CNC Cyclone Milling Method for Convex and Elliptical Piston

A processing method and ellipse-changing technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems that the tool is difficult to accurately track the spindle angle, poor stability, and difficult to ensure machining accuracy, etc., to achieve good cutting stability and cutting The effect of small force and reduction of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

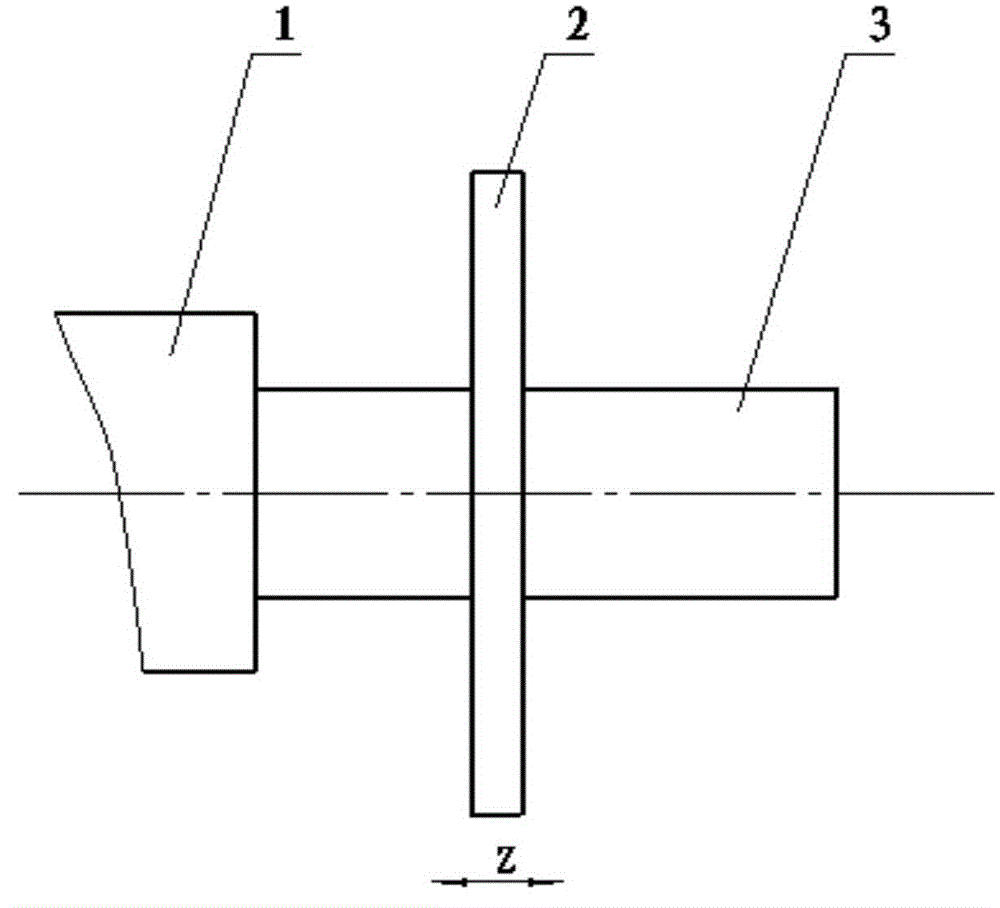

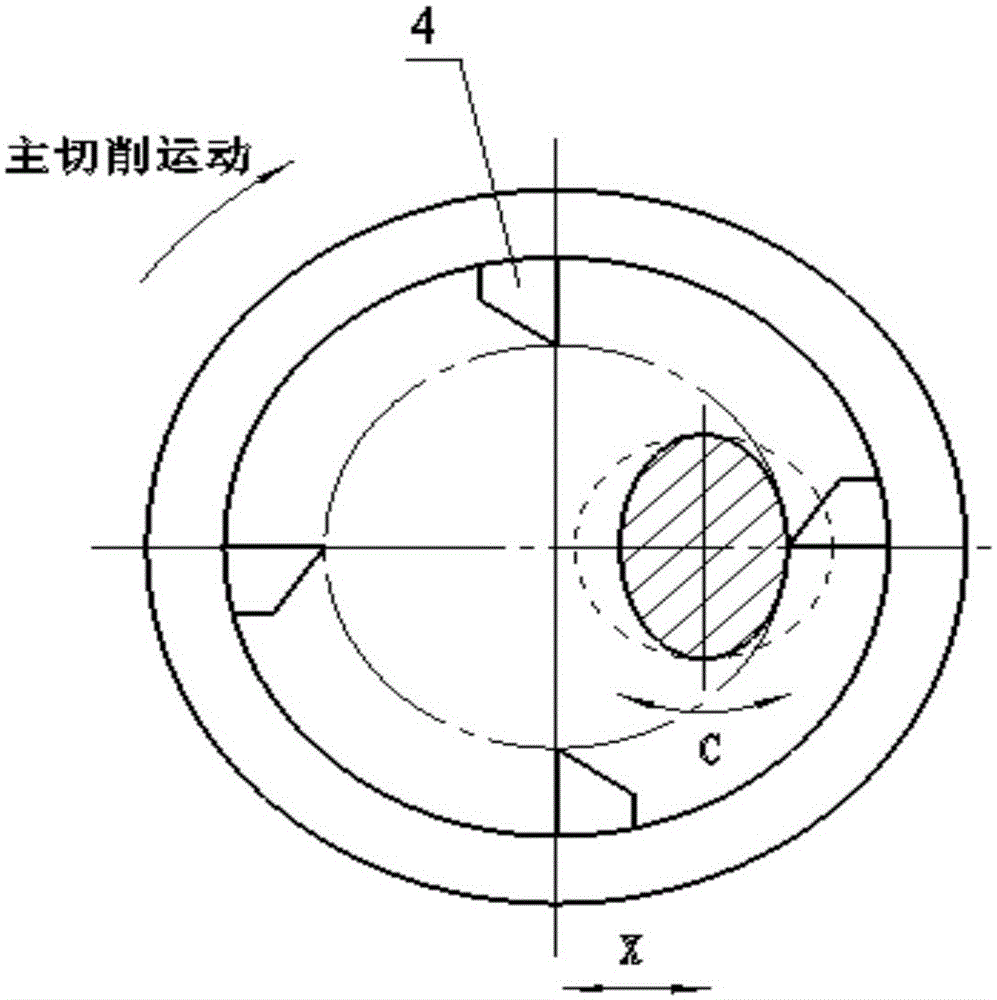

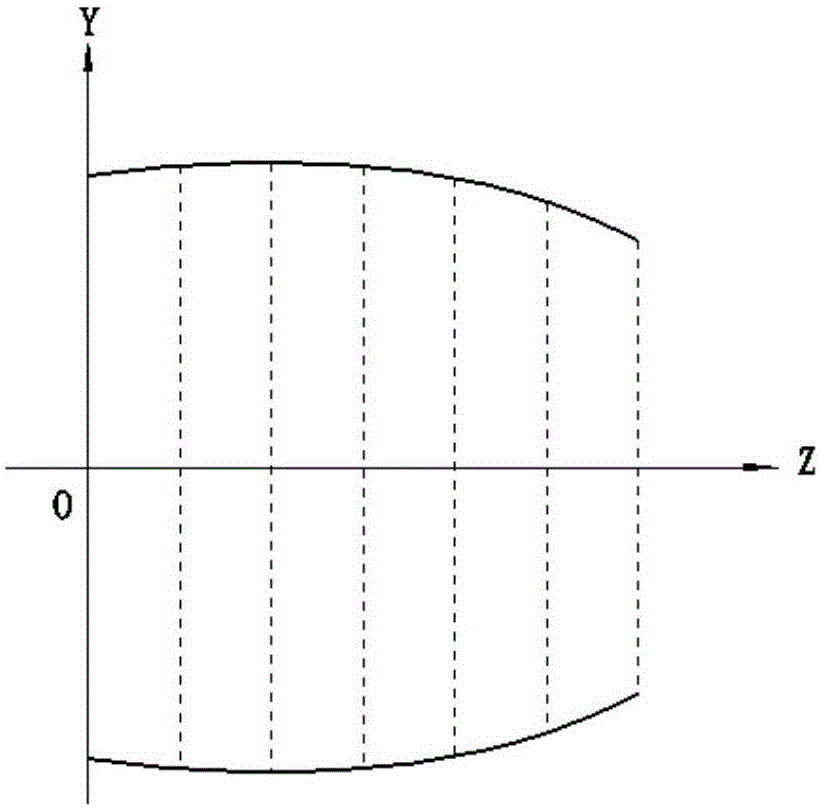

[0038] Such as Figure 1-2 As shown, the workpiece 3 is clamped on the machine tool spindle 1, and the rotary axis of the cutter head 2 on the whirlwind milling head is parallel to the machine tool spindle 1; several cutting tools 4 can be installed on the cutter head 2 and can rotate at high speed under the drive of the motor ; The center of the inscribed circle of the tool tip of the tool 4 is on the axis of rotation of the cutter head 2, and its diameter is greater than the maximum diameter of the workpiece 3. The linear motion of the cutter head 2 along the axial direction of the workpiece (Z axis), the linear motion of the radial direction of the workpiece (X axis) and the rotation angle of the machine tool spindle 1 (C axis) can be precisely controlled. During processing, the spindle 1 drives the workpiece 3 to rotate (feed in the C direction), and the cutter head 2 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com