Full-function bucket-wheel stacker-reclaimer and material reclaiming method thereof

A bucket-wheel stacker-reclaimer and full-function technology, which is applied in the field of full-function bucket-wheel stacker-reclaimer and its reclaimer, can solve the problems of reduced stockyard utilization, huge equipment procurement costs, infrastructure construction costs, and increased operating costs and other issues, to achieve the effect of reducing civil construction costs, improving stockyard utilization, reducing equipment investment and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

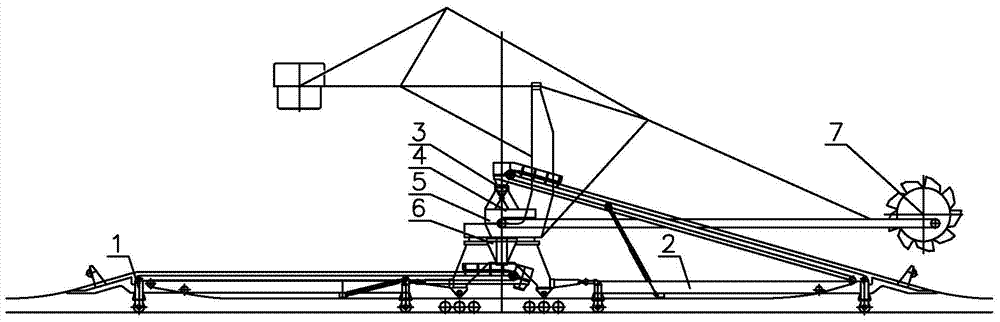

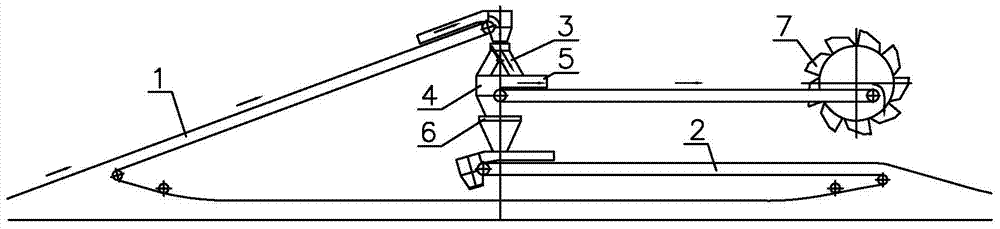

[0040] like figure 1 As shown, a full-featured bucket wheel stacker and reclaimer includes a main machine 7, a movable tail car device I1 and a movable tail car device II2 arranged on both sides of the main machine 7, a bifurcated funnel device 3, and a cantilever guide Groove device 4, inclined funnel device 5, center lower funnel device 6;

[0041] The bifurcated funnel device 3 is provided with a movable plate for adjusting the flow direction of the material, the bifurcated funnel device 3 is arranged above the cantilever chute device 4, and the cantilever chute device 4 is provided below the Described inclined funnel device 5, below described inclined funnel device 5 is provided with described center lower funnel device 6;

[0042] The head of the movable tail car device I1 is provided with a material guide groove I and a funnel I; the head of the movable tail car device II2 is provided with a material guide groove II and a funnel II;

[0043] When the movable tail car d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com