Gas generation and storage integrated biomass pool

A biogas digester and gas storage technology, applied in the field of biogas digesters, can solve the problems of inability to move up and down, heavy workload, and harm to people entering, and achieve the effects of reducing the amount of on-site construction, adjusting the gas production, and reducing the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

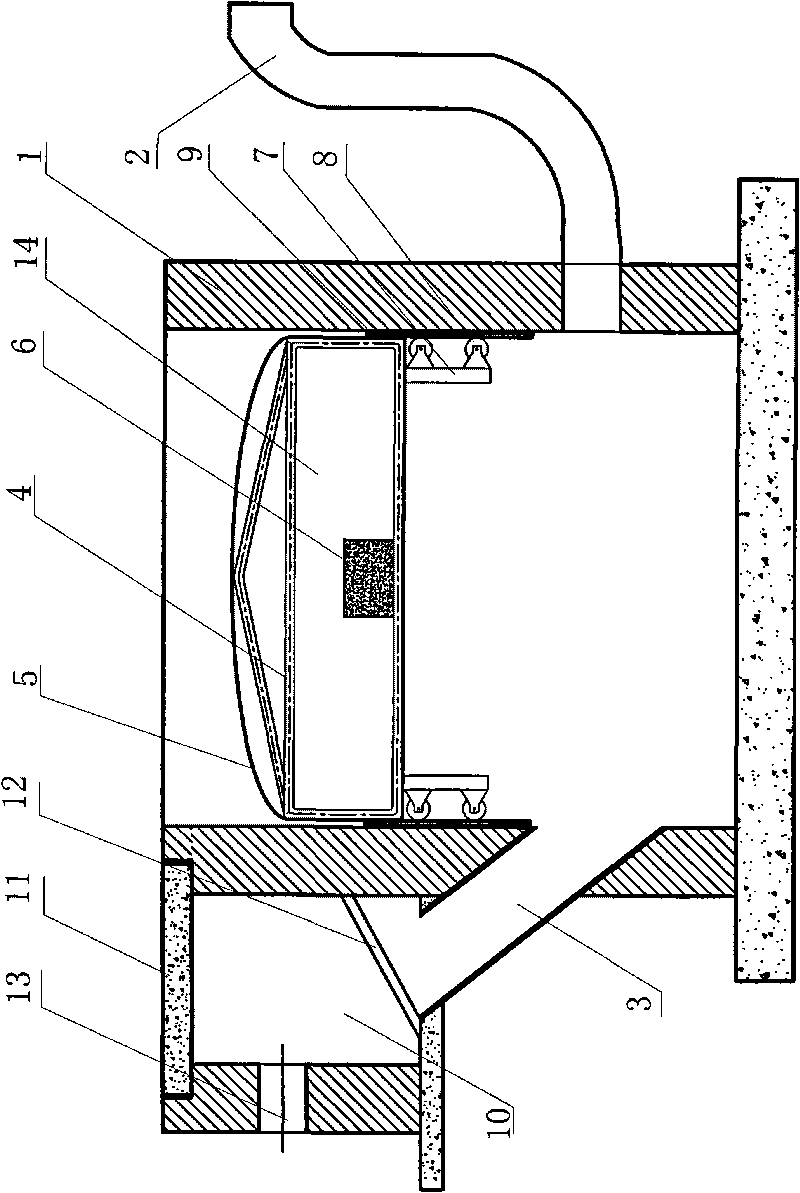

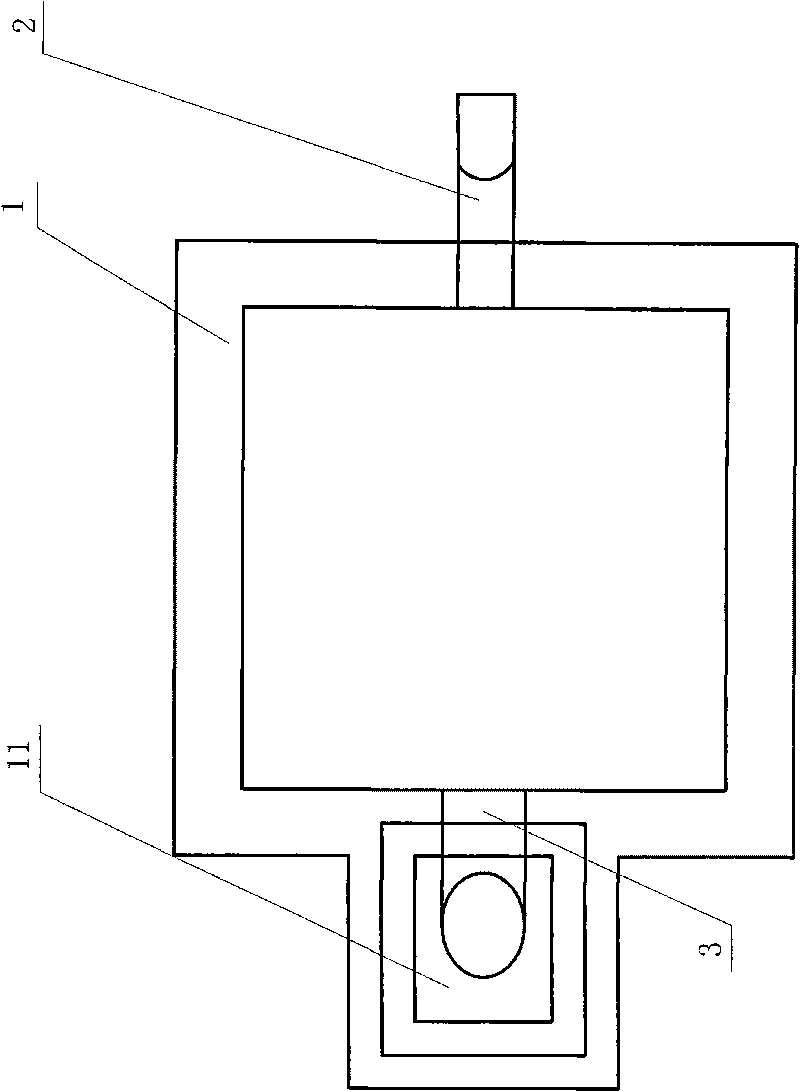

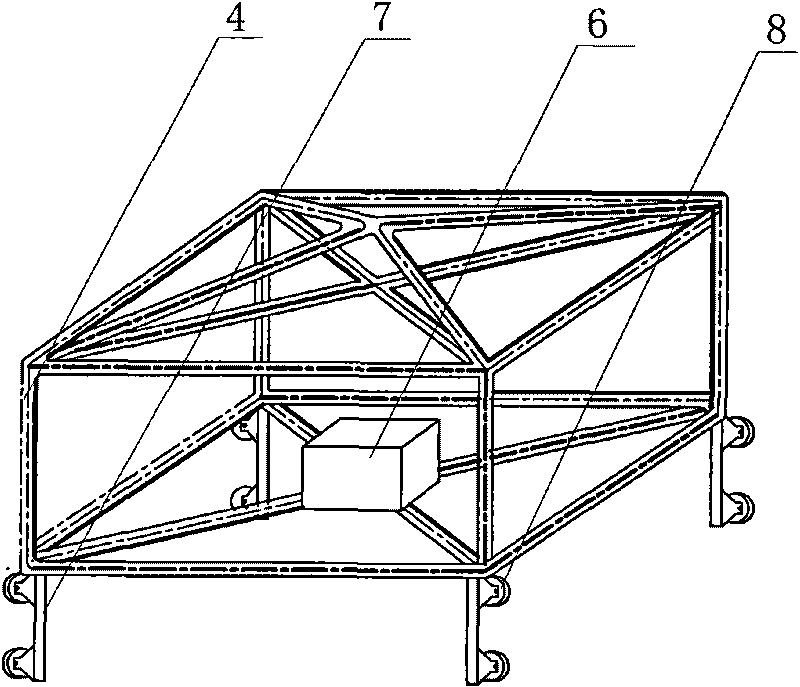

[0023] A biogas digester integrated with gas production and storage, such as figure 1 , figure 2 and image 3 As shown, the biogas digester body 1, the discharge water seal pipe 2, the inclined feed pipe 3, the counterweight 6, the pulley frame 7, the pulley 8, the sliding track 9, the feed well 10, the movable cover plate 11, the lattice Grid 12 and floating top cover 14, wherein floating top cover 14 is made up of sealed gas storage cover 5 and skeleton 4 (see figure 1 , image 3 ), the skeleton 4 is a cuboid, and the sealed gas storage cover 5 covers the surroundings and the top surface of the skeleton 4. The top surface of the skeleton 4 protrudes upwards, and the upper part of the sealed gas storage cover 5 covering the top surface of the skeleton 4 is arc-shaped, so that the strength is better. Counterweight 6 is housed in this framework 4 botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com