Variable-frequency heating system for electric heating plate

A heating system and electric heating technology, which is applied in the field of variable frequency heating systems for electric heating panels, can solve the problems of inability to separate short circuits of electric heating panels, high maintenance costs, and difficulty in reducing environmental impact, and achieves easy and precise control and automatic control. Convert energy efficiency ratio, realize real-time control and protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

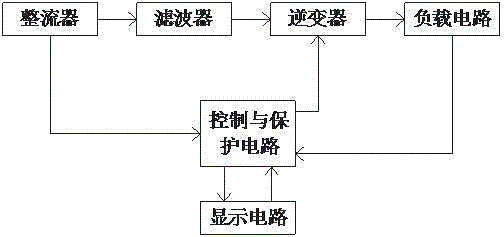

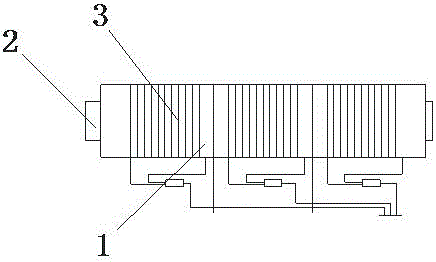

[0015] like figure 1 As shown in -2, a frequency conversion heating system for electric heating panels corresponds to the electric heating panels, including a controller and a frequency conversion heating device connected to the controller.

[0016] The controller includes a control box body, a circuit board is arranged in the control box body, a power module, a single-chip microcomputer, a rectifier, a filter, an inverter, a load circuit and a display module are arranged on the circuit board, the power module is connected to an external power supply, and the power module Connect the single-chip microcomputer and the rectifier, the single-chip microcomputer is connected to the display module, the rectifier is connected to the filter, the filter is connected to the inverter, the inverter is connected to the load circuit, and the load circuit is connected to the frequency conversion heating device; the control box is provided with a display screen, which is connected to the Disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com