Fault alarm non-return drainage system and non-return drainage method

A fault alarm and drainage system technology, applied in waterway systems, alarms, sewage removal, etc., can solve problems such as check valve stuck and unable to reset in time, unable to prevent backflow, system failure, etc., to improve work safety and reliability. , The effect of convenient installation and reduced initial investment during construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

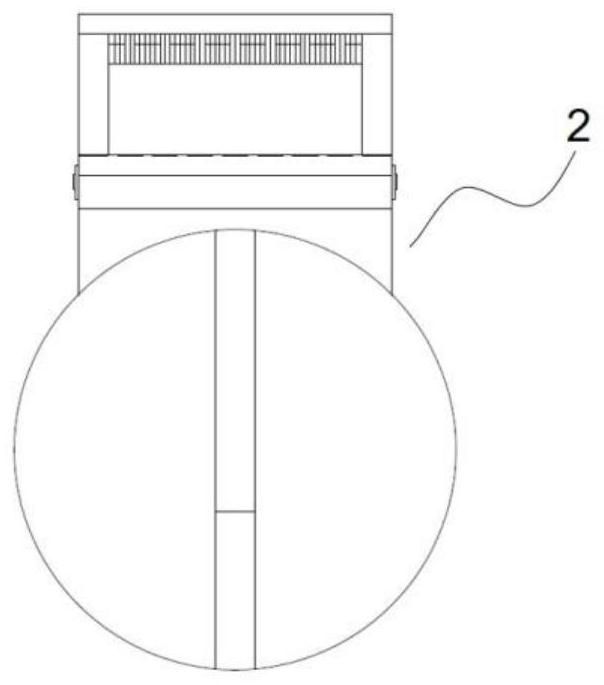

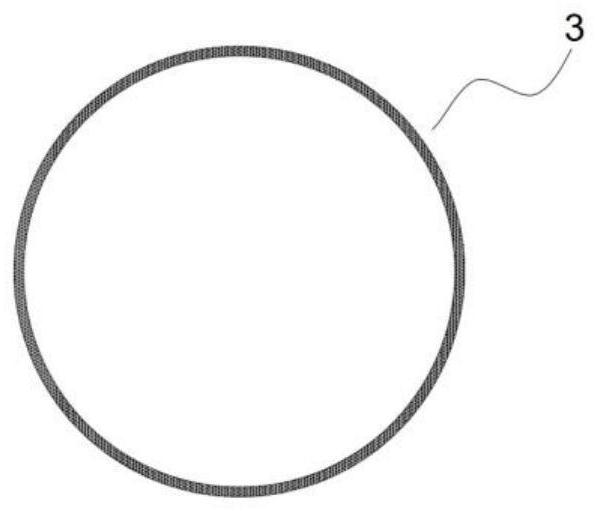

[0070] A specific embodiment of the present invention discloses a drainage check system, such as Figure 24 to Figure 28 As shown, including check valve 101, check valve outer tube 5 and outer tube cover 6; wherein, check valve 101 is located in check valve outer tube 5, check valve outer tube 5 is divided into upstream cavity and For the downstream cavity, the check valve 101 can be opened under the impact of upstream water flow or controlled by external force, so that the upstream cavity can communicate with the downstream cavity, and the check valve 101 can be closed under the control of its own gravity or external force, so that the upstream cavity can communicate with the downstream cavity. The downstream cavity is sealed and separated; the outer tube cover 6 is detachably arranged on the outer tube 5 of the check valve, and the outer tube cover 6 is opened for maintenance or replacement of the check valve 101 .

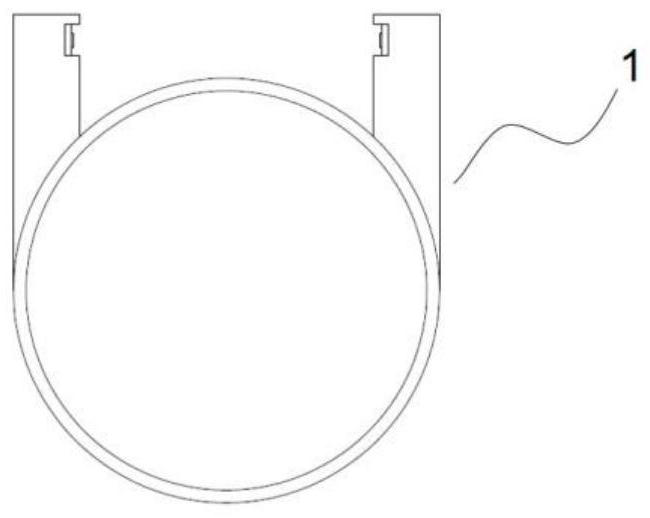

[0071] In this example, if Figure 1 to Figure 3 As shown...

Embodiment 2

[0109] Considering that only one check valve 101 is installed in the drainage check system, once the check valve 101 fails, if the rear end of the check valve 101 is blocked by foreign matter, the drainage check system cannot work normally, and it is difficult to maintain when the drainage is large. The working stability of the drainage check system is poor.

[0110] Based on the above problems, another specific embodiment of the present invention discloses a double check drainage system on the basis of the common drainage check system in Embodiment 1, such as Figure 29 As shown, including the check valve outer tube 5 and the outer tube cover 6, at least two check valves 101 of embodiment 1 are arranged in the check valve outer tube 5, and the check valve 101 can be controlled by the impact of upstream water flow or external force. Open, and the check valve 101 can be closed under the control of its own gravity or external force. Among them, the check valve 101 is a purely mec...

Embodiment 3

[0121] Due to the relatively single function of the existing drainage check valve products, it only plays the role of preventing backflow in the pipeline, and does not have the ability to discharge backwater downstream. Another specific embodiment of the present invention discloses a downstream pipeline backwater alarm non-return drainage system, such as Figure 30 to Figure 31 As shown, the system includes the check valve 101 of Embodiment 1, the outer tube 5 of the check valve and the outer tube cover 6 , and the check valve 101 is a purely mechanical check valve or an electric check valve. Among them, the pure mechanical check valve relies on the impact of drainage and the gravity of the check valve to open and close; the electric check valve relies on the control motor to open and close.

[0122] In this embodiment, the check valve outer pipe 5 is used to install components such as the check valve 101 , the submersible sewage pump 9 , and the sensor (liquid level gauge). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com