Automatic spill-proof cover

An anti-overflow and automatic technology, which is applied in the direction of anti-overflow, cooking utensil lids, kitchen utensils, etc., can solve the problems of increasing exhaust space, heat loss, energy waste, etc., and achieve the effect of increasing exhaust space and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

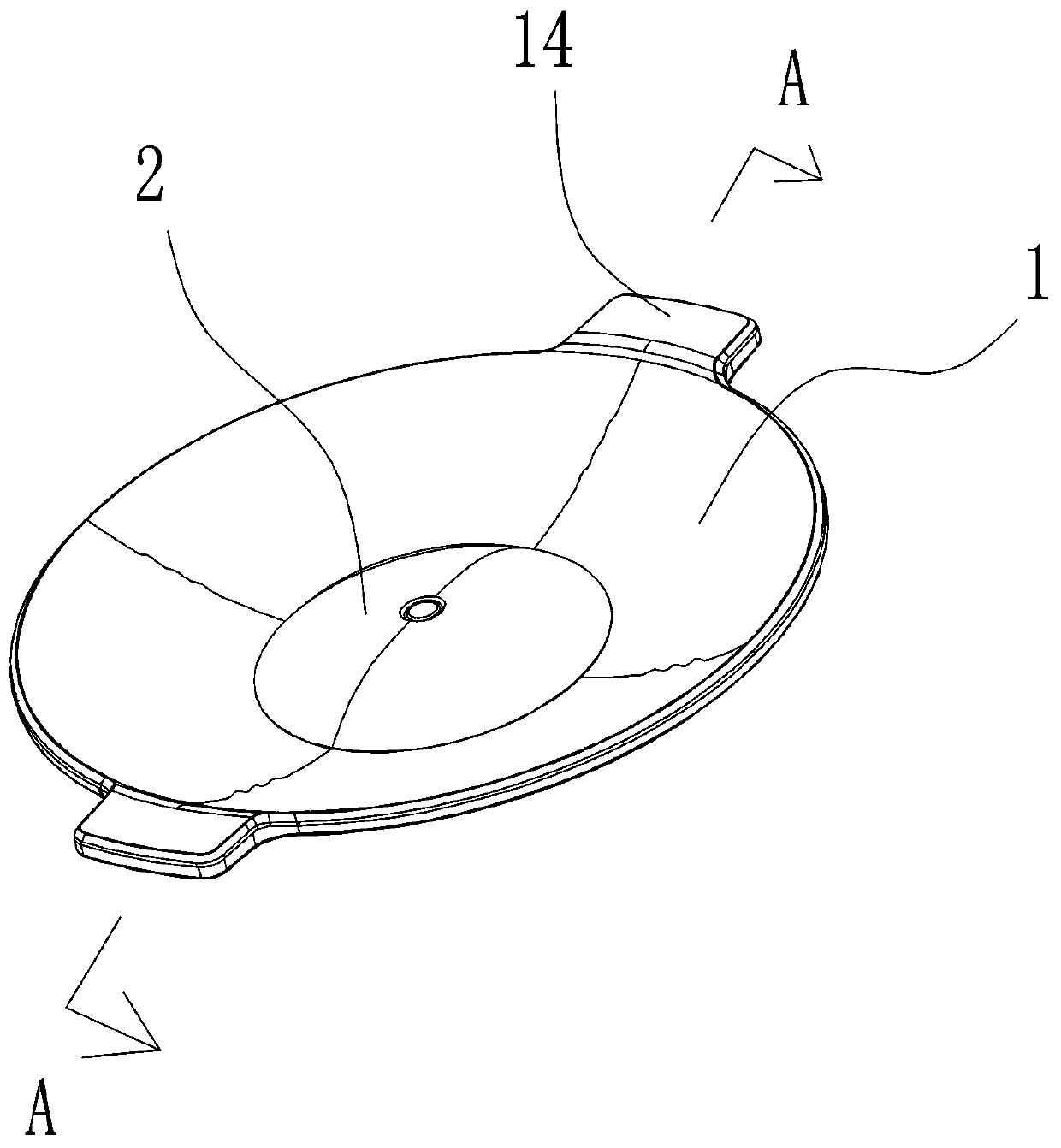

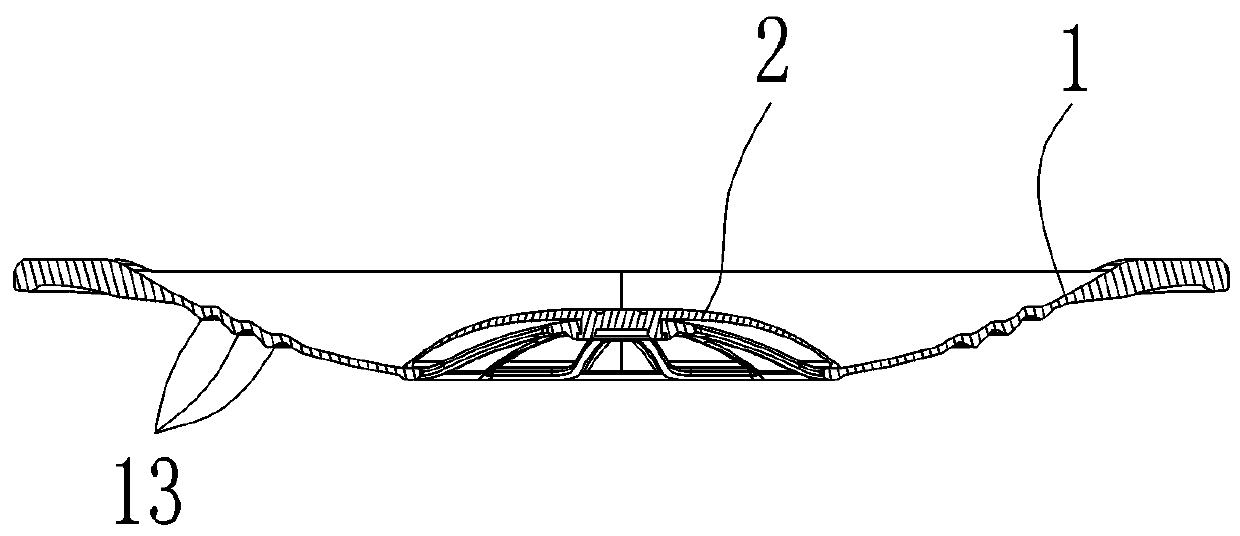

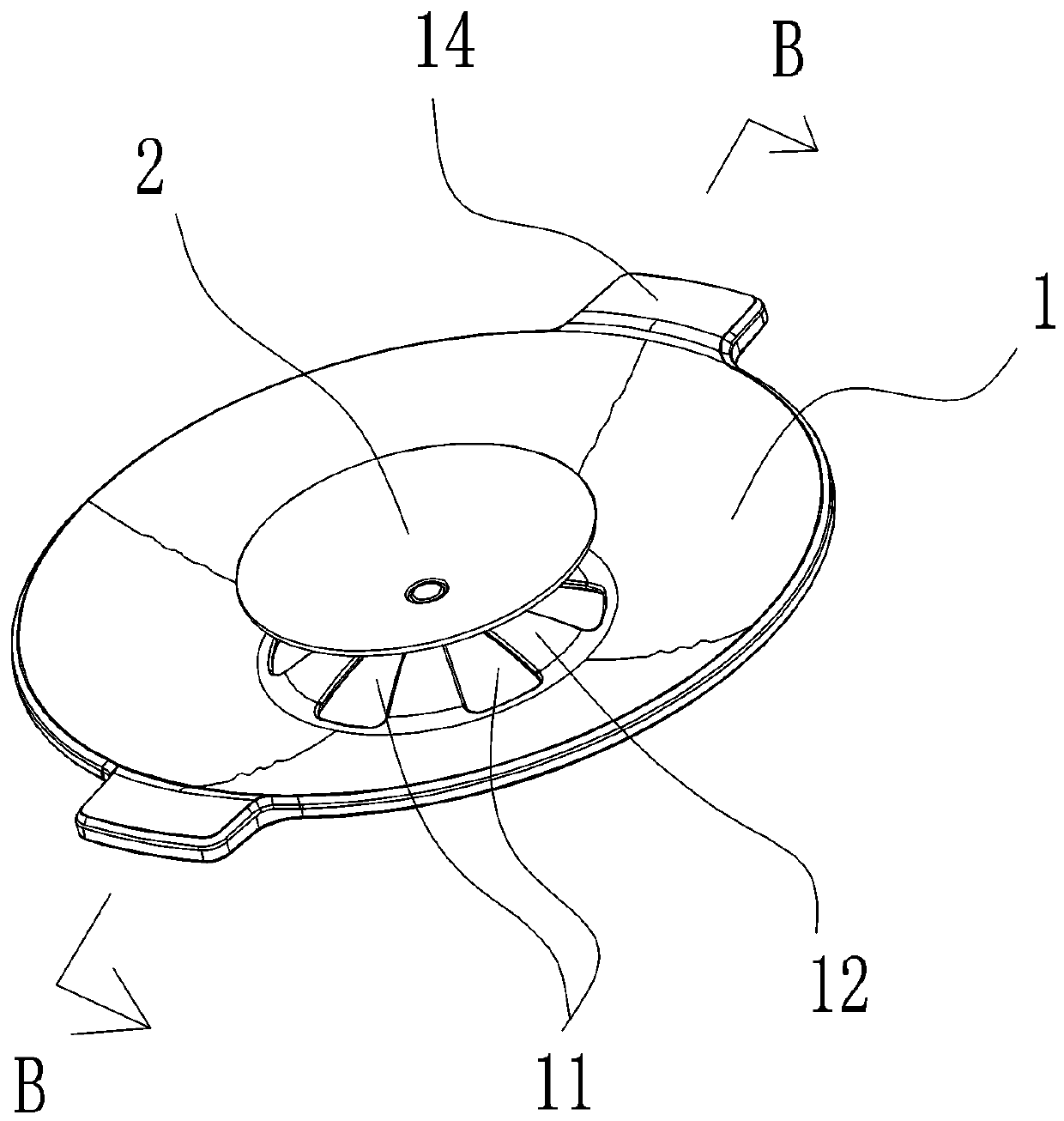

[0035] Such as Figure 1-6 As shown, the present embodiment provides an automatic anti-spill cover, which includes a pot cover body 1 and a cover 2, wherein the pot cover body 1 is a circular disc-shaped structure, and the cover 2 is a bowl-shaped structure, which is protected by an external force. , the bowl opening of the cover 2 can be deformed by switching between the downward and upward states. And the middle part of pot cover body 1 is provided with a plurality of exhaust outlets 11 that are arranged in a circle, and the middle part lower side of retaining cover 2 is connected with pot cover body 1 in the middle, and when the bowl mouth of retaining cover 2 faces down, retaining cover 2 covers On the upper side of all the exhaust ports 11 , and the edge of the cover 2 is in contact with the upper side of the main body 10 of the pot cover, so that a closed air storage space is formed between the cover 2 and the cover body 1 .

[0036]During use, the anti-spill cover is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com