Bilateral plow unloader with material dividing function

A plow-type unloader and unloader technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increased civil construction costs, increased operation and maintenance costs, and inability to feed materials, achieving simple structure, reduced civil construction costs and The effect of operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0027] The orientation words such as width involved in this article are defined based on the incoming material direction of the material, and the incoming material direction is defined as the length direction and the direction perpendicular to the incoming material direction is the width direction. It should be understood that the orientation words used herein shall not limit the protection scope of this patent.

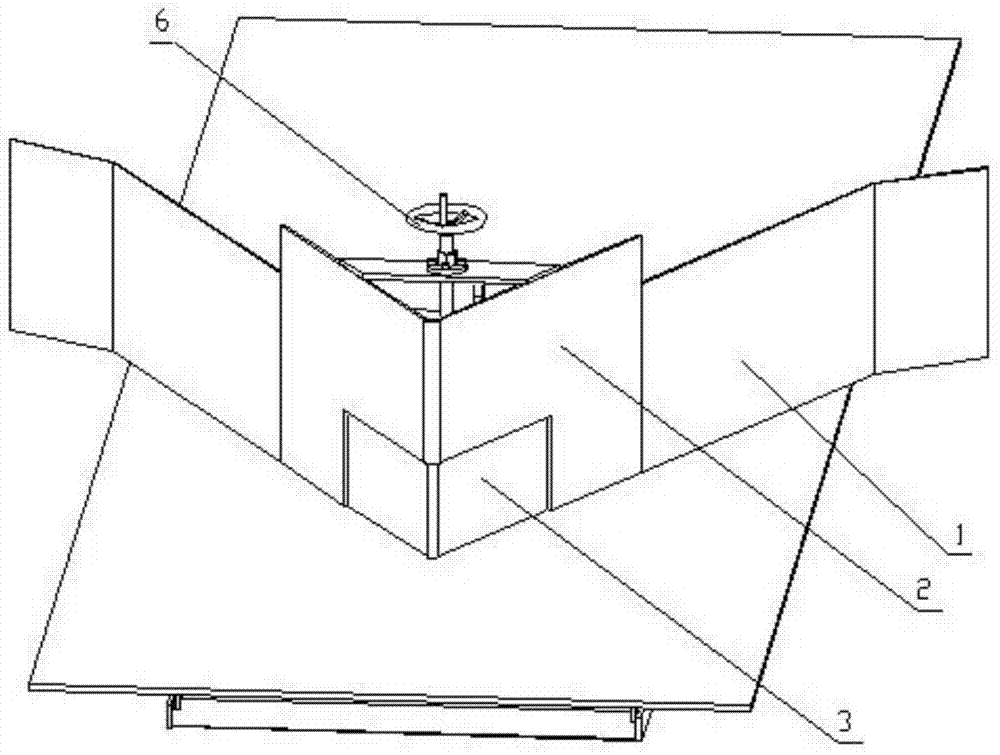

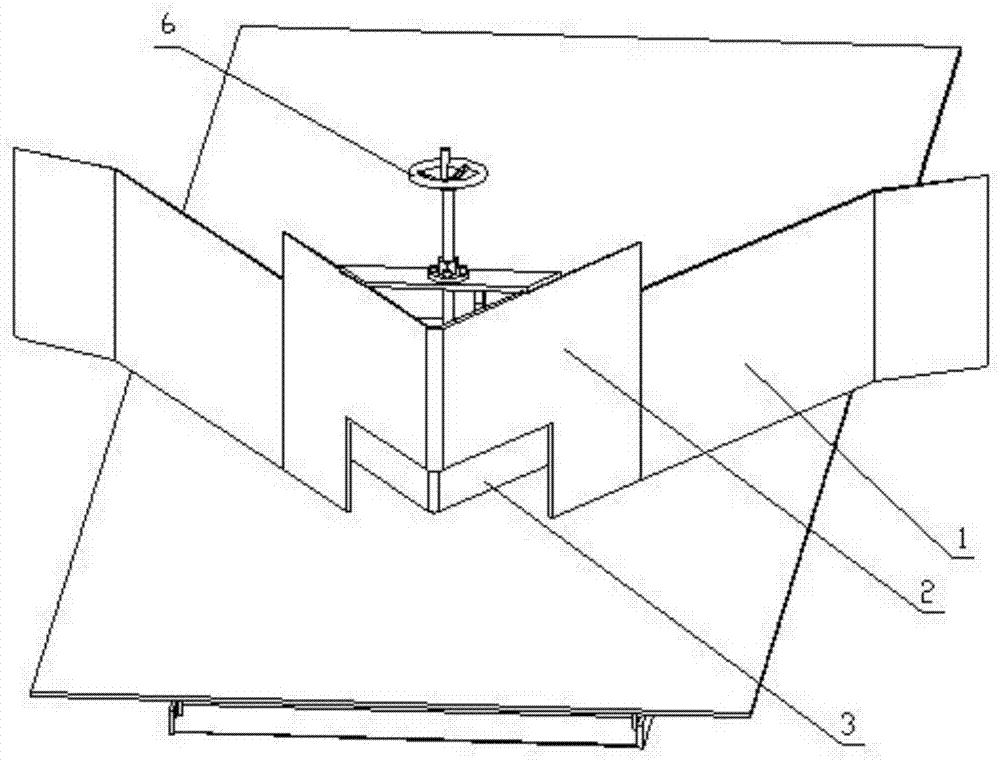

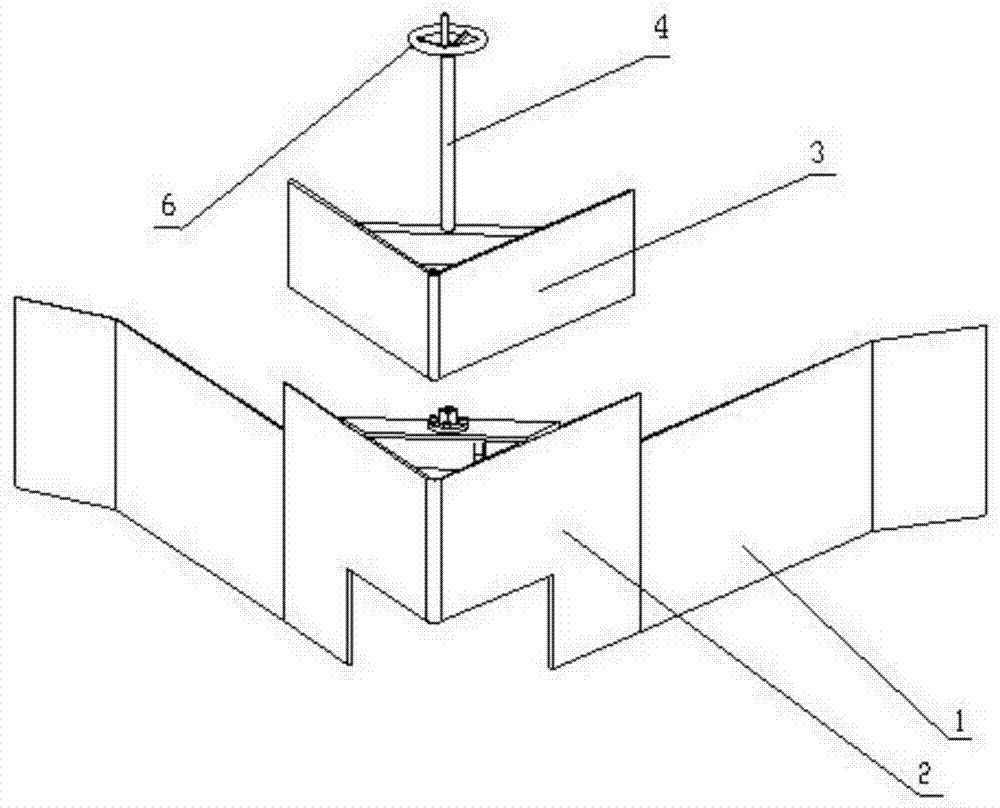

[0028] Such as Figure 1~6 As shown, the present invention mainly comprises unloader body 1, fixed plow share 2, movable plow share 3, transmission mechanism 4 and drive mechanism 6, is fixedly connected on unloader main body 1 and fixes plow share 2, and fixed plow share 2 and The movable plowshares 3 are connected by a transmission mechanism 4, and the upper end of the transmission mechanism 4 is connected with a driving mechanism 6.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com