All-door-type double-hoisting-point scraper reclaimer

A technology of double hoisting points and reclaimer, applied in the directions of conveyor, transportation and packaging, can solve the problems of inability to meet the requirements of process reclaiming, increase the cost of equipment manufacturing, and the construction cost of the factory building, and achieve light weight, compact structure, cross-section, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

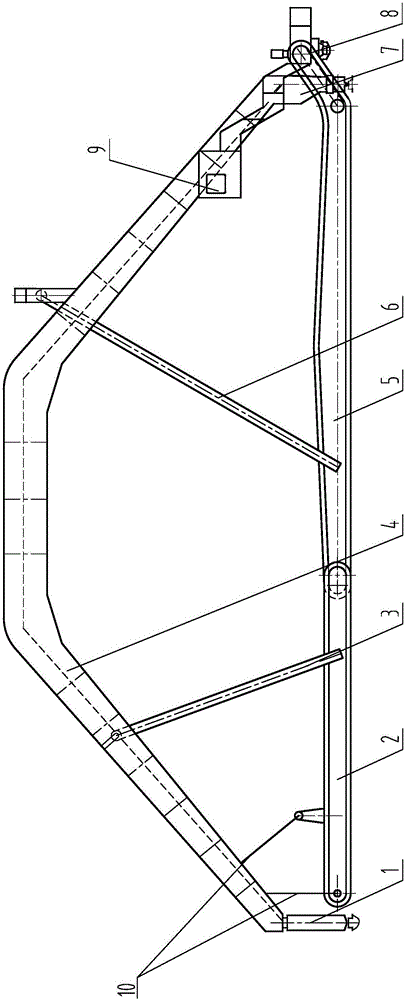

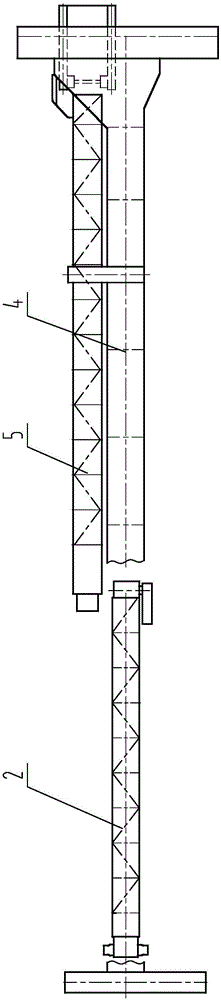

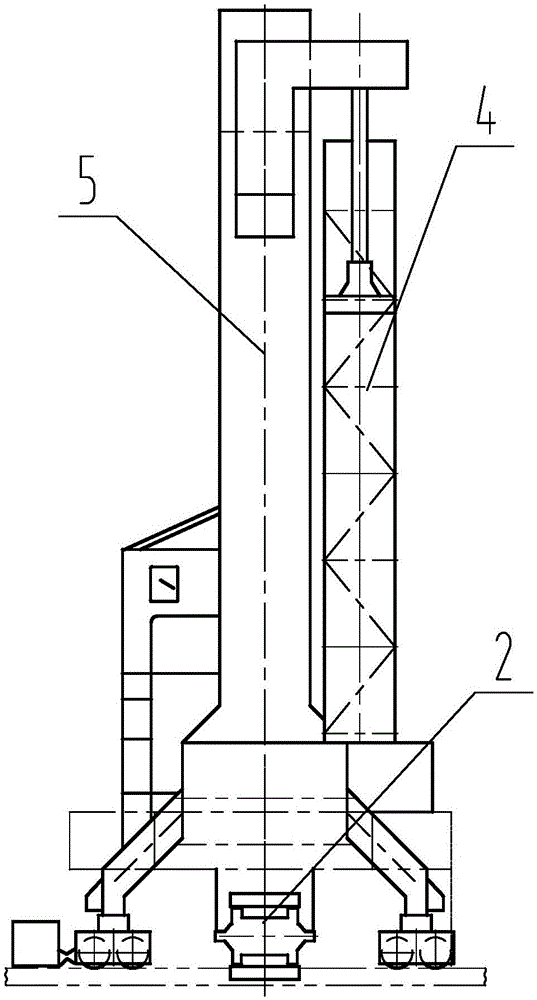

[0018]Referring to the accompanying drawings, a full-door double-suspension point scraper reclaimer includes a swing end traveling mechanism 1, an auxiliary scraper conveying system 2, an auxiliary scraper winch system 3, a door frame 4, a main scraper conveying system 5, Main scraper hoisting system 6, fixed-end traveling mechanism 7, material guide trough 8, micro-positive pressure control room 9, linkage mechanism 10, characterized in that: swing-end traveling mechanism 1 is composed of ball hinge 1-1, swing end beam 1-2, the first wheel set 1-3, the first drive device 1-4, the first horizontal stop wheel device 1-5, the first hydraulic rail clamp 1-6, the lower support of the ball joint 1-1 Welded on the swing end beam 1-2, the upper support of the ball joint 1-1 is welded and fixed to the door frame 4, the first wheel set 1-3 is connected to the swing end beam 1-2 through high-strength bolts, and the first driving device 1 -4 The hollow shaft torsion arm locking disc is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com