Difunctional vane type hydraulic transformer controlled by motor

A hydraulic transformer and motor control technology, which is applied in the direction of fluid pressure converters, mechanical equipment, etc., can solve the problems of complex structure of plunger-type hydraulic transformers, limited application range of hydraulic transformers, and high oil filtering precision requirements, and achieves rich varieties and easy operation. The effect of precise control and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

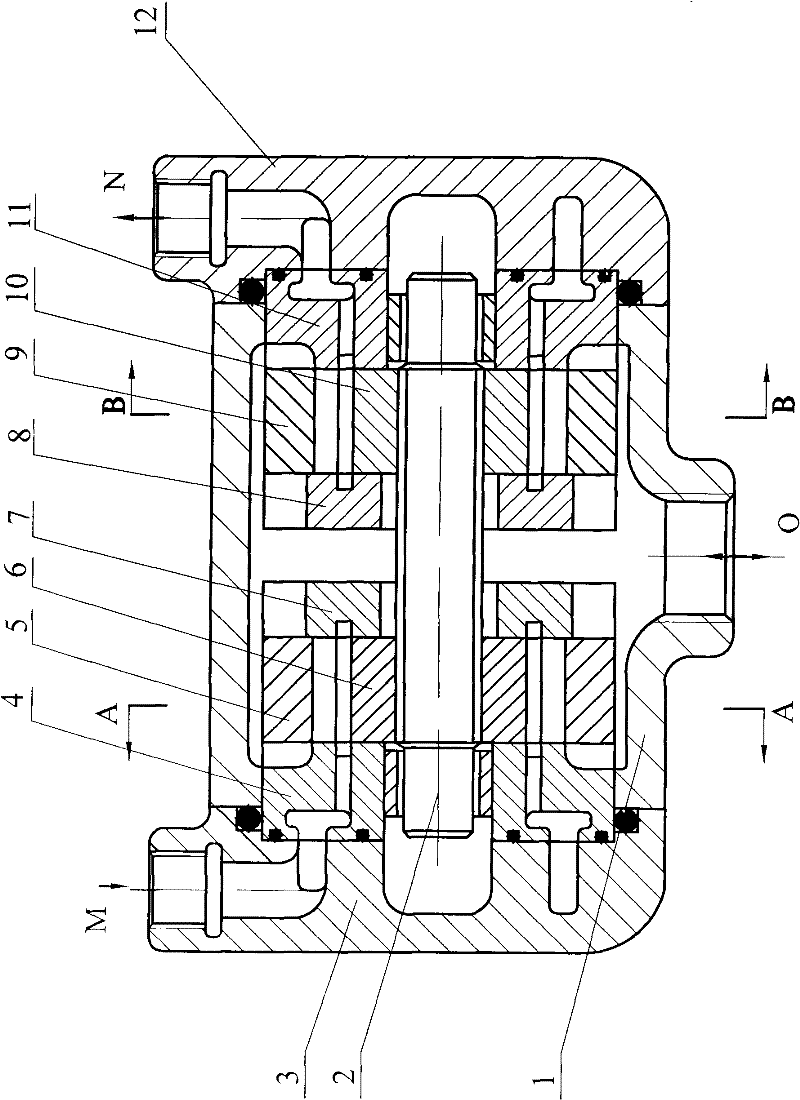

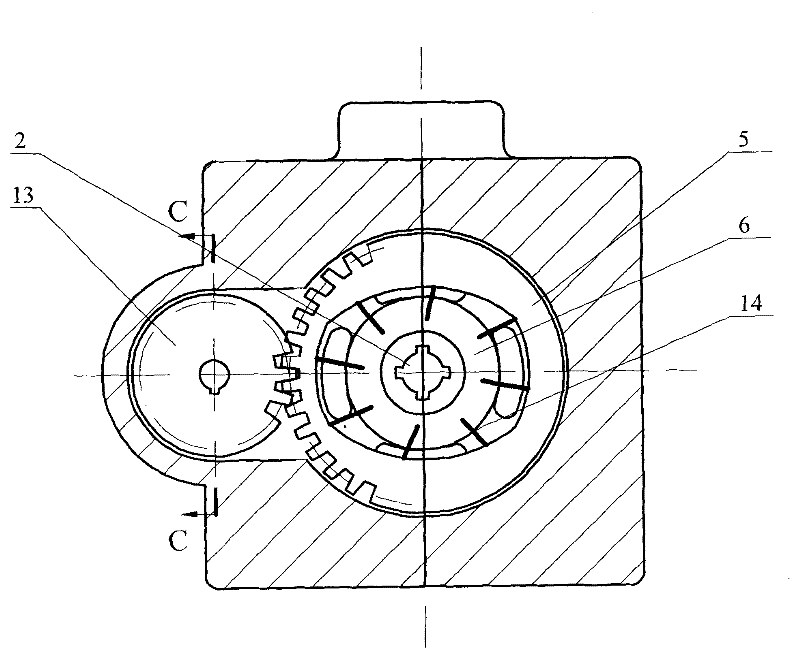

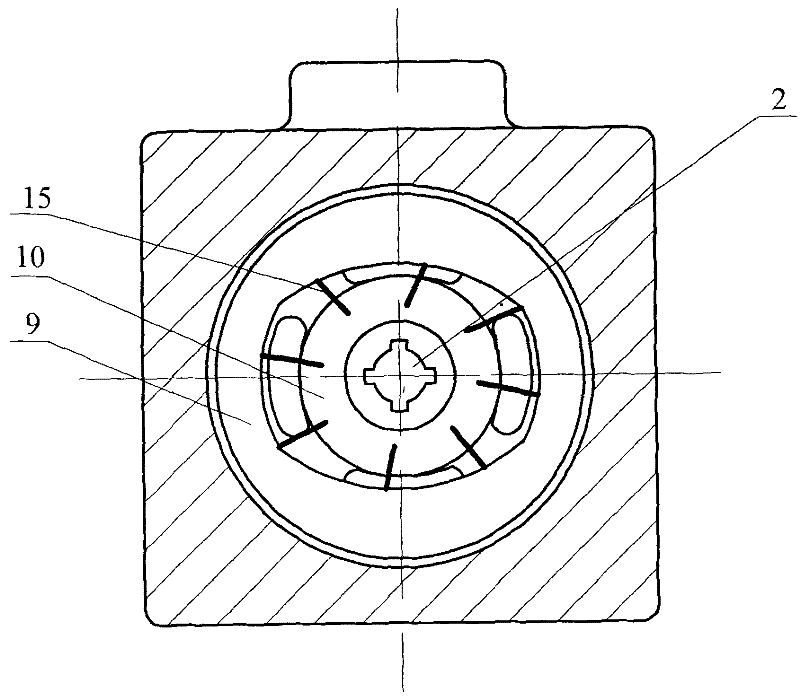

[0021] Such as figure 1 , 2 , 3, and 4, a motor-controlled double-acting vane hydraulic transformer of the present invention is mainly composed of a housing 1, a rotating shaft 2, a left end cover 3, a first group of flow plates 4, 7 and a first fixed 5, the first rotor 6, the second set of flow plates 8, 11, the second stator 9, the second rotor 10, the right end cover 12, the gear 13, the motor 16, the first set of blades 14, the second set of blades 15, etc. The centers of the first rotor 6 and the first stator 5 are fixed and coincident, the width of the first rotor 6 is slightly smaller than the width of the first stator 5, the first rotor 6 is installed in the first stator 5, and the first rotor 6 is installed in the first stator 5. One end of a group of blades 14 is placed in the blade groove of the first rotor 6, and the other end is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com