Design Method of Slit Nozzle Diffusion Section of Side Force Engine

A design method and engine technology, applied in the direction of machine/engine, rocket engine device, mechanical equipment, etc., can solve the problems of unable to achieve airflow acceleration, unable to meet the large aspect ratio of the nozzle outlet, and achieve the effect of reducing the coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be further described in conjunction with the drawings and embodiments.

[0030] First, the rounded rectangle of the transitional section is described by equations.

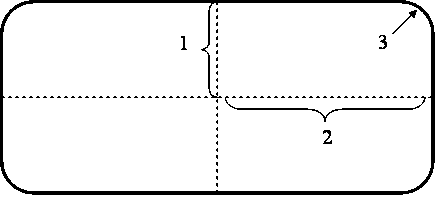

[0031] figure 1 Schematic diagram of the cross-sectional rounded corner rectangle of the diffuser section of the lateral force engine slit nozzle provided for the embodiment of the present invention. During the design process, the half width of the rectangle is controlled by 1, the half length of the rectangle is 2, and the chamfer radius of the rectangle is 3 To realize the control of the transition section.

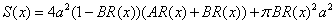

[0032] The length and width of the rectangle are controlled by the following formula:

[0033] (1)

[0034] (2)

[0035] in AR(x)=b(x) / a(x) ,in a(x) is the half-width of the rectangle, b(x) is the half-length of the rectangle, at the entrance , the section aspect ratio at the entrance ;exit , the aspect ratio of the section at the exit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com