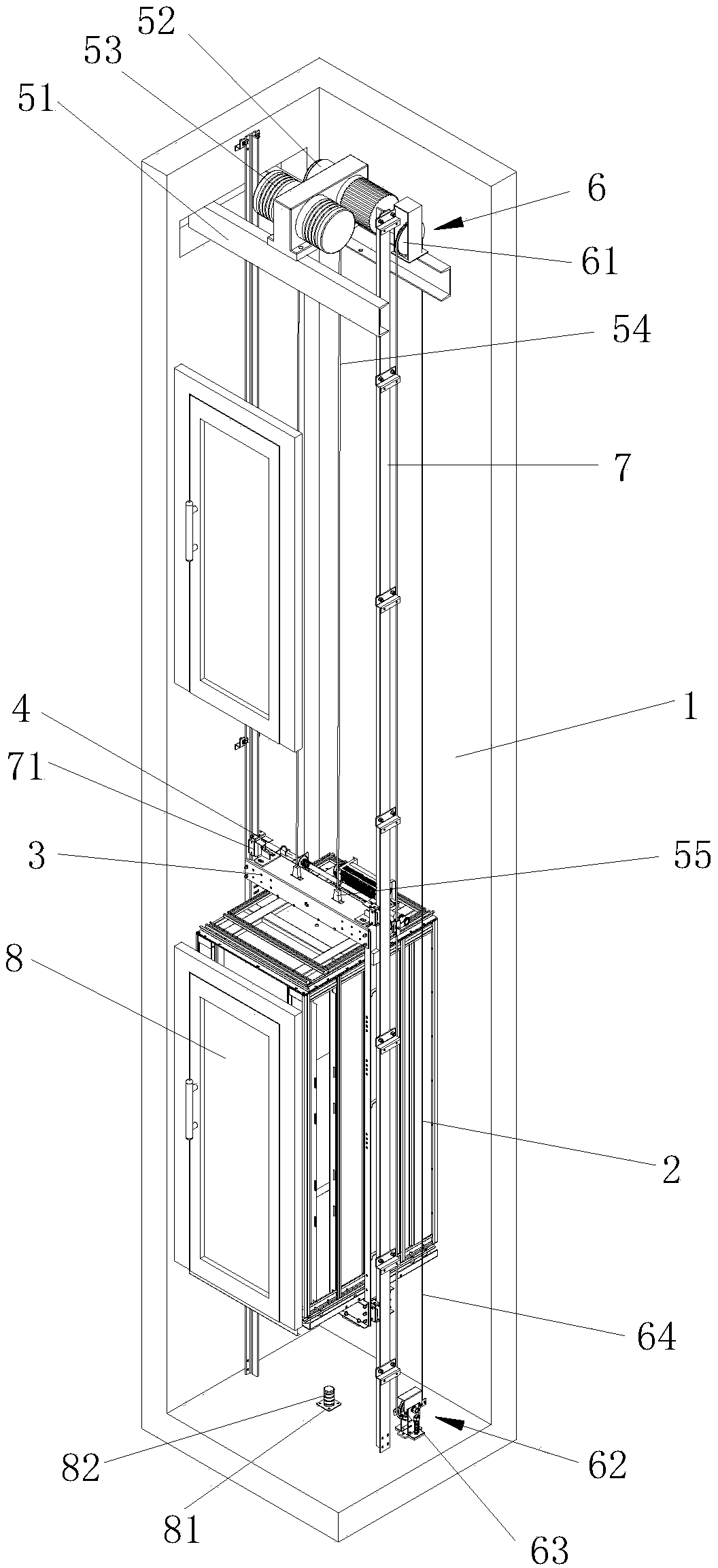

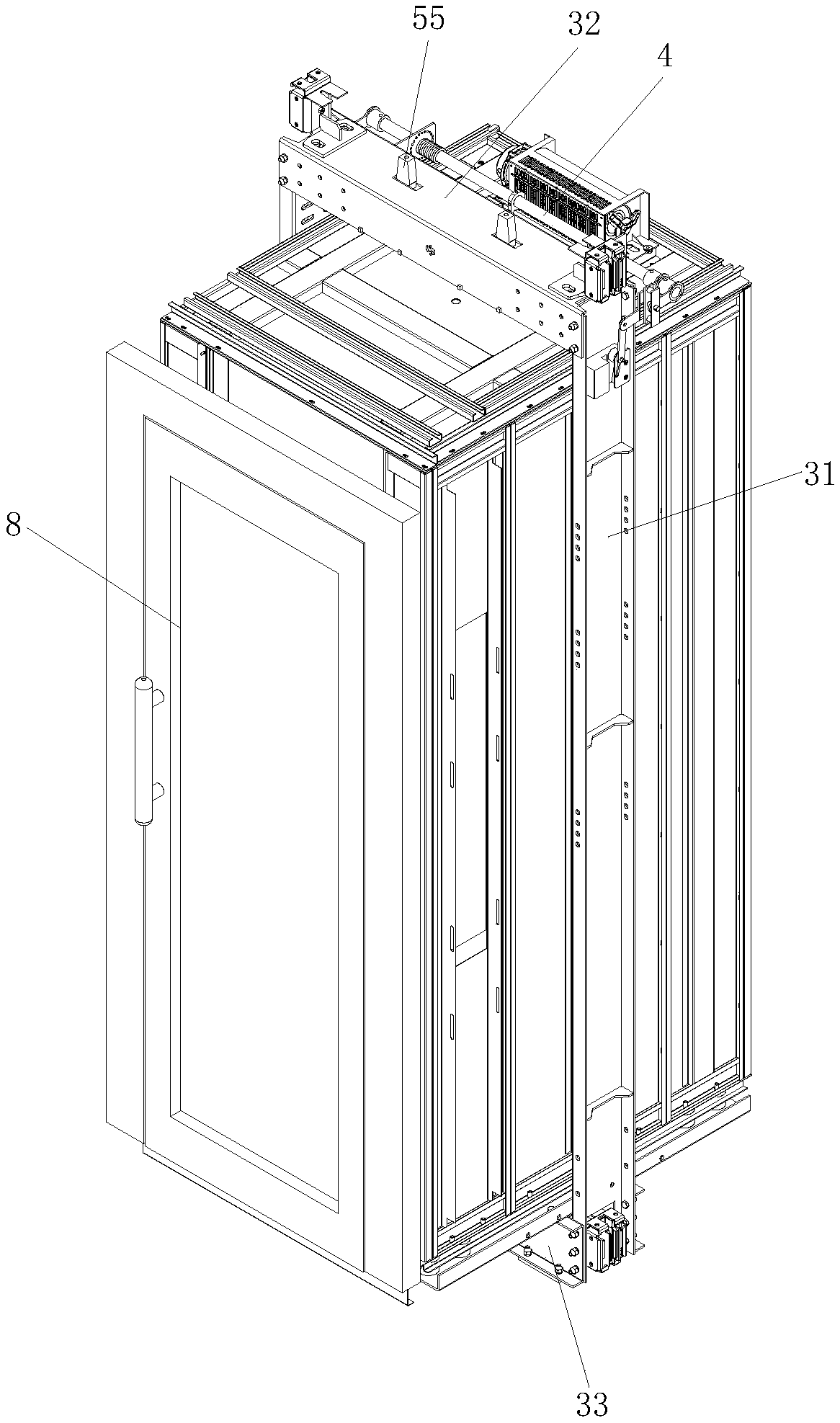

Compact type shallow pit counterweight-free elevator

The invention discloses a compact type shallow pit counterweight-free elevator. The compact type shallow pit counterweight-free elevator comprises a hoistway. A lift car is arranged in the hoistway. Acar frame is arranged at the periphery of the lift car. A safety tongs lifting mechanism is arranged on the rear side of the top end of the car frame. A mounting rack which is transversely distributed is arranged at the top end of the hoistway. A traction machine and an overspeed governor are arranged on the mounting rack. Two steel wire ropes are winded around a traction sheave of the traction machine. Both the two steel wire ropes downwards extend to be fixedly connected with the top end of the car frame. The overspeed governor comprises a speed limitation pulley arranged on the mounting rack. A tensioning device is arranged at the position, corresponding to the speed limitation pulley, of the bottom end of the hoistway. The tensioning device comprises a tensioning wheel. An overspeed governor rope is winded between the speed limitation pulley and the tensioning wheel. The overspeed governor rope is further and fixedly connected with the safety tongs lifting mechanism. The compact type shallow pit counterweight-free elevator has the characteristics that the whole occupied space is reduced, the area of the lift car is enlarged, the total cost and energy are reduced, and the application range is broadened.

Owner:SICHER ELEVATOR

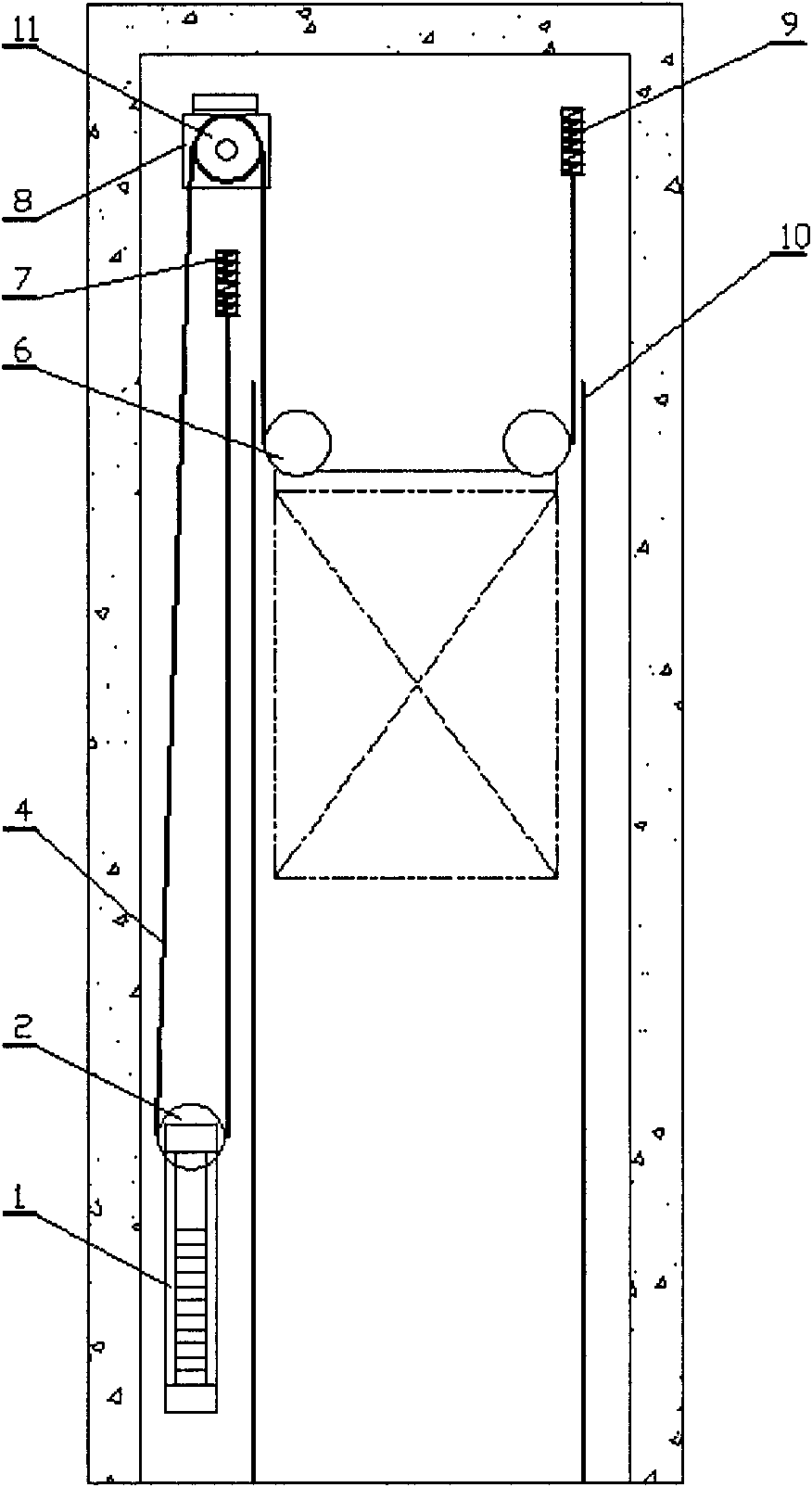

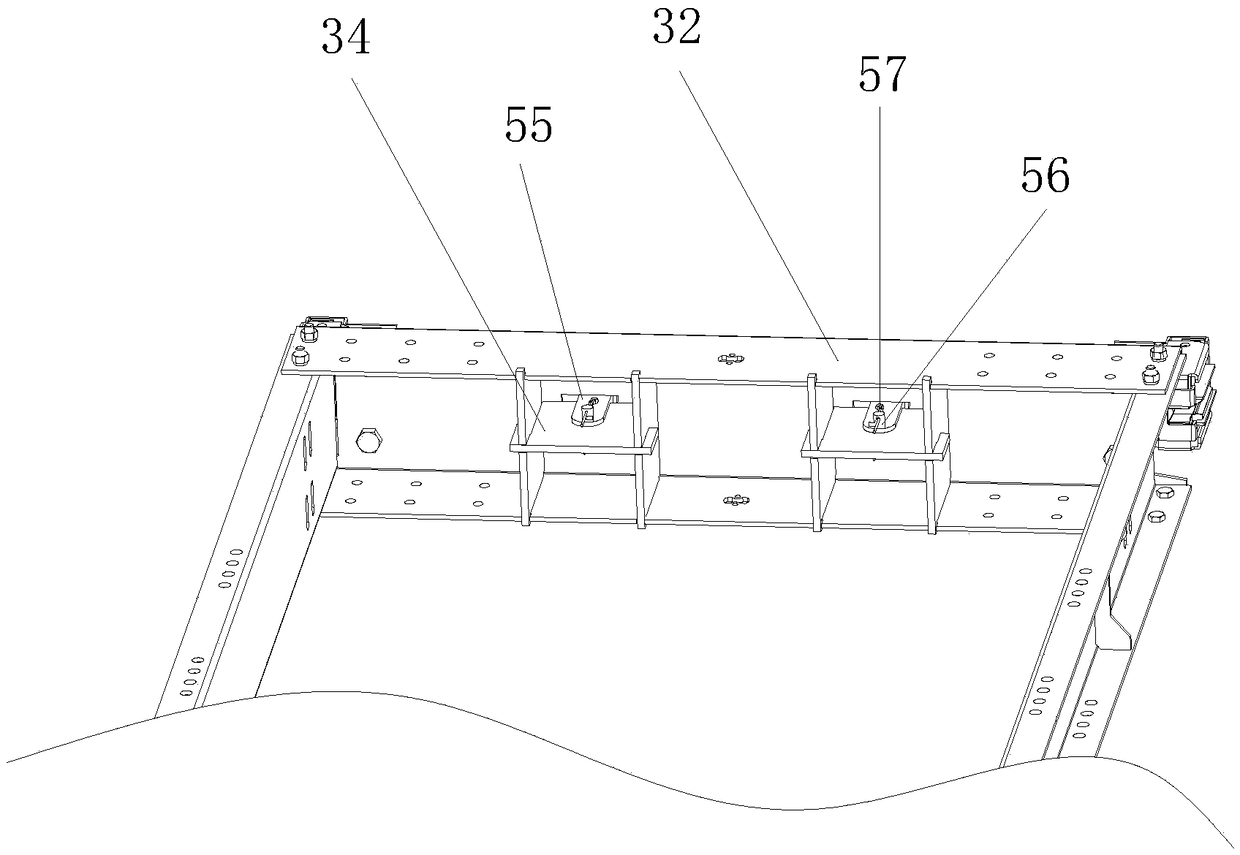

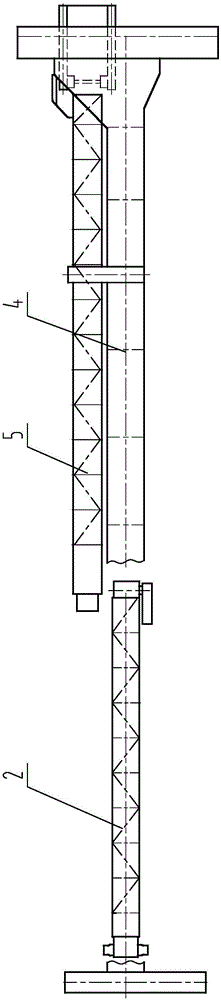

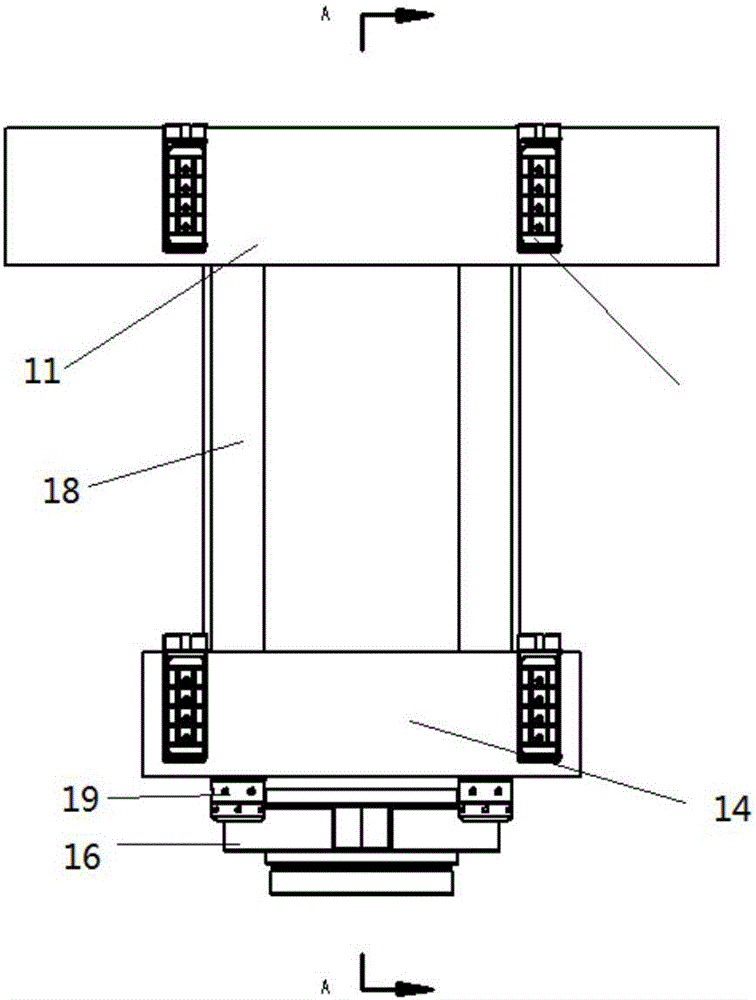

Elevator lower beam structure with car bottom wheels

InactiveCN105197730AEffectively fixedReduced Depth RequirementsBuilding liftsStructural engineeringControl theory

The invention discloses an elevator lower beam structure with car bottom wheels. The elevator lower beam structure comprises a car frame lower beam (1), and two car bottom wheel fixing seats (6) distributed at the two ends of the car frame lower beam (1) are arranged at the bottom of the car frame lower beam (1). The car bottom wheels are arranged on the car bottom wheel fixing seats (6) respectively. One end of an axle of each car bottom wheel (2) is fixed to the corresponding car bottom wheel fixing seat (6), and the other ends of the axles are fixed to the bottoms of car bottom wheel supporting pieces (4). A buffer plate (3) is fixed to the middle of the bottom of the car frame lower beam (1). The car bottom wheel fixing seats (6) are of a hollow structure, and safety tongs (5) are arranged in the car bottom wheel fixing seats (6). Notches corresponding to tong openings of the safety tongs (5) are formed in the upper ends and the lower ends of the car bottom wheel fixing seats (6). The elevator lower beam structure is simple, high in space utilization rate and small in occupied height, and therefore the requirement of an elevator for pit depth can be reduced, and then civil engineering cost is reduced.

Owner:SICHER ELEVATOR

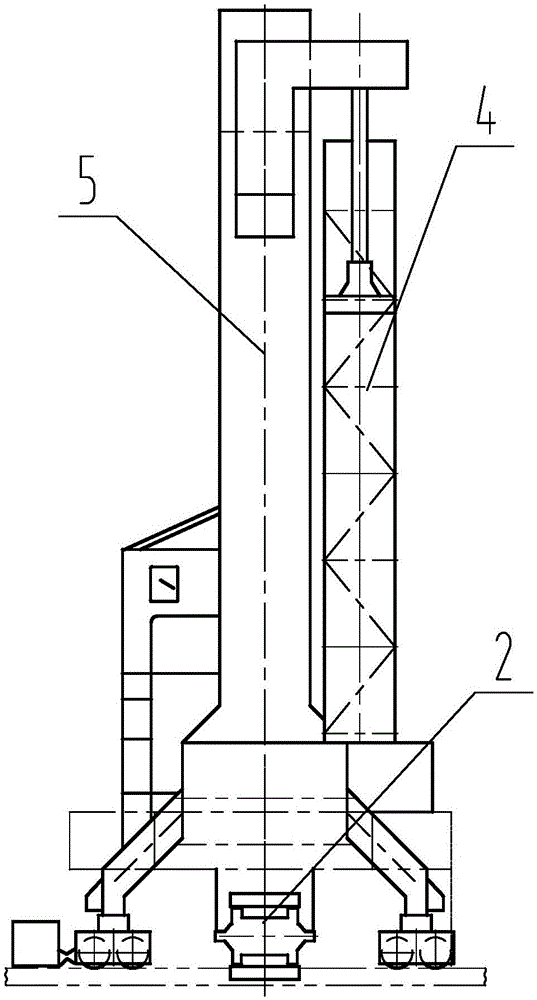

All-door-type double-hoisting-point scraper reclaimer

An all-door-type double-hoisting-point scraper reclaimer applied to the field of steel and cement port bulk cargo storage yard equipment comprises a swing end traveling mechanism, an auxiliary scraper conveying system, an auxiliary scraper winch system, a portal, a main scraper conveying system, a main scraper winch system, a fixed end traveling mechanism, a guiding groove, a micro-positive-pressure control chamber and a connecting rod mechanism. The swing end traveling mechanism is composed of a ball hinge, a swing end beam, a first wheel set, a first driving device, a first horizontal wheel blocking device and a first hydraulic rail clamping device. A lower supporting base of the ball hinge is welded to the swing end beam. An upper supporting base of the ball hinge is welded and fixed to the portal. The wheel set is connected with the swing end beam through high-strength bolts. The first driving device is assembled and installed on the first wheel set in a manner of a hollow shaft, a torsion arm and a locking disk. The all-door-type double-hoisting-point scraper reclaimer can be used in cooperation with an adhesive tape conveyor for work, work efficiency is improved, and equipment manufacturing cost is reduced; and the all-door-type double-hoisting-point scraper reclaimer is high in reclaiming rate, large in span, environment-friendly, large in application range, compact in structure, low in weight, flexible in control and capable of achieving automation.

Owner:NORTHERN HEAVY IND GRP CO LTD

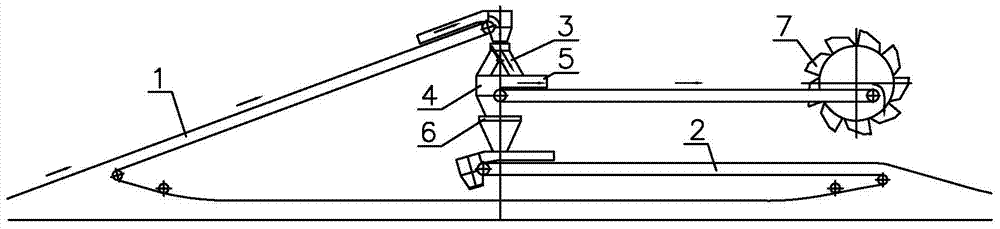

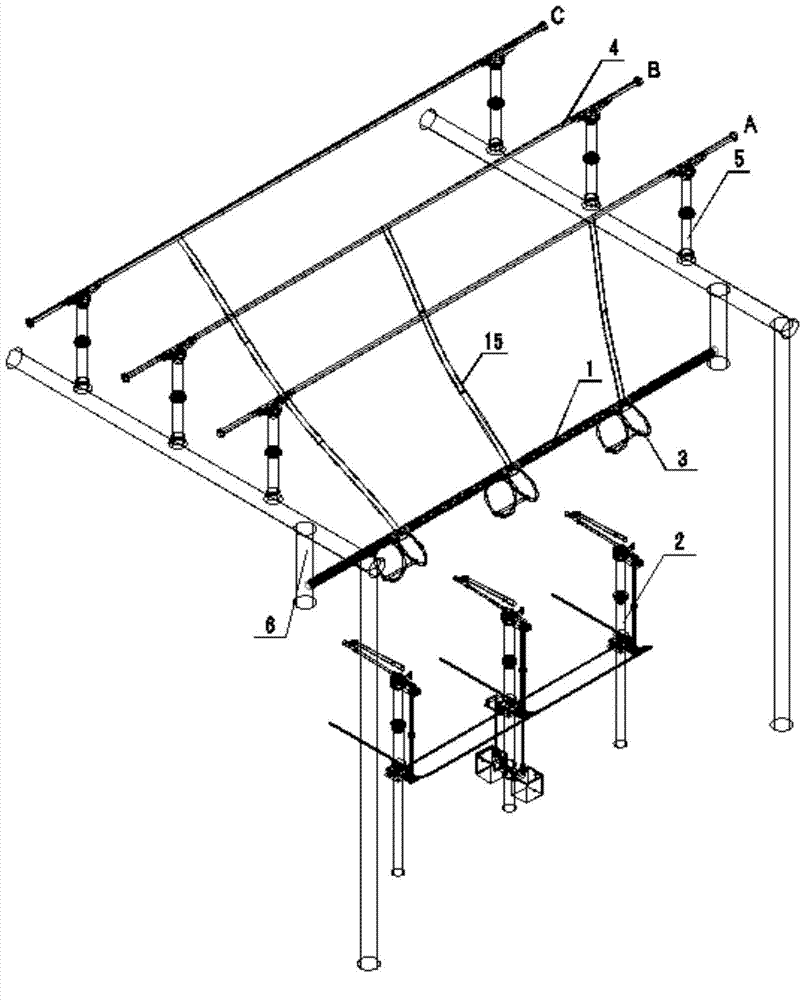

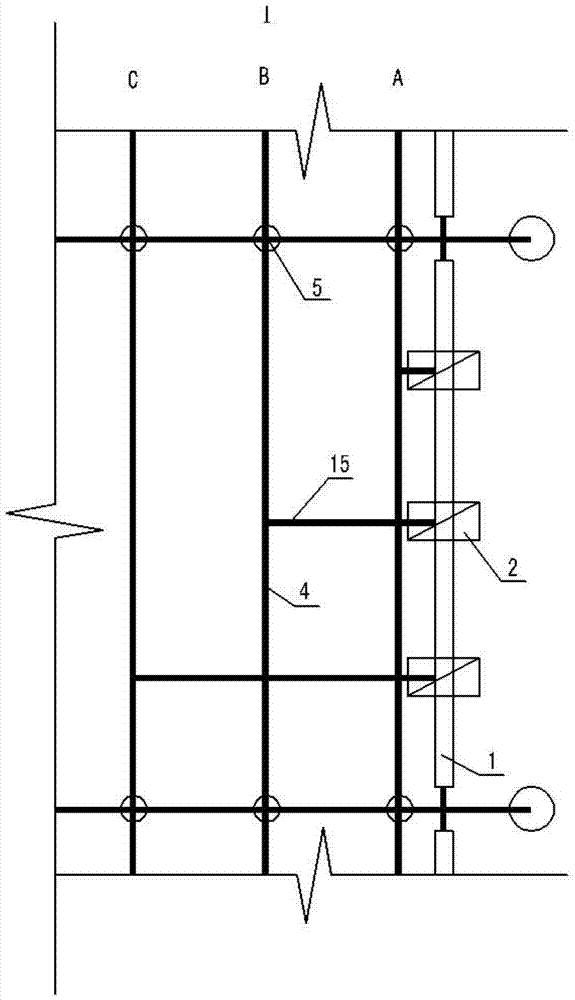

Three tail trolleys fixed in staggered mode and arranged on arm type bucket-wheel stacker-reclaimer and material taking method thereof

The invention discloses three tail trolleys fixed in a staggered mode and arranged on an arm type bucket-wheel stacker-reclaimer, and a material taking method of the three tail trolleys fixed in the staggered mode and arranged on the arm type bucket-wheel stacker-reclaimer. Included angles exist between the tail trolley II and the horizontal ground and between the tail trolley III and the horizontal ground respectively, the tail trolley II and the tail trolley III are arranged in an inclined mode relative to the horizontal ground, an included angle exists between the tail trolley I and the horizontal ground, the tail trolley I is arranged in an inclined mode relative to the horizontal ground, the bottom portion of the tail trolley I, the head portion of the tail trolley II and the head portion of the tail trolley III are located in the same vertical straight line, a tail trolley II head portion funnel device is arranged on the top of the tail trolley II, and a tail trolley I head portion funnel device is arranged on the top of the tail trolley I. According to the three tail trolleys fixed in the staggered mode and arranged on the arm type bucket-wheel stacker-reclaimer and the material taking method of the three tail trolleys fixed in the staggered mode and arranged on the arm type bucket-wheel stacker-reclaimer, a single machine can pile supplied materials to material fields in two directions, achieve direct connection of the supplied materials in two directions, transport the taken materials in two directions and achieve two-direction supplied material diversion on a ground belt conveying belt by controlling the running direction of the ground belt conveying belt, the position of an interior movable plate of a bifurcate funnel device I, and the position of an interior movable plate of a bifurcate funnel device II, and therefore the technical capacity of an enterprise is improved, new functions are added to single machine equipment, various requirements of users are met, and the market competitiveness of products of the enterprise can be remarkably improved.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction

ActiveCN103848542BSolve the problem that phosphorus cannot be removed by using aloneReduce pool capacityMultistage water/sewage treatmentFiberWastewater

The invention discloses an advanced wastewater treatment technology for sewage treatment and upgrading and reconstruction. The advanced wastewater treatment technology is a combined technology of an efficient settling basin and a riser fiber filter cloth filter tank added between a secondary sedimentation tank and a disinfecting tank of the original process of a sewage treatment plant; an efficient sedimentation tank is composed of two modules of a quick mixing region and an efficient sedimentation region; a FeCl3 chemical is fed to the quick mixing region so as to be agitated to react with sewage; the adding amount of the FeCl3 chemical is 5-8mg / L; the standing time of the quick mixing region is 1.5-2 minutes; the standing time of the efficient sedimentation region is 15-20 minutes; the standing time of the riser fiber filter cloth filter tank is 8-12 minutes; effluent of the secondary sedimentation tank is firstly processed by the efficient sedimentation tank, and then processed by the riser fiber filter cloth filter tank, finally achieves the first level A of discharge standard for sewage treatment after passing through the disinfecting tank. By adopting the advanced wastewater treatment technology, the problems that the efficient sedimentation tank process is independently used, so that effluent SS is unstable, and the filter cloth filter tank is independently used and thus phosphorus cannot be removed are effectively solved, a flocculating agent does not need to be excessively fed again, the dosing cost is greatly reduced, and fouling on an online monitoring instrument probe caused by feeding polyacrylamide (PAM) is avoided.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

Combined arrangement structure of four outlets of dust remover and rear smoke and air systems of two rows of induced draft fans for power plant

The invention relates to a combined arrangement structure of four outlets of a dust remover and rear smoke and air systems of two rows of induced draft fans for a power plant. The combined arrangement structure comprises the four outlets of the dust remover, an induced draft fan structure, a desulfurizing absorption tower, a wet electric dust remover and a chimney, wherein the induced draft fan structure is a two-row induced draft fan structure which is composed of two induced draft fans, and every two outlets of the dust remover are connected with an air inlet of one induced draft fan; air outlets of the two induced draft fans are connected with an air inlet of the desulfurizing absorption tower, and an air outlet of the desulfurizing absorption tower is connected with an air inlet of the chimney through the wet electric dust remover; the desulfurizing absorption tower is of a vertical structure, an air inlet of the desulfurizing absorption tower is formed in the lower portion of the side wall, and the air outlet of the desulfurizing absorption tower is formed in the top; the induced draft fan structure and the four outlets of the dust remover are located between the desulfurizing absorption tower and the chimney, the induced draft fan structure is located below the four outlets of the dust remover, the wet electric dust remover is located above the four outlets of the dust remover, a wet electric dust remover structure is located over the induced draft fans, the outlets of the dust remover are horizontally arranged, an air inlet of the induced draft fan structure is vertically arranged, and an air outlet of the induced draft fan structure is horizontally arranged. The combined arrangement structure is low in cost, small in occupied area, and good in operating effect.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Kitchen wastewater treatment device and treatment method

PendingCN110540342ASmall footprintAchieve relocationFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesFlocculationSmall footprint

The invention discloses a kitchen wastewater treatment device which comprises a pretreatment zone, an anaerobic tank, a dosing device and a main treatment zone, wherein a first pH value adjusting tank, a flocculation basin, an air floating water outlet tank and a second pH value adjusting tank of the pretreatment zone are distributed close to the outer side of an air floating reaction tank; and aprimary anoxic pond, a primary aerobiotic pond, a secondary anoxic pond and a secondary aerobiotic pond of the main treatment zone are sequentially arranged. The invention further discloses a kitchenwastewater treatment method. The kitchen wastewater treatment device can be easily arranged in a same reaction tank, is compact in structure, reasonable in arrangement, easy in wastewater treatment device integration, small in floor space and possible in overall movement, transfer and hoisting and is low in civil engineering cost and convenient and rapid to mount because of a pry block mounting mode.

Owner:UNIVERSAL ENVIROMENTAL PROTECTION EQUIP YIXING CITY

Water-circulated fishery multi-functional pond

InactiveCN111034666AGood purification effectGood water qualityWater contaminantsWater aerationWater trapWater use

The invention relates to a fishery breeding device, in particular to a water-circulated fishery multi-functional pond which can purify water quality and enable water to be circulated for use. A communicating pipe which communicates with an inner bin and is near the bottom of the inner bin is arranged on the hopper wall of a conical hopper, and a sewage collecting and precipitating bin is arrangedat the bottom of the conical hopper; a circulating water pump is arranged outside a pond body, a water inlet pipe of the circulating water pump communicates with the bottom of the inner bin, and a water outlet pipe communicates with the upper part of the pond body; and biological fillings are arranged in the inner bin. According to the water-circulated fishery multi-functional pond disclosed by the invention, in the breeding process, excrement and urine of aquatic products and feed residues slide downwards into the sewage collecting and precipitating bin along the conical hopper; besides, water in the inner bin is circulated into the pond body from the water outlet pipe by the circulating water pump, because the water outlet direction is tangent to the inner wall of the pond body, the water can be pushed to move to form a whirlpool, and sewage collection is convenient; and in addition, the biological fillings are also arranged in the inner bin and can achieve better purifying effects on the water quality, so that the circulated water quality is well maintained, and growth of the aquatic products is convenient.

Owner:南京太心动信息技术有限公司

Multifunctional vertical metal extruding machine

The invention discloses a multifunctional vertical metal extruding machine and belongs to the field of pressure machining forming equipment for metals. The machine comprises a main cylinder, a bearing rack, a moving workbench, a supporting seat and a guiding unit; the bearing rack comprises four vertical stand column beams arranged symmetrically as well as an upper semi-circular beam and a lower semi-circular beam which are located at two ends of each vertical stand column beam; a taking port is further formed in the upper semi-circular beam; the main cylinder is close to lower parts of the four vertical stand column beams and comprises a main cylinder block and a main cylinder plunger located inside the main cylinder block; the main cylinder block is fixed on the ground through the supporting seat located around the vertical stand column beams; the bearing rack is driven the main cylinder plunger to move vertically; guidance is realized through the guiding unit; and the moving workbench is located at the top of the supporting seat and moves horizontally on the supporting seat. Operation conditions of the vertical extruding machine are improved with the discharging method adopted by the extruding machine, the construction cost is reduced, and multiple technologies can be completed on one machine.

Owner:TSINGHUA UNIV

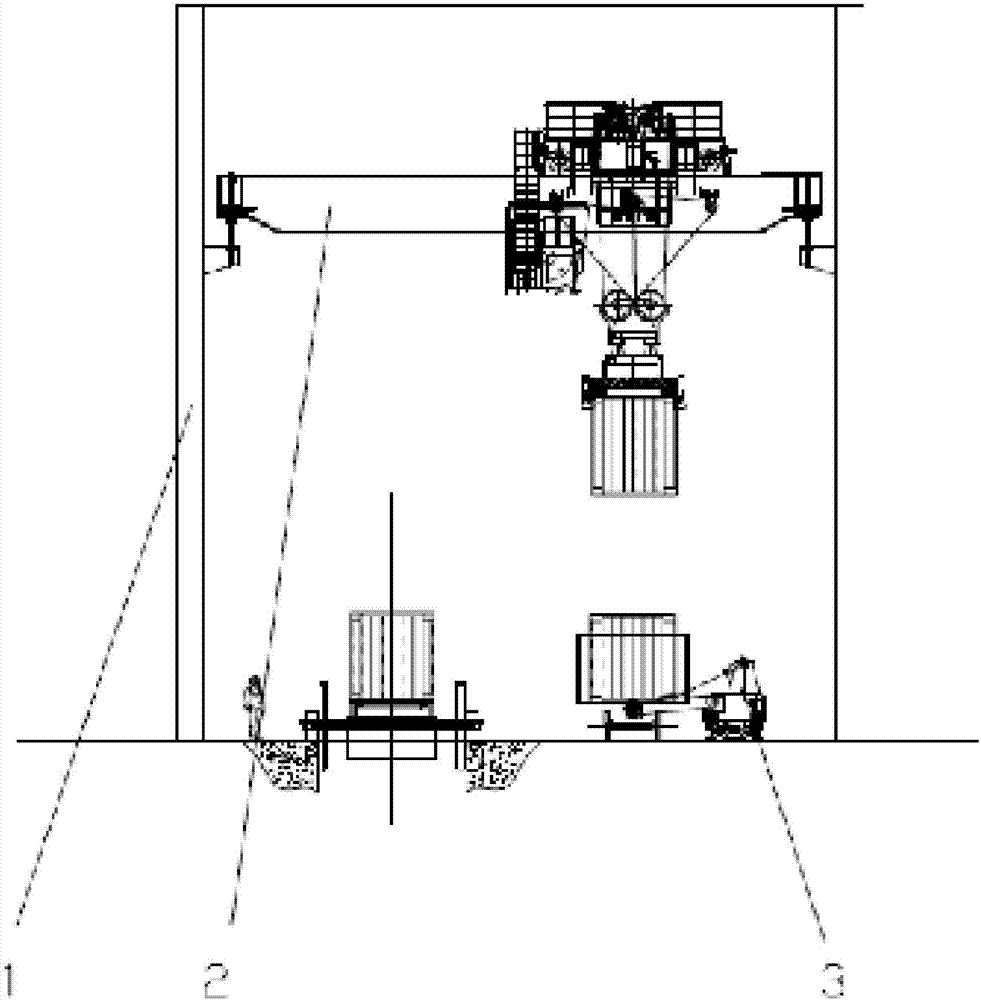

Railway transportation container unloading system with shunting equipment

PendingCN106865277AAvoid layoutReduce civil costLoading/unloadingStorage devicesContainer craneEngineering

The invention discloses a railway transportation container unloading system with shunting equipment. The railway transportation container unloading system comprises a railway vehicle, a container crane, a container tipping machine and a shunting locomotive which are arranged on a railway transportation line; the container tipping machine is fixedly mounted at one side of the railway transportation line; the shunting locomotive is located at the other side of the railway transportation line; and the container crane is mounted above railway transportation line and the container tipping machine. Train sets are dragged to an unloading point by the shunting locomotive, and containers are hoisted to the upside of the container tipping machine by the container crane so as to be tipped. The railway transportation container unloading system has the beneficial effects that the train sets are subjected to shunting operation by the shunting locomotive, and the container crane only needs to move within a small range, so that arranging equipment on the whole length of the train sets is avoided; and the container tipping machine is fixedly arranged on the ground, so that the cost is greatly reduced. The system is safe and reliable, compact and efficient, appropriate in cost, high in adaptability and wide in popularization and application space.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Bilateral plow unloader with material dividing function

InactiveCN103587935ASimple structureReduce civil construction costs and operation and maintenance costsConveyor partsPlowshareEngineering

The invention relates to an unloader, in particular to a bilateral plow unloader with a material dividing function, and belongs to the technical field of logistics equipment. The unloader comprises an unloader body, a fixed plowshare, a moving plowshare, a transmission mechanism and a driving mechanism. The unloader body is fixedly connected to the fixed plowshare, the fixed plowshare and the moving plowshare are connected through the transmission mechanism, and the upper end of the transmission mechanism is connected to the driving mechanism. The lower end of the fixed plowshare is provided with a discharging gate. By the aid of the unloader, according to the actual requirements, after the width of the conveyor belt of a conveyor and the unloading capability of the conveyor are determined, the specification of the unloader body is determined; the specification of the moving plowshare can be determined to realize material division with various proportions according to the requirements of the actual material dividing proportion; a belt-type conveyor can further divide the material during conveying, so that conveying lines can be switched according to the conveying design requirements or the proportion, and material can be conveyed to two conveying lines.

Owner:无锡华九机械设备有限公司 +1

Fault alarm non-return drainage system and non-return drainage method

ActiveCN111677081ASolve the problem of failureFailure guaranteeLevel controlSewerage structuresControl systemCheck valve

The invention relates to a fault alarm non-return drainage system and non-return drainage method, belongs to the technical field of building water supply and drainage, and solves the problem that backward flowing cannot be prevented when an existing gravity drainage system is applied to basement drainage. The fault alarm non-return drainage system comprises a non-return valve, a non-return valve outer pipe, a fault monitor, a monitoring assembly and a control system; the monitoring assembly is used for monitoring the water level state in the non-return valve outer pipe; the control system comprises a controller and an alarm device; the controller is connected with the monitoring assembly and the fault monitor, the controller is used for receiving water level signals monitored by the monitoring assembly and information about whether the non-return valve breaks down or not monitored by the fault monitor and can judge whether the non-return valve breaks down or not, and an action instruction is sent to the non-return valve and the alarm device according to the information whether the non-return valve breaks down or not. The drainage system and the method can be applied to basement drainage, the problem that the drainage system fails due to the fact that the non-return valve mistakenly reports water blocking due to faults is solved, and the reliability of the drainage system is improved.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com