Patents

Literature

37results about How to "Easy to achieve precise control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

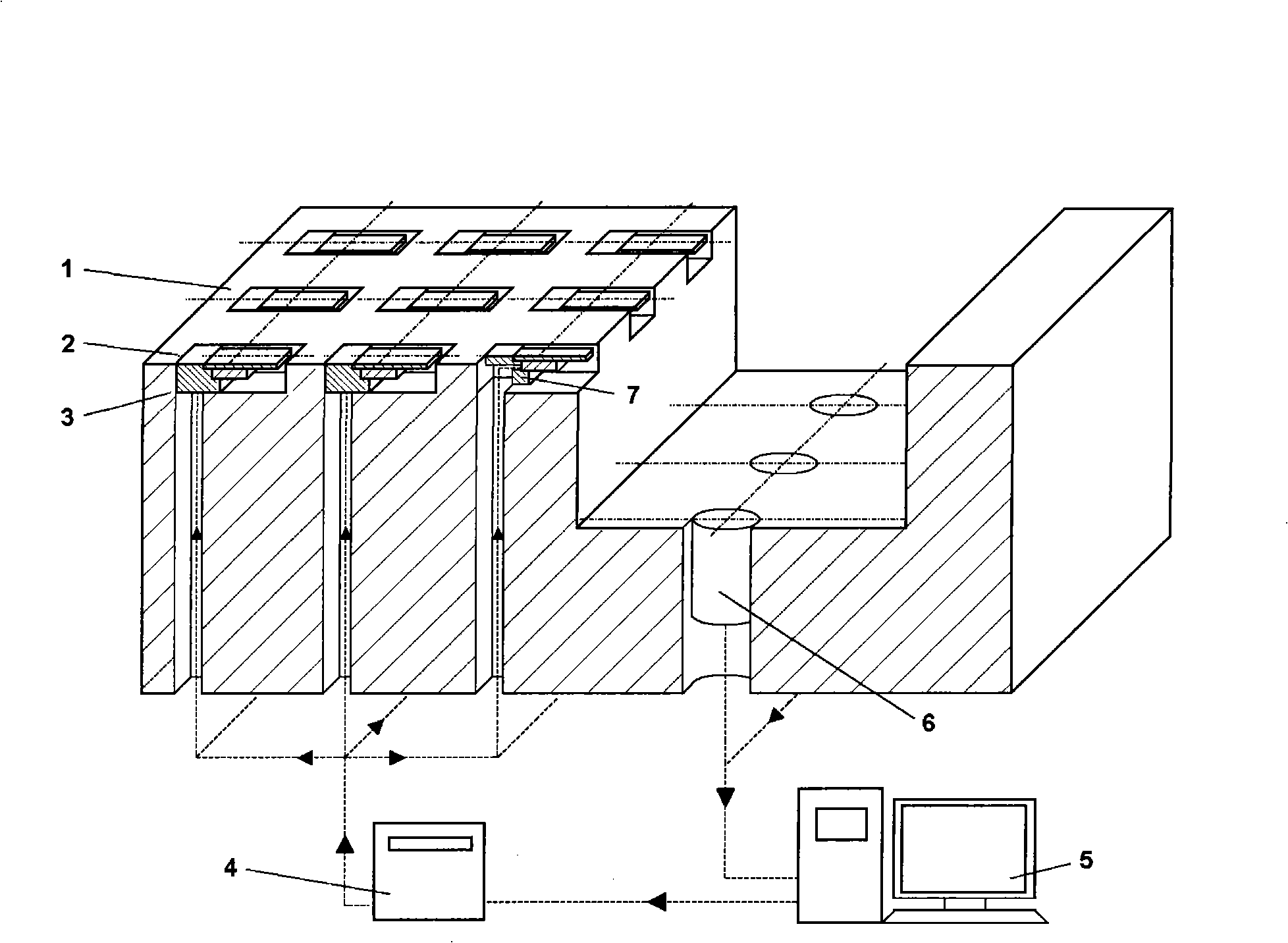

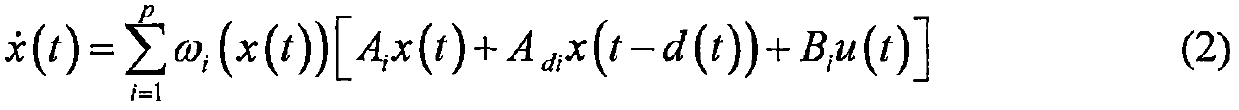

Three-dimensional cavity resonance pulsating pressure and aerodynamic noise inhibition device

InactiveCN101264798AImprove carrying capacityEasy to achieve precise controlAir-flow influencersControl signalCavity resonance

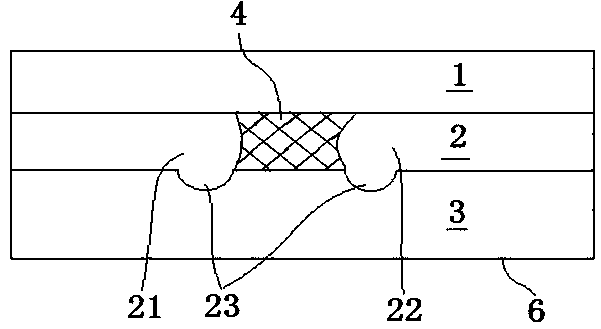

The invention relates to a fluctuating pressure and pneumatic noise suppression device for three-dimensional cavity resonates, belonging to flow control technical field, comprising an aligned array groove, an actuating reed, a piezoelectric ceramic piece, an installing seat, a special high voltage power supply for piezoelectric ceramic, a dynamic pressure transducer and a computer with an A / D acquisition card. The dynamic pressure transducer is arranged under the cavity, and is connected with the computer with A / D acquisition card by the through hole under the cavity. The actuating reed is arranged in the aligned array groove. The piezoelectric ceramic piece is pasted on the bottom of the reed to be the excitation element. The piezoelectric ceramic piece is connected with the special high voltage power supply for piezoelectric ceramic. The piezoelectric ceramic piece produces extensional deformation under the control signal excitation, and drives the actuating reed to vibrate, the oscillation frequency of the shear layer is changed, the cavity resonates is broken down, and the cavity pneumatic noise is suppressed. The fluctuating pressure and pneumatic noise suppression device for three-dimensional cavity resonates has the advantages of wide adjustable range, realizing the accurate control of the phased array for the three-dimensional space of the cavity by the real time feedback of the fluctuating pressure of cavity.

Owner:SHANGHAI JIAO TONG UNIV

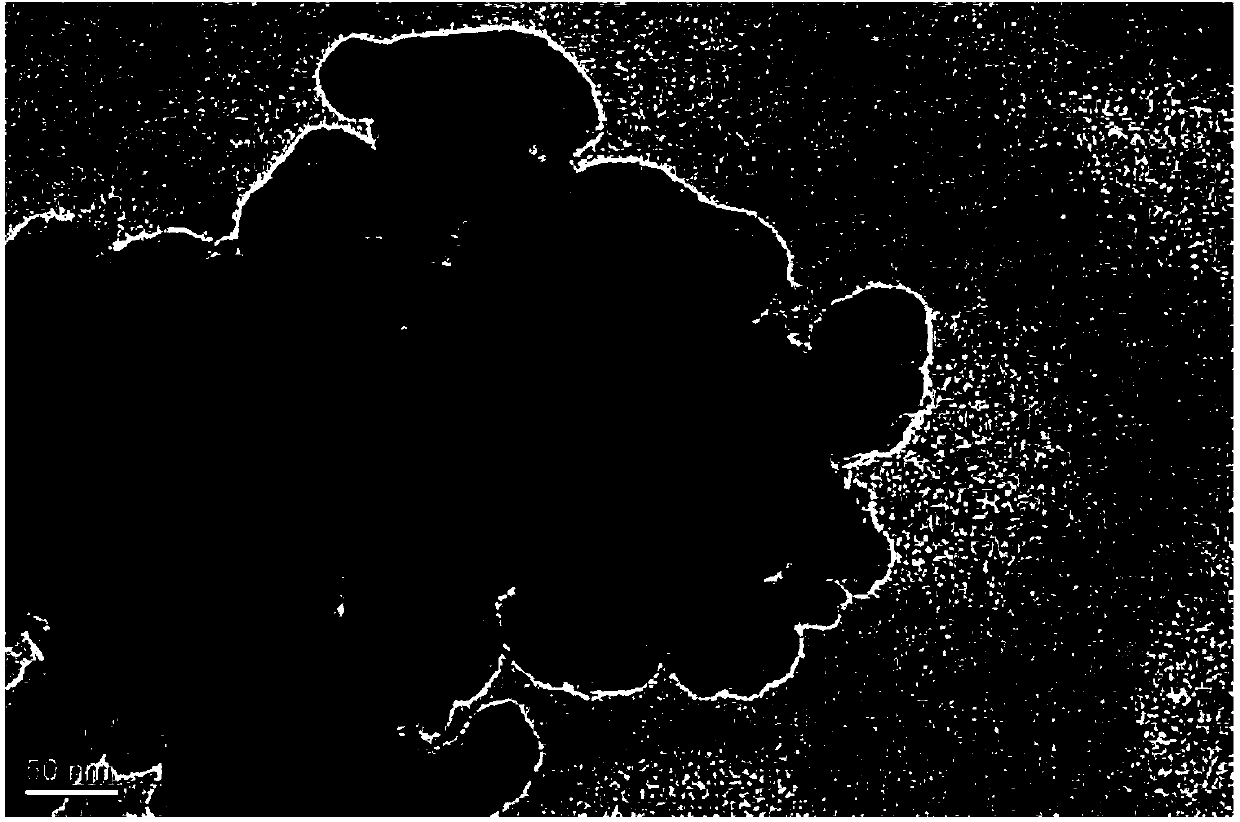

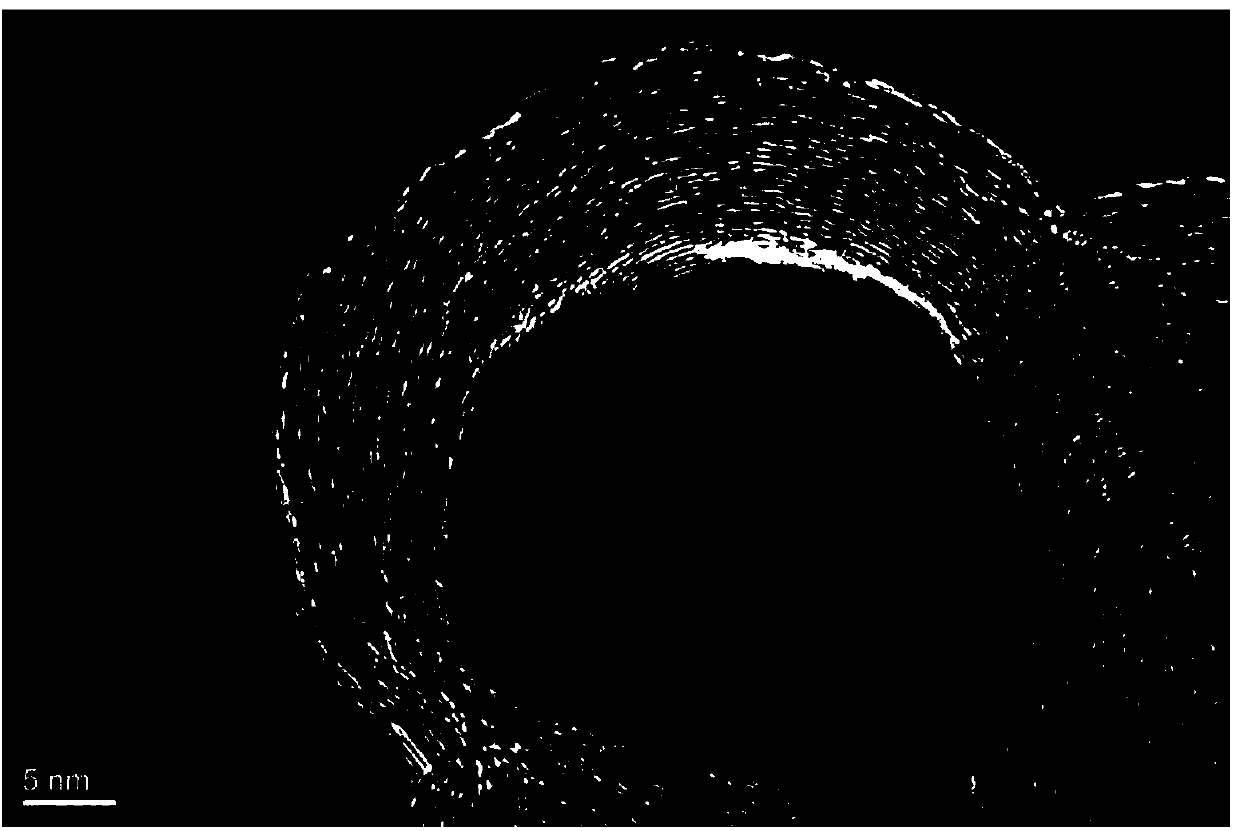

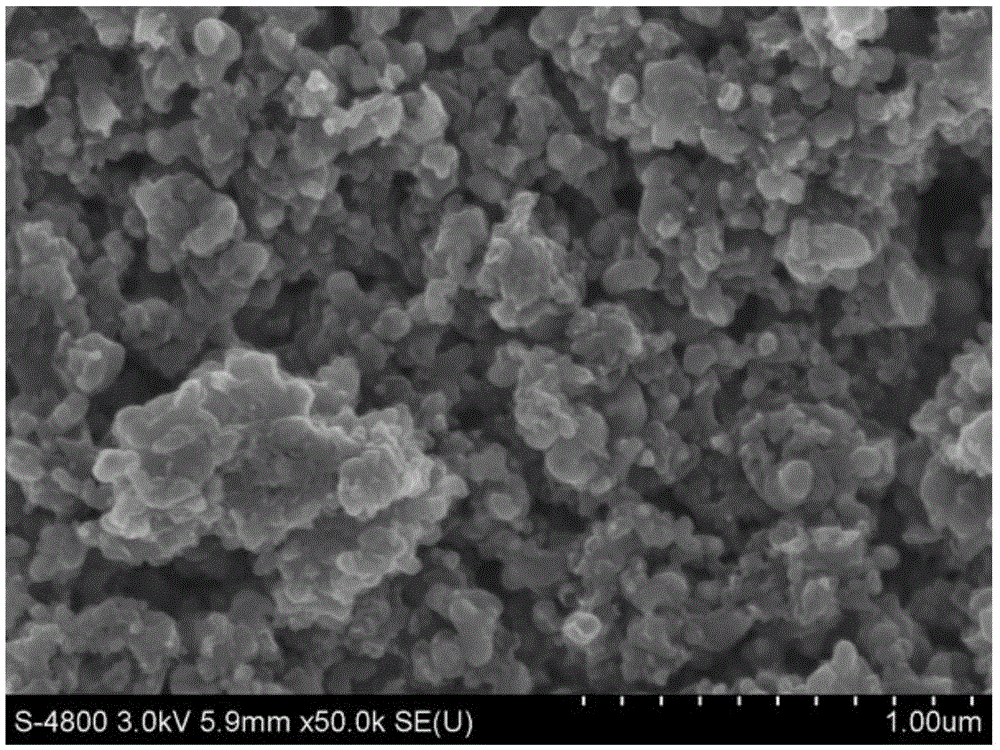

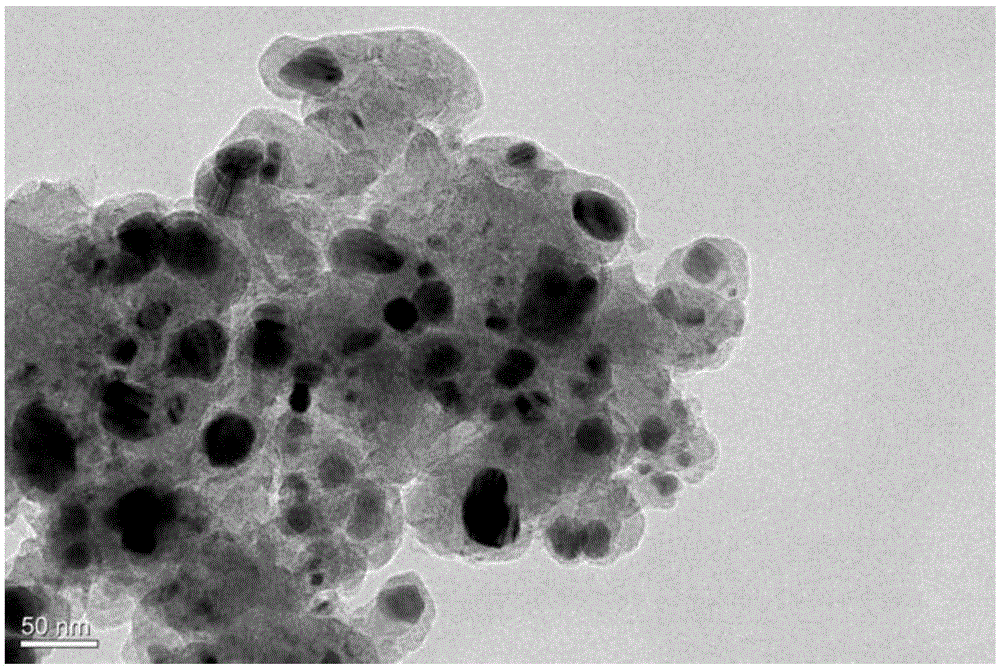

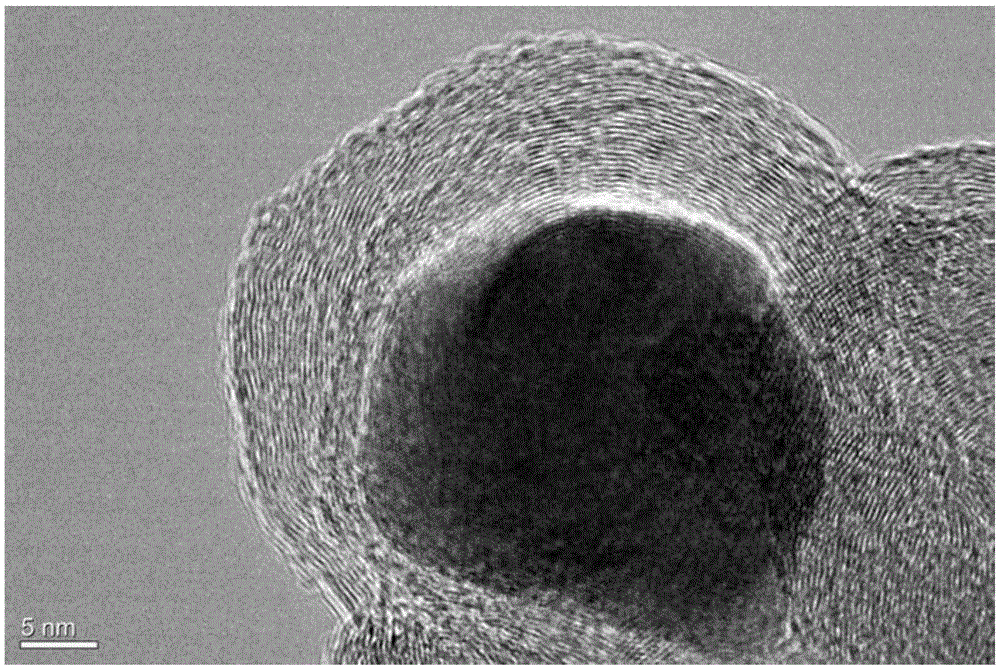

Preparation method of carbon-coated cobalt metal nano-particles

InactiveCN103695864AHigh purityPurity is easy to controlNanotechnologyChemical vapor deposition coatingCobalt metalChemical plating

The invention discloses a preparation method of carbon-coated cobalt metal nano-particles, which relates to a gaseous compound decomposition-based chemical plating by which reaction product of surface material is not preserved in a plating layer and only carbon is deposited, and is a method for decomposing ethyne and synthesizing carbon-coated cobalt metal nano-particles on potassium chloride carrier by means of chemical vapor deposition. The preparation method comprises the following steps: firstly, preparing cobalt-potassium chloride catalyst, then, synthesizing carbon-coated cobalt metal nano-particles, and finally, performing purification to obtain the carbon-coated cobalt metal nano-particles with purity of 95-99%. The preparation method overcomes the defects that the carbon-coated metal nano-particles synthesized by the existing technology have low purity, poor performance and low yield, and contains overmuch impurities, and the impurities are not easy to remove.

Owner:HEBEI UNIV OF TECH

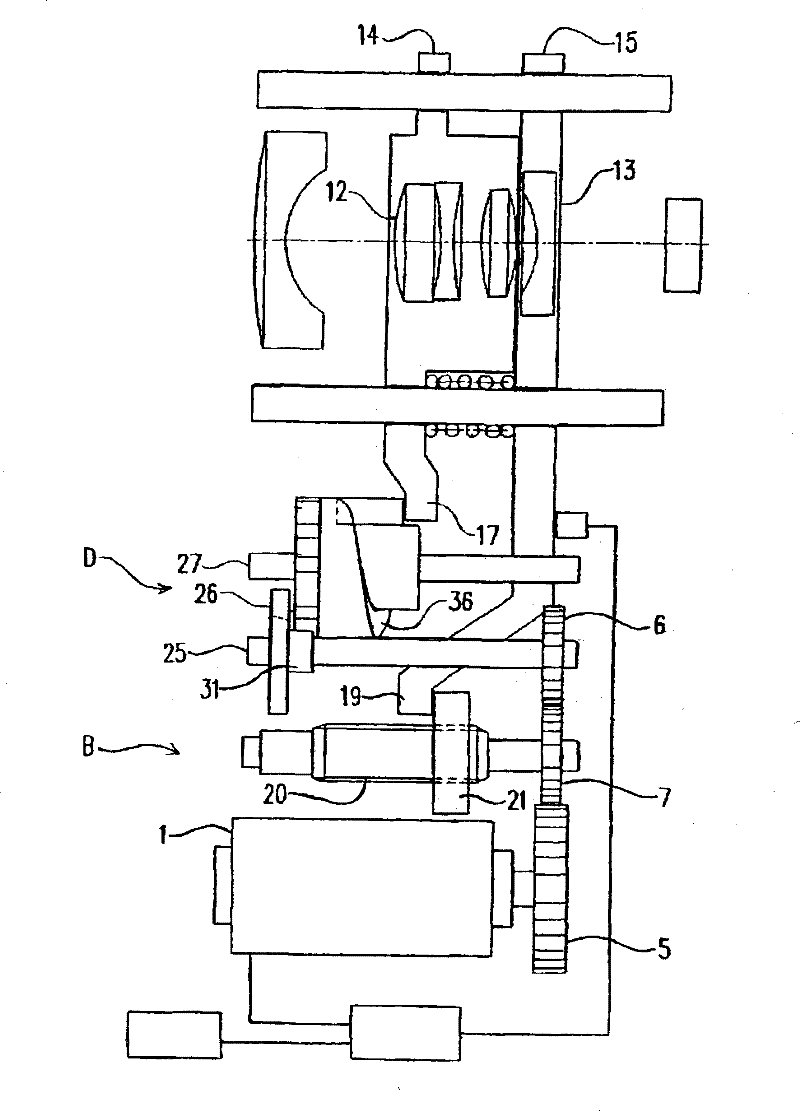

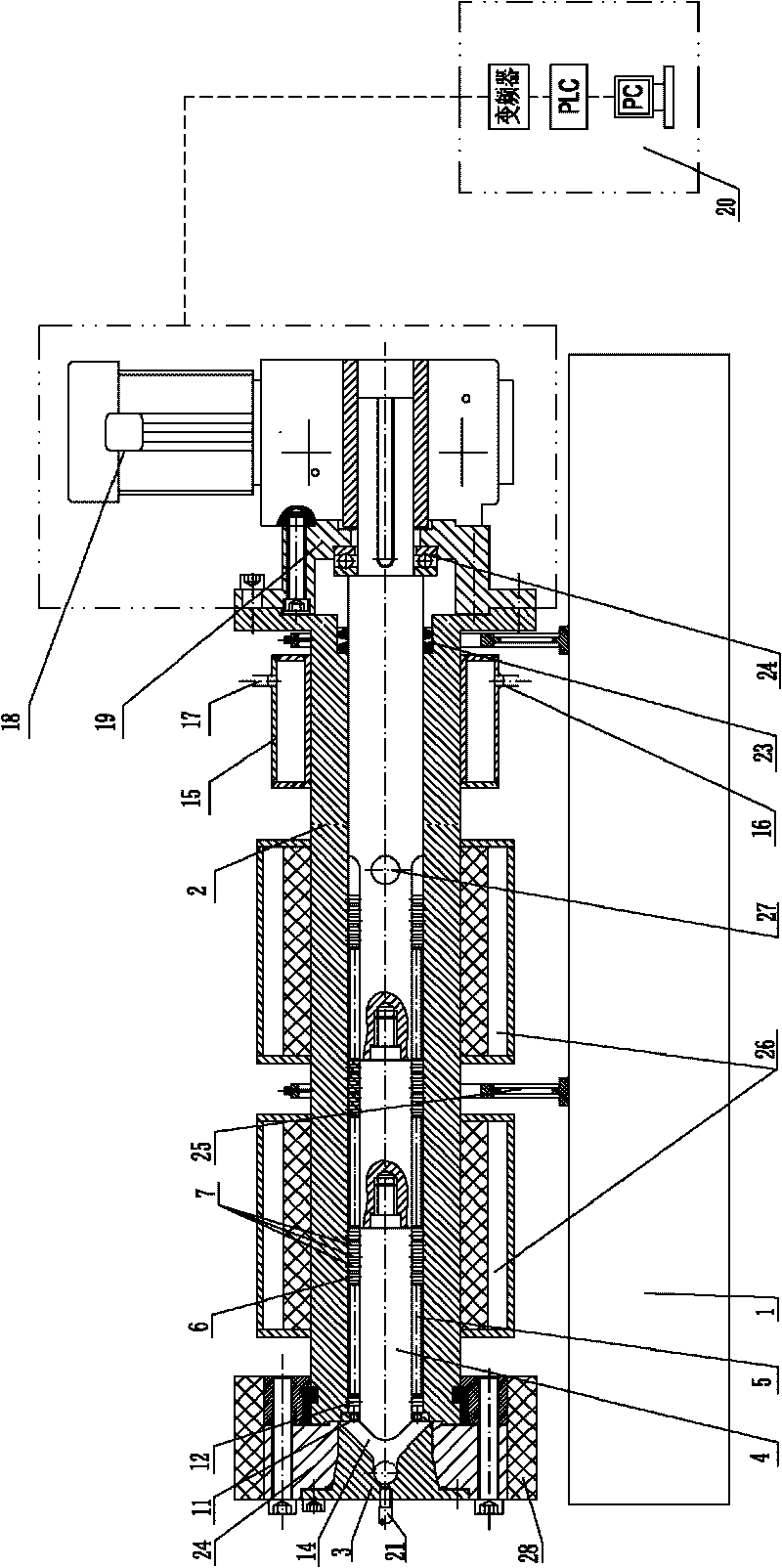

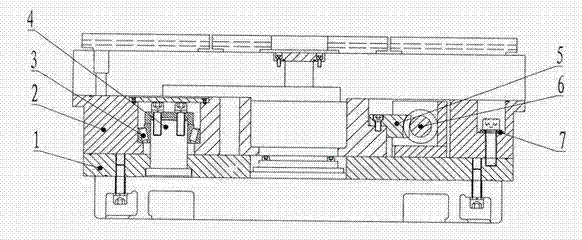

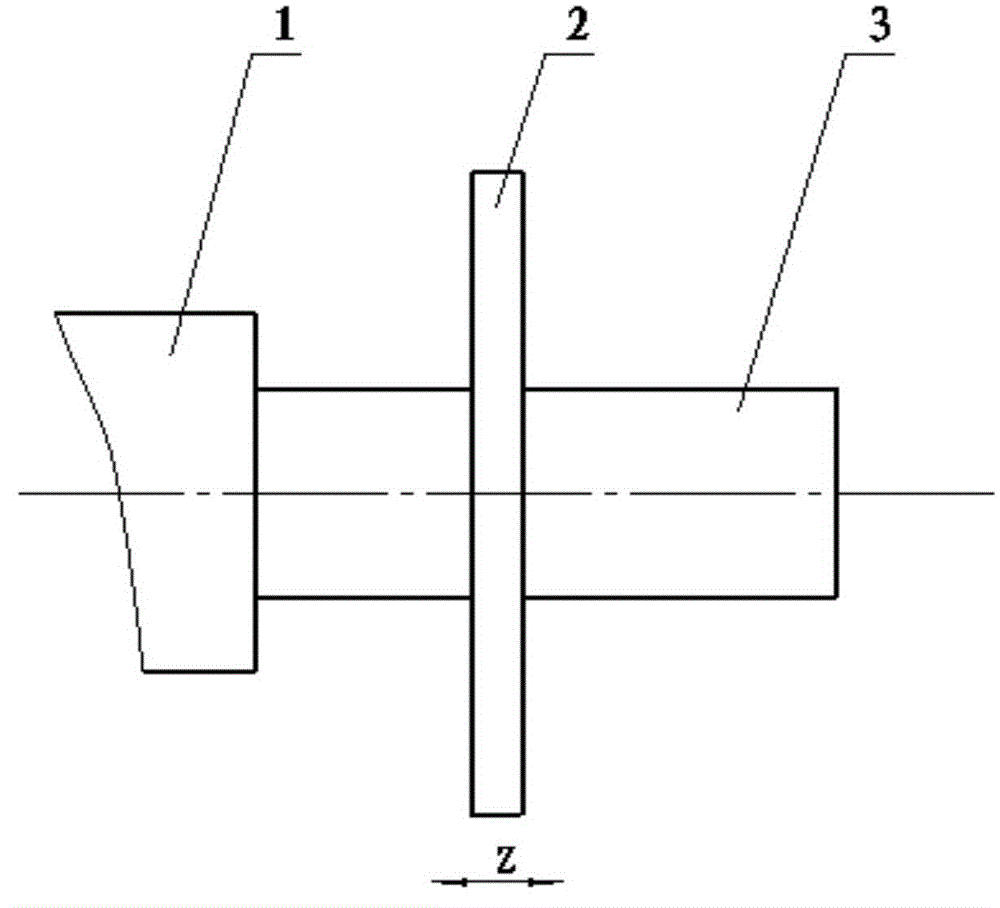

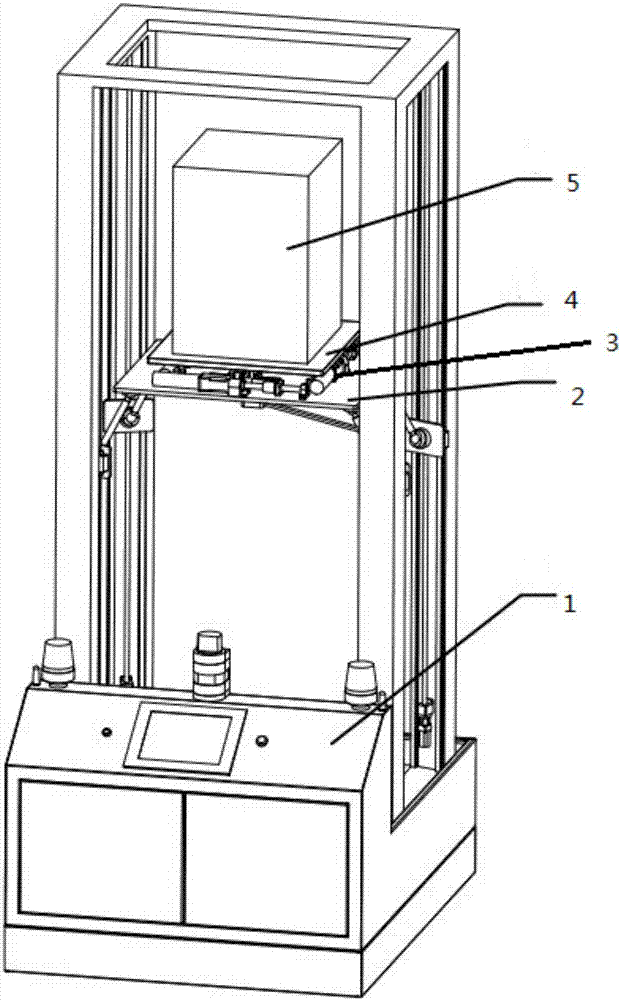

High-precision high-acceleration low-frequency sinusoidal vibration system

InactiveCN104180820AAvoid many problems with experimentationEasy to testMeasurement devicesVibration amplitudeHigh acceleration

The invention relates to a high-precision high-acceleration low-frequency sinusoidal vibration system which comprises a rotating motor, a crank disc, a crankshaft, a horizontal rolling guide rail, a vertical rolling linear bearing, an upright post, a worktable, a balance weight and a position sensor, wherein a left guide post and a right guide post are arranged on a base; a left linear bearing and a right linear bearing are respectively arranged on the left guide post and the right guide post and can move up and down on the guide posts; two ends of a transverse beam are respectively connected with the left linear bearing and the right linear bearing; the horizontal rolling guide rail is fixedly connected to the transverse beam; a horizontal guide rail slide block can move from left to right on the horizontal rolling guide rail; and the upright post and the worktable are arranged on the transverse beam. According to the mechanical system, high-precision and high-acceleration low-frequency sinusoidal vibration can be realized, the defects of a centrifuge test are overcome, the flexibility of research trial is improved, the problems that a low-frequency section of the conventional vibration table is low in vibration amplitude and vibration frequency precision, the testing requirements of a high-precision inertia type instrument cannot be met and the like are solved, and a high-order error item coefficient of the inertia type instrument is tested.

Owner:HARBIN INST OF TECH

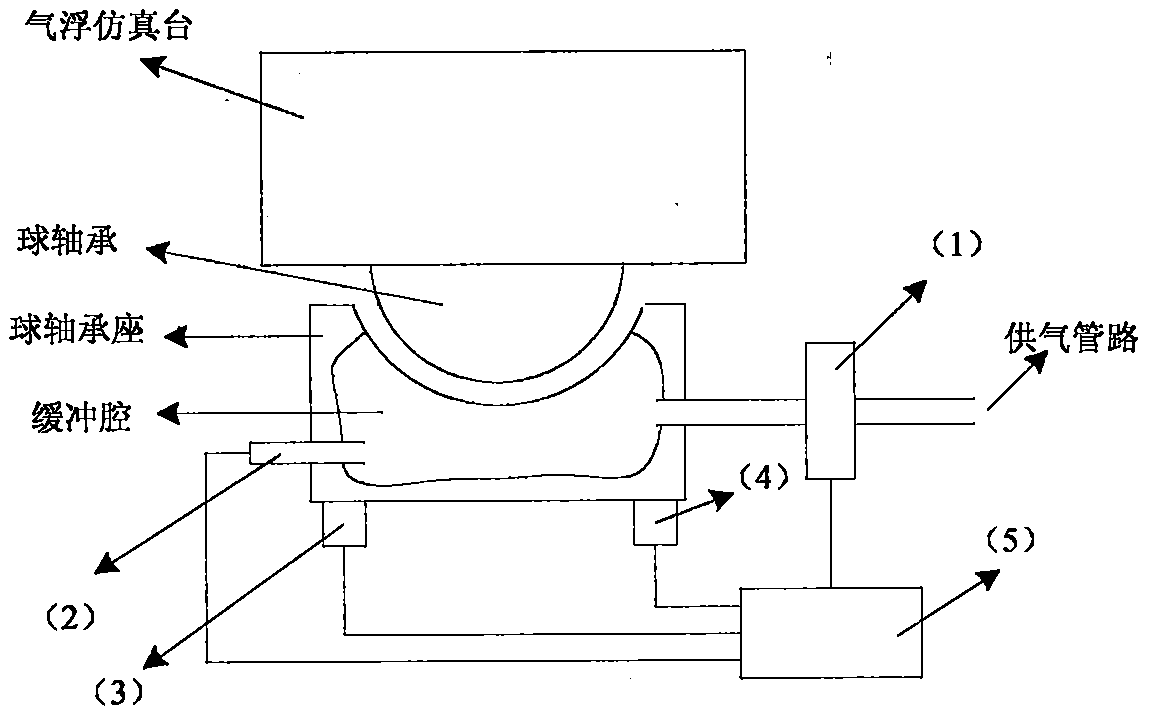

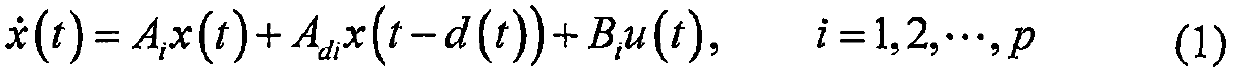

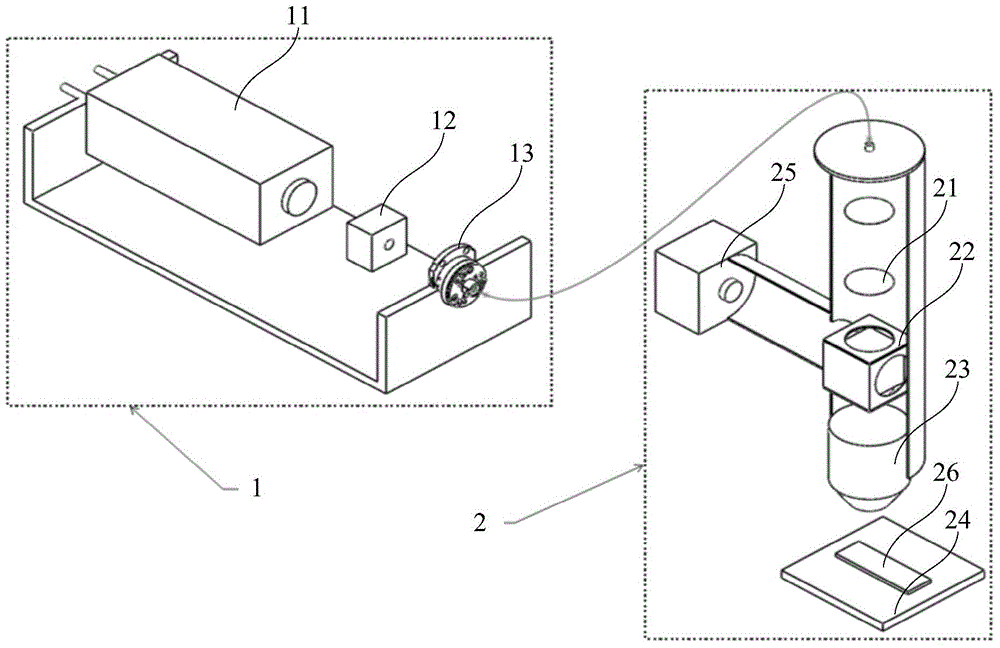

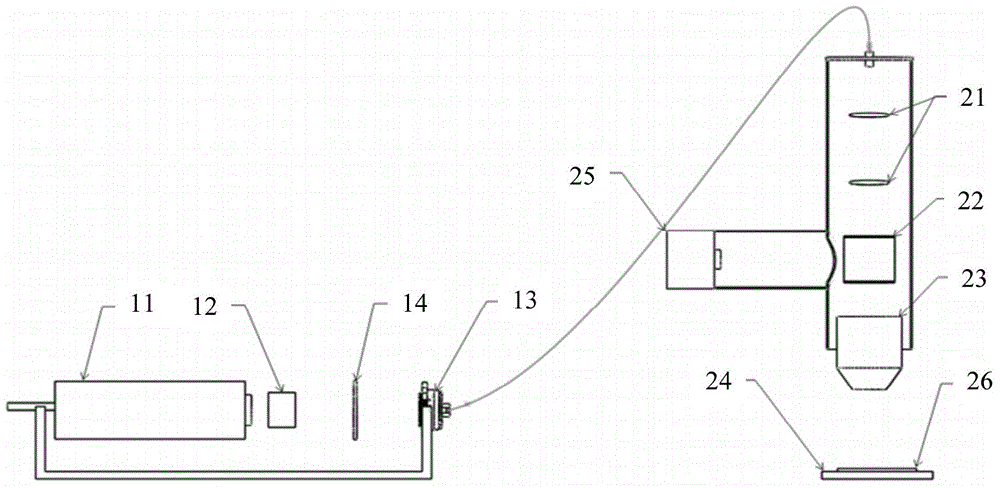

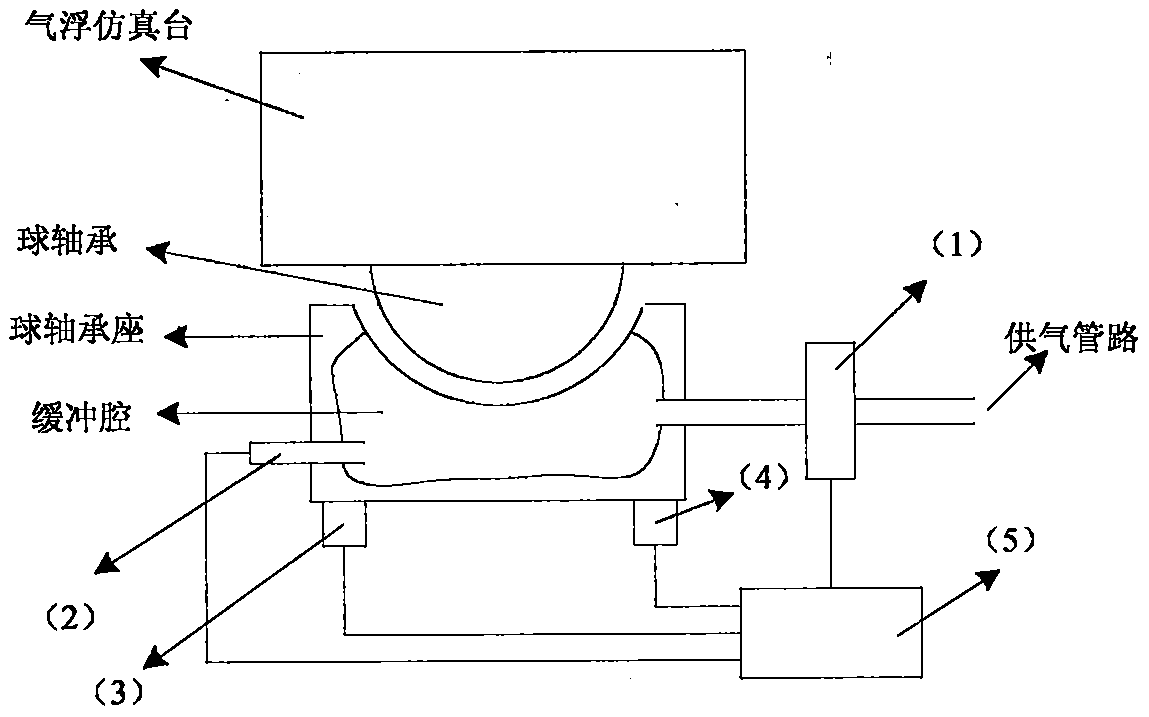

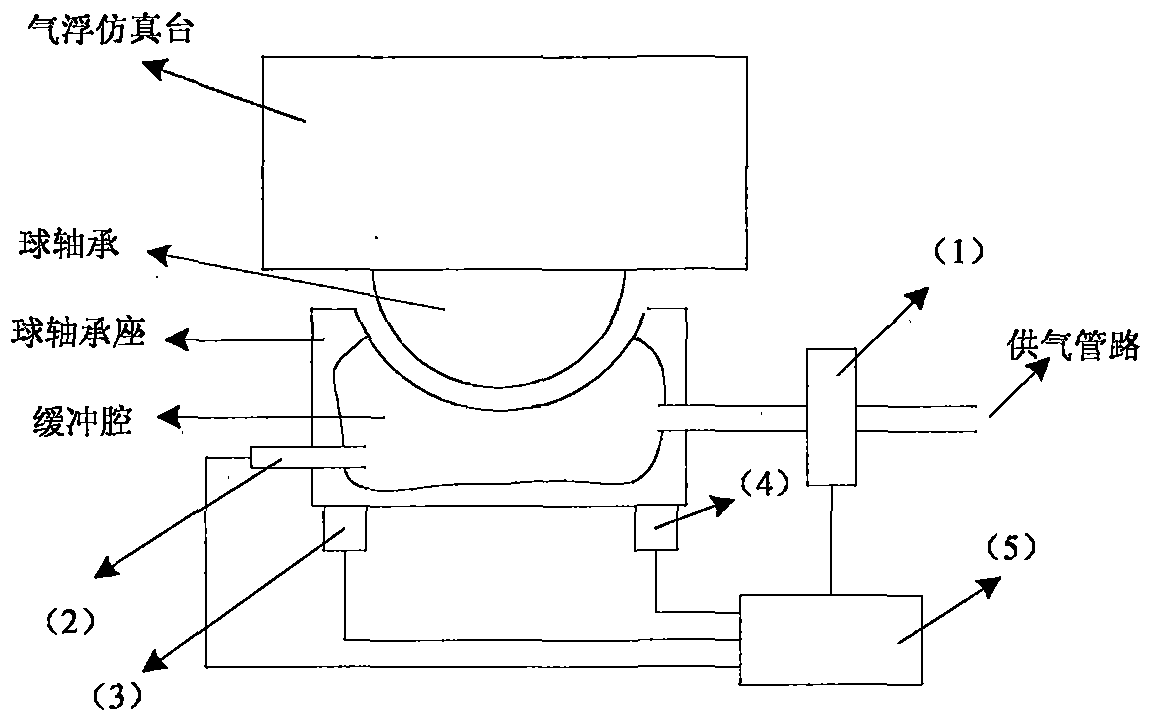

Satellite attitude controlled ground full-physical simulation intelligent control system

The invention provides a satellite attitude controlled ground full-physical simulation intelligent control system, comprising a pressure regulating valve, a pressure sensor, a spirit level, a weighing sensor and a controller, wherein the control end of the pressure regulating valve and the output end of the pressure sensor are connected with the controller, and the spirit level and the output end of the weighing sensor are connected with the controller; the spirit level measures the levelness of a base and outputs data to the controller, and the weighing sensor measures the weight of a test bed in real time and outputs data to the controller; based on the thought of fussy intelligent control, a dependent variable is selected for establishing a system model, the controller enabling the system to be asymptotically stable is designed according to the Lyapunov stability analysis theory, the conservatism of the system design is lower by adopting the thought of piecewise linearization, and the description rules of the controlled object and the controller are not limited so as to improve the flexibility of the system design. The system is simple in principle and convenient to maintain.

Owner:HARBIN INST OF TECH

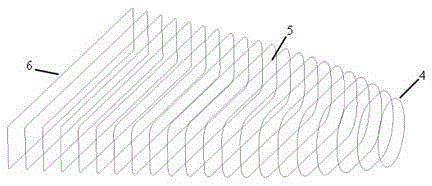

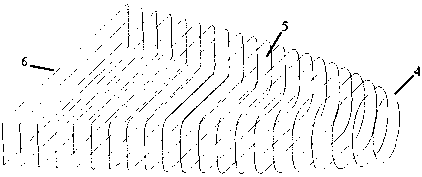

Aluminum and aluminum alloy spiral pipe forming stirring friction welding method

InactiveCN103240571ARealize digital inputRealize remote precise controlWelding/soldering/cutting articlesTubular articlesFriction weldingSeam welding

The invention discloses an aluminum and aluminum alloy spiral pipe forming stirring friction welding method which includes: coiling aluminum and aluminum alloy coiled materials into pipe billets according to preset angles; using rotation roll positioning to align pipe seams, and supporting formed pipe billets to avoid deformation; and using a stirring friction method for pipe seam welding. The method is widely applicable to welding of various grades of aluminum and aluminum alloy spiral pipes and high in efficiency.

Owner:姚雪飞

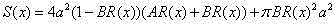

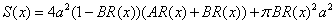

Design method for diffusing section of narrow-slit spray pipe of lateral-force engine

ActiveCN106677925AReduce the coupling effect of external flowEasy to achieve precise controlRocket engine plantsEngineeringDesign methods

The invention discloses a design method for a diffusing section of a narrow-slit spray pipe of a lateral-force engine. According to the design method for the diffusing section of the narrow-slit spray pipe of the lateral-force engine provided by the invention, transition from a circular inlet to a rectangular outlet with a large length-width ratio is realized through rectangular smoothing.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

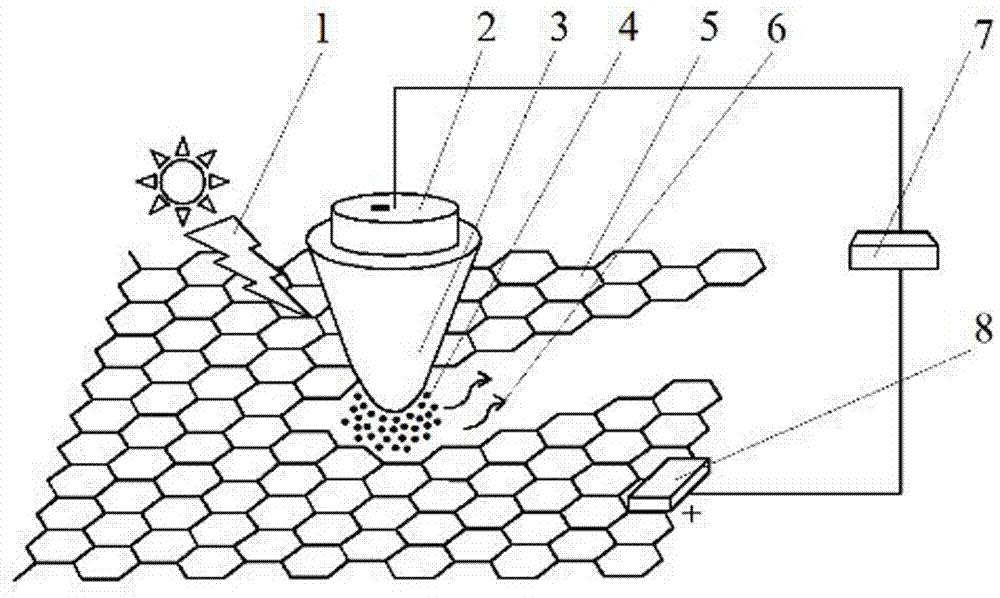

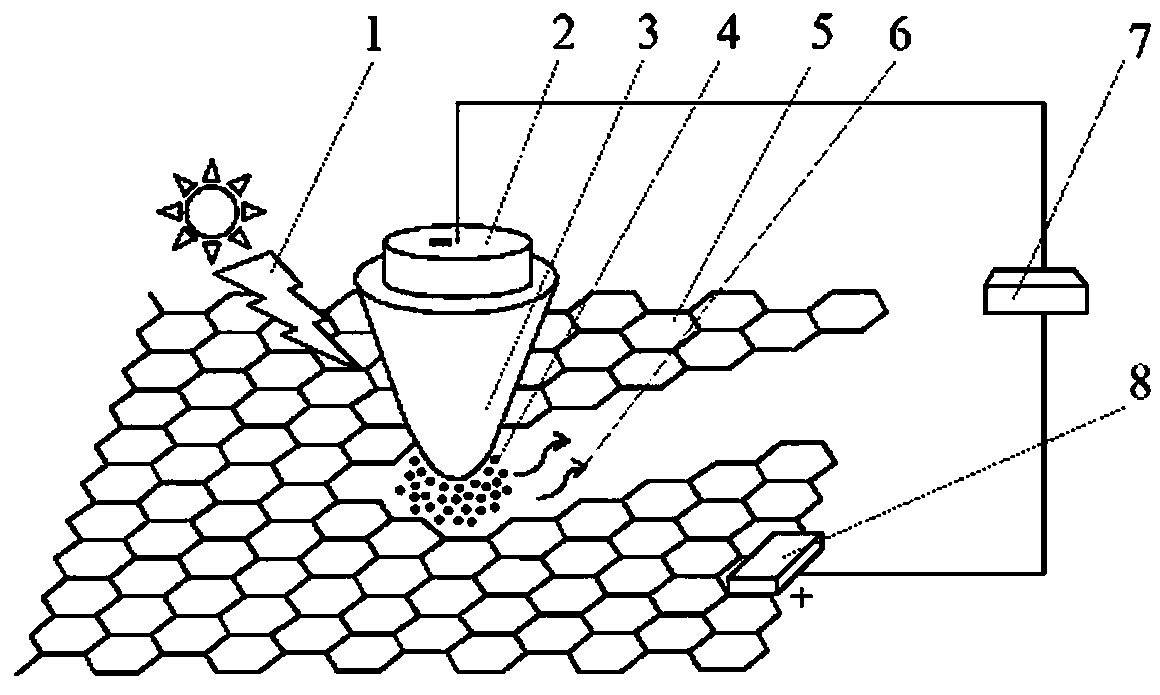

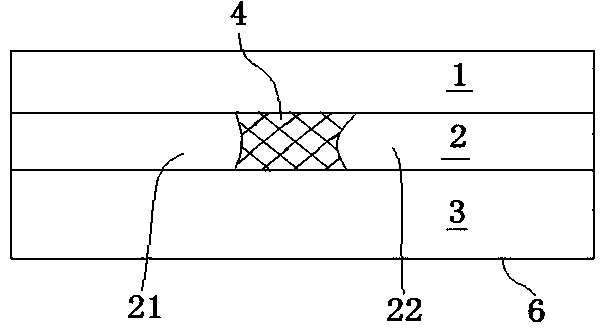

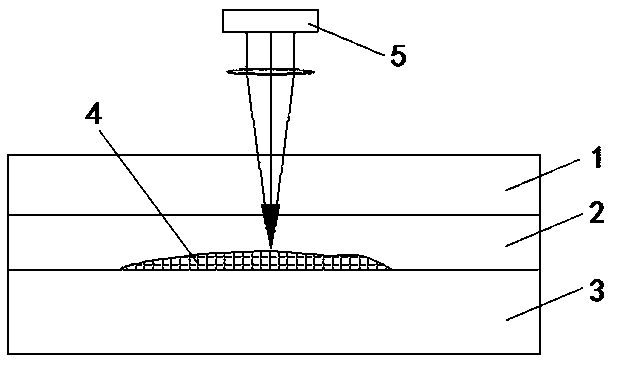

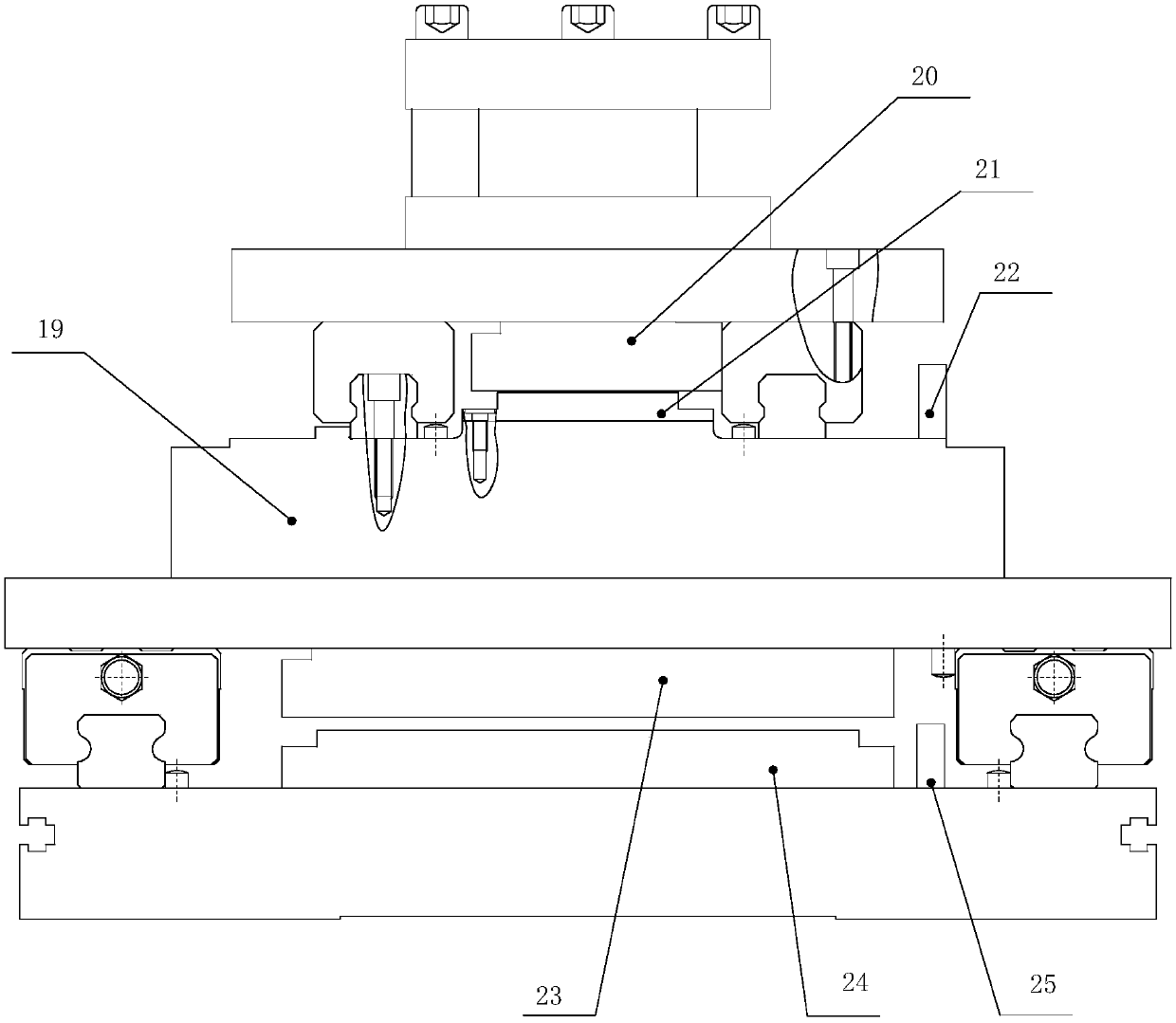

Method and device for precisely and controllably cutting graphene bands through photo-catalytic oxidation function

ActiveCN106985213AAvoid harmEasy to achieve precise controlMetal working apparatusUltraviolet lightsEngineering

The invention relates to a method and device for precisely and controllably cutting graphene bands through a photo-catalytic oxidation function. The method is characterized by comprising the steps that firstly, graphene with a substrate is fixed to a two-dimensional micromotion platform driven by piezoelectric ceramic; secondly, Z-direction locating of a semiconductor probe is achieved through a magnetostriction mechanism with the help of a power controller; thirdly, an atomizer is used for atomizing auxiliary liquid, and the atomized auxiliary liquid is adsorbed to the surface of the semiconductor probe; and fourthly, an ultraviolet source emits ultraviolet light, the ultraviolet light irradiates the semiconductor probe through a light source transmission device after being focused through a collecting lens, and meanwhile through combination of ultraprecise motion of the two-dimensional micromotion platform in the direction X and the direction Y, the graphene bands with different two-dimensional patterns are cut. By means of the method and device, the problems of equipment corrosion, environment pollution, human body hurt and easy failing caused by using a traditional enhancement reagent and the problems of expensive equipment, complex operation conditions, control difficulty and the like caused by plasma and transition metal are solved.

Owner:SHENYANG POLYTECHNIC UNIV

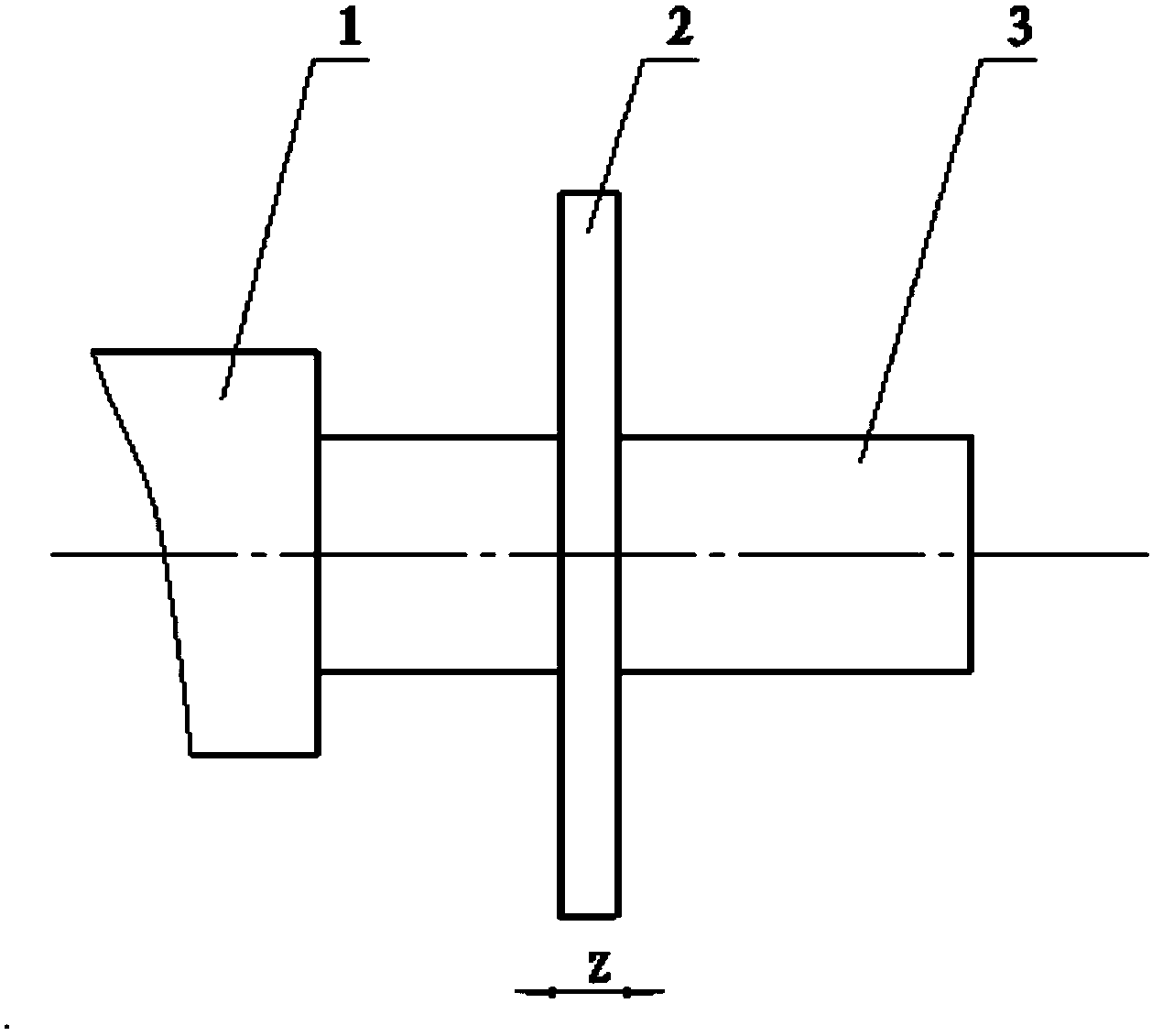

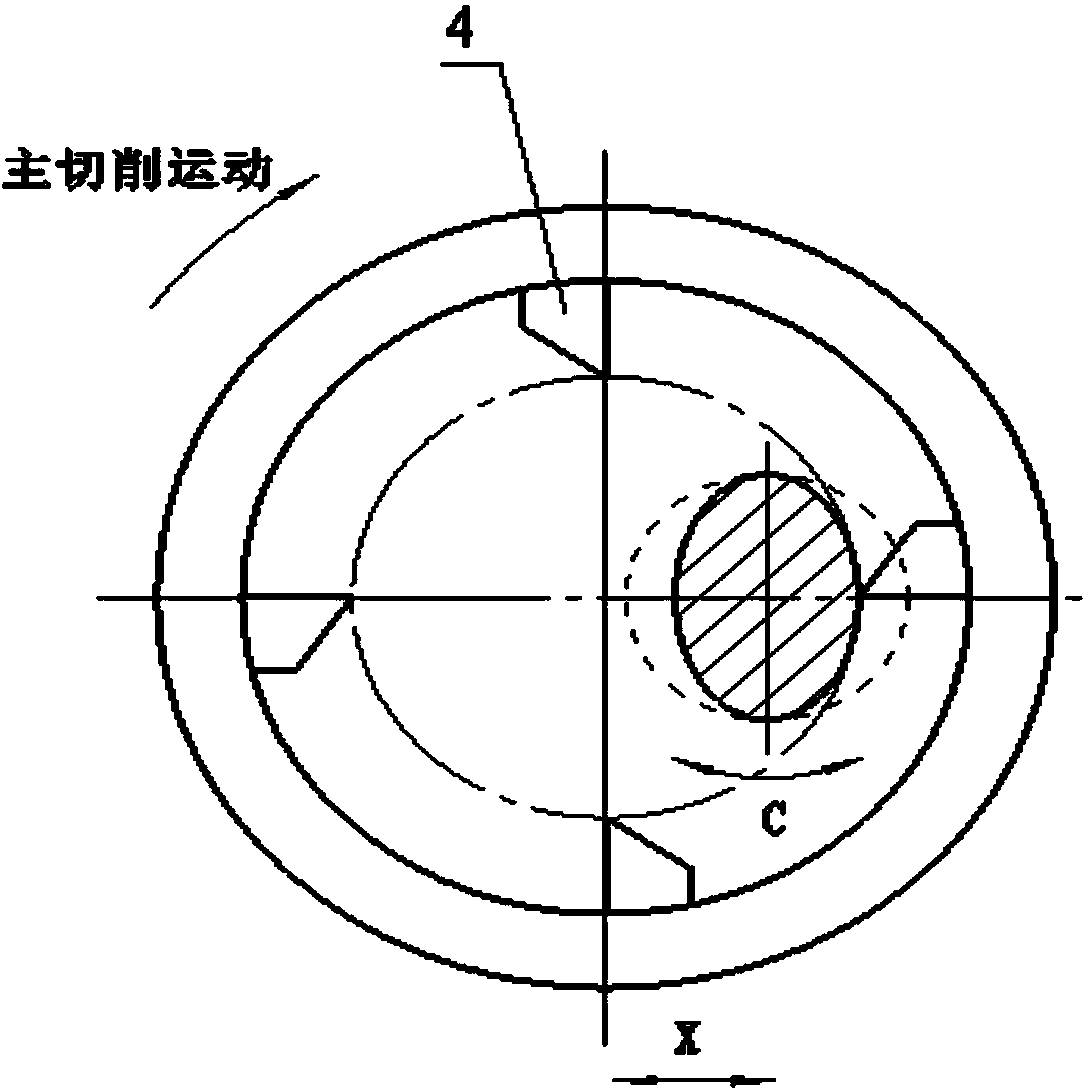

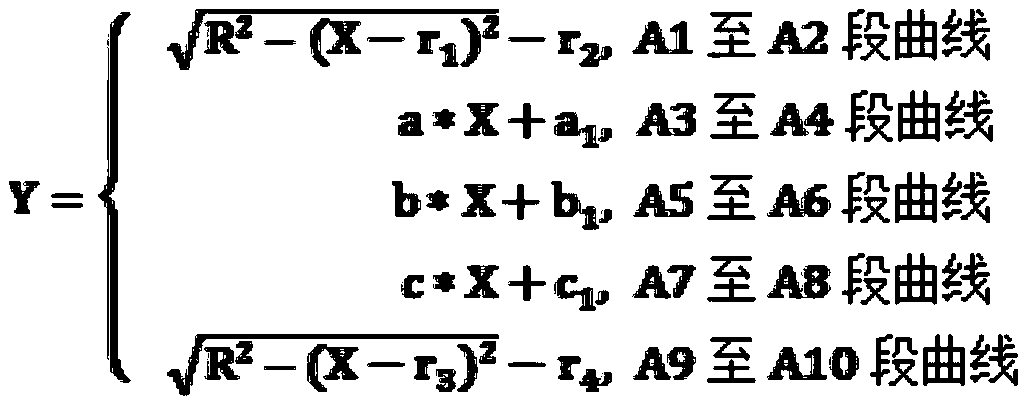

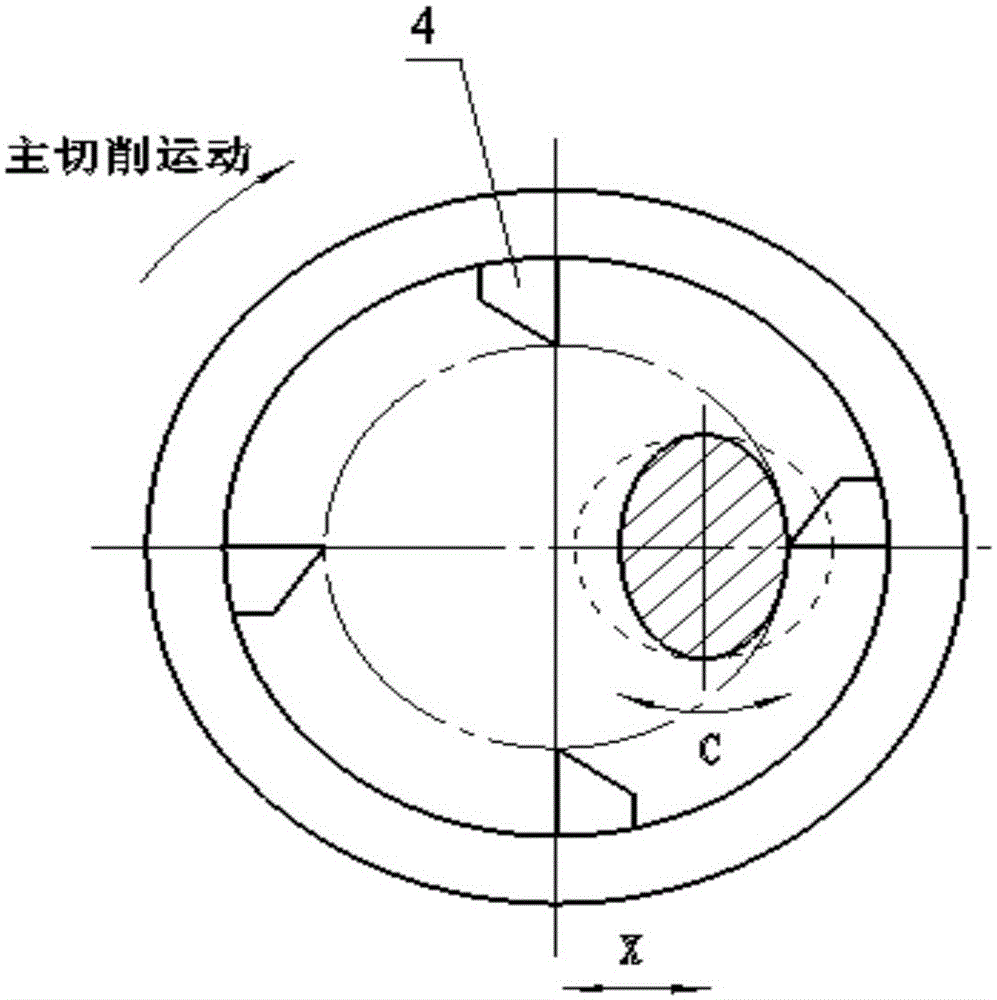

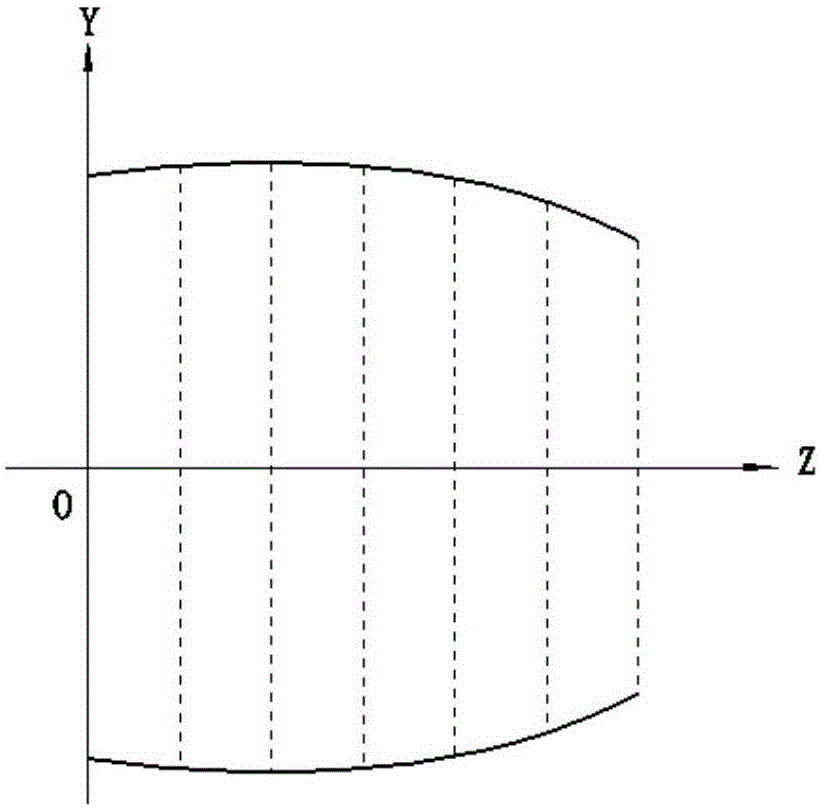

Numerical control whirlwind milling method for middle-convex and varying ellipse pistons

ActiveCN103658786AHigh movement precisionImprove dynamic stabilityMilling equipment detailsMagnetostrictive actuatorWhirlwind

The invention discloses a numerical control whirlwind milling method for middle-convex and varying ellipse pistons. The method comprises the following steps of inputting parameters: the design size and the technical requirements of a workpiece are input into a numerical control system; selecting a cutting tool and calculating the tool path data via the numerical control system according to the input parameters in step one to determine the linkage tool path data of C, Z and X axes of a machining tool; checking the tool path data via a simulation module; clamping and positioning; machining, starting a numerical control machining procedure, using a motor to drive a cutter head to revolve at high speed, and simultaneously controlling the spindle of the machine tool to drive the workpiece for C axis movement; controlling the cutter head for Z axis and X axis movement, and obtaining the outer surface of the piston through the linkage machining of C, X and Y axes. The method adopts the whirlwind milling process to machine the middle-convex and varying ellipse piston; the machine tool has the advantages of high movement accuracy and good dynamic stability. The method is easy to realize the accurate control to the machining process, and does not require corresponding high-frequency actuating mechanisms such as a linear motor, a magnetostrictive actuator and the like; therefore, the equipment cost is reduced.

Owner:SHANDONG UNIV

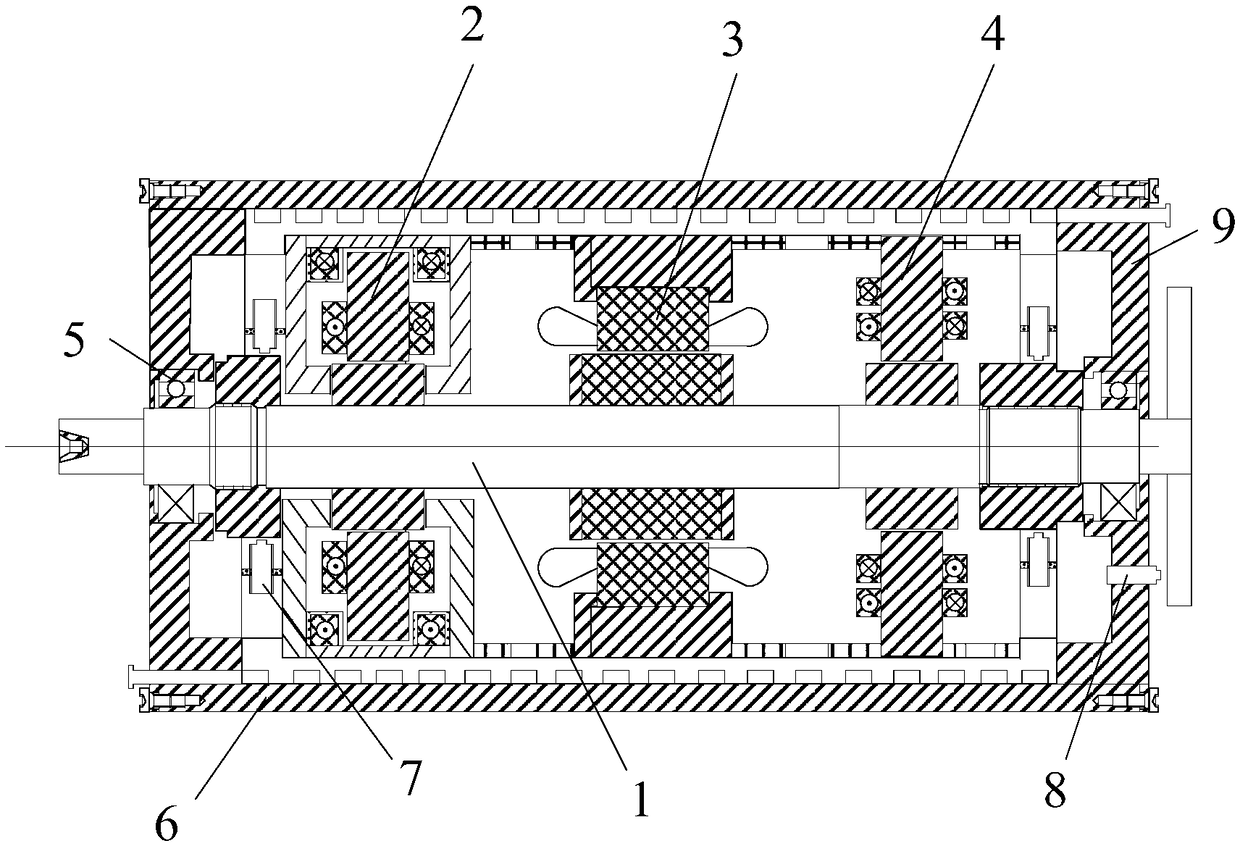

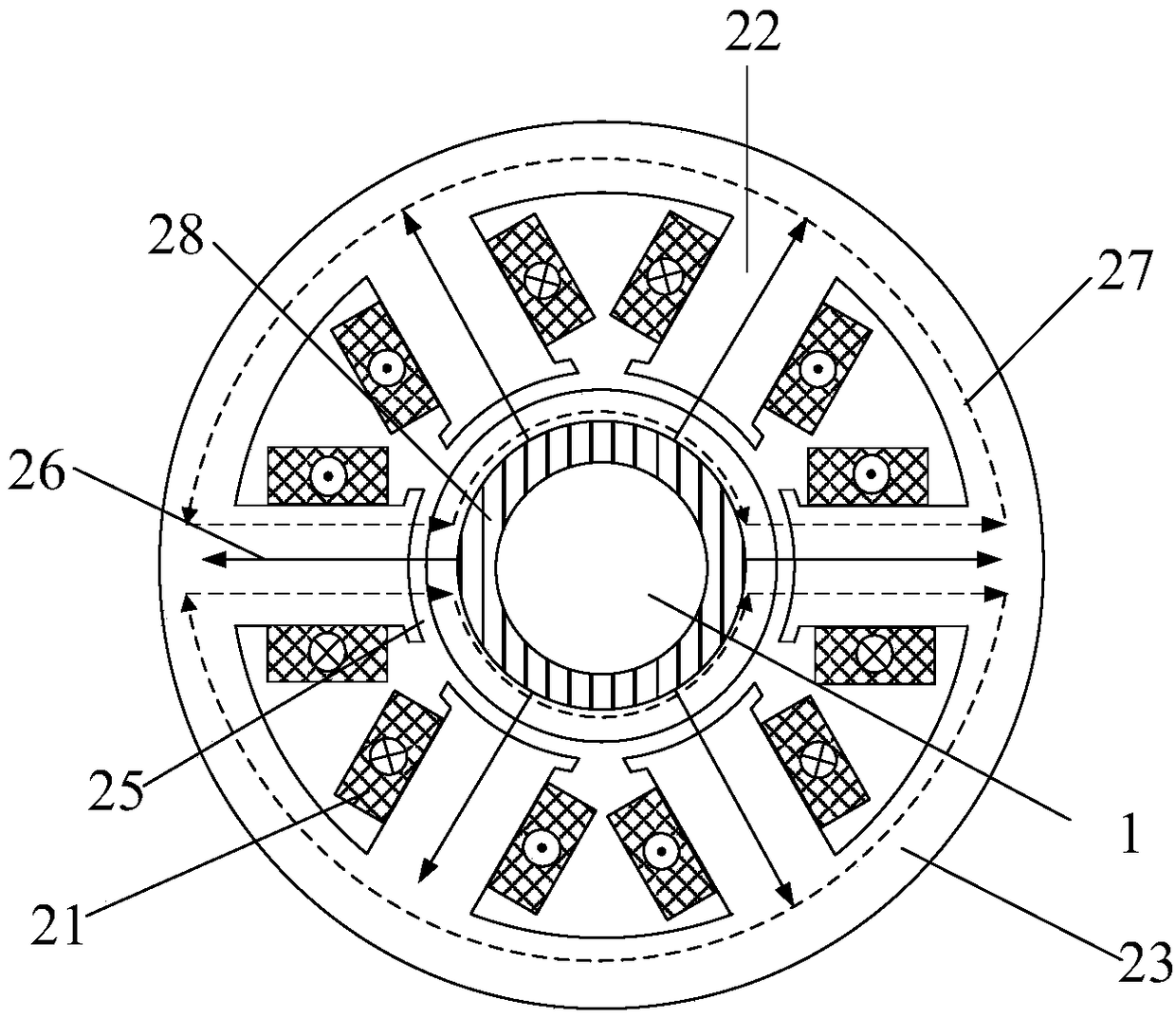

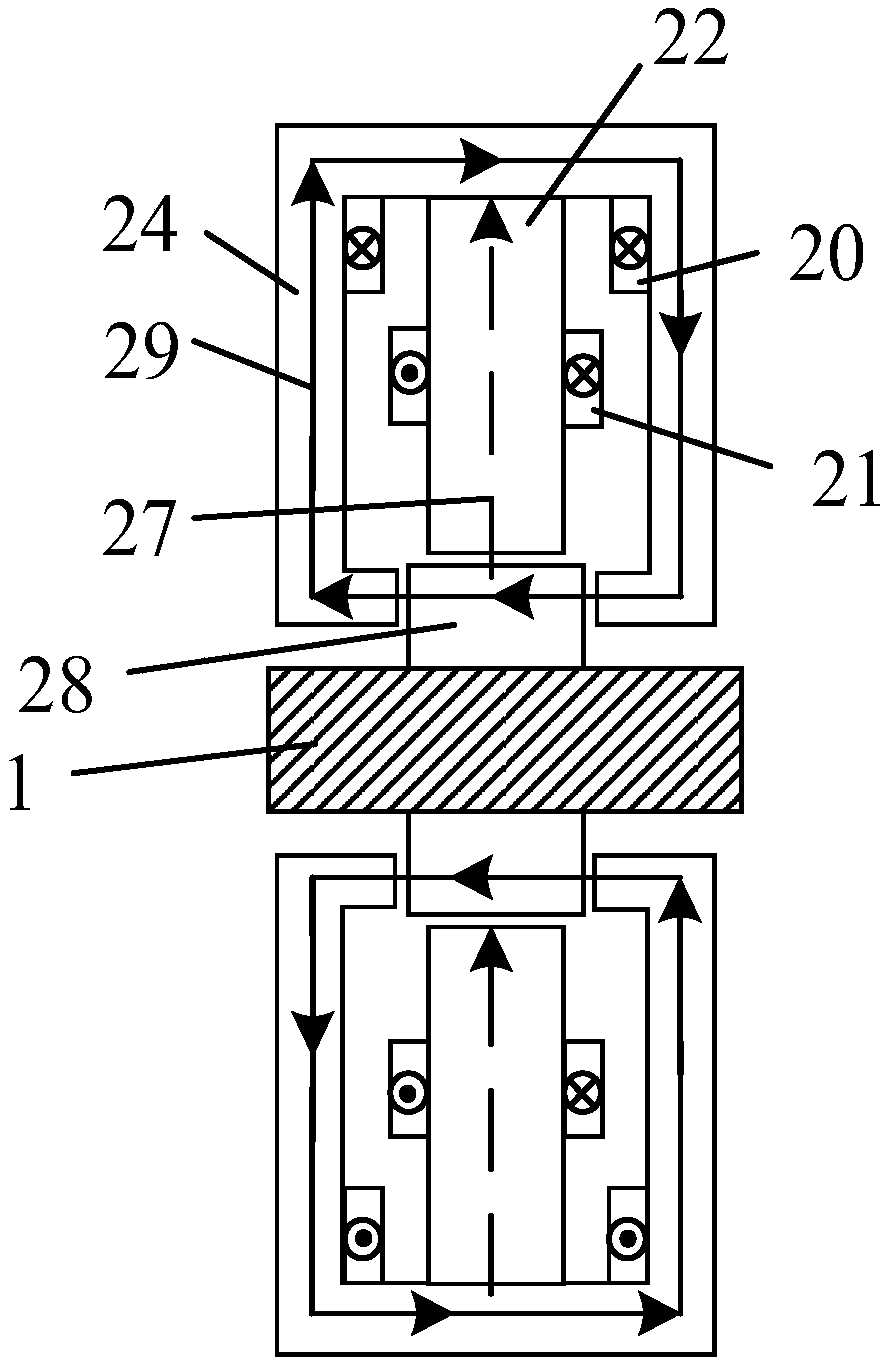

An electric spindle supported by a five-degree-of-freedom alternating current six-pole active magnetic bearing

InactiveCN109194021ANo pollution in the processLow costMechanical energy handlingMagnetic holding devicesMagnetic bearingLevitation

The invention discloses an electric spindle supported by a five-degree-of-freedom alternating current six-pole active magnetic bearing, comprising a three-degree-of-freedom active magnetic bearing, ahigh-speed spindle motor, a two-degree-of-freedom active magnetic bearing and a rotating shaft. The rotating shaft, a rotor of the three-degree-of-freedom active magnetic bearing, the high-speed spindle motor and a rotor of the two-degree-of-freedom active magnetic bearing are fixedly connected in a pivoted manner. Both of the three-degree-of-freedom active magnetic bearing and the two-degree-of-freedom active magnetic bearing adopt three-phase inverter drive cotnrol, which significantly reduces the power consumption and cost of the power amplifier circuit. Both active magnetic bearings adoptsix-pole structure in the radial direction, which greatly reduces the nonlinearity and coupling relationship of levitation force characteristics and makes it easier to achieve accurate control. The invention realizes frictionless rotation between the motor and the rotating spindle, and has the advantages of no mechanical friction and wear, no noise, low power consumption, high speed, high precision and the like.

Owner:JIANGSU UNIV

Numerical control machining method of brake head

InactiveCN109759894AEasy to adjustImprove machining accuracyAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention relates to a numerical control machining method of a brake head. The numerical control machining method is characterized by comprising the following steps that a), a numerical control machining program of the brake head is input into a storage unit of a machine tool; b), X, Y and Z coordinates values of a machining original point in a workpiece coordinate system of the machine tool are set; c), according to a), the workpiece is machined into the brake head through the numerical control machining program in the middle, and then the contour deviation position and the deviation sizecaused by deformation in the machining process of the brake head are determined; and d), according to the machining track and the c), the contour deviation of the brake head in the reverse directionis corrected. According to the numerical control machining method, machining parameters are controllable, the stability is good, the machining track can be accurately adjusted, accurate control on themachining process can be easily realized, and the method is high in flexibility and wide in application range.

Owner:常州创领机械有限公司

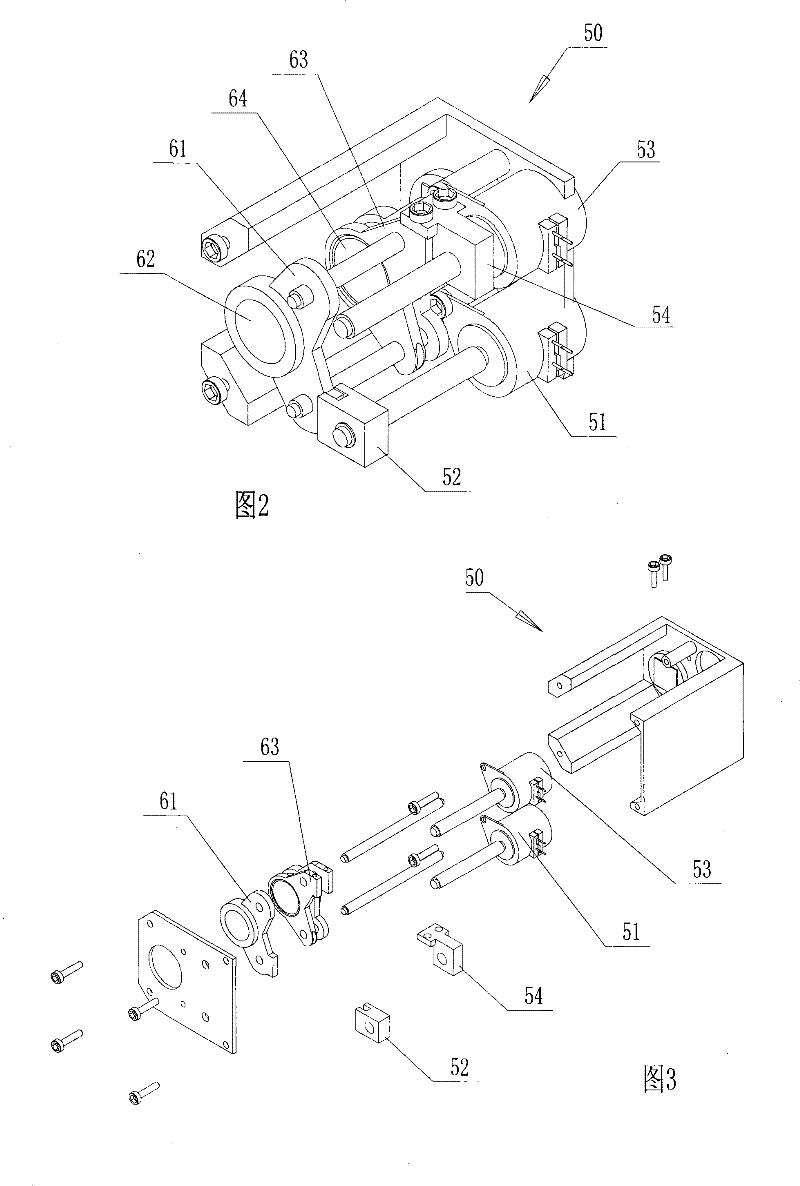

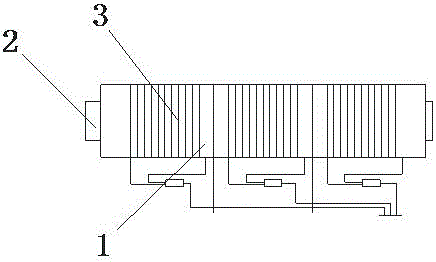

Single-channel optical super-resolution imaging instrument

ActiveCN105300934AEasy to achieve precise controlRealize electronic controlFluorescence/phosphorescenceOptical axisCombined method

The invention provides a single-channel optical super-resolution imaging instrument which at least comprises an excitation light source module and an imaging, scanning and detecting module, wherein the excitation light source module comprises an optical laser, an acousto-optic modulator and an optical fiber coupler; the optical laser, the acousto-optic modulator and the optical fiber coupler are arranged in sequence; the optical axes of the optical laser, the acousto-optic modulator, a frequency scanning and selecting device and the optical fiber coupler are positioned on the same straight line; the imaging, scanning and detecting module comprises two lenses, a polarization beam splitter, a microscope objective, a sample stage and an imaging device; the optical axes of the lenses, the polarization beam splitter and the microscope objective are positioned on the same straight line and the optical axes of the imaging device and the polarization beam splitter are positioned on the same straight line. According to the invention, a single-channel frequency scanning, resonance excitation and polarization filtering combined method is adopted, so that the single-channel excitation super-resolution imaging of samples is realized. The single-channel optical super-resolution imaging instrument provided by the invention is simple in structure, obvious in effect and applied to the technical field of experiential and industrial super-resolution imaging.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

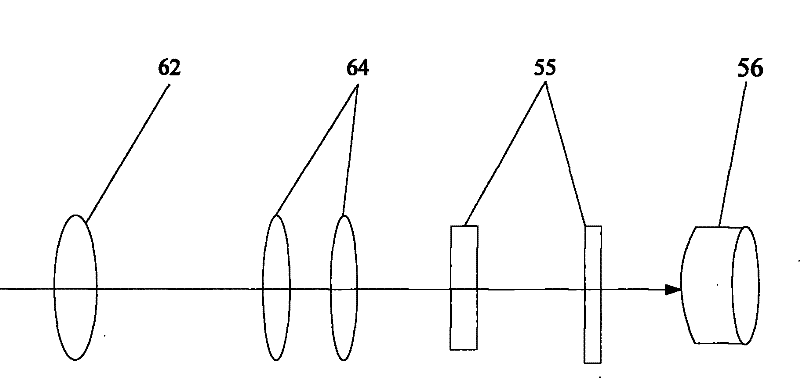

Zoom lens system

ActiveCN101644815BEasy to manufactureLow costProjector focusing arrangementCamera focusing arrangementOptical axisControl theory

The invention provides a zoom lens system, which comprises a zooming unit, a compensating unit and an imaging unit arranged on a same optical axis in turn, a driving transmission mechanism and a micro-processing control unit, wherein the driving transmission mechanism comprises a zooming stepping motor and a compensating stepping motor. The zooming unit is arranged on an output shaft of the zooming stepping motor through a driving piece; the compensating unit is arranged on an output shaft of the compensating stepping motor through the driving piece; and the micro-processing control unit adjusts the distance between the compensating unit driven by the compensating stepping motor and the imaging unit according to the distance changes between the zooming unit driven by the zooming stepping motor and the imaging unit. The zoom lens system has the advantages of compact structure, small volume, simple manufacturing, low cost, economization and portability.

Owner:THE HONG KONG POLYTECHNIC UNIV

Combined efficient low-temperature trickle dynamic mixing device and special method thereof

The invention relates to a production method of a synthetic fibre, in particular to a combined efficient low-temperature trickle dynamic mixing device and a special method thereof, which mainly solve the technical problems that the prior art cannot apply on-line addition on a direct spinning production line and that a fusion method has high cost, high energy consumption and the like. The combined efficient low-temperature trickle dynamic mixing device comprises a framework, wherein the framework is provided with a sleeve component which is provided with a feeding component and a discharge outlet; the inside of the sleeve component is provided with an efficient mixing shaft component; the shaft body of the efficient mixing shaft component is provided with a blending mechanism; and the blending mechanism consists of a trickle mixing unit, a cutting unit and a low-temperature homogenizing unit which are arranged in order. The special method comprises the following steps: inletting a blended melt into an arc-shaped ring groove through the feeding component; introducing the blended melt into a pre-cutting unit to be cut after being trickled by a pre-trickling unit; introducing the blended melt into the blending mechanism to blend uniformly; and discharging a mixture from the discharging outlet.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

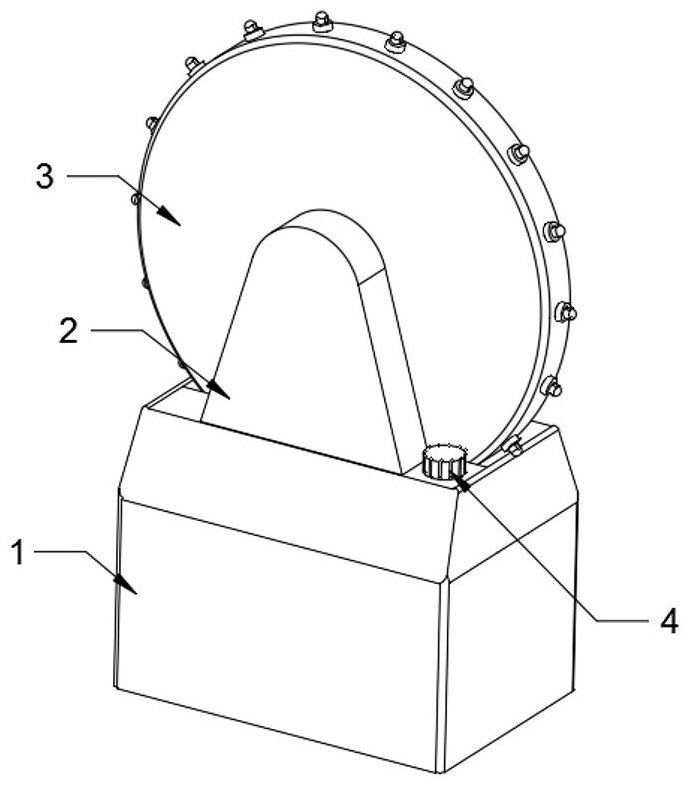

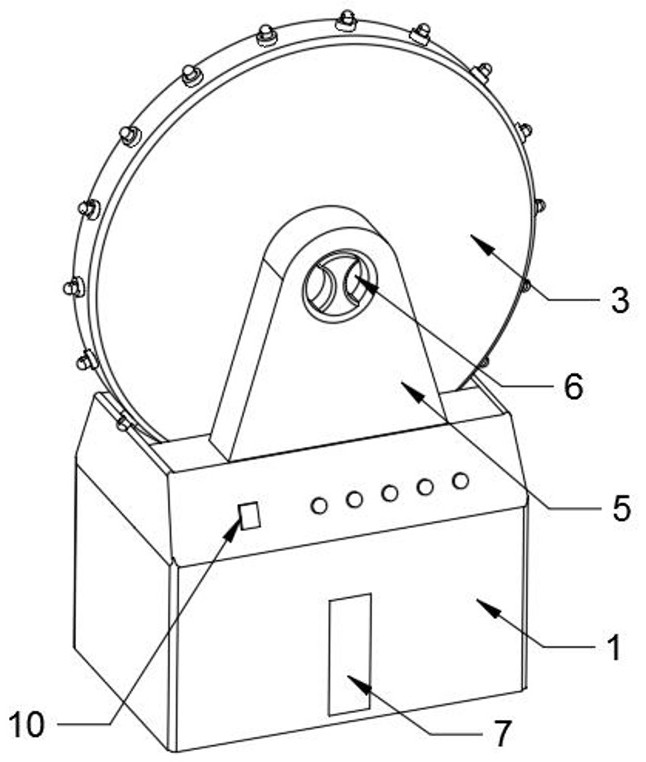

Satellite attitude control Ground full physical simulation intelligent control system

ActiveCN105242573BThe principle is simpleLow retrofit costSimulator controlLyapunov stabilitySystems design

The invention provides a satellite attitude controlled ground full-physical simulation intelligent control system, comprising a pressure regulating valve, a pressure sensor, a spirit level, a weighing sensor and a controller, wherein the control end of the pressure regulating valve and the output end of the pressure sensor are connected with the controller, and the spirit level and the output end of the weighing sensor are connected with the controller; the spirit level measures the levelness of a base and outputs data to the controller, and the weighing sensor measures the weight of a test bed in real time and outputs data to the controller; based on the thought of fussy intelligent control, a dependent variable is selected for establishing a system model, the controller enabling the system to be asymptotically stable is designed according to the Lyapunov stability analysis theory, the conservatism of the system design is lower by adopting the thought of piecewise linearization, and the description rules of the controlled object and the controller are not limited so as to improve the flexibility of the system design. The system is simple in principle and convenient to maintain.

Owner:HARBIN INST OF TECH

an air humidifier

ActiveCN111928400BRapid Eruption StationDistribute quicklyAir treatment detailsLighting and heating apparatusEngineeringMechanical engineering

Owner:SHENZHEN JISU TECHNOLOGV CO LTD

Method and device for precise and controllable cutting of graphene ribbons by photocatalytic oxidation

ActiveCN106985213BAvoid harmEasy to achieve precise controlMetal working apparatusUltraviolet lightsEngineering

The invention relates to a method and device for precise and controllable cutting of graphene ribbons by photocatalytic oxidation, characterized in that: step 1: fixing graphene with a substrate on a two-dimensional micro-motion stage driven by piezoelectric ceramics ; Step 2: Use the magnetostrictive mechanism and the power controller to realize the Z-direction positioning of the semiconductor probe; Step 3: Use the atomizer to atomize the auxiliary liquid, and the atomized auxiliary liquid is adsorbed on the surface of the semiconductor probe; Four: The ultraviolet light emitted by the ultraviolet light source is focused by the condenser and irradiated on the semiconductor probe by the light source transmission device. At the same time, combined with the ultra-precise movement of the two-dimensional micro-motion table in the X and Y directions, the cutting of graphene ribbons with different two-dimensional patterns is realized. The invention solves the problems of equipment corrosion, environmental pollution, human injury and easy failure caused by the use of traditional strengthening reagents, as well as the problems of expensive equipment, complicated operating conditions and difficult control caused by plasma and transition metals.

Owner:SHENYANG POLYTECHNIC UNIV

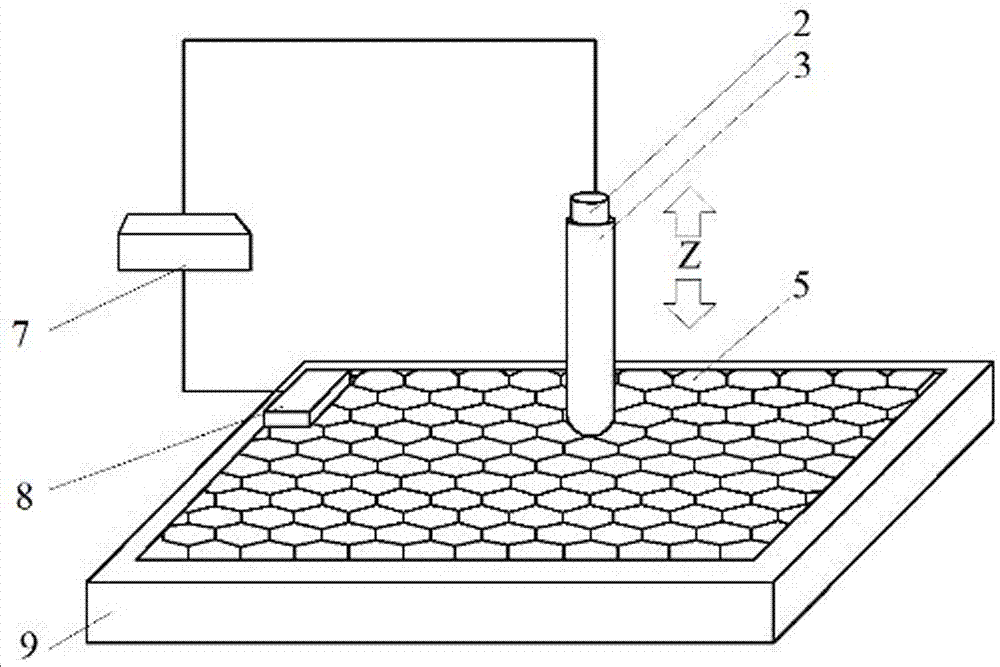

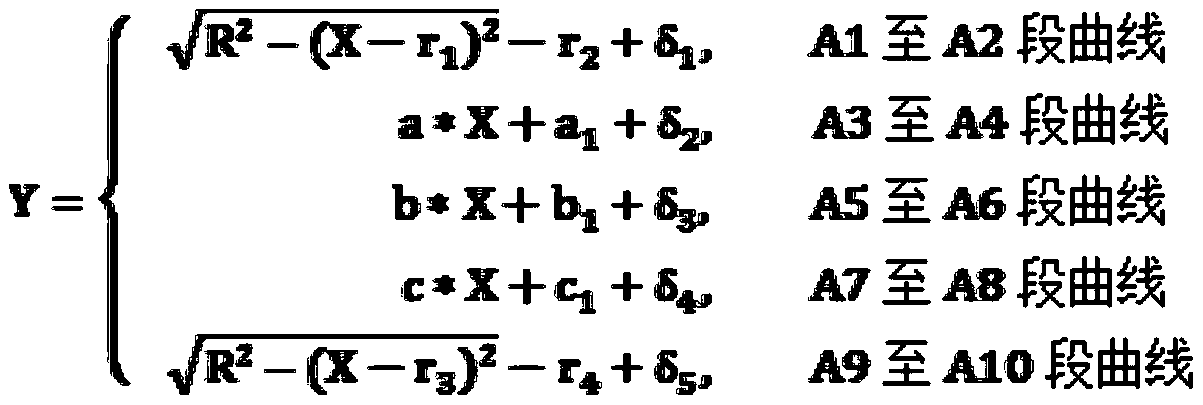

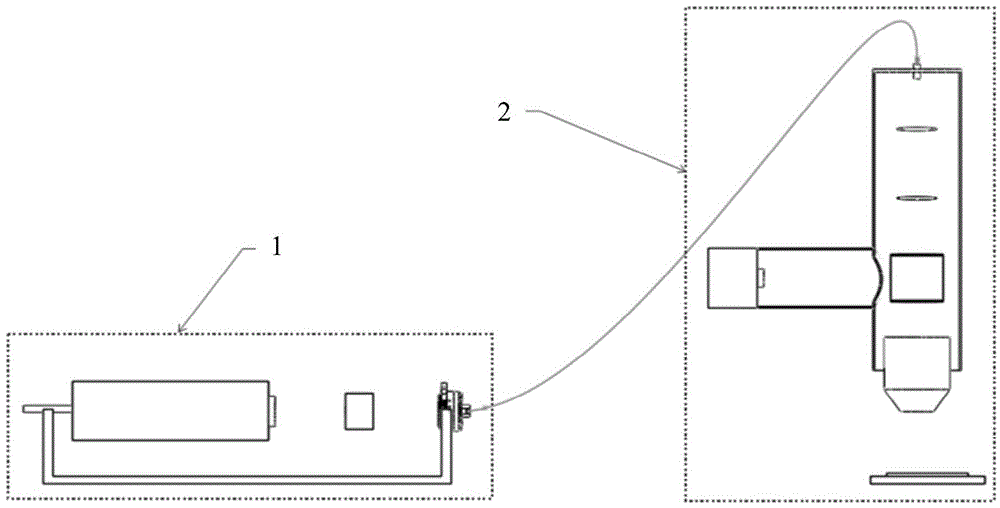

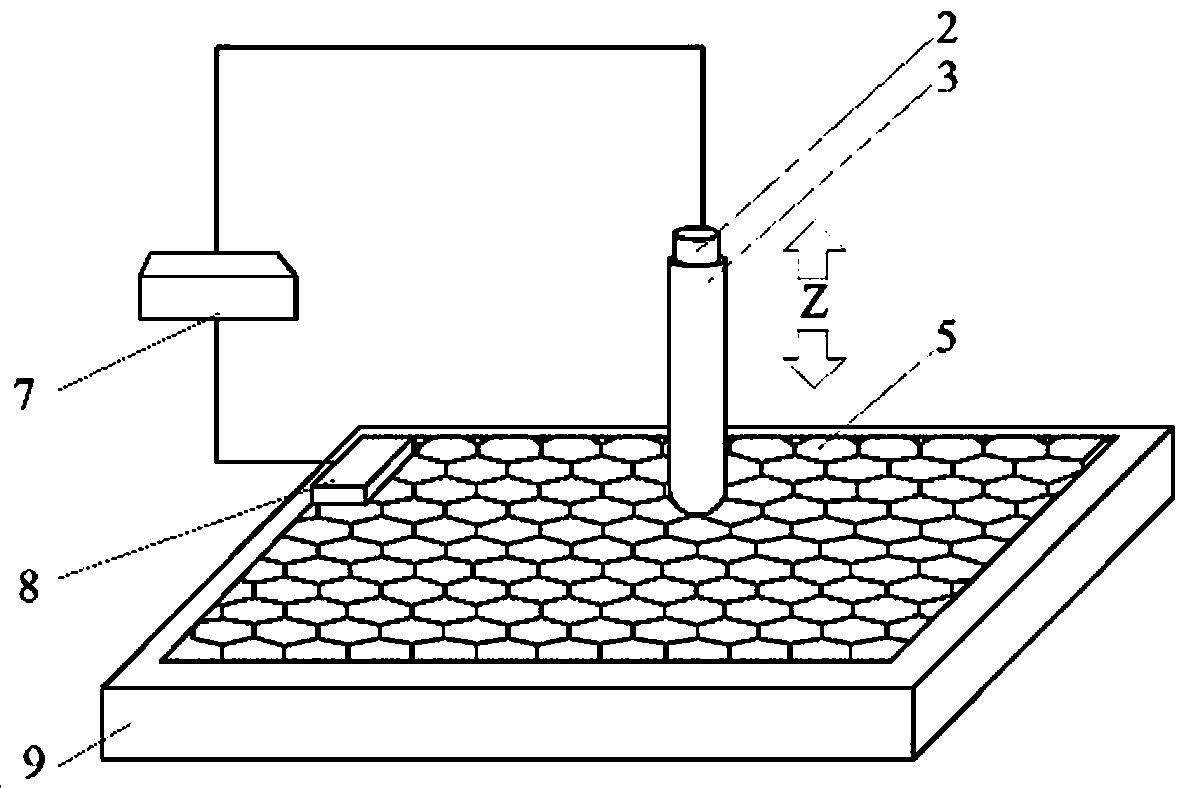

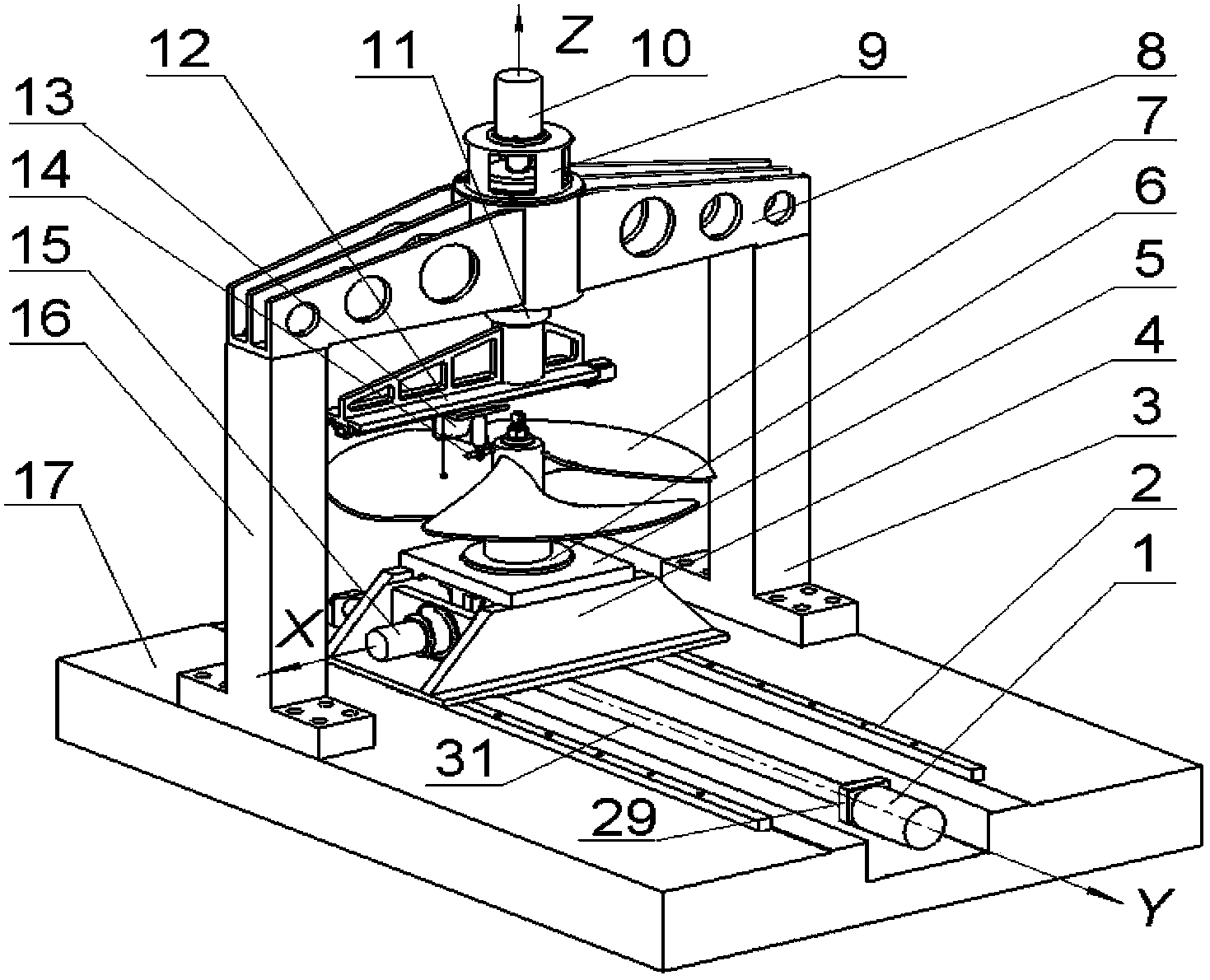

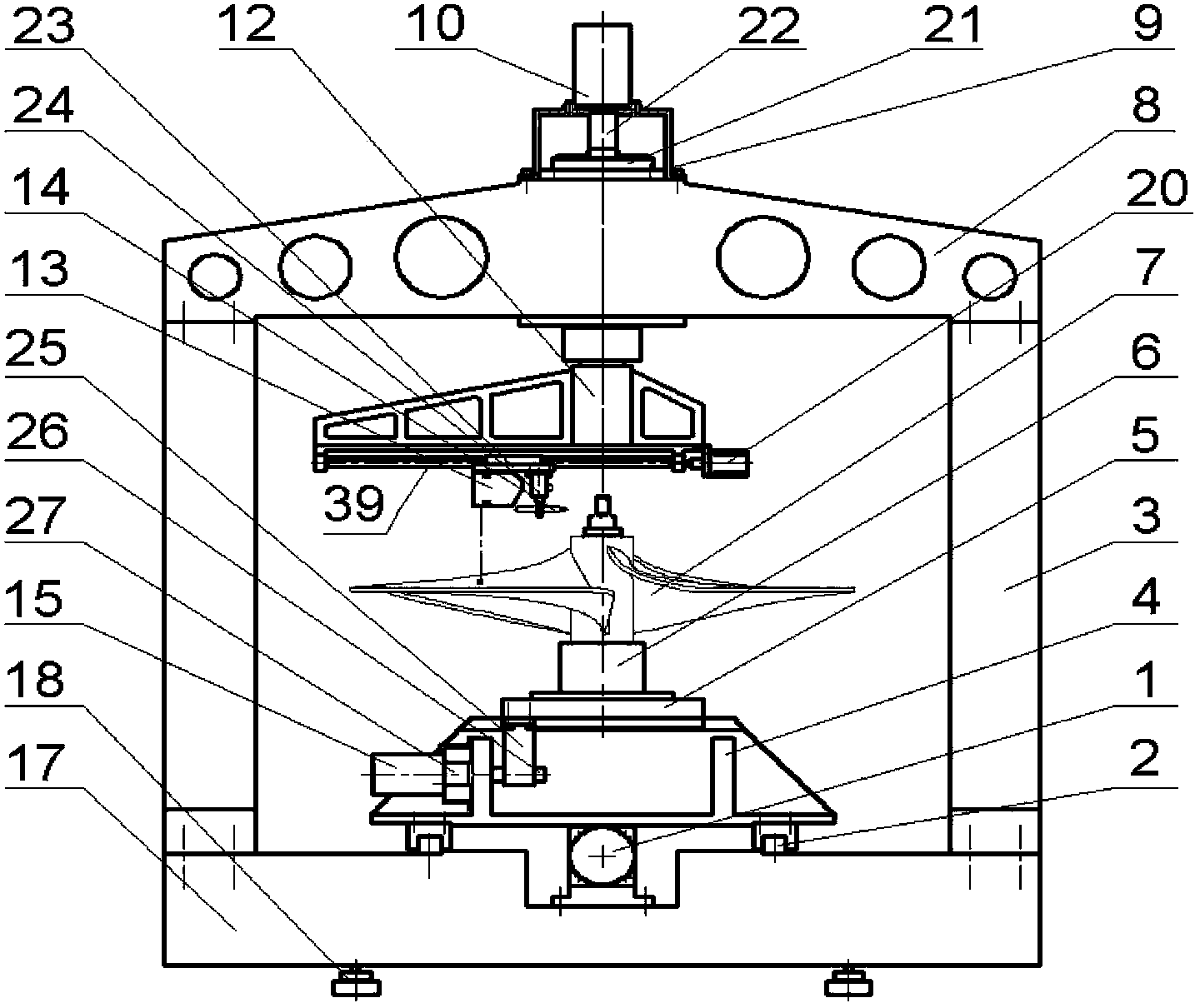

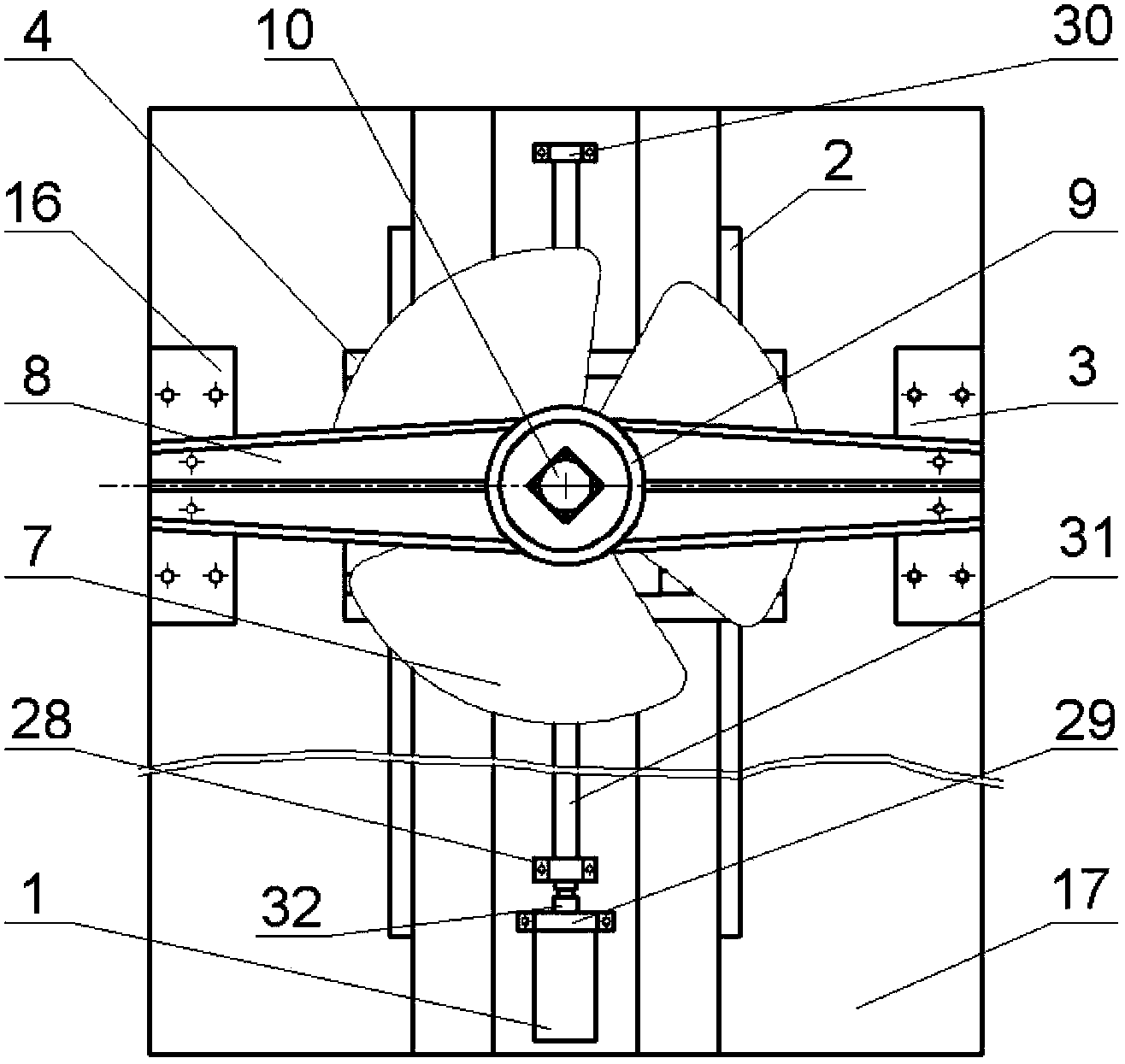

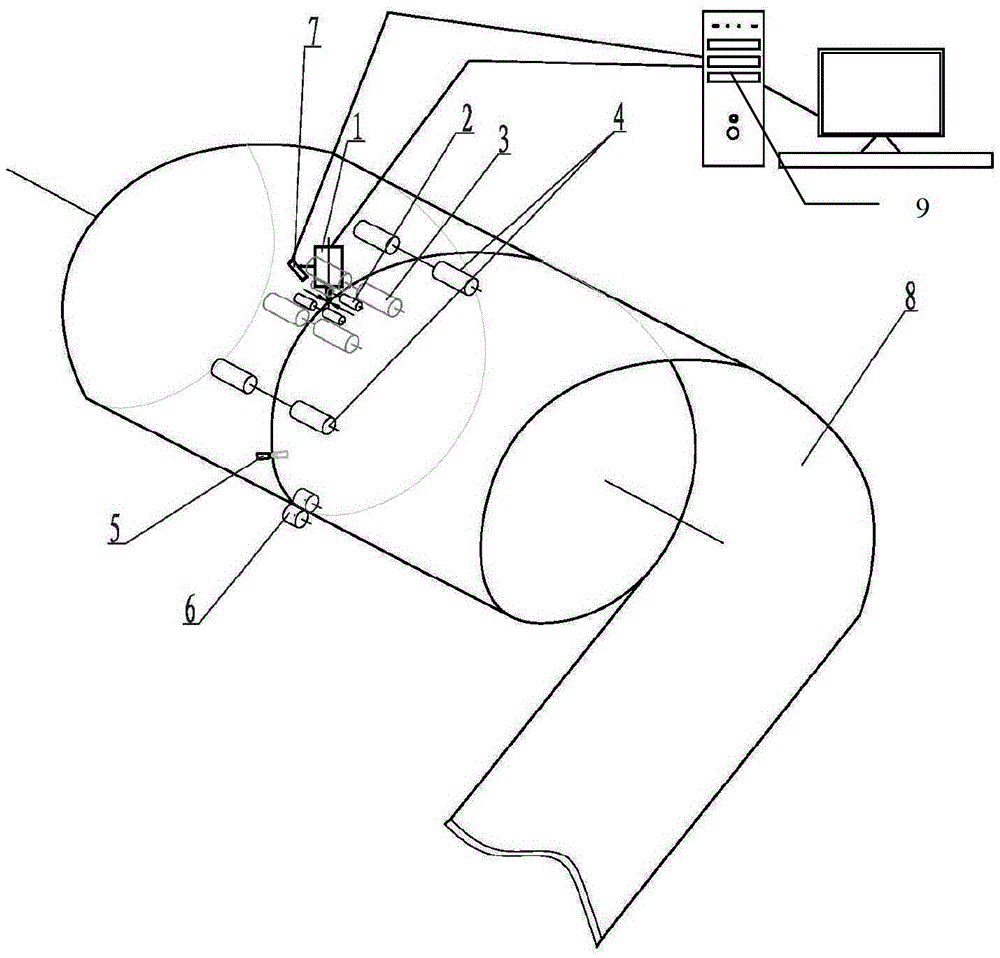

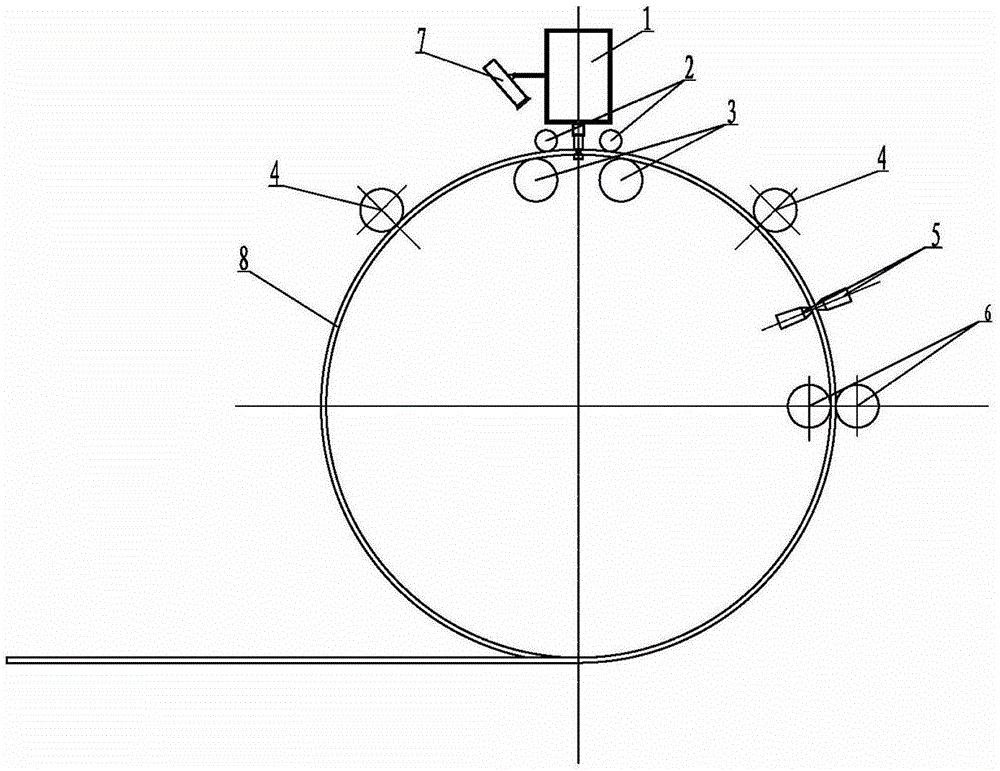

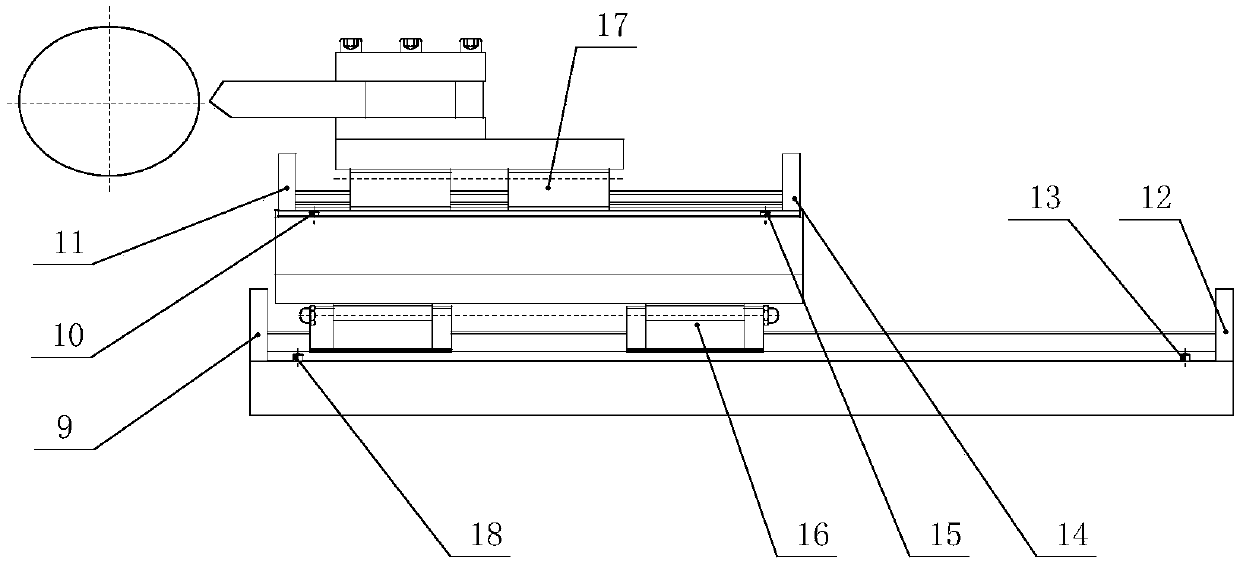

A kind of propeller profile error measuring instrument and measuring method

ActiveCN102749041BEasy to achieve 3D reconstructionAvoiding Probe Radius Compensation ProblemsElectric/magnetic contours/curvatures measurementsUsing optical meansGeometric errorMeasurement device

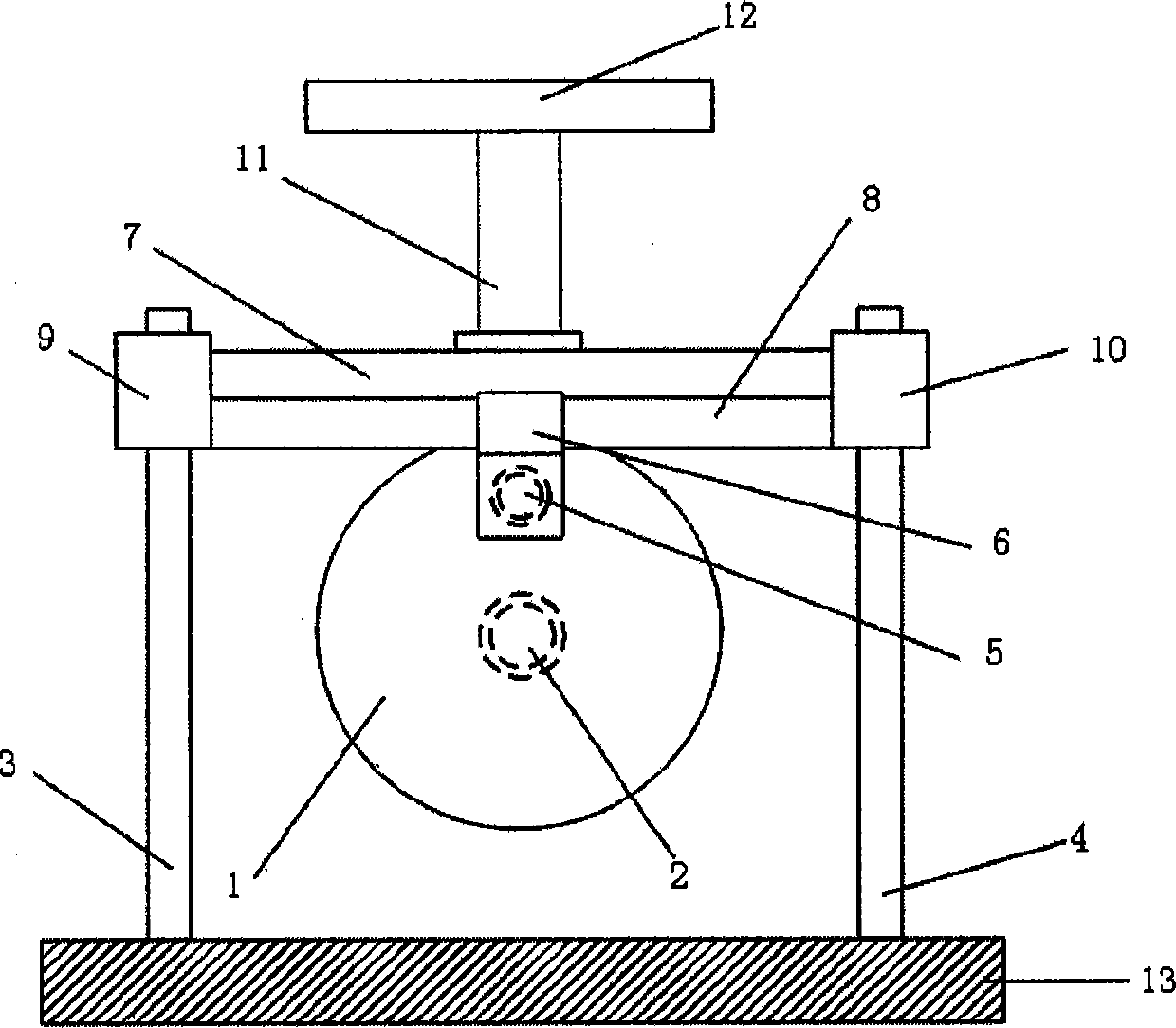

The invention discloses propeller type surface contour error measurement instrument and method. The propeller type surface contour error measurement instrument is characterized in that a gantry structure is adopted, a left upright, a right upright and a top cross beam are arranged on a base, and a revolving spindle is arranged on a cross beam; the lower end of the revolving spindle is horizontally and fixedly connected with a measuring arm; a linear guiderail is arranged on the bottom surface of the measuring arm along the radial direction of the revolving plane of the measuring arm, a working platform capable of doing linear movement along the linear guiderail is arranged on the linear guiderail, and a displacement sensor is arranged on the working platform; and a Y-direction working platform and an X-direction working platform are arranged on the base in an overlapping, and the blade of a detected propeller is arranged in a positioning groove at the top surface of the X-direction working platform. The measuring device and the measuring method are established by adopting a cylindrical coordinate system according to the axial symmetry structure characteristics of the propeller blade. The measuring device and the measuring method are fast in data acquisition, have no objective errors of an operator, and are simple in follow-up error processing and analysis, and can be used for precision measurement on size parameters and geometric error parameters of large revolving parts.

Owner:HEFEI UNIV OF TECH

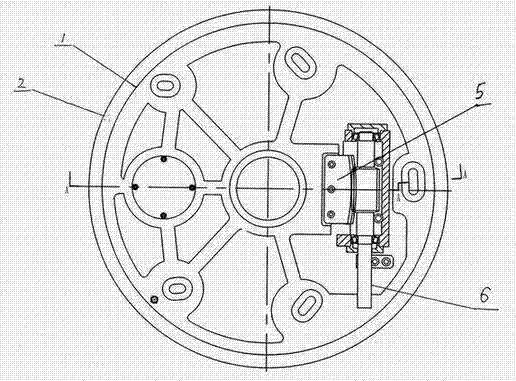

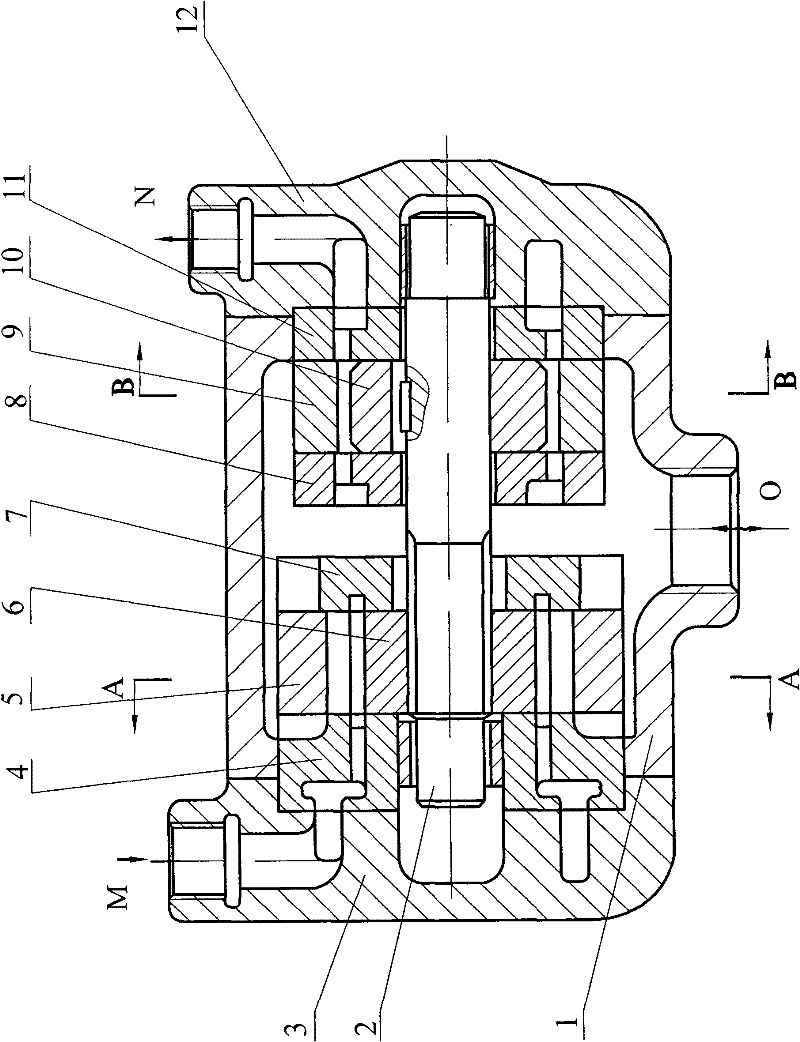

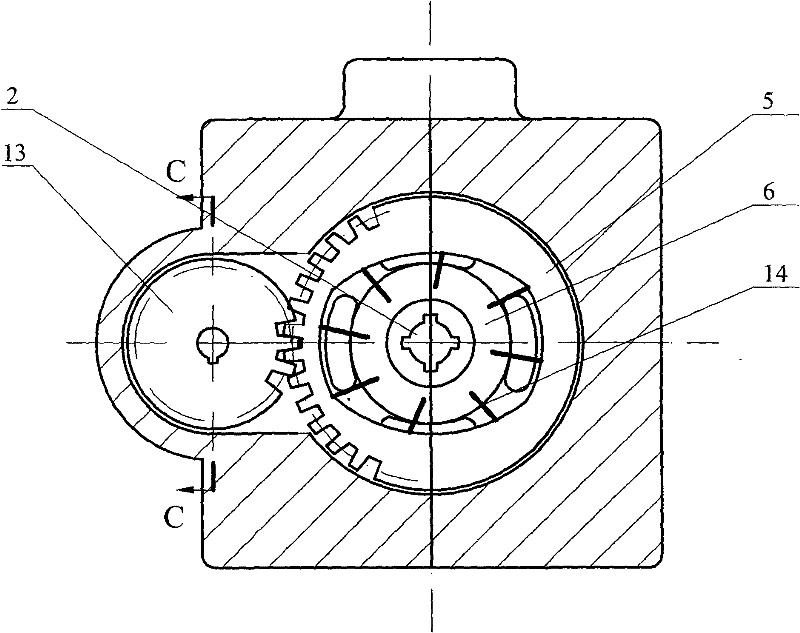

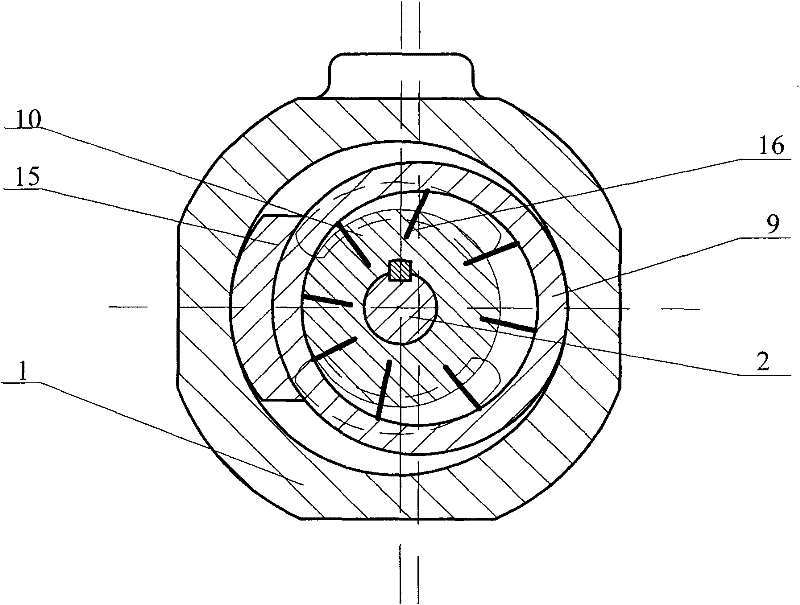

Eccentric mechanism used on working table of vertical grinder

ActiveCN102941523BEasy to achieve precise controlGuaranteed no gapToothed gearingsGrinding machinesEngineeringMachining process

Owner:XINXIANG SUNRISE CNC BEARING EQUIP

Aluminum and aluminum alloy spiral tube forming welding equipment

ActiveCN103273187BRealize digital inputRealize remote precise controlOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingFriction stir welding

Owner:姚雪飞

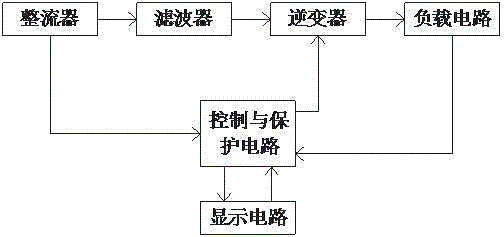

Variable-frequency heating system for electric heating plate

InactiveCN105934013AImprove performanceImprove securityCoil arrangementsLighting and heating apparatusLoad circuitMicrocontroller

The invention discloses a variable-frequency heating system for an electric heating plate. The variable-frequency heating system corresponds to the electric heating plate and comprises a controller and a variable-frequency heating device, wherein the variable-frequency heating device is connected with the controller; the controller comprises a control box body; a circuit board is arranged in the control box body and is provided with a power module, a single chip microcomputer, a rectifier, a filter, an inverter, a load circuit and a display module; the power module is connected with an external power supply and is connected with the single chip microcomputer and the rectifier; the single chip microcomputer is connected with the display module; the rectifier is connected with the filter; the filter is connected with the inverter; the inverter is connected with the load circuit; the load circuit is connected with the variable-frequency heating device; and the control box body is provided with a display screen. The variable-frequency heating system is reasonable in design; the performance of the power supply is improved; the heating cost is reduced; the heating volume is reduced; local heating can be finished; and the heating capacity and the heating temperature can be accurately controlled according to the demand quantity, so that waste of energy is reduced; the cost is reduced; and the electro-thermal conversion energy efficiency ratio is greatly improved.

Owner:青岛鑫鸿暖石墨烯科技有限公司

Micro-flow control system, normally-closed micro-valve and control method

PendingCN108843855AThe production process is simpleReduce generation costValve arrangementsMicro valveEngineering

The invention discloses a micro-flow control system, a normally-closed micro-valve and a control method. The normally-closed micro-valve comprises a micro-flow pipeline which is formed inside a base body; a valve element is arranged inside the micro-flow pipeline and is used for dividing the micro-flow pipeline into a first pipeline and a second pipeline; when the valve element is molten or gasified, the first pipeline communicates with the second pipeline; the valve element and the wall of the micro-flow pipeline are made from the same material; and a transparent material is arranged betweenthe outer wall surface of the base body and the valve element. The micro-valve disclosed by the invention is simple in structure, can solve the problem of integration of the micro-valve and the micro-flow control system and greatly reduces the machining difficulty because the valve element and the wall of the micro-flow pipeline are made from the same material, so the production cost is lowered.

Owner:HUNAN LEGEND AI CHIP BIOTECH CO LTD

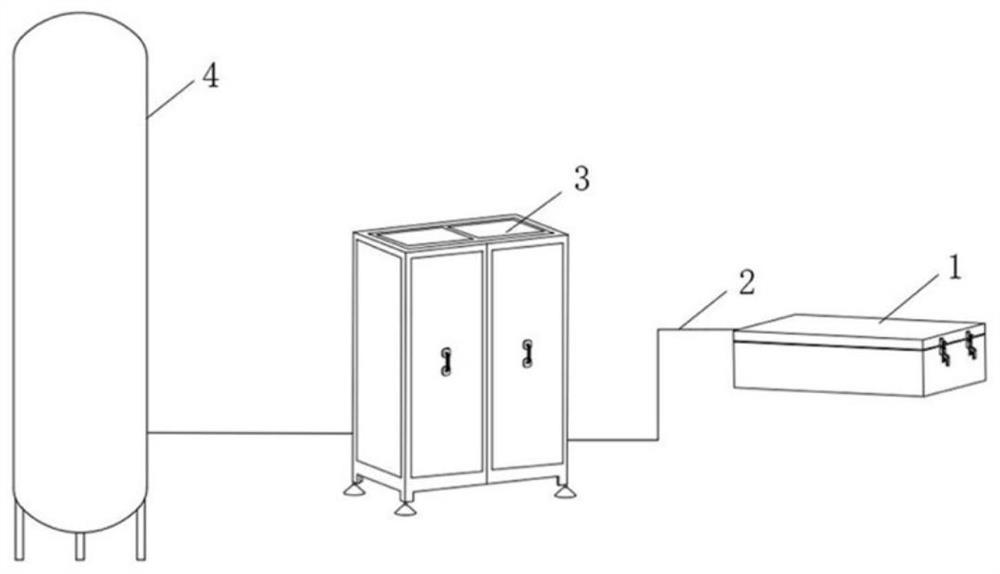

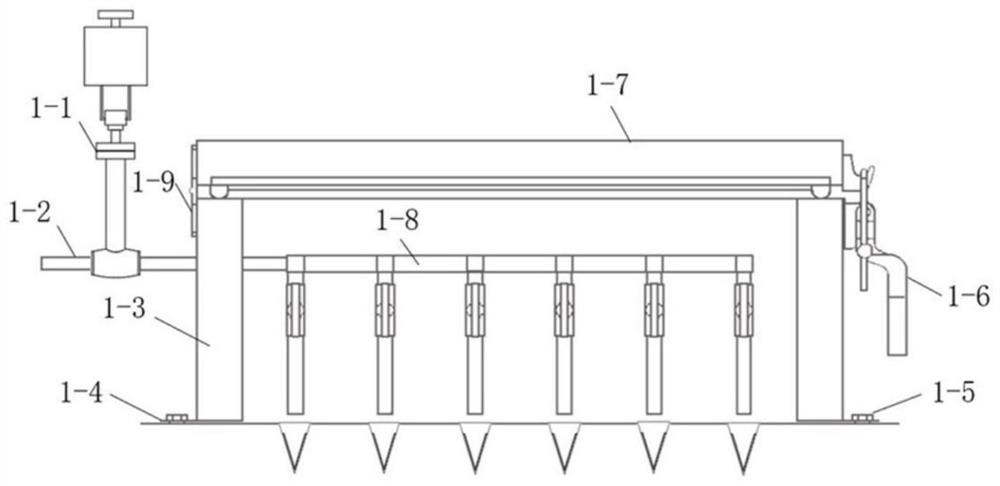

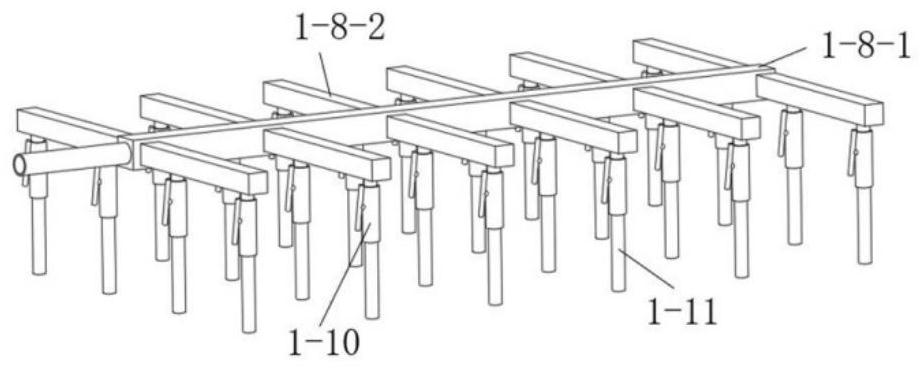

Freezing device capable of realizing rapid condensation of chocolate coating in ice cream crisp cone

PendingCN114719486AGood for condensationFull utilization of cold energyDomestic cooling apparatusLighting and heating apparatusIce CreamsManufacturing line

The invention relates to a freezing device capable of realizing rapid condensation of a chocolate coating in an ice cream cone. The freezing device comprises a condensation box, a vacuum pipe, an integrated vaporization box and a liquid nitrogen storage tank. A plurality of spray pipes are arranged in the condensation box, and connecting plates connected with an ice cream cone production line are welded to the lower end faces of the two sides of the condensation box; and the spray pipe is opposite to the opening of the ice cream cone on the production line. The device can be directly installed on a mature ice cream cone production line, chocolate coatings can be rapidly condensed, the structure is simple and compact, and cold energy is fully utilized.

Owner:CHENGDU CRYOSTECH EQUIP CO LTD

Blade-type hydraulic transformer controlled by motor

Owner:SHANDONG JIAOTONG UNIV

CNC Cyclone Milling Method for Convex and Elliptical Piston

ActiveCN103658786BHigh movement precisionImprove dynamic stabilityMilling equipment detailsMagnetostrictive actuatorEngineering

The invention discloses a numerical control whirlwind milling method for middle-convex and varying ellipse pistons. The method comprises the following steps of inputting parameters: the design size and the technical requirements of a workpiece are input into a numerical control system; selecting a cutting tool and calculating the tool path data via the numerical control system according to the input parameters in step one to determine the linkage tool path data of C, Z and X axes of a machining tool; checking the tool path data via a simulation module; clamping and positioning; machining, starting a numerical control machining procedure, using a motor to drive a cutter head to revolve at high speed, and simultaneously controlling the spindle of the machine tool to drive the workpiece for C axis movement; controlling the cutter head for Z axis and X axis movement, and obtaining the outer surface of the piston through the linkage machining of C, X and Y axes. The method adopts the whirlwind milling process to machine the middle-convex and varying ellipse piston; the machine tool has the advantages of high movement accuracy and good dynamic stability. The method is easy to realize the accurate control to the machining process, and does not require corresponding high-frequency actuating mechanisms such as a linear motor, a magnetostrictive actuator and the like; therefore, the equipment cost is reduced.

Owner:SHANDONG UNIV

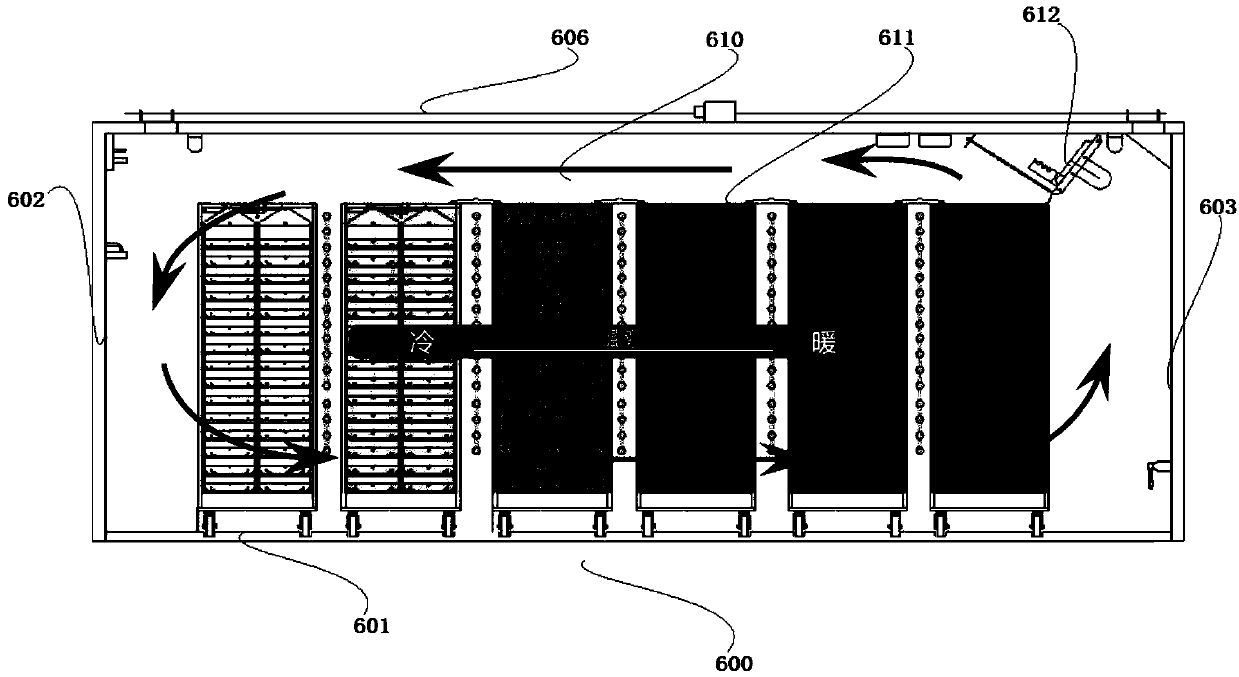

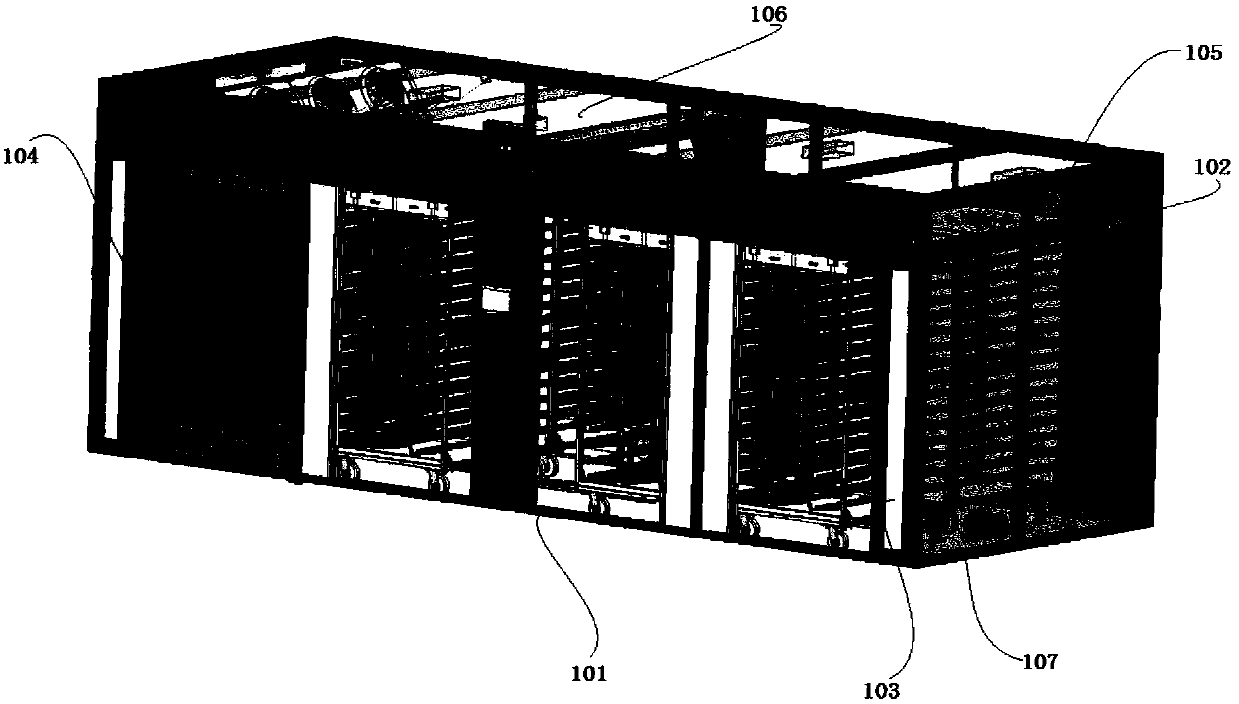

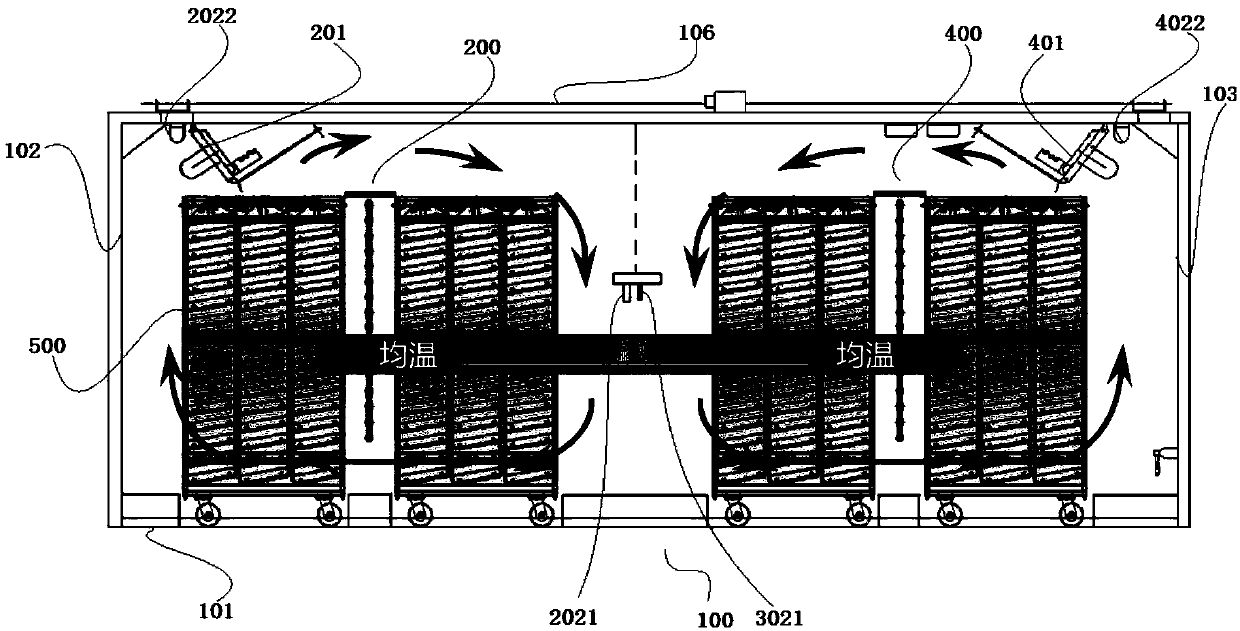

Intelligent dual-circulation incubator

PendingCN107926760AGuaranteed temperature difference controlReduce loadPoultry incubationTemperature controlEngineering

The invention discloses an intelligent dual-circulation incubator. The intelligent dual-circulation incubator comprises at least two incubation spaces, a temperature control system and stirring fan units. The number of the incubation spaces is even; each incubation space is composed of a bottom plate, an upper cover plate, two side walls and at least two doors, wherein the side walls are vertically and fixedly arranged between the bottom plate and the upper cover plate, and the doors are arranged at the two ends of every two incubation spaces and installed on the side walls. The stirring fan units correspond to the incubation spaces and are installed in the incubation spaces respectively; specifically, the stirring fan units correspond to the incubation spaces and installed in every two incubation spaces. Aiming at a single-stage high-volume incubator, the air flow path can be shortened, then the temperature gradient of the incubator is improved, the uniformity of a temperature field is optimized, the incubation rate and the healthy nestling rate of eggs are improved, and the incubator has an important significance in incubation and breeding.

Owner:ANHUI RUIGE ELECTRONICS TECH

Design Method of Slit Nozzle Diffusion Section of Side Force Engine

ActiveCN106677925BReduce the coupling effect of external flowEasy to achieve precise controlRocket engine plantsEngineeringDesign methods

Owner:SHANGHAI XINLI POWER EQUIP RES INST

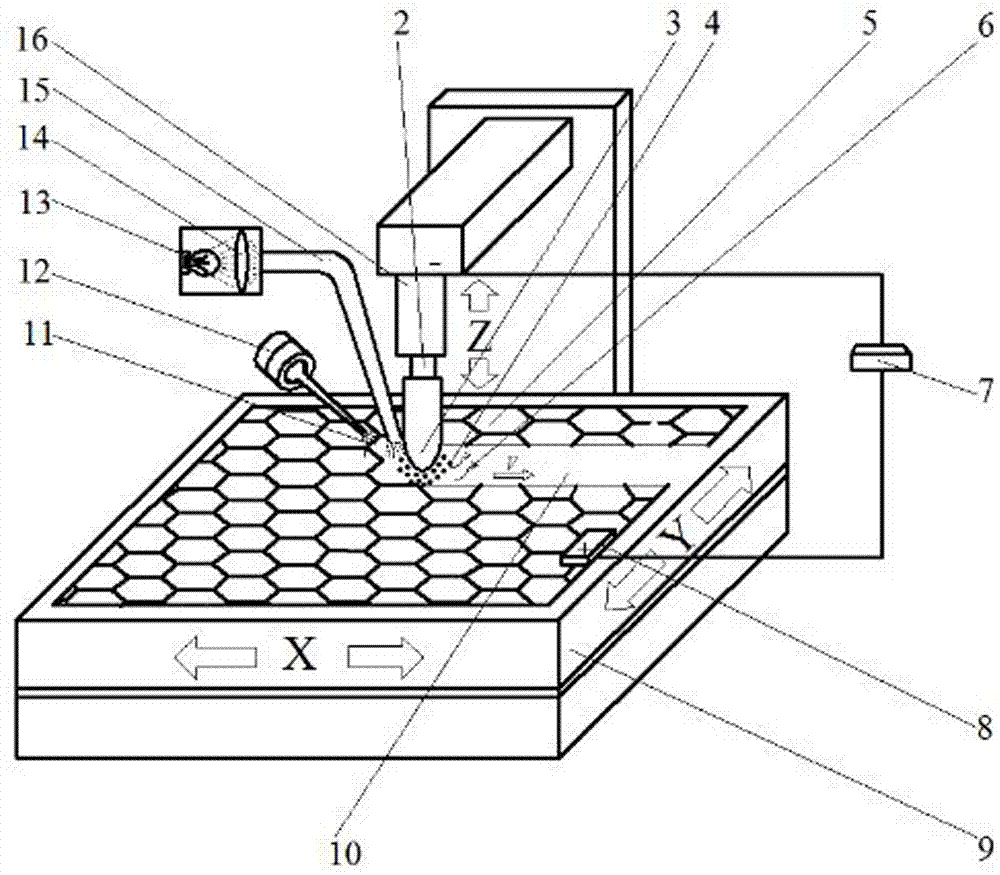

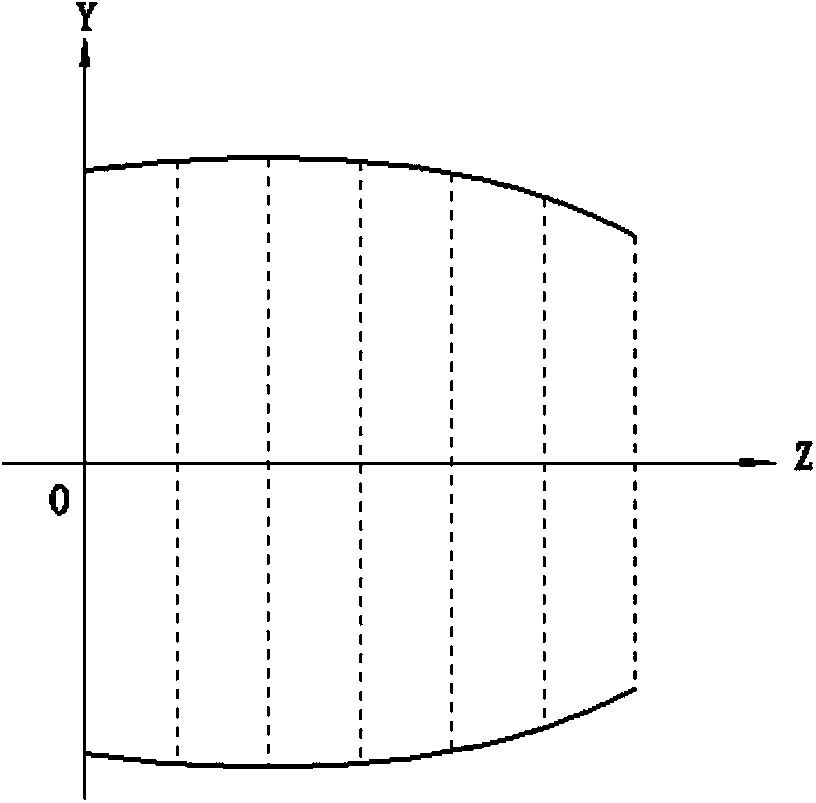

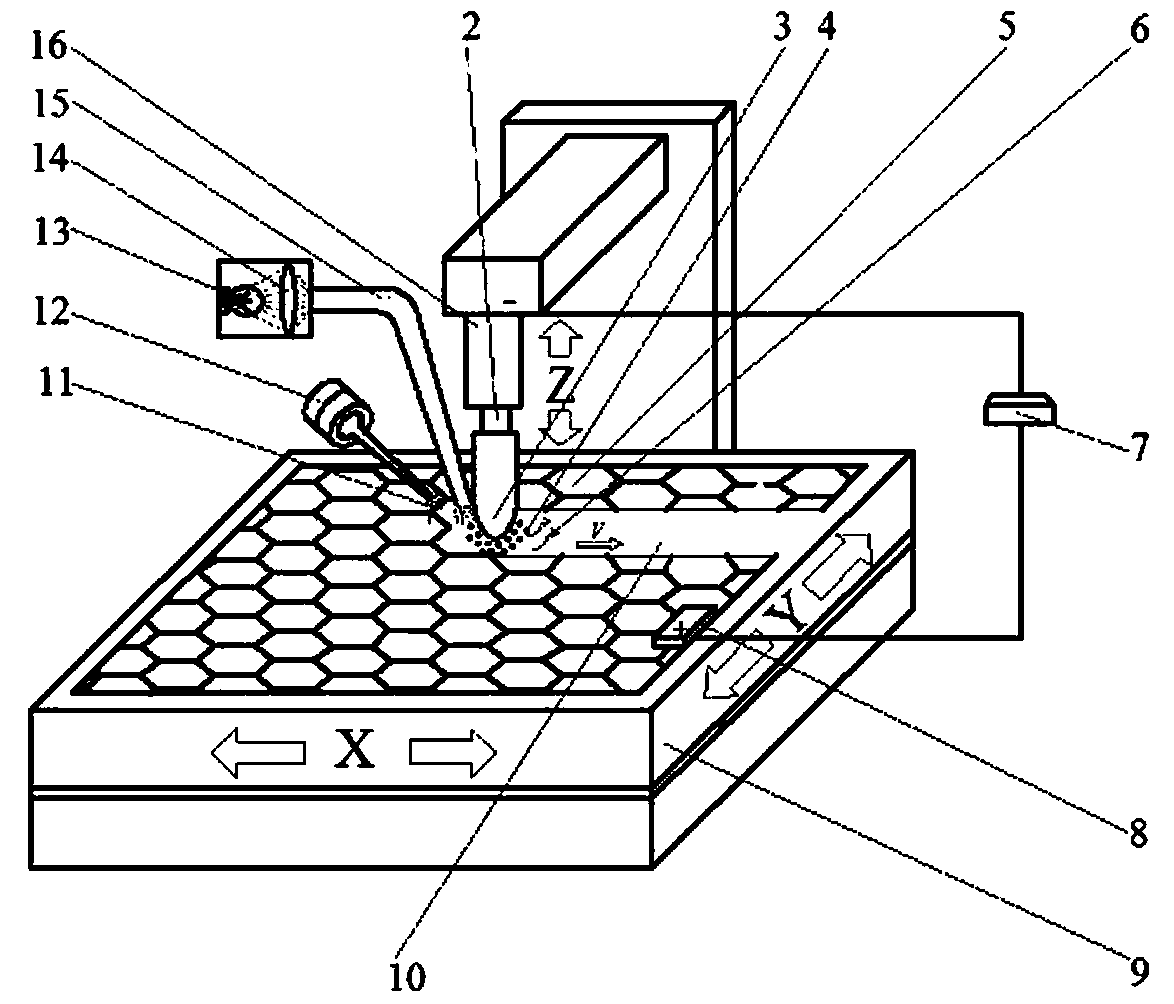

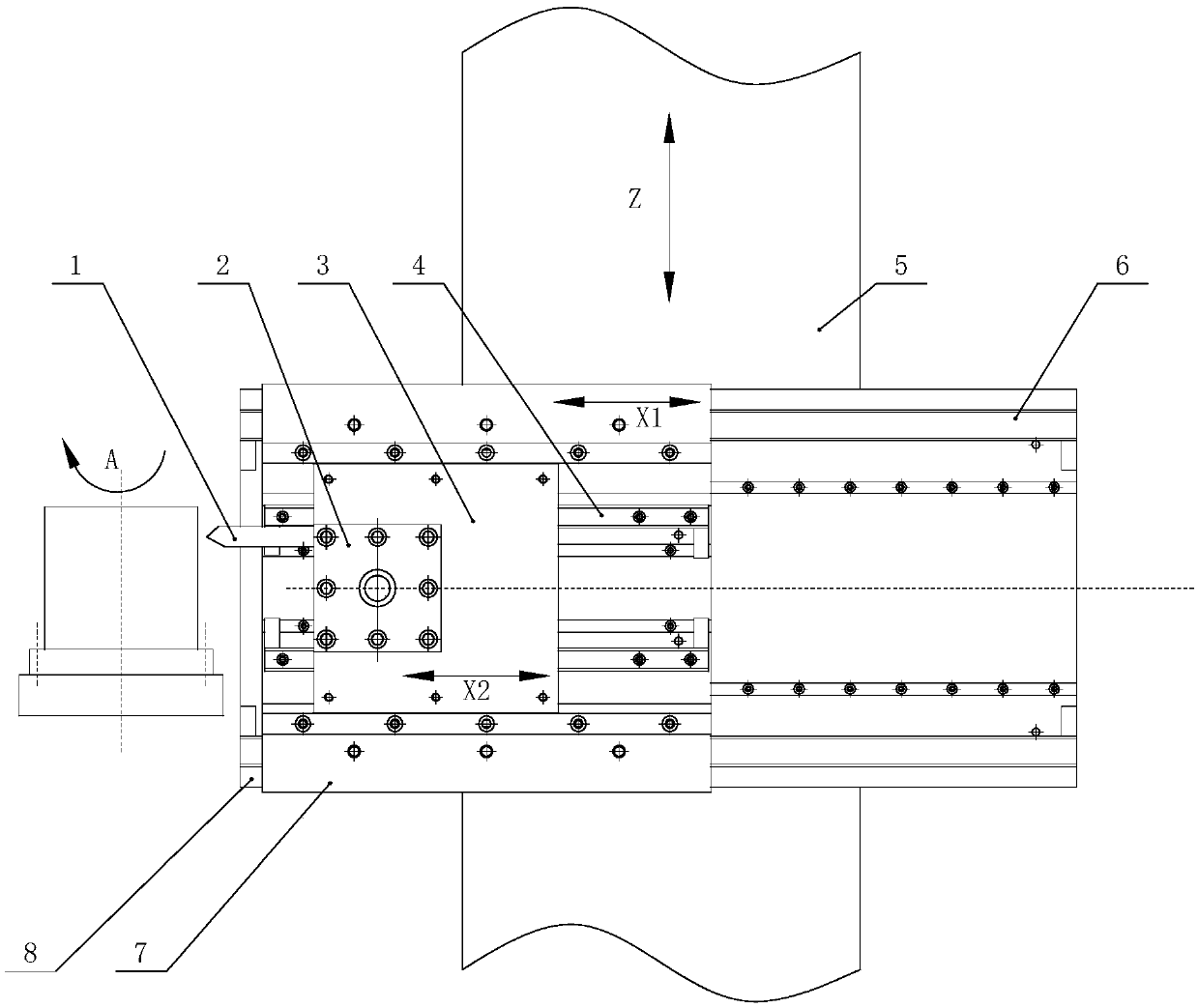

Child-mother sliding table device for rapid response for piston machining

InactiveCN109571057AHigh movement precisionEasy to achieve precise controlFeeding apparatusLarge fixed membersConvex sideEngineering

The invention provides a child-mother sliding table device for rapid response for piston machining. The child-mother sliding table device comprises a vertically-mounted Z axis feed system, a mother sliding table X1 system, and a child sliding table X2 system. A workpiece is clamped and fixed by a fixture and can rotate around the A axis of the workpiece. Feeding of the Z axis feed system is achieved by driving of a servo motor. The mother sliding table X1 system is vertically mounted on the Z axis feed system and can slide leftwards and rightwards with respect to the workpiece under driving ofa first linear motor. The mother sliding table X1 system and the Z axis feed system are interpolatedto form a generatrix of the middle-convex side of the workpiece. The child sliding table X2 systemis vertically mounted on a first sliding table of the mother sliding table X1 system and can reciprocate at high frequency with respect to the mother sliding table X1 system under driving of a secondlinear motor. The child sliding table X2 system and the self-rotating A shaft of the workpiece are interpolated to from a non-circular cross section of the workpiece. Compared with the prior art, large-stroke feeding is achieved, high-frequency reciprocating feeding is achieved, machine tool moving accuracy is high, and accurate machining procedure control is easy to achieve.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Preparation method of carbon-coated cobalt metal nanoparticles

InactiveCN103695864BHigh purityPurity is easy to controlNanotechnologyChemical vapor deposition coatingCobalt metalChemical plating

The invention discloses a preparation method of carbon-coated cobalt metal nano-particles, which relates to a gaseous compound decomposition-based chemical plating by which reaction product of surface material is not preserved in a plating layer and only carbon is deposited, and is a method for decomposing ethyne and synthesizing carbon-coated cobalt metal nano-particles on potassium chloride carrier by means of chemical vapor deposition. The preparation method comprises the following steps: firstly, preparing cobalt-potassium chloride catalyst, then, synthesizing carbon-coated cobalt metal nano-particles, and finally, performing purification to obtain the carbon-coated cobalt metal nano-particles with purity of 95-99%. The preparation method overcomes the defects that the carbon-coated metal nano-particles synthesized by the existing technology have low purity, poor performance and low yield, and contains overmuch impurities, and the impurities are not easy to remove.

Owner:HEBEI UNIV OF TECH

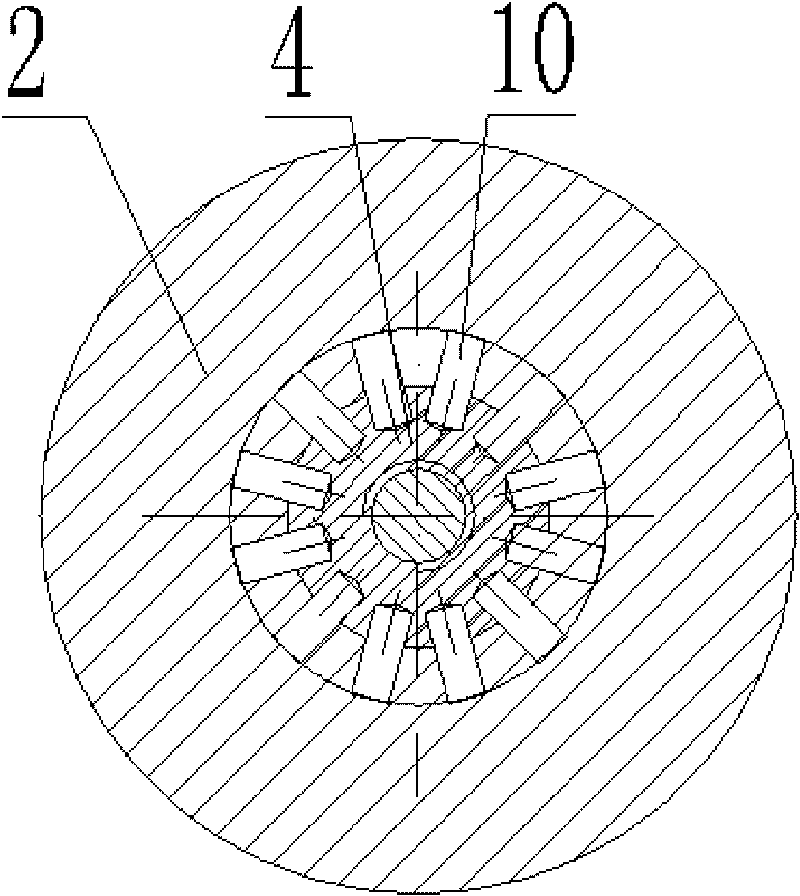

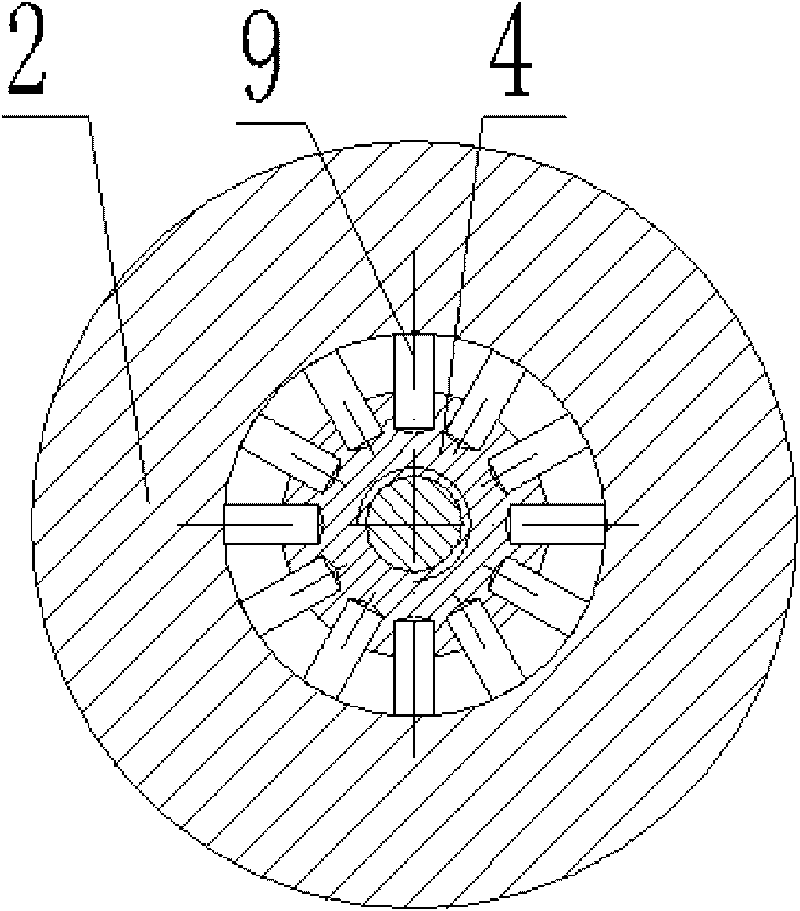

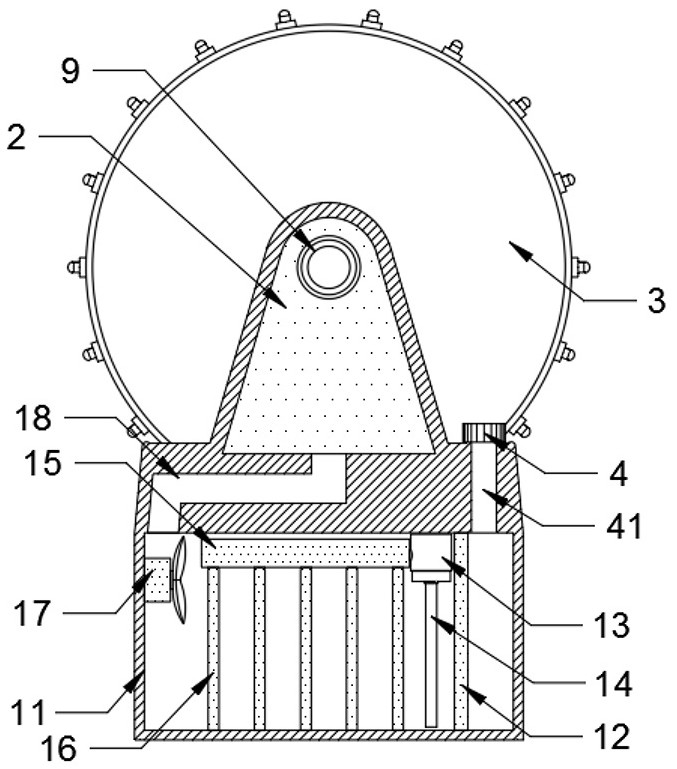

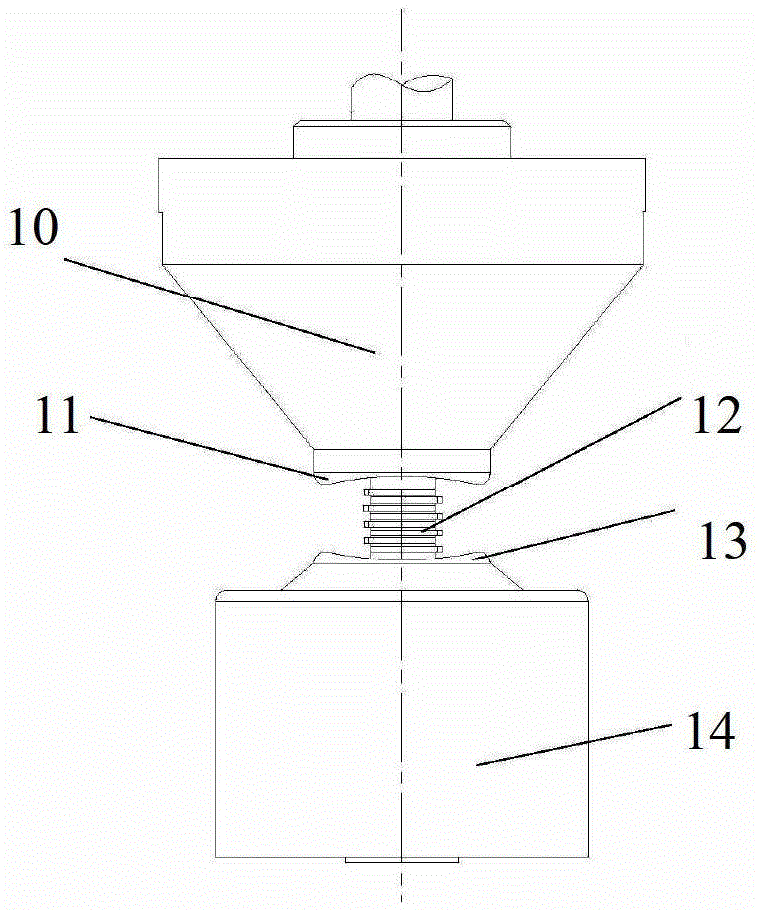

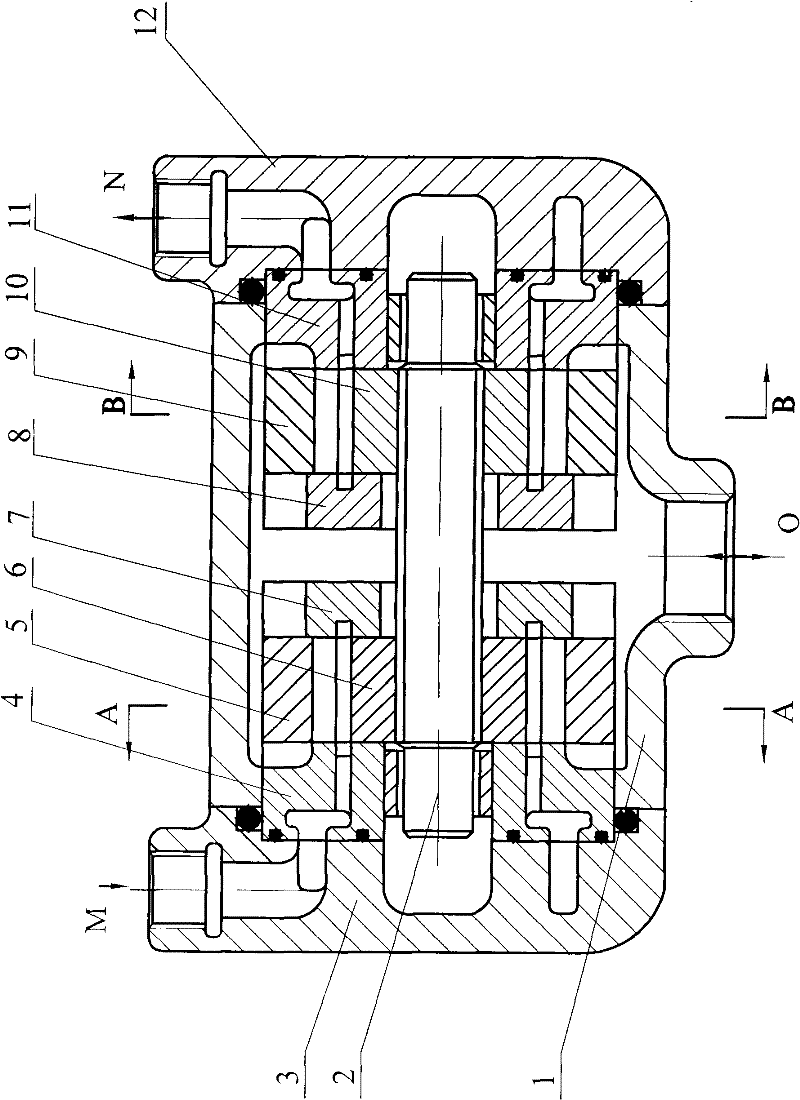

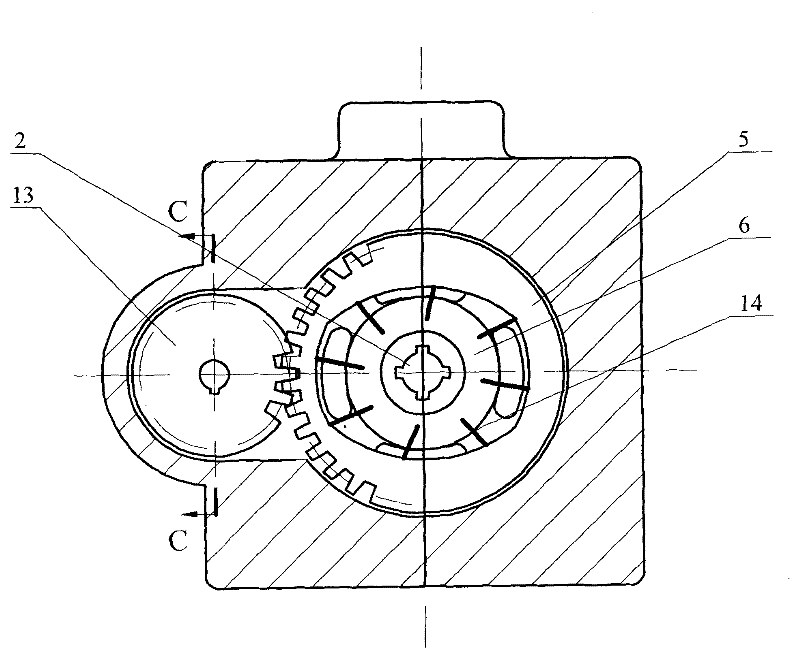

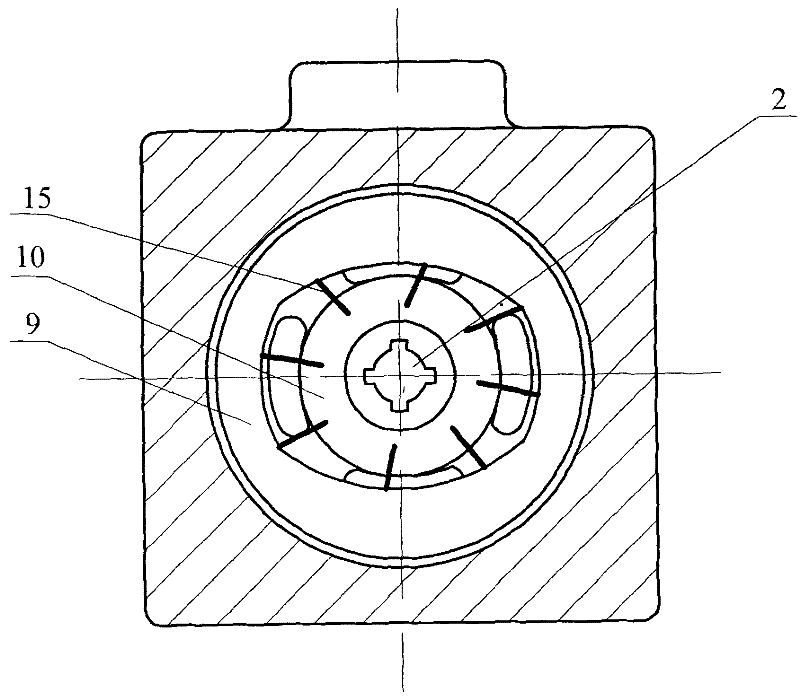

Difunctional vane type hydraulic transformer controlled by motor

The invention discloses a difunctional vane type hydraulic transformer controlled by a motor, comprising a housing, a rotation axis, a left end cap, a port plate, stators, rotors, a right end cap, a gear, a vane, a motor, etc. The invention is characterized in that the centers of the rotor and the center of the stator are fixed and coincident, and the vane is arranged along the radial direction of the rotor; one rotor is connected with the left half axis of the rotation axis in a matching mode by a spline, and the other rotor is connected with the right half axis of the rotation axis in a matching mode by a spline; the outer ring of one stator is made into a gear form by taking the major radius arc center as the center and ranging within 150 degrees, and one stator and the gear form a gear transmission pair; the gear is installed on the output axis of the motor, the motor is arranged on the housing, and the port plate is arranged on the rotation axis and is tightly pressed on the leftside surface and the right side surface of the rotor; and the left end cap and the right end cap are fixed on the housing via bolts. The invention has the beneficial effect that the invention can adjust the voltage of a constant-voltage network system to any value within induced pressure variation range in the way of no throttle loss, and can be used in medium-voltage hydraulic systems and high-voltage hydraulic systems.

Owner:SHANDONG JIAOTONG UNIV

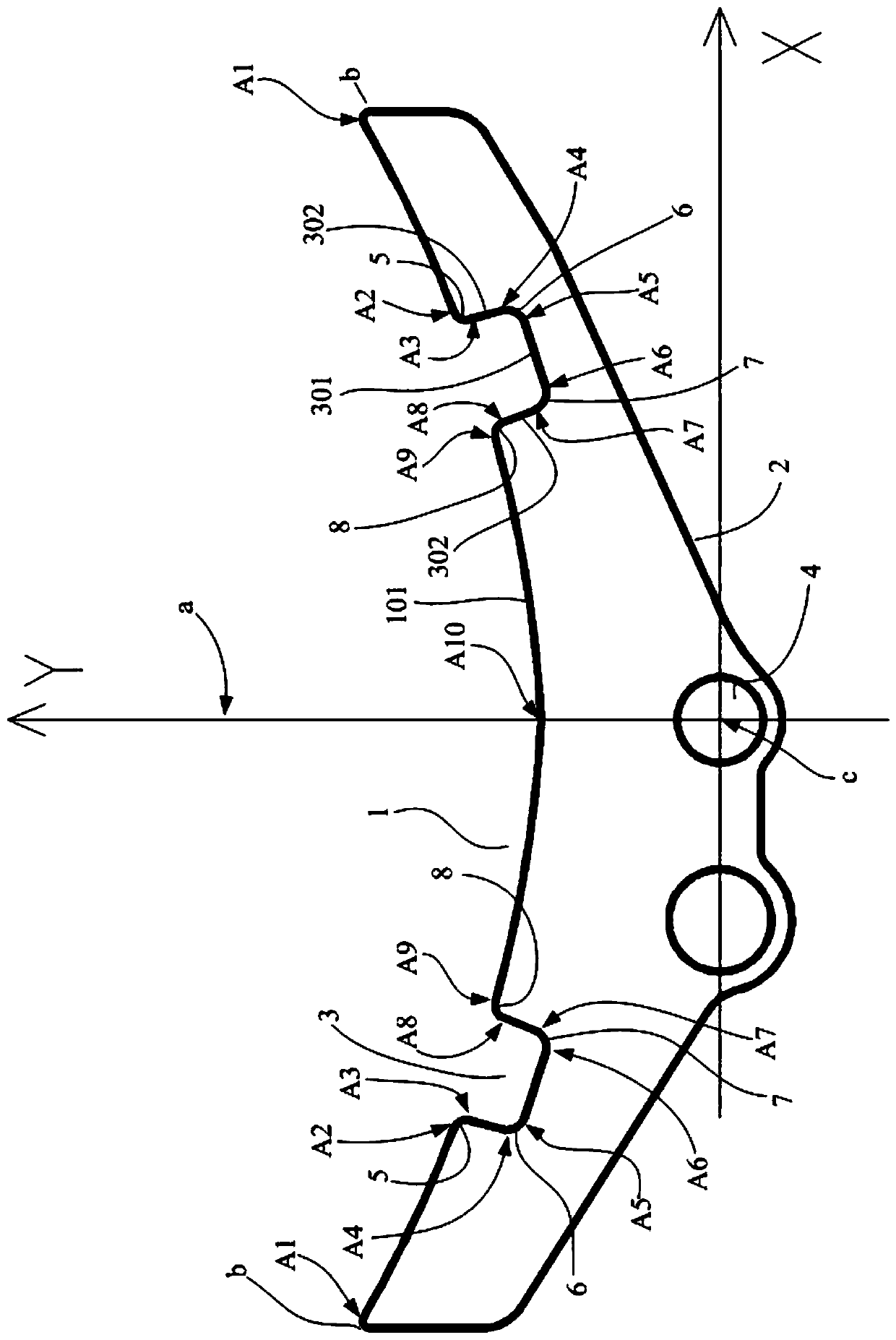

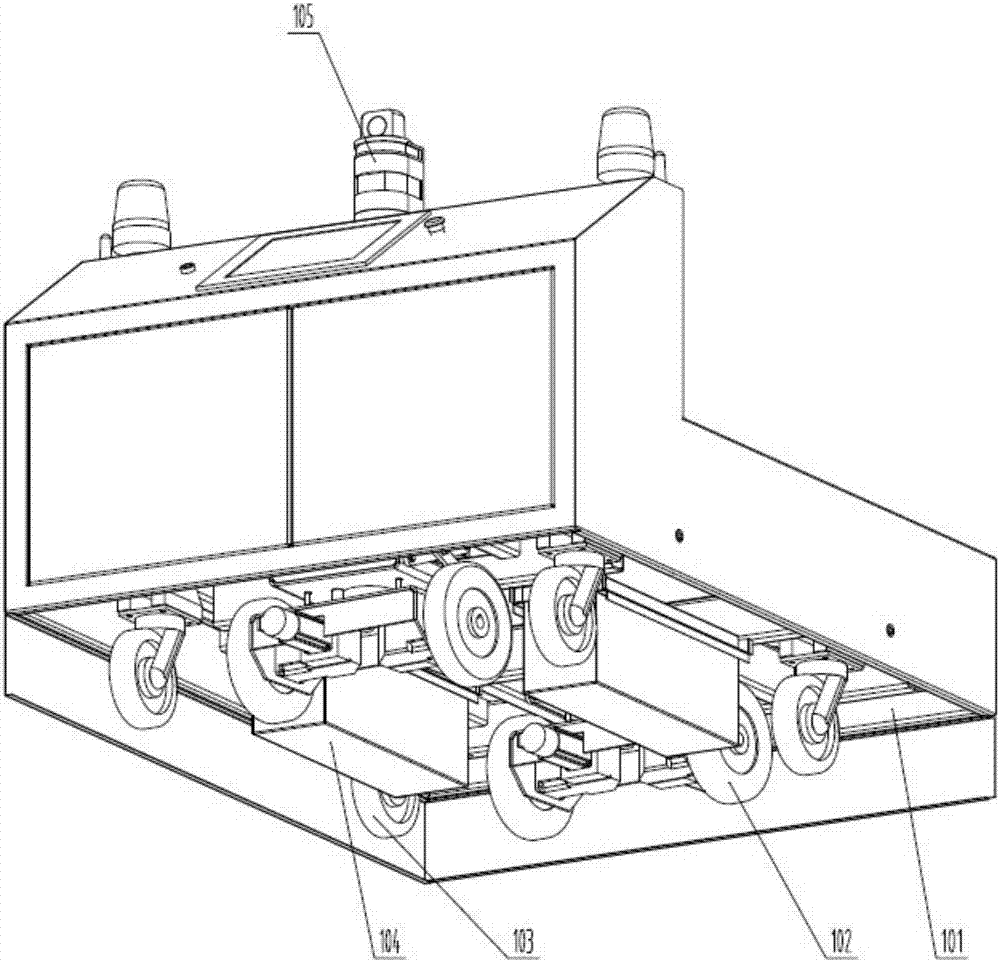

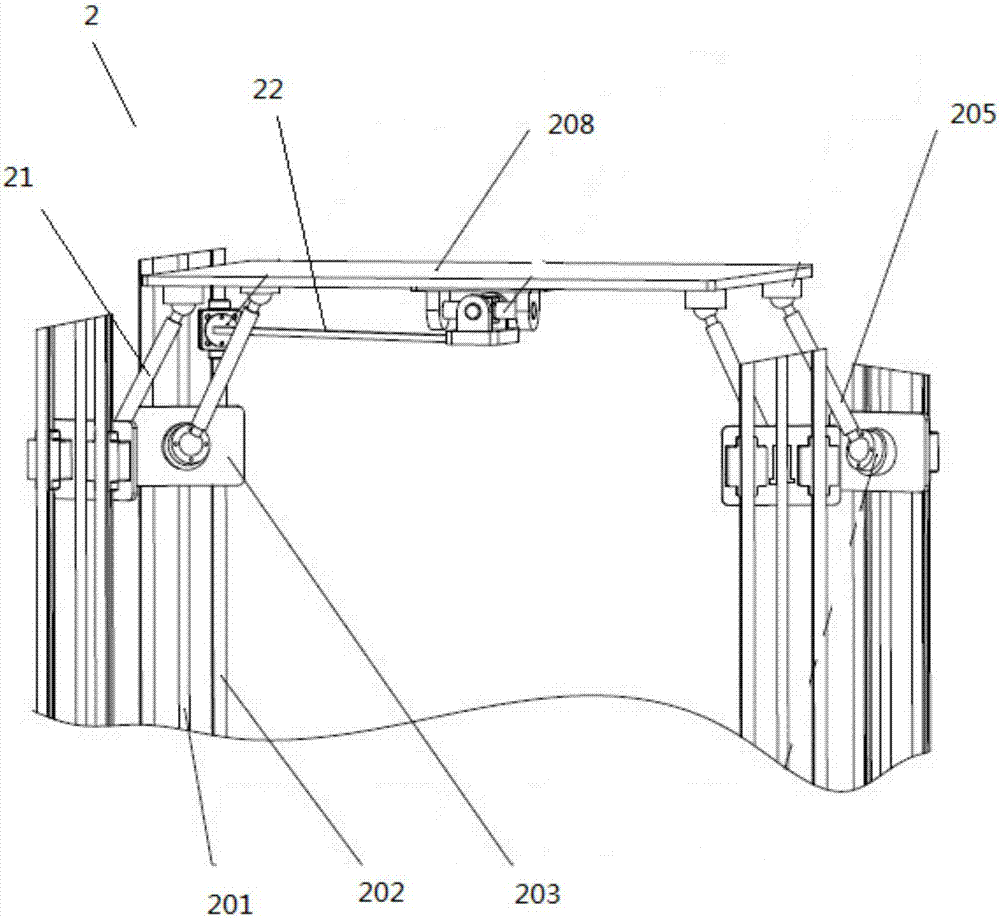

Trans-dimension six-freedom-degree automatic butt joint system

InactiveCN107053131AImprove carrying capacityFlexible movementProgramme-controlled manipulatorButt jointDegrees of freedom

The invention discloses a trans-dimension six-freedom-degree automatic butt joint system. The trans-dimension six-freedom-degree automatic butt joint system comprises a self-walking mechanism, a horizontal adjusting mechanism, a plane adjusting mechanism and a bottom plate. The horizontal adjusting mechanism is arranged on the self-walking mechanism. The plane adjusting mechanism is arranged on the horizontal adjusting mechanism. The bottom plate is arranged on the plane adjusting mechanism. The self-walking mechanism drives the horizontal adjusting mechanism and the plane adjusting mechanism to move. The horizontal adjusting mechanism adjusts the X-direction rotation, the Y-direction rotation and the Z-direction large-stroke movement. The plane adjusting mechanism adjusts the X-direction movement, the Y-direction movement and the Z-direction rotation, and the bottom plate is fixedly connected with one butt joint module. Thus, the self-walking mechanism, the horizontal adjusting mechanism and the plane adjusting mechanism are used for adjusting the posture of the butt joint modules so that long-distance transportation and accurate six-freedom-degree posture adjustment and butt joint of two butt joint modules in the space are achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com