Biogas collection and control equipment

A technology for controlling equipment and biogas collection, applied in the field of biogas collection, can solve problems such as unavailability of dead gas, and achieve the effect of increasing gas storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

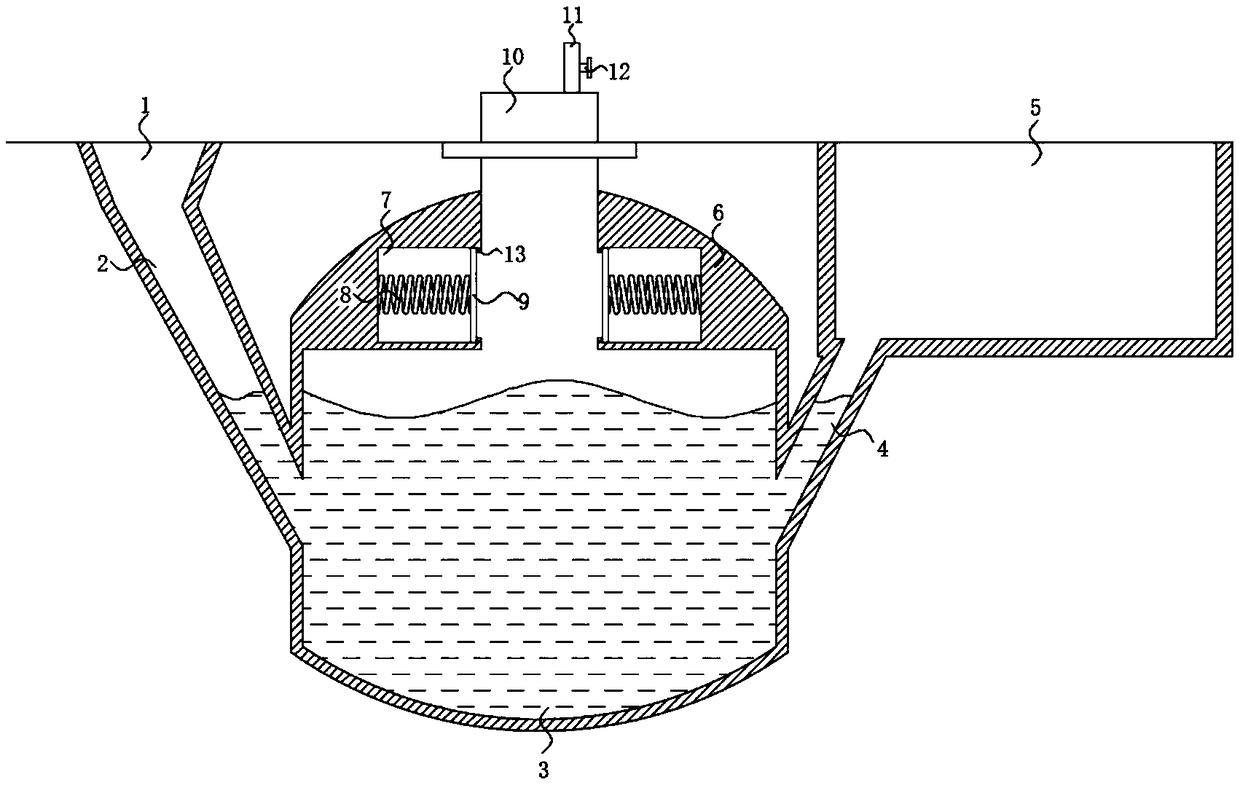

[0017] Such as figure 1 As shown, a biogas collection control device of the present invention includes a biogas fermentation tank 6, a biogas fermentation chamber 3 is provided in the biogas fermentation tank 6, a feed pipe 2 is installed at one end of the biogas fermentation tank 6, and the feed pipe 2 is connected to the biogas The fermentation chamber 3 is connected, the end of the feed pipe 2 away from the biogas fermentation tank 6 is equipped with a feed funnel 1, and the feed funnel 1 is connected with the feed pipe 2, and the end of the biogas fermentation tank 6 is equipped with a discharge pipe 4, and the outlet The material pipe 4 communicates with the biogas fermentation chamber 3, the end of the discharge pipe 4 away from the biogas fermentation tank 6 is installed with a collection box 5, and the collection box 5 is connected with the discharge pipe 4, and the top of the biogas fermentation tank 6 is equipped with a cover 10. An air outlet pipe 11 is installed on...

Embodiment 2

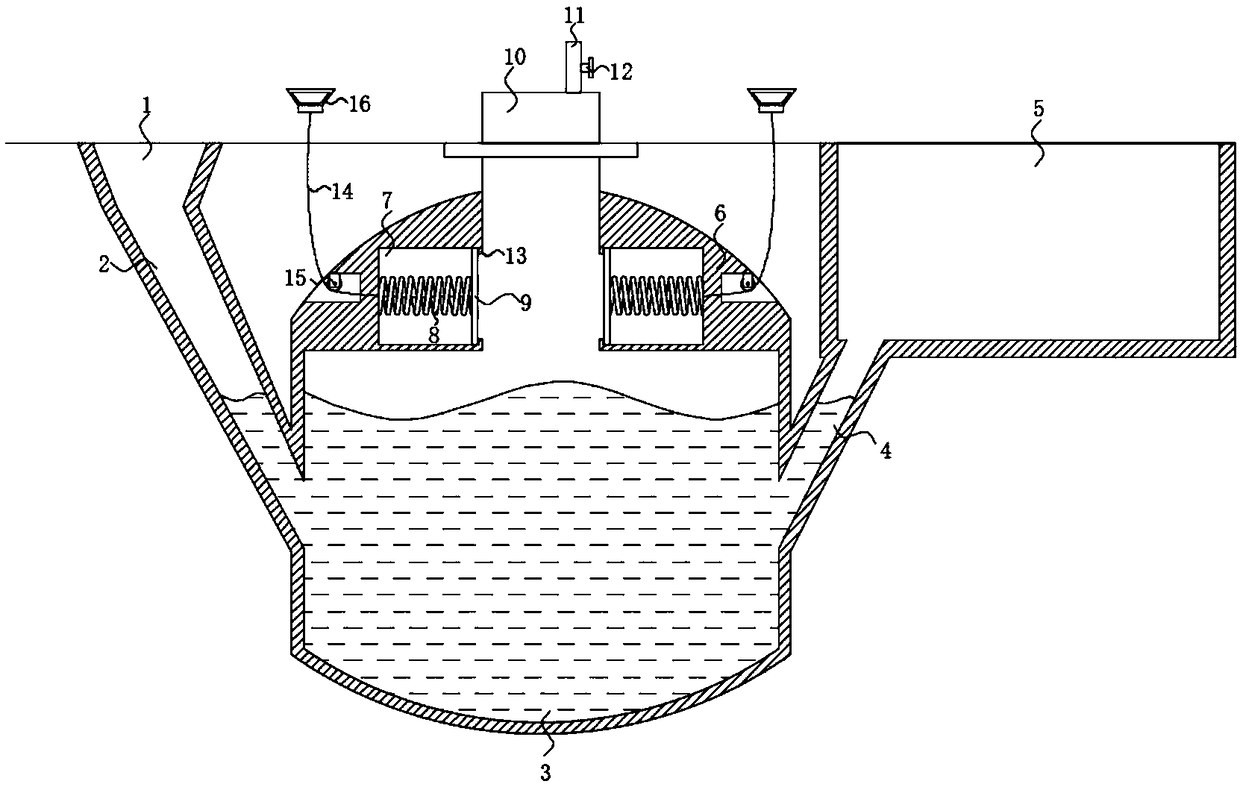

[0022] Such as figure 2 As shown, this embodiment adds a stay rope, a fixed pulley and a pull ring on the basis of Embodiment 1, thereby realizing the artificial regulation of the baffle 9 and increasing the flexibility of use. One end of the baffle 9 close to the cavity 7 is fixedly connected There is a stay rope 14, and the end of the stay rope 14 away from the baffle plate 9 runs through the biogas fermentation tank 6 and is fixedly connected with a pull ring 16. There is a slot on the biogas fermentation tank 6, and a fixed pulley 15 is installed in the slot, and the stay rope 14 passes through it. Over fixed pulley 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com