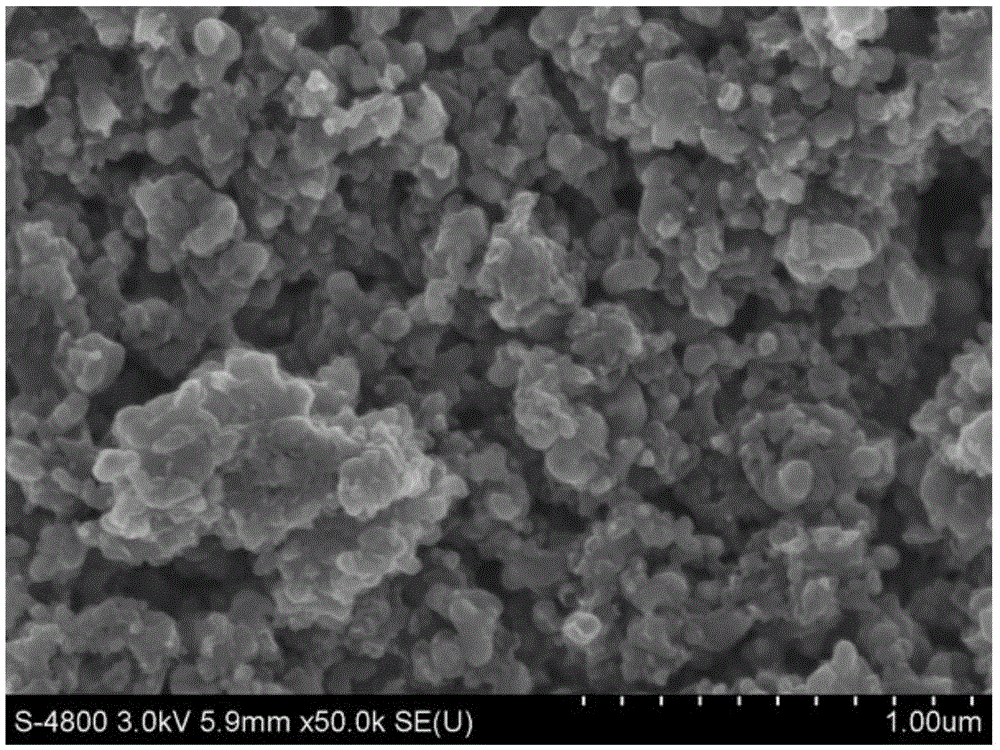

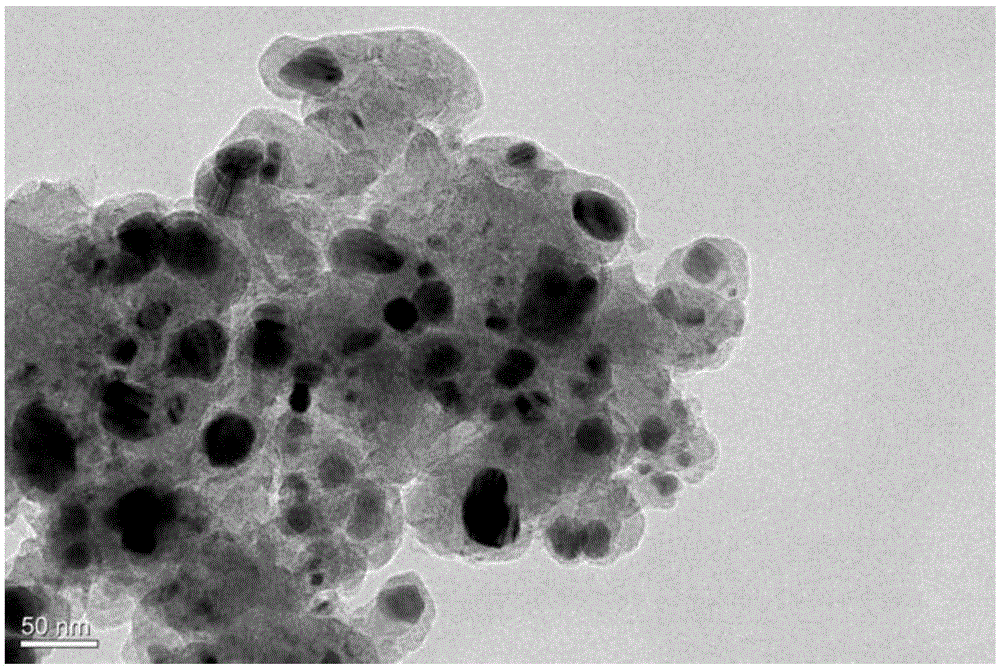

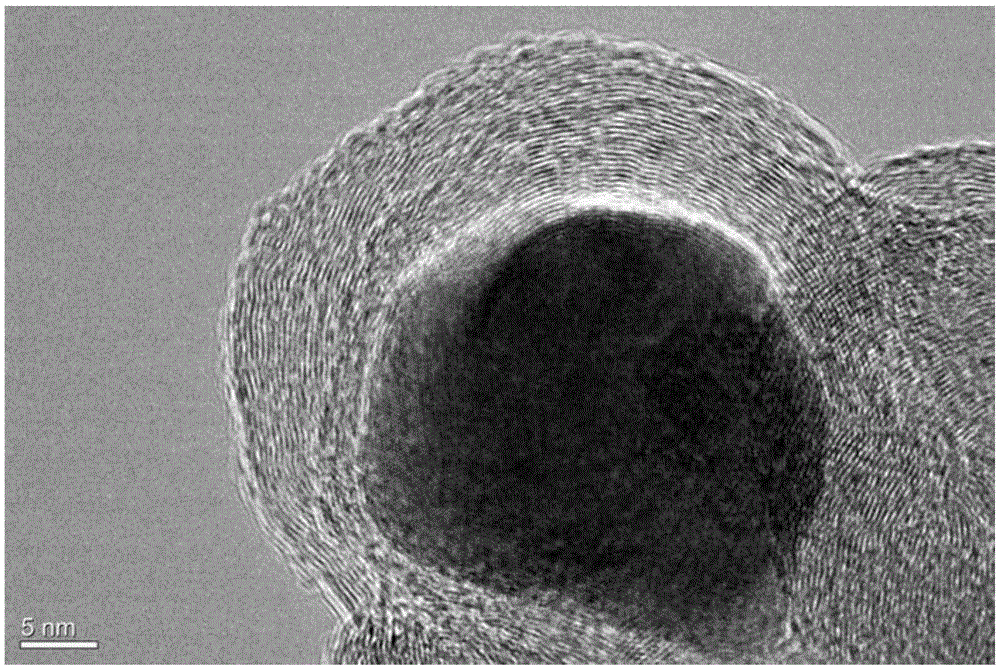

Preparation method of carbon-coated cobalt metal nanoparticles

A technology of nano-particles and cobalt metal, applied in the direction of nano-technology, metal material coating process, gaseous chemical plating, etc., can solve the problems of poor performance, difficult removal, and low yield of carbon-coated metal nanoparticles, and achieve easy Precise control, good degree of crystallization and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The first step, the preparation of cobalt-potassium chloride catalyst

[0043] A total weight of 10g of cobalt carbonate and potassium chloride mixture is added to 200ml deionized water to ensure that the molar mass ratio of cobalt in cobalt carbonate and potassium chloride is 0.01:1, then stir with a magnetic stirrer, and the rotating speed is 400r / min until stirring to form a suspension, place the beaker containing the suspension in an ultrasonic disperser, disperse with 30kHz ultrasonic waves for 30 minutes, and then let it stand for 24 hours, then place the beaker containing the suspension in an electric heating constant temperature In a drying oven, dry at 120°C for 3 hours until the water is completely evaporated, put the dried mixture in a ball mill jar, use a planetary ball mill at a speed of 900r / min for 1 hour, and put the ball milled mixture in a quartz ark , place the quartz ark in the constant temperature zone of the horizontal tube furnace, and the tube f...

Embodiment 2

[0053] The first step, the preparation of cobalt-potassium chloride catalyst

[0054] A total weight of 12g of cobalt carbonate and potassium chloride mixture is added to 200ml deionized water to ensure that the molar mass ratio of cobalt in cobalt carbonate and potassium chloride is 0.05:1, then stir with a magnetic stirrer, and the rotating speed is 500r / min until stirring to form a suspension, place the beaker containing the suspension in an ultrasonic disperser, disperse with 35kHz ultrasonic waves for 30 minutes, and then let it stand for 24 hours, then place the beaker containing the suspension in an electric heating constant temperature In a drying oven, dry at 135°C for 4 hours until the water is completely evaporated, put the dried mixture in a ball mill jar, use a planetary ball mill at a speed of 1100r / min for 3 hours, and place the ball milled mixture in a quartz ark , place the quartz ark in the constant temperature zone of the horizontal tube furnace, and the tu...

Embodiment 3

[0060] The first step, the preparation of cobalt-potassium chloride catalyst

[0061] A total weight of 15g of cobalt carbonate and potassium chloride mixture is added to 200ml deionized water to ensure that the molar mass ratio of cobalt in cobalt carbonate and potassium chloride is 0.09:1, then stir with a magnetic stirrer, and the rotating speed is 600r / min until stirring to form a suspension, place the beaker containing the suspension in an ultrasonic disperser, disperse with 40kHz ultrasonic waves for 30 minutes, and then let it stand for 24 hours, then place the beaker containing the suspension in an electric heating constant temperature In a drying oven, dry at 150°C for 6 hours until the water evaporates completely, place the dried mixture in a ball mill jar, use a planetary ball mill to mill at a speed of 1300r / min for 5 hours, and place the milled mixture in a quartz ark , place the quartz ark in the constant temperature zone of the horizontal tube furnace, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com