Combined efficient low-temperature trickle dynamic mixing device and special method thereof

A combined, trickle-flow technology, applied in chemical instruments and methods, mixers, dissolution, etc., can solve the problems of stagnant addition technology, high cost, high energy consumption, etc., and achieve easy and precise control, avoid environmental pollution, and high product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

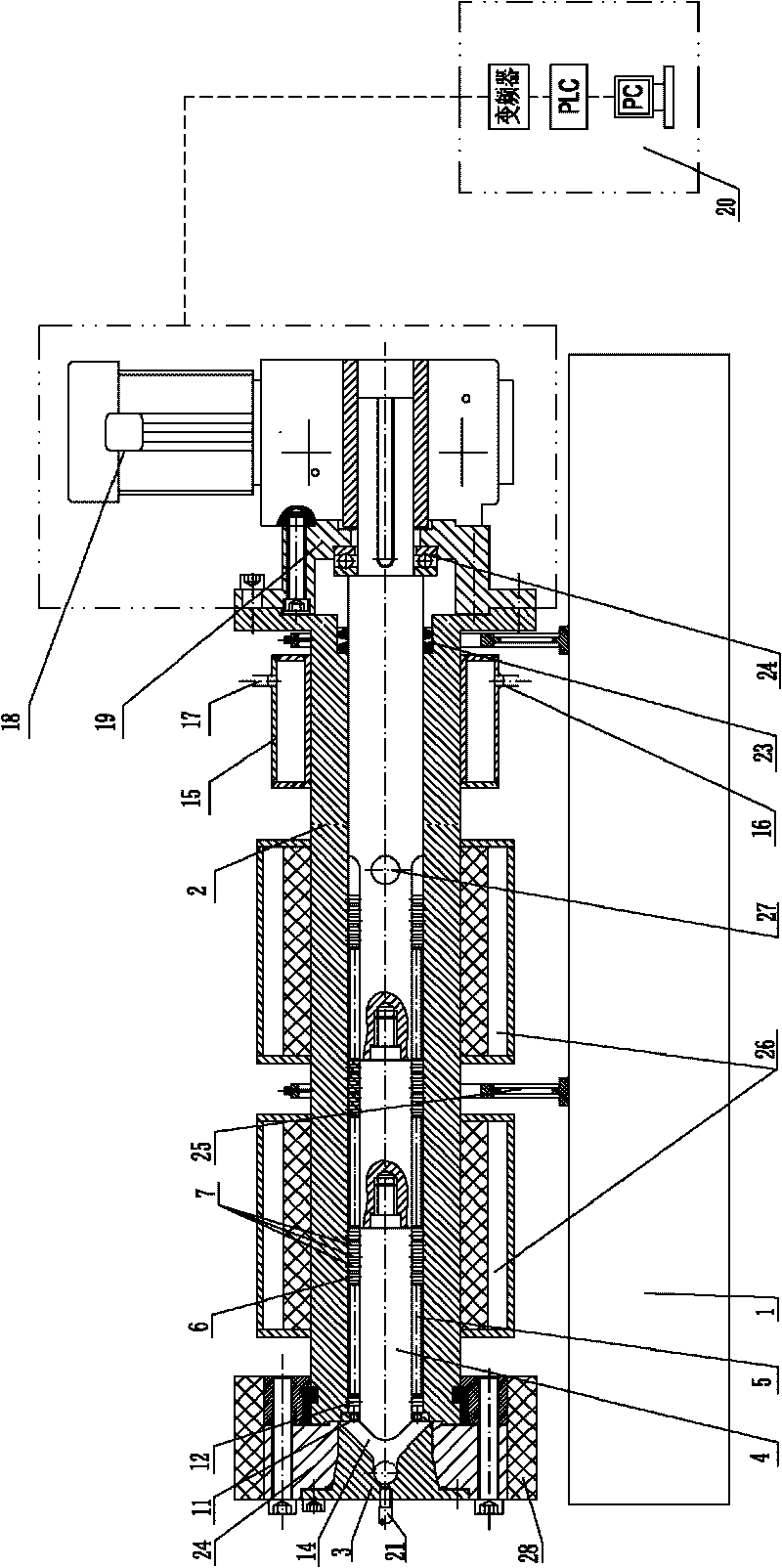

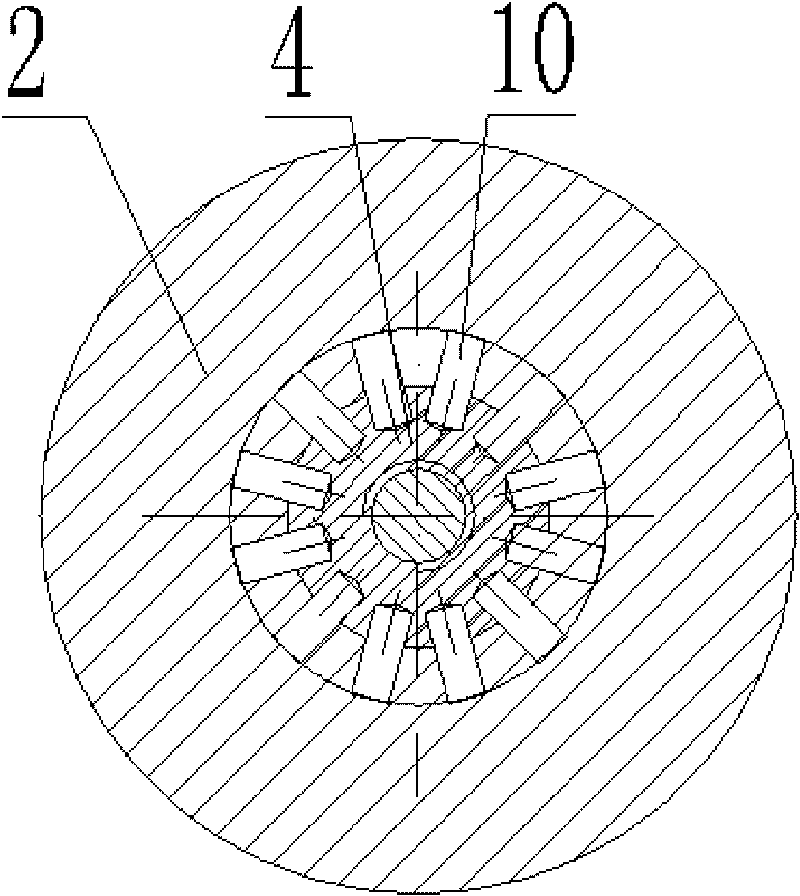

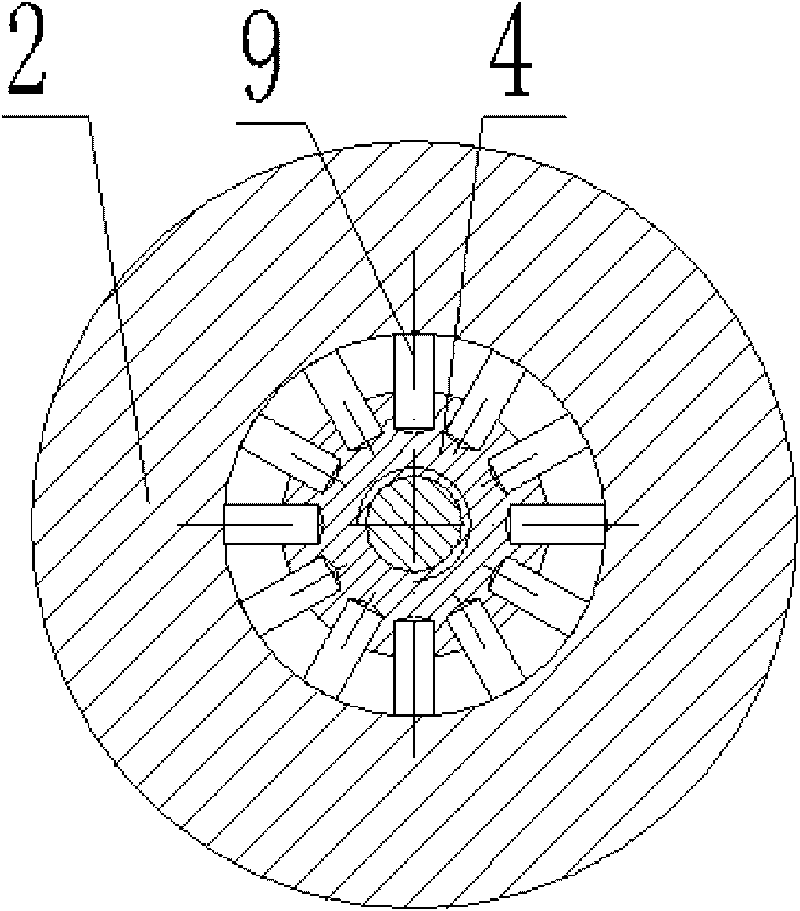

[0031] Embodiment: the combined low-temperature trickle high-efficiency dynamic mixing device of this example, such as figure 1, there is a frame 1, on which the sleeve part 2 is fixed through two supports 25, and the front and rear ends of the sleeve part are respectively connected with a front cover 22 and a rear cover 23 through flanges. The inside of the sleeve part is provided with The high-efficiency mixing shaft component 4, the rear end of the high-efficiency mixing shaft component is connected to a reducer through a keyway, and the reducer is connected to the motor 18. The motor and the reducer are connected to the control unit 20 through a line. Between the rear end of the high-efficiency mixing shaft component and the sleeve component A seal 23 is provided, and a bearing 24 is provided between the rear end of the high-efficiency mixing shaft part and the rear cover 19. The front end of the sleeve part 2 is connected to the feed part 3, and the middle and end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com