High-precision high-acceleration low-frequency sinusoidal vibration system

A high-acceleration and vibration system technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low vibration frequency accuracy and inability to meet the needs of high-precision inertial instrument testing, and achieve long accuracy retention, convenient use and maintenance, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

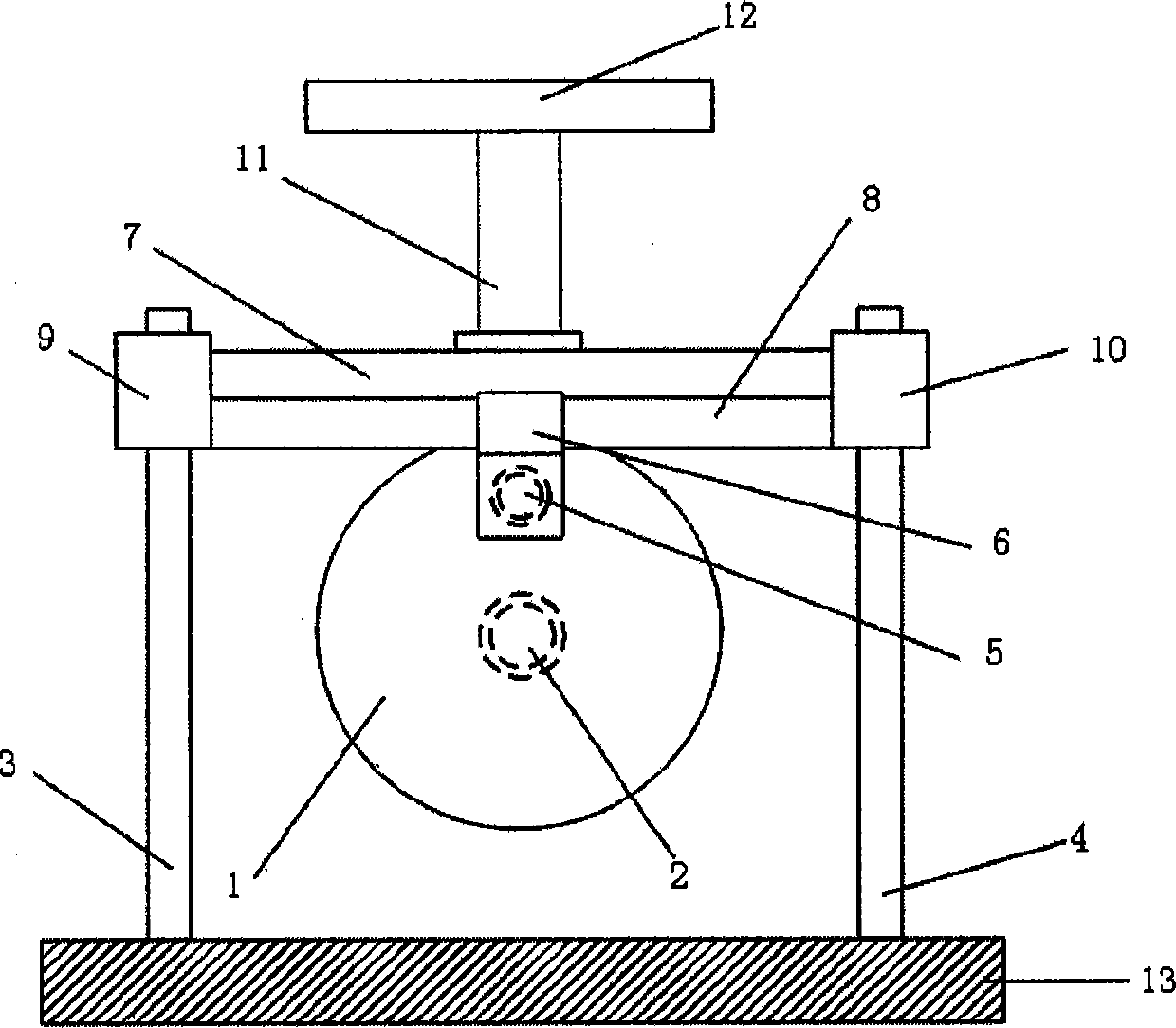

[0018] Such as figure 1 As shown, a high-precision, high-acceleration, low-frequency sinusoidal vibration system includes a rotating motor, a crank plate 1, left and right guide columns 3.4, a crank shaft 5, a horizontal slider 6, a beam 7, a horizontal rolling guide 8, left and right Vertical rolling linear bearing 9.10, column 11, workbench 12 and position sensor, left and right guide post 3.4 are installed on the horizontal base 13, left and right linear bearing 9.10 are respectively installed on the left and right guide post 3.4 and can move along the guide post Move up and down; the two ends of the beam 7 are respectively connected with the left and right vertical rolling linear bearings 9.10, the horizontal rolling guide rail 8 is fixedly connected to the beam 7, the guide rail horizontal slider 6 moves left and right on the horizontal rolling guide rail 8, and the horizontal rolling guide rail 8 is installed on the beam 7 The column 11 and the workbench 12 are installed...

Embodiment 2

[0042] Calculation of beam deformation affecting vibration amplitude accuracy:

[0043] Rolled aluminum E=6.8×10 10 Pa=6.8×10 6 N / cm 2 , ρ=3g / cm 3

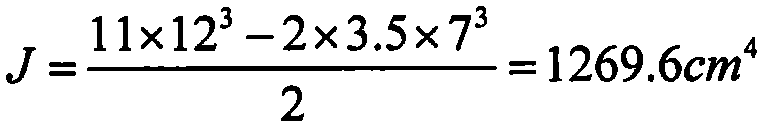

[0044] J = 11 × 12 3 - 2 × 3.5 × 7 3 2 = 1269.6 cm 4

[0045] (1) beam weight

[0046] m=(11×12-2×3.5×7)×42×ρ=10458g, weight Q=104.6N

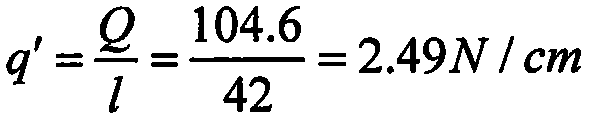

[0047] Unit length (cm) weight q ′ = Q l = 104.6 42 = 2.49 N / cm

[0048] Install rolling guide rail on beam (SNS 45C) q ′ ′ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com